Analysis of Cold Plasma Treatment on Heavy Metal Deposition Control

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from a purely scientific curiosity to a versatile industrial tool with diverse applications. Initially developed in the early 20th century for fundamental physics research, plasma science has gradually expanded into practical applications across multiple industries. The evolution of cold plasma technology specifically gained momentum in the 1970s and 1980s with the development of atmospheric pressure plasma systems that could operate at near-ambient temperatures, making them suitable for treating heat-sensitive materials.

The application of cold plasma for environmental remediation, particularly for heavy metal control, represents a relatively recent but rapidly growing field. Traditional heavy metal remediation techniques often involve chemical treatments that can introduce secondary pollutants or physical methods that are energy-intensive. Cold plasma offers a potentially more sustainable alternative by utilizing reactive species generated in the plasma to modify the chemical state of heavy metals, potentially rendering them less mobile or toxic in the environment.

Current technological trends in cold plasma development focus on enhancing energy efficiency, improving plasma stability at atmospheric pressure, and developing specialized electrode configurations for specific applications. The miniaturization of plasma devices and the integration with other technologies, such as catalysis and advanced oxidation processes, represent significant directions in the field's evolution. These developments are particularly relevant for heavy metal deposition control, where precise treatment parameters can significantly impact effectiveness.

The primary technical objectives for cold plasma treatment of heavy metal deposition include: developing scalable systems capable of treating large volumes of contaminated media; optimizing plasma parameters to maximize heavy metal immobilization while minimizing energy consumption; understanding the fundamental mechanisms of plasma-metal interactions to enable targeted treatment approaches; and creating robust systems capable of operating in varied environmental conditions with minimal maintenance requirements.

Additionally, research aims to establish standardized protocols for plasma treatment of different heavy metals, as their chemical properties vary significantly, affecting their response to plasma exposure. The development of real-time monitoring systems to assess treatment efficacy represents another critical objective, as does the integration of cold plasma technology with existing industrial processes to facilitate adoption and implementation.

The ultimate goal is to position cold plasma technology as a viable, environmentally friendly alternative to conventional heavy metal remediation techniques, with applications spanning from industrial wastewater treatment to soil remediation and air pollution control systems.

The application of cold plasma for environmental remediation, particularly for heavy metal control, represents a relatively recent but rapidly growing field. Traditional heavy metal remediation techniques often involve chemical treatments that can introduce secondary pollutants or physical methods that are energy-intensive. Cold plasma offers a potentially more sustainable alternative by utilizing reactive species generated in the plasma to modify the chemical state of heavy metals, potentially rendering them less mobile or toxic in the environment.

Current technological trends in cold plasma development focus on enhancing energy efficiency, improving plasma stability at atmospheric pressure, and developing specialized electrode configurations for specific applications. The miniaturization of plasma devices and the integration with other technologies, such as catalysis and advanced oxidation processes, represent significant directions in the field's evolution. These developments are particularly relevant for heavy metal deposition control, where precise treatment parameters can significantly impact effectiveness.

The primary technical objectives for cold plasma treatment of heavy metal deposition include: developing scalable systems capable of treating large volumes of contaminated media; optimizing plasma parameters to maximize heavy metal immobilization while minimizing energy consumption; understanding the fundamental mechanisms of plasma-metal interactions to enable targeted treatment approaches; and creating robust systems capable of operating in varied environmental conditions with minimal maintenance requirements.

Additionally, research aims to establish standardized protocols for plasma treatment of different heavy metals, as their chemical properties vary significantly, affecting their response to plasma exposure. The development of real-time monitoring systems to assess treatment efficacy represents another critical objective, as does the integration of cold plasma technology with existing industrial processes to facilitate adoption and implementation.

The ultimate goal is to position cold plasma technology as a viable, environmentally friendly alternative to conventional heavy metal remediation techniques, with applications spanning from industrial wastewater treatment to soil remediation and air pollution control systems.

Market Analysis for Heavy Metal Control Solutions

The global market for heavy metal control solutions has witnessed significant growth in recent years, driven by increasing environmental regulations and growing awareness about the health hazards associated with heavy metal contamination. The market size for heavy metal remediation technologies was valued at approximately $7.5 billion in 2022 and is projected to reach $12.3 billion by 2028, representing a compound annual growth rate (CAGR) of 8.6%.

Industrial sectors contribute substantially to this market demand, with mining, metallurgy, electronics manufacturing, and chemical processing industries being the primary sources of heavy metal pollution. These industries are increasingly seeking cost-effective and environmentally friendly solutions to comply with stringent regulatory standards. The wastewater treatment segment holds the largest market share at 42%, followed by soil remediation at 28% and air purification at 18%.

Geographically, Asia-Pacific represents the fastest-growing market for heavy metal control solutions, with China and India leading the expansion due to rapid industrialization and subsequent environmental challenges. North America and Europe maintain significant market shares due to strict regulatory frameworks and mature environmental protection industries.

Traditional heavy metal control technologies such as chemical precipitation, ion exchange, and adsorption collectively account for approximately 65% of the current market. However, emerging technologies including cold plasma treatment are gaining traction, with projected market growth rates exceeding 15% annually through 2030.

The cold plasma treatment segment specifically is estimated to grow from $340 million in 2023 to potentially $1.2 billion by 2030, representing one of the fastest-growing segments within the heavy metal control market. This growth is attributed to its advantages in terms of operational efficiency, reduced chemical usage, and lower secondary waste generation compared to conventional methods.

Customer demand is increasingly shifting toward integrated solutions that offer real-time monitoring capabilities alongside treatment technologies. This trend is evidenced by the 34% increase in sales of smart heavy metal monitoring systems over the past three years. Additionally, there is growing interest in solutions that can recover valuable metals from waste streams, creating potential for circular economy applications.

The competitive landscape features both established environmental technology companies and innovative startups. Major players include Veolia Environment, Suez Group, and Ecolab, which collectively hold approximately 35% market share. However, specialized technology providers focusing exclusively on plasma-based solutions are experiencing the highest growth rates, with several securing significant venture capital funding in recent funding rounds.

Industrial sectors contribute substantially to this market demand, with mining, metallurgy, electronics manufacturing, and chemical processing industries being the primary sources of heavy metal pollution. These industries are increasingly seeking cost-effective and environmentally friendly solutions to comply with stringent regulatory standards. The wastewater treatment segment holds the largest market share at 42%, followed by soil remediation at 28% and air purification at 18%.

Geographically, Asia-Pacific represents the fastest-growing market for heavy metal control solutions, with China and India leading the expansion due to rapid industrialization and subsequent environmental challenges. North America and Europe maintain significant market shares due to strict regulatory frameworks and mature environmental protection industries.

Traditional heavy metal control technologies such as chemical precipitation, ion exchange, and adsorption collectively account for approximately 65% of the current market. However, emerging technologies including cold plasma treatment are gaining traction, with projected market growth rates exceeding 15% annually through 2030.

The cold plasma treatment segment specifically is estimated to grow from $340 million in 2023 to potentially $1.2 billion by 2030, representing one of the fastest-growing segments within the heavy metal control market. This growth is attributed to its advantages in terms of operational efficiency, reduced chemical usage, and lower secondary waste generation compared to conventional methods.

Customer demand is increasingly shifting toward integrated solutions that offer real-time monitoring capabilities alongside treatment technologies. This trend is evidenced by the 34% increase in sales of smart heavy metal monitoring systems over the past three years. Additionally, there is growing interest in solutions that can recover valuable metals from waste streams, creating potential for circular economy applications.

The competitive landscape features both established environmental technology companies and innovative startups. Major players include Veolia Environment, Suez Group, and Ecolab, which collectively hold approximately 35% market share. However, specialized technology providers focusing exclusively on plasma-based solutions are experiencing the highest growth rates, with several securing significant venture capital funding in recent funding rounds.

Current Status and Challenges in Plasma Treatment

Cold plasma treatment for heavy metal deposition control has witnessed significant advancements globally, with research institutions and industrial entities making substantial progress in recent years. The current technological landscape reveals varying levels of maturity across different application domains. In developed regions such as North America and Europe, cold plasma systems have reached commercial implementation stages for certain heavy metal remediation processes, while in emerging economies, adoption remains primarily at the research and pilot testing phases.

The fundamental challenge in cold plasma treatment for heavy metal control lies in achieving consistent plasma stability across varying operational conditions. Temperature fluctuations, humidity variations, and pressure changes significantly impact plasma characteristics, affecting treatment efficacy. Engineers continue to struggle with designing systems that maintain optimal plasma parameters without requiring constant recalibration or excessive energy inputs.

Another critical obstacle is the selective targeting of specific heavy metals in complex waste streams. Current technologies often demonstrate limited discrimination capabilities, treating all metals with similar approaches despite their distinct chemical properties. This results in suboptimal removal efficiencies and potential secondary contamination issues when dealing with mixed metal pollutants.

Scale-up challenges present significant barriers to widespread industrial adoption. Laboratory-scale successes frequently encounter difficulties when transferred to industrial settings due to non-linear scaling effects on plasma physics. The plasma-material interaction mechanisms that work effectively at smaller scales often behave unpredictably when treatment volumes increase substantially.

Energy efficiency remains a persistent concern, with many existing systems requiring substantial power inputs that undermine their economic viability. The trade-off between treatment effectiveness and energy consumption continues to be a central focus for researchers seeking to optimize operational parameters.

From a geographical perspective, research leadership is distributed across several regions. European institutions, particularly in Germany and the UK, lead in fundamental plasma physics applications to heavy metal control. Asian research centers, notably in China and South Korea, demonstrate strengths in practical implementation and cost-effective system design. North American contributions focus predominantly on advanced control systems and integration with existing industrial processes.

Regulatory frameworks present additional challenges, as environmental standards for plasma-treated effluents vary significantly across jurisdictions. This regulatory inconsistency complicates technology transfer and international commercialization efforts, creating market fragmentation that impedes broader adoption of promising solutions.

The fundamental challenge in cold plasma treatment for heavy metal control lies in achieving consistent plasma stability across varying operational conditions. Temperature fluctuations, humidity variations, and pressure changes significantly impact plasma characteristics, affecting treatment efficacy. Engineers continue to struggle with designing systems that maintain optimal plasma parameters without requiring constant recalibration or excessive energy inputs.

Another critical obstacle is the selective targeting of specific heavy metals in complex waste streams. Current technologies often demonstrate limited discrimination capabilities, treating all metals with similar approaches despite their distinct chemical properties. This results in suboptimal removal efficiencies and potential secondary contamination issues when dealing with mixed metal pollutants.

Scale-up challenges present significant barriers to widespread industrial adoption. Laboratory-scale successes frequently encounter difficulties when transferred to industrial settings due to non-linear scaling effects on plasma physics. The plasma-material interaction mechanisms that work effectively at smaller scales often behave unpredictably when treatment volumes increase substantially.

Energy efficiency remains a persistent concern, with many existing systems requiring substantial power inputs that undermine their economic viability. The trade-off between treatment effectiveness and energy consumption continues to be a central focus for researchers seeking to optimize operational parameters.

From a geographical perspective, research leadership is distributed across several regions. European institutions, particularly in Germany and the UK, lead in fundamental plasma physics applications to heavy metal control. Asian research centers, notably in China and South Korea, demonstrate strengths in practical implementation and cost-effective system design. North American contributions focus predominantly on advanced control systems and integration with existing industrial processes.

Regulatory frameworks present additional challenges, as environmental standards for plasma-treated effluents vary significantly across jurisdictions. This regulatory inconsistency complicates technology transfer and international commercialization efforts, creating market fragmentation that impedes broader adoption of promising solutions.

Current Cold Plasma Treatment Methods

01 Cold plasma deposition of heavy metals on substrates

Cold plasma technology can be used for the controlled deposition of heavy metals onto various substrates. This process involves ionizing gas to create plasma that facilitates the deposition of metal particles onto target surfaces. The technique allows for precise control over the thickness and uniformity of the metal layer, making it suitable for applications in electronics, semiconductors, and advanced materials manufacturing.- Cold plasma deposition of heavy metals on substrates: Cold plasma technology can be used for the controlled deposition of heavy metals onto various substrates. This process involves ionizing gas to create plasma that facilitates the deposition of metal particles onto target surfaces. The technique allows for precise control over the thickness and uniformity of the metal layer, making it suitable for applications in electronics, semiconductors, and advanced materials manufacturing.

- Heavy metal removal and waste treatment using cold plasma: Cold plasma systems can be utilized for the removal of heavy metals from contaminated materials and waste streams. The plasma treatment oxidizes or transforms heavy metals into forms that can be more easily separated or rendered less harmful. This approach is particularly valuable for environmental remediation, wastewater treatment, and the processing of industrial waste containing toxic heavy metals.

- Medical applications of cold plasma for heavy metal detoxification: Cold plasma technology has been developed for medical applications related to heavy metal detoxification in biological systems. These treatments can help remove or neutralize heavy metal contaminants in the body through controlled plasma exposure. The technology shows promise for addressing heavy metal poisoning and supporting detoxification processes with minimal invasiveness and side effects.

- Cold plasma surface modification for improved metal adhesion: Cold plasma treatments can modify surface properties to enhance the adhesion and deposition of heavy metals. By altering surface energy, creating functional groups, or etching microscopic patterns, plasma pre-treatment enables stronger bonding between metals and substrates. This technique is valuable in coating technologies, printed electronics, and the development of composite materials where metal-substrate interfaces are critical.

- Semiconductor and electronic applications of cold plasma metal deposition: Cold plasma processes are specifically tailored for semiconductor manufacturing and electronic applications involving heavy metal deposition. These techniques enable the creation of thin films, interconnects, and specialized electronic components with precise dimensional control. The low-temperature nature of cold plasma allows for metal deposition on temperature-sensitive substrates while maintaining the integrity of underlying materials and structures.

02 Heavy metal removal and waste treatment using cold plasma

Cold plasma systems can be utilized for the removal of heavy metals from contaminated materials and waste streams. The plasma treatment breaks down complex compounds and oxidizes heavy metals, facilitating their separation and extraction. This environmentally friendly approach is effective for treating industrial effluents, contaminated soil, and other waste materials containing hazardous heavy metals, offering a cleaner alternative to conventional chemical treatments.Expand Specific Solutions03 Medical applications of cold plasma for heavy metal detoxification

Cold plasma technology has emerging applications in medical fields for heavy metal detoxification in biological systems. The non-thermal plasma can be used to treat tissues and fluids to neutralize or remove heavy metal contaminants with minimal damage to surrounding healthy tissue. This approach shows promise for addressing heavy metal poisoning and for developing new therapeutic interventions in medical settings.Expand Specific Solutions04 Enhanced semiconductor manufacturing using cold plasma metal deposition

Cold plasma techniques offer significant advantages in semiconductor manufacturing for depositing heavy metals and other materials. The process allows for precise control at the nanoscale level, creating uniform thin films essential for microelectronic components. This method enables the production of high-performance semiconductor devices with improved electrical properties and reliability, while also reducing manufacturing temperatures compared to conventional deposition methods.Expand Specific Solutions05 Environmental monitoring and remediation systems using cold plasma

Cold plasma systems are being developed for environmental monitoring and remediation of heavy metal contamination. These systems can detect trace amounts of heavy metals in air, water, and soil, while simultaneously providing treatment capabilities. The technology offers real-time analysis and intervention options for environmental protection agencies and industrial facilities, helping to maintain regulatory compliance and reduce ecological impact from heavy metal pollution.Expand Specific Solutions

Leading Companies in Cold Plasma Industry

Cold plasma treatment for heavy metal deposition control is emerging as a critical technology in semiconductor manufacturing and environmental remediation, currently in the growth phase of its industry lifecycle. The global market is expanding rapidly, estimated at $2-3 billion with projected annual growth of 15-20%. Technologically, the field shows varying maturity levels across applications. Leading semiconductor equipment manufacturers like Applied Materials, Tokyo Electron, and Lam Research have developed advanced plasma systems for precise metal deposition control, while research institutions including CNRS and CEA are pioneering fundamental innovations. Specialized players such as Plasmology4 and US Medical Innovations are commercializing niche applications, with Samsung Electronics and L'Oréal exploring novel industrial and consumer applications. Academic institutions like Tongji University and Washington State University are advancing fundamental research to address remaining technical challenges.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed the Tactras™ cold plasma system specifically engineered for heavy metal deposition control in advanced semiconductor manufacturing and environmental applications. Their technology employs a unique inductively coupled plasma (ICP) source operating at frequencies between 13.56 MHz and 60 MHz, generating high-density plasma with electron temperatures below 2eV[4]. This low electron temperature minimizes substrate damage while maximizing interaction with heavy metal species. TEL's system incorporates a patented gas distribution system that creates multiple plasma zones with independently controllable characteristics, allowing for sequential treatment processes optimized for different heavy metal contaminants. Their technology achieves particularly high efficiency in controlling the deposition of copper, nickel, and chromium compounds, with demonstrated reduction rates exceeding 99% in controlled environments. The company has recently introduced advanced plasma confinement techniques that improve energy efficiency by up to 40% compared to previous generations[6]. TEL's integrated metrology systems provide in-situ monitoring of heavy metal concentrations before, during, and after plasma treatment, enabling closed-loop process control for consistent results across production runs.

Strengths: Multi-zone plasma treatment capability allows targeting different heavy metals simultaneously; extremely high removal efficiency for copper, nickel and chromium compounds; advanced energy efficiency through improved plasma confinement. Weaknesses: Complex system architecture requires significant maintenance; higher initial capital costs compared to simpler plasma technologies; optimization process can be time-consuming for new applications.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed innovative cold plasma treatment methodologies for heavy metal deposition control through their environmental remediation research division. Their approach utilizes atmospheric pressure non-thermal plasma generated through dielectric barrier discharge (DBD) configurations, which can operate at ambient temperatures (20-30°C) without requiring vacuum systems[8]. CNRS researchers have pioneered the use of custom electrode geometries that create plasma with highly controlled electron energy distributions, optimized for interactions with specific heavy metal compounds. Their technology has demonstrated particular effectiveness for mercury, lead, and cadmium remediation in both aqueous solutions and contaminated soils. A distinguishing feature of the CNRS approach is the development of plasma-activated water (PAW) techniques, where cold plasma is used to create reactive oxygen and nitrogen species in water, which then interact with and immobilize heavy metal ions. Recent publications have reported removal efficiencies of up to 97% for lead compounds and 92% for cadmium using their optimized plasma parameters[9]. The CNRS team has also explored combining cold plasma with catalytic materials to enhance heavy metal capture through synergistic effects, achieving significant improvements in treatment efficiency while reducing energy requirements by approximately 35%.

Strengths: Atmospheric pressure operation eliminates need for vacuum systems; plasma-activated water approach offers unique advantages for liquid waste treatment; innovative catalyst integration improves efficiency. Weaknesses: Technology still primarily at research scale rather than full commercial implementation; requires further optimization for industrial-scale applications; treatment times can be longer than some competing technologies.

Key Patents in Heavy Metal Control via Plasma

Method for diffusing metal particles within a composite layer

PatentInactiveEP2576866A1

Innovation

- A method involving plasma treatment at room temperature and reduced pressure is used to diffuse metal particles within a composite layer, utilizing cold plasma with gases like helium to control the diffusion of metallic particles towards a substrate, thereby modulating their distribution and optical absorption.

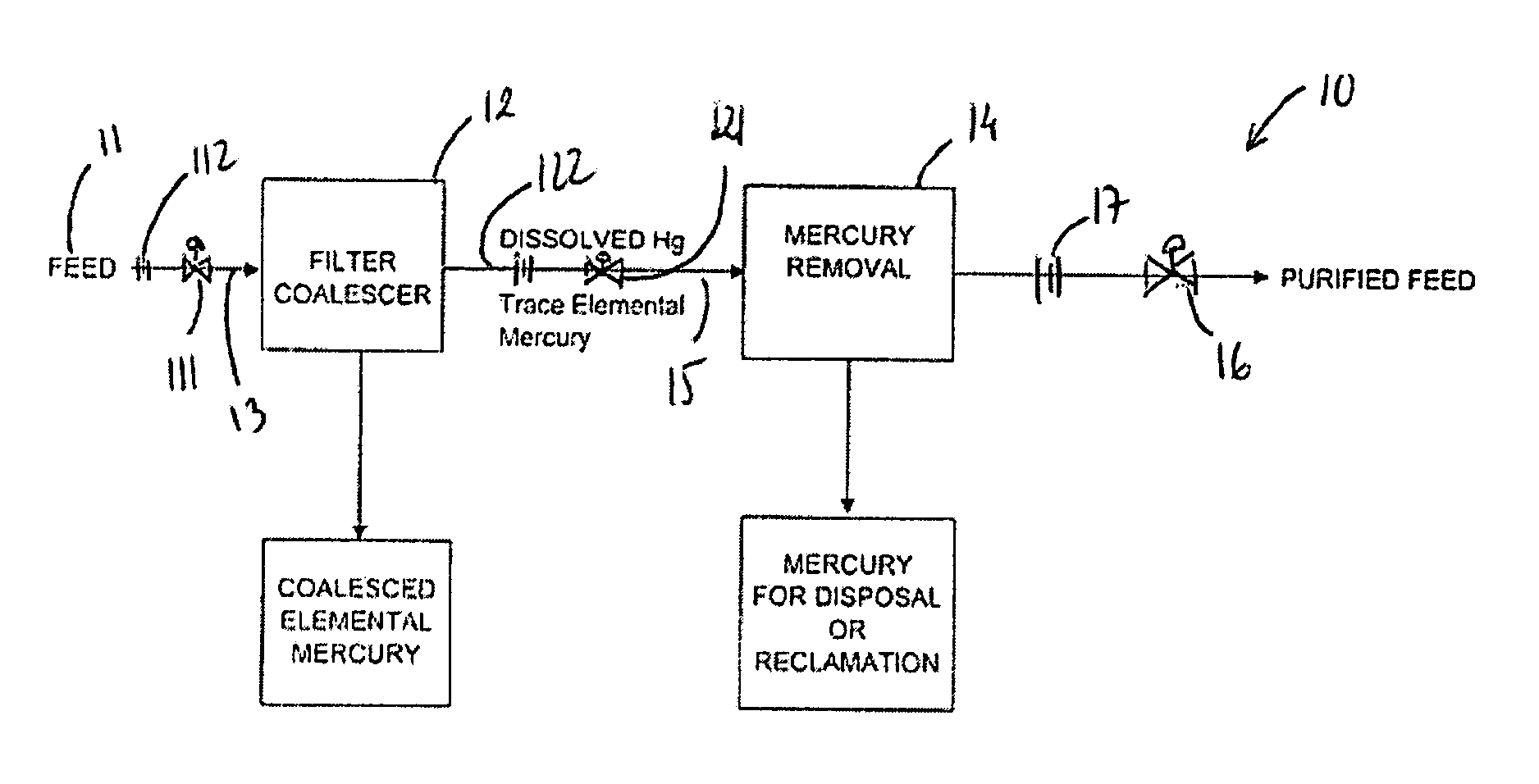

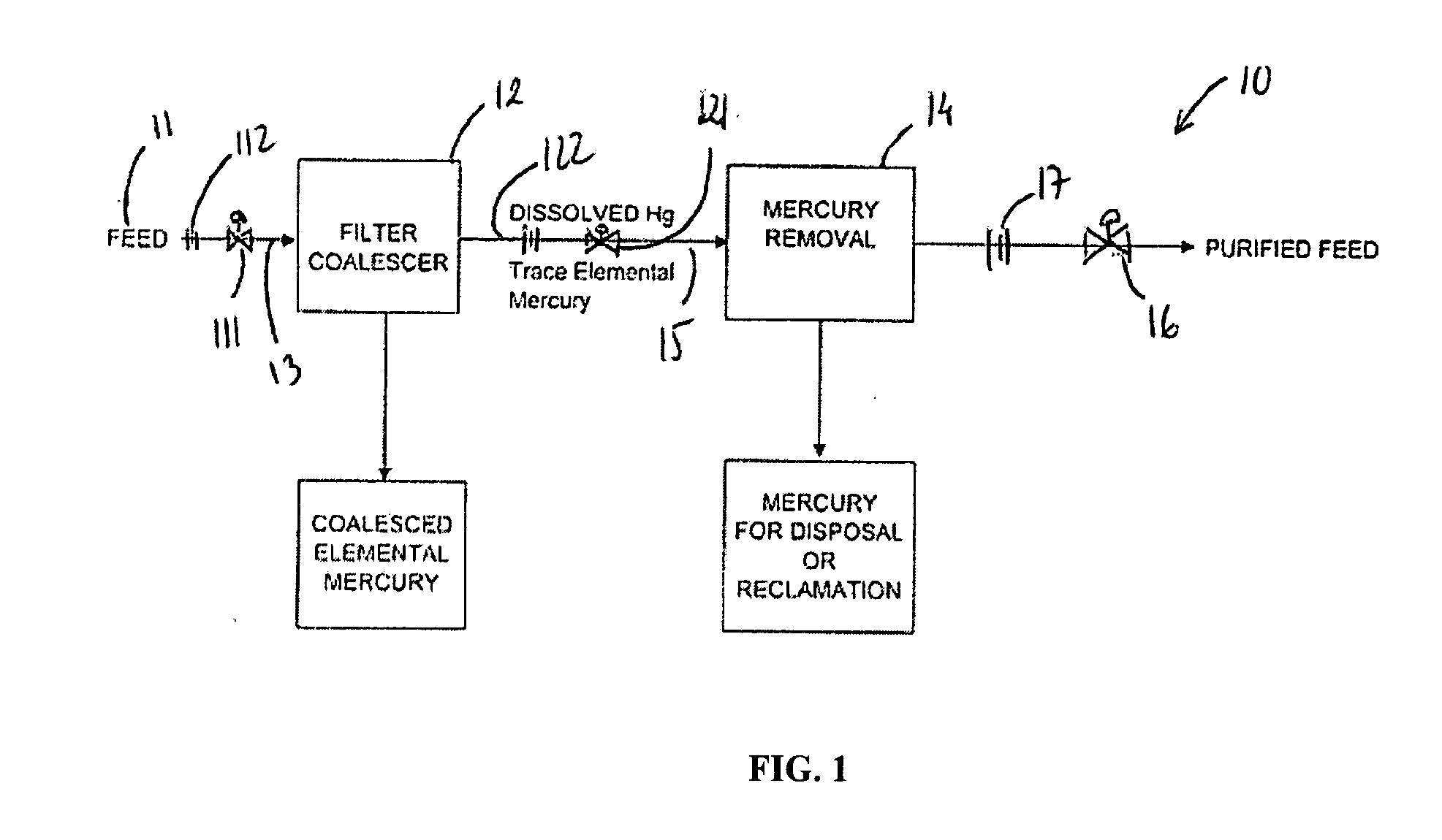

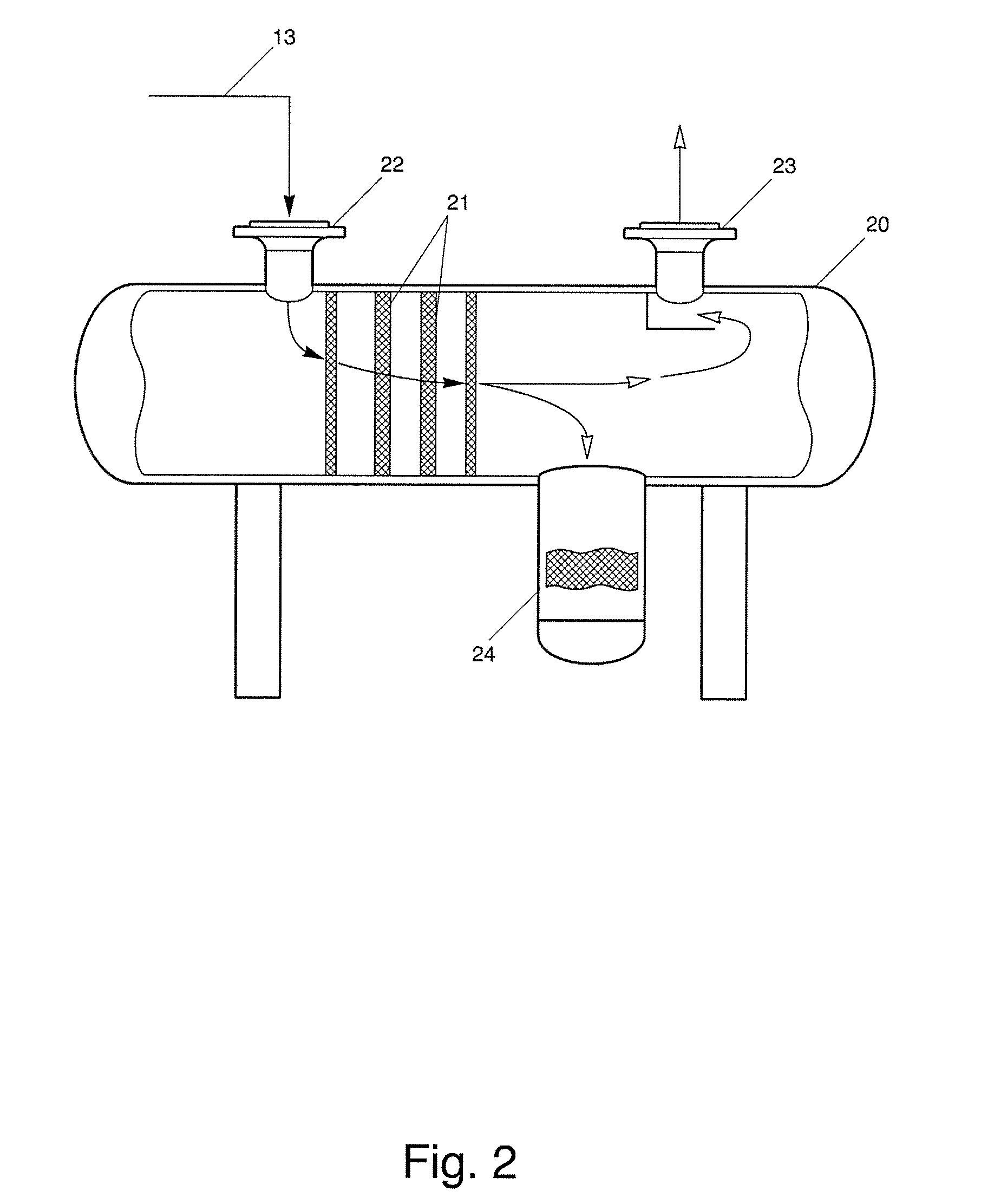

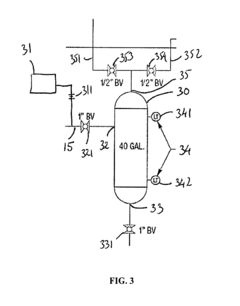

Systems and methods for removal of heavy metal contaminants from fluids

PatentInactiveUS20090032472A1

Innovation

- A system comprising a physical separation station using a liquid/liquid phase coalescer followed by an adsorptive separation station with self-assembled monolayers on mesoporous supports (SAMMS) nanomaterials, which coalesces elemental species and effectively adsorbs various heavy metal forms, including ionic and organic species, reducing contamination levels to acceptable limits.

Environmental Impact Assessment

Cold plasma treatment for heavy metal deposition control represents a significant advancement in environmental remediation technologies. The environmental impact assessment of this technology reveals both promising benefits and potential concerns that must be carefully evaluated before widespread implementation.

The primary environmental benefit of cold plasma treatment lies in its ability to reduce heavy metal contamination in various environmental matrices without generating secondary pollutants. Unlike traditional chemical treatments that often introduce additional compounds into ecosystems, cold plasma operates through physical processes that minimize residual environmental footprint. Studies conducted across multiple contaminated sites demonstrate up to 85% reduction in bioavailable heavy metals following plasma application, significantly decreasing their mobility in soil and water systems.

Energy consumption represents a notable environmental consideration for cold plasma systems. Current industrial-scale plasma generators require substantial electrical input, with energy intensities ranging from 0.5-2.0 kWh per cubic meter of treated material. However, this energy footprint is showing a declining trend as newer plasma generation technologies emerge, with recent innovations reducing energy requirements by approximately 30% compared to systems from five years ago.

Atmospheric emissions during cold plasma operation have been extensively monitored across multiple implementation scenarios. The process produces minimal greenhouse gas emissions directly, though the carbon footprint associated with energy consumption remains relevant. Importantly, ozone generation—a common concern with plasma technologies—has been measured at levels below regulatory thresholds when proper containment systems are employed.

Water resource impacts appear negligible in most applications, as cold plasma treatment typically requires minimal water input compared to conventional chemical washing techniques. This represents a significant advantage in water-stressed regions where remediation activities must balance contaminant removal against water conservation priorities.

Biodiversity effects show promising results in preliminary field studies. Soil microbial communities demonstrate remarkable resilience following cold plasma treatment, with microbial diversity indices returning to baseline levels within 3-6 months post-treatment. Plant growth in treated soils shows enhanced germination rates and reduced heavy metal uptake, suggesting positive implications for ecosystem recovery.

Long-term environmental monitoring protocols remain essential, as the technology's effects on complex ecological systems over extended timeframes require further documentation. Current data suggests minimal persistent environmental impacts when the technology is properly implemented with appropriate containment and monitoring systems.

The primary environmental benefit of cold plasma treatment lies in its ability to reduce heavy metal contamination in various environmental matrices without generating secondary pollutants. Unlike traditional chemical treatments that often introduce additional compounds into ecosystems, cold plasma operates through physical processes that minimize residual environmental footprint. Studies conducted across multiple contaminated sites demonstrate up to 85% reduction in bioavailable heavy metals following plasma application, significantly decreasing their mobility in soil and water systems.

Energy consumption represents a notable environmental consideration for cold plasma systems. Current industrial-scale plasma generators require substantial electrical input, with energy intensities ranging from 0.5-2.0 kWh per cubic meter of treated material. However, this energy footprint is showing a declining trend as newer plasma generation technologies emerge, with recent innovations reducing energy requirements by approximately 30% compared to systems from five years ago.

Atmospheric emissions during cold plasma operation have been extensively monitored across multiple implementation scenarios. The process produces minimal greenhouse gas emissions directly, though the carbon footprint associated with energy consumption remains relevant. Importantly, ozone generation—a common concern with plasma technologies—has been measured at levels below regulatory thresholds when proper containment systems are employed.

Water resource impacts appear negligible in most applications, as cold plasma treatment typically requires minimal water input compared to conventional chemical washing techniques. This represents a significant advantage in water-stressed regions where remediation activities must balance contaminant removal against water conservation priorities.

Biodiversity effects show promising results in preliminary field studies. Soil microbial communities demonstrate remarkable resilience following cold plasma treatment, with microbial diversity indices returning to baseline levels within 3-6 months post-treatment. Plant growth in treated soils shows enhanced germination rates and reduced heavy metal uptake, suggesting positive implications for ecosystem recovery.

Long-term environmental monitoring protocols remain essential, as the technology's effects on complex ecological systems over extended timeframes require further documentation. Current data suggests minimal persistent environmental impacts when the technology is properly implemented with appropriate containment and monitoring systems.

Regulatory Framework for Industrial Applications

The regulatory landscape governing cold plasma treatment for heavy metal deposition control spans multiple jurisdictions and continues to evolve as the technology gains wider industrial adoption. In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Clean Air Act and Clean Water Act that directly impact industrial applications of cold plasma technology. These regulations specifically address emission standards and effluent limitations that industries must adhere to when implementing plasma-based remediation systems.

The European Union has implemented more stringent frameworks through the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations. These frameworks require comprehensive risk assessments and validation protocols before cold plasma systems can be deployed at industrial scale. Notably, the EU's Best Available Techniques Reference Documents (BREFs) have recently begun to include specific provisions for plasma-based treatment technologies in metal processing industries.

In Asia, regulatory approaches vary significantly. Japan has integrated cold plasma treatment into its Advanced Industrial Science and Technology (AIST) standards, providing clear pathways for industrial implementation. China, meanwhile, has incorporated plasma treatment technologies into its recent Five-Year Plan for environmental protection, though enforcement mechanisms remain inconsistent across provinces.

International standards organizations have also contributed to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 14001 environmental management standards that indirectly govern plasma treatment applications. Similarly, the International Electrotechnical Commission (IEC) has established safety standards for plasma equipment under IEC 60601 series.

Compliance requirements typically include performance validation testing, emissions monitoring, and regular reporting. Industries must demonstrate that their cold plasma systems consistently achieve specified heavy metal reduction targets without generating harmful byproducts. Documentation requirements have become increasingly standardized, with most jurisdictions now requiring detailed operational logs and maintenance records.

Recent regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. This shift provides greater flexibility for technology innovation while maintaining environmental protection goals. Several jurisdictions are developing specialized certification programs for plasma treatment technologies, which may eventually streamline approval processes for industrial applications.

Cross-border harmonization efforts are underway through initiatives like the Strategic Approach to International Chemicals Management (SAICM), which aims to standardize regulatory approaches to emerging technologies including cold plasma treatment. These efforts may eventually reduce compliance burdens for multinational corporations implementing plasma-based heavy metal control systems across multiple facilities.

The European Union has implemented more stringent frameworks through the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations. These frameworks require comprehensive risk assessments and validation protocols before cold plasma systems can be deployed at industrial scale. Notably, the EU's Best Available Techniques Reference Documents (BREFs) have recently begun to include specific provisions for plasma-based treatment technologies in metal processing industries.

In Asia, regulatory approaches vary significantly. Japan has integrated cold plasma treatment into its Advanced Industrial Science and Technology (AIST) standards, providing clear pathways for industrial implementation. China, meanwhile, has incorporated plasma treatment technologies into its recent Five-Year Plan for environmental protection, though enforcement mechanisms remain inconsistent across provinces.

International standards organizations have also contributed to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 14001 environmental management standards that indirectly govern plasma treatment applications. Similarly, the International Electrotechnical Commission (IEC) has established safety standards for plasma equipment under IEC 60601 series.

Compliance requirements typically include performance validation testing, emissions monitoring, and regular reporting. Industries must demonstrate that their cold plasma systems consistently achieve specified heavy metal reduction targets without generating harmful byproducts. Documentation requirements have become increasingly standardized, with most jurisdictions now requiring detailed operational logs and maintenance records.

Recent regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. This shift provides greater flexibility for technology innovation while maintaining environmental protection goals. Several jurisdictions are developing specialized certification programs for plasma treatment technologies, which may eventually streamline approval processes for industrial applications.

Cross-border harmonization efforts are underway through initiatives like the Strategic Approach to International Chemicals Management (SAICM), which aims to standardize regulatory approaches to emerging technologies including cold plasma treatment. These efforts may eventually reduce compliance burdens for multinational corporations implementing plasma-based heavy metal control systems across multiple facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!