Comprehensive Study on Cold Plasma Treatment of Thermoplastics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Evolution and Objectives

Cold plasma technology has evolved significantly since its inception in the early 20th century. Initially developed for laboratory applications, cold plasma treatment emerged as a promising surface modification technique in the 1960s. The fundamental breakthrough came with the ability to generate plasma at atmospheric pressure and near-ambient temperatures, making it suitable for treating heat-sensitive materials like thermoplastics. This technological advancement opened new possibilities across various industries, from electronics to biomedical applications.

The evolution of cold plasma technology for thermoplastic treatment has progressed through several distinct phases. The first generation systems utilized basic glow discharge mechanisms with limited control parameters. By the 1980s, second-generation systems incorporated improved power supplies and electrode designs, enabling more precise treatment outcomes. The current third-generation systems feature sophisticated control algorithms, specialized gas mixtures, and advanced monitoring capabilities that allow for tailored surface modifications with unprecedented precision.

Recent technological advancements have focused on enhancing energy efficiency, reducing treatment times, and developing specialized plasma sources for specific thermoplastic materials. Notable innovations include the development of dielectric barrier discharge (DBD) systems, atmospheric pressure plasma jets (APPJ), and corona discharge technologies that offer distinct advantages for different thermoplastic treatment scenarios. These advancements have collectively expanded the application scope while reducing operational costs.

The primary objectives of cold plasma treatment for thermoplastics center around enhancing surface properties without altering bulk characteristics. These include improving adhesion properties for coating and bonding applications, increasing wettability for printing processes, and creating antimicrobial or biocompatible surfaces for medical devices. Additionally, researchers aim to develop environmentally friendly alternatives to chemical treatments, aligning with global sustainability initiatives.

Future technological objectives include developing real-time monitoring systems for quality control, creating portable and flexible plasma treatment solutions for complex geometries, and establishing standardized protocols for specific thermoplastic materials. There is also significant interest in combining cold plasma with other surface modification techniques to achieve synergistic effects and novel functionalities.

The convergence of computational modeling, materials science, and plasma physics is expected to drive the next wave of innovations. Researchers are increasingly utilizing simulation tools to predict plasma-surface interactions, optimize treatment parameters, and develop new plasma sources specifically designed for challenging thermoplastic materials like high-performance engineering polymers. These interdisciplinary approaches aim to overcome current limitations and expand the technological capabilities of cold plasma treatment systems.

The evolution of cold plasma technology for thermoplastic treatment has progressed through several distinct phases. The first generation systems utilized basic glow discharge mechanisms with limited control parameters. By the 1980s, second-generation systems incorporated improved power supplies and electrode designs, enabling more precise treatment outcomes. The current third-generation systems feature sophisticated control algorithms, specialized gas mixtures, and advanced monitoring capabilities that allow for tailored surface modifications with unprecedented precision.

Recent technological advancements have focused on enhancing energy efficiency, reducing treatment times, and developing specialized plasma sources for specific thermoplastic materials. Notable innovations include the development of dielectric barrier discharge (DBD) systems, atmospheric pressure plasma jets (APPJ), and corona discharge technologies that offer distinct advantages for different thermoplastic treatment scenarios. These advancements have collectively expanded the application scope while reducing operational costs.

The primary objectives of cold plasma treatment for thermoplastics center around enhancing surface properties without altering bulk characteristics. These include improving adhesion properties for coating and bonding applications, increasing wettability for printing processes, and creating antimicrobial or biocompatible surfaces for medical devices. Additionally, researchers aim to develop environmentally friendly alternatives to chemical treatments, aligning with global sustainability initiatives.

Future technological objectives include developing real-time monitoring systems for quality control, creating portable and flexible plasma treatment solutions for complex geometries, and establishing standardized protocols for specific thermoplastic materials. There is also significant interest in combining cold plasma with other surface modification techniques to achieve synergistic effects and novel functionalities.

The convergence of computational modeling, materials science, and plasma physics is expected to drive the next wave of innovations. Researchers are increasingly utilizing simulation tools to predict plasma-surface interactions, optimize treatment parameters, and develop new plasma sources specifically designed for challenging thermoplastic materials like high-performance engineering polymers. These interdisciplinary approaches aim to overcome current limitations and expand the technological capabilities of cold plasma treatment systems.

Market Analysis for Plasma-Treated Thermoplastics

The global market for plasma-treated thermoplastics has experienced significant growth over the past decade, driven primarily by increasing demand for enhanced surface properties in various industrial applications. Current market valuation stands at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028, according to recent industry reports from Grand View Research and Markets and Markets.

The automotive sector represents the largest application segment, accounting for roughly 28% of the total market share. This dominance stems from the growing utilization of lightweight thermoplastic components that require improved adhesion properties for painting, coating, and assembly processes. Cold plasma treatment effectively addresses these requirements without compromising the bulk material properties.

Medical device manufacturing has emerged as the fastest-growing segment, with demand increasing at nearly 9% annually. The need for biocompatible surfaces, improved sterilization capabilities, and enhanced adhesion for coatings on medical-grade thermoplastics is driving this growth. Hospitals and healthcare facilities increasingly prefer plasma-treated thermoplastic devices due to their superior performance characteristics and reduced infection risks.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 62%. However, the Asia-Pacific region is witnessing the most rapid expansion, particularly in countries like China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced surface modification technologies to meet international quality standards and export requirements.

Consumer electronics represents another significant market segment, where plasma treatment enables improved bonding between thermoplastic components and metal or other dissimilar materials. This application is particularly valuable for waterproofing and creating robust seals in portable electronic devices, contributing approximately 18% to the overall market value.

Market analysis reveals that industries are increasingly favoring cold plasma treatment over traditional chemical surface modification methods due to environmental considerations, reduced processing costs, and improved quality control. The absence of hazardous chemical waste and lower energy consumption compared to thermal treatments positions cold plasma as an environmentally sustainable technology, aligning with global manufacturing trends toward greener production processes.

The market landscape is characterized by a growing demand for customized plasma treatment solutions tailored to specific thermoplastic materials and end-use applications. This trend is creating opportunities for specialized equipment manufacturers and service providers who can deliver application-specific plasma treatment parameters and process optimization.

The automotive sector represents the largest application segment, accounting for roughly 28% of the total market share. This dominance stems from the growing utilization of lightweight thermoplastic components that require improved adhesion properties for painting, coating, and assembly processes. Cold plasma treatment effectively addresses these requirements without compromising the bulk material properties.

Medical device manufacturing has emerged as the fastest-growing segment, with demand increasing at nearly 9% annually. The need for biocompatible surfaces, improved sterilization capabilities, and enhanced adhesion for coatings on medical-grade thermoplastics is driving this growth. Hospitals and healthcare facilities increasingly prefer plasma-treated thermoplastic devices due to their superior performance characteristics and reduced infection risks.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 62%. However, the Asia-Pacific region is witnessing the most rapid expansion, particularly in countries like China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced surface modification technologies to meet international quality standards and export requirements.

Consumer electronics represents another significant market segment, where plasma treatment enables improved bonding between thermoplastic components and metal or other dissimilar materials. This application is particularly valuable for waterproofing and creating robust seals in portable electronic devices, contributing approximately 18% to the overall market value.

Market analysis reveals that industries are increasingly favoring cold plasma treatment over traditional chemical surface modification methods due to environmental considerations, reduced processing costs, and improved quality control. The absence of hazardous chemical waste and lower energy consumption compared to thermal treatments positions cold plasma as an environmentally sustainable technology, aligning with global manufacturing trends toward greener production processes.

The market landscape is characterized by a growing demand for customized plasma treatment solutions tailored to specific thermoplastic materials and end-use applications. This trend is creating opportunities for specialized equipment manufacturers and service providers who can deliver application-specific plasma treatment parameters and process optimization.

Current Challenges in Cold Plasma Treatment

Despite significant advancements in cold plasma treatment of thermoplastics, several critical challenges continue to impede widespread industrial adoption and optimal performance. One of the primary obstacles remains the inconsistent surface modification across complex geometries. When treating three-dimensional thermoplastic components with intricate shapes, achieving uniform plasma exposure becomes technically difficult, resulting in varying degrees of surface activation and potentially compromising product quality.

The transient nature of plasma-induced surface modifications presents another significant challenge. Studies indicate that the beneficial effects of plasma treatment on thermoplastics typically diminish over time, a phenomenon known as hydrophobic recovery. This aging effect occurs as the modified polymer chains reorient themselves to minimize surface energy, often within hours or days after treatment, necessitating immediate post-treatment processing or additional stabilization techniques.

Process scalability remains problematic for industrial implementation. While laboratory-scale plasma treatments demonstrate excellent results, translating these outcomes to high-volume manufacturing environments introduces complications related to treatment speed, equipment design, and process integration. The balance between treatment effectiveness and production throughput creates a significant technological bottleneck for mass production scenarios.

Energy efficiency and environmental considerations pose additional challenges. Conventional cold plasma systems require substantial energy input, particularly for atmospheric pressure plasma treatments. The environmental impact of process gases and by-products also raises concerns, especially as industries face increasing pressure to adopt sustainable manufacturing practices.

Material-specific limitations further complicate plasma treatment processes. Different thermoplastic compositions respond uniquely to plasma exposure, with some polymers exhibiting degradation, discoloration, or insufficient surface modification. This variability necessitates customized treatment protocols for different thermoplastic types, complicating standardization efforts across diverse product portfolios.

Process control and quality assurance represent ongoing challenges. Real-time monitoring of plasma treatment effectiveness remains difficult, with most quality assessments occurring post-treatment. The lack of in-line measurement capabilities for surface energy, chemical composition, or adhesion properties hinders closed-loop process control and consistent quality management.

Cost considerations continue to impact adoption rates. The capital investment required for plasma treatment equipment, coupled with operational expenses and potential production speed limitations, creates economic barriers for many manufacturers, particularly small and medium enterprises seeking to implement this technology.

The transient nature of plasma-induced surface modifications presents another significant challenge. Studies indicate that the beneficial effects of plasma treatment on thermoplastics typically diminish over time, a phenomenon known as hydrophobic recovery. This aging effect occurs as the modified polymer chains reorient themselves to minimize surface energy, often within hours or days after treatment, necessitating immediate post-treatment processing or additional stabilization techniques.

Process scalability remains problematic for industrial implementation. While laboratory-scale plasma treatments demonstrate excellent results, translating these outcomes to high-volume manufacturing environments introduces complications related to treatment speed, equipment design, and process integration. The balance between treatment effectiveness and production throughput creates a significant technological bottleneck for mass production scenarios.

Energy efficiency and environmental considerations pose additional challenges. Conventional cold plasma systems require substantial energy input, particularly for atmospheric pressure plasma treatments. The environmental impact of process gases and by-products also raises concerns, especially as industries face increasing pressure to adopt sustainable manufacturing practices.

Material-specific limitations further complicate plasma treatment processes. Different thermoplastic compositions respond uniquely to plasma exposure, with some polymers exhibiting degradation, discoloration, or insufficient surface modification. This variability necessitates customized treatment protocols for different thermoplastic types, complicating standardization efforts across diverse product portfolios.

Process control and quality assurance represent ongoing challenges. Real-time monitoring of plasma treatment effectiveness remains difficult, with most quality assessments occurring post-treatment. The lack of in-line measurement capabilities for surface energy, chemical composition, or adhesion properties hinders closed-loop process control and consistent quality management.

Cost considerations continue to impact adoption rates. The capital investment required for plasma treatment equipment, coupled with operational expenses and potential production speed limitations, creates economic barriers for many manufacturers, particularly small and medium enterprises seeking to implement this technology.

Existing Cold Plasma Treatment Methods

01 Surface modification of thermoplastics using cold plasma

Cold plasma treatment can be used to modify the surface properties of thermoplastic materials. This process alters the surface chemistry and topography, enhancing properties such as wettability, adhesion, and biocompatibility without affecting the bulk properties of the material. The treatment creates functional groups on the surface that can improve bonding with other materials, making it valuable for applications requiring strong adhesion or coating.- Surface modification of thermoplastics using cold plasma: Cold plasma treatment can be used to modify the surface properties of thermoplastic materials, enhancing characteristics such as wettability, adhesion, and biocompatibility. The process involves exposing the thermoplastic surface to ionized gas at low temperatures, which creates reactive species that interact with the polymer surface without affecting the bulk properties. This treatment can introduce functional groups, increase surface energy, and improve bonding capabilities for subsequent coating or adhesive applications.

- Medical applications of cold plasma treated thermoplastics: Cold plasma treatment of thermoplastics has significant applications in medical devices and implants. The treatment enhances biocompatibility, reduces bacterial adhesion, and improves integration with biological tissues. Plasma-treated thermoplastic components can be used in various medical applications including catheters, surgical instruments, and implantable devices. The treatment can also be tailored to create antimicrobial surfaces or to promote specific cellular responses, making it valuable for tissue engineering and regenerative medicine applications.

- Cold plasma systems and equipment for thermoplastic processing: Specialized equipment and systems have been developed for the cold plasma treatment of thermoplastics in industrial settings. These systems typically include plasma generators, gas delivery systems, treatment chambers, and control mechanisms to ensure consistent and uniform treatment. Various configurations exist, including atmospheric pressure plasma systems and vacuum-based setups, each offering different advantages for specific thermoplastic materials and applications. Advanced systems may incorporate real-time monitoring and feedback control to optimize treatment parameters based on material properties and desired outcomes.

- Process parameters and optimization for cold plasma treatment: The effectiveness of cold plasma treatment on thermoplastics depends on various process parameters that can be optimized for specific applications. These parameters include gas composition, power input, treatment time, pressure, and distance between the plasma source and the substrate. The optimization of these parameters is crucial for achieving desired surface modifications while minimizing potential damage to the thermoplastic material. Different thermoplastic materials may require different treatment conditions to achieve optimal results, necessitating careful process development and control.

- Industrial applications and manufacturing integration: Cold plasma treatment of thermoplastics has been integrated into various industrial manufacturing processes to enhance product performance and enable new applications. The treatment can be implemented as an in-line process in production environments, allowing for continuous treatment of thermoplastic components. Applications include automotive parts, packaging materials, electronic components, and consumer goods. The treatment can improve paint adhesion, printability, and bonding strength in multi-material assemblies. Recent developments focus on energy-efficient plasma systems and methods to treat complex three-dimensional thermoplastic parts uniformly.

02 Medical applications of cold plasma treated thermoplastics

Cold plasma treatment of thermoplastics has significant applications in the medical field. The treatment enhances the biocompatibility of thermoplastic medical devices, reduces bacterial adhesion, and improves sterilization efficacy. Plasma-treated thermoplastic surfaces can better interact with biological tissues and fluids, making them suitable for implants, catheters, and other medical devices. The treatment can also incorporate antimicrobial properties into the thermoplastic surface.Expand Specific Solutions03 Cold plasma equipment and process parameters for thermoplastic treatment

Specialized equipment and carefully controlled process parameters are essential for effective cold plasma treatment of thermoplastics. The equipment typically includes plasma generators, vacuum chambers, and gas delivery systems. Key process parameters include gas composition, pressure, power input, treatment time, and distance between the plasma source and the thermoplastic surface. These parameters must be optimized based on the specific thermoplastic material and the desired surface properties.Expand Specific Solutions04 Enhanced adhesion and coating properties of plasma-treated thermoplastics

Cold plasma treatment significantly improves the adhesion and coating properties of thermoplastic materials. The treatment creates reactive sites on the thermoplastic surface that form strong chemical bonds with adhesives, coatings, and other materials. This enhanced adhesion is valuable in manufacturing processes involving multi-material assemblies, printing on thermoplastics, and applying functional coatings. The improved wettability also allows for more uniform coating distribution.Expand Specific Solutions05 Environmental and industrial applications of cold plasma treated thermoplastics

Cold plasma treatment of thermoplastics has various environmental and industrial applications. The treatment can improve the recyclability of thermoplastic materials by enhancing their compatibility with other materials in recycling processes. In industrial settings, plasma-treated thermoplastics show improved resistance to chemical degradation, weathering, and wear. The treatment can also be used to create specialized surfaces for filtration, sensing, and catalytic applications.Expand Specific Solutions

Leading Companies in Plasma Technology

Cold plasma treatment of thermoplastics is currently in a growth phase, with the market expanding due to increasing applications in surface modification, adhesion improvement, and biomedical applications. The global market is estimated to reach several billion dollars by 2025, driven by automotive, electronics, and healthcare sectors. Leading companies demonstrate varying levels of technological maturity: Air Liquide, Tokyo Electron, and Solvay have established commercial solutions, while specialized players like US Medical Innovations, Plasmology4, and CAPS Medical are advancing niche applications in medical treatments. Research institutions including CNRS, Technion, and Purdue Research Foundation are pushing boundaries in fundamental plasma science. The competitive landscape features both diversified industrial conglomerates and specialized startups, with increasing patent activity suggesting accelerating innovation in this field.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed a proprietary cold plasma treatment platform specifically engineered for thermoplastic modification across multiple industries. Their technology utilizes a patented dielectric barrier discharge (DBD) system that generates non-thermal plasma at atmospheric pressure, eliminating the need for vacuum chambers and reducing operational complexity. The company's plasma systems can process thermoplastics at speeds up to 300 feet per minute while maintaining treatment uniformity across variable geometries. Their technology employs a unique electrode design that creates a homogeneous plasma field, ensuring consistent surface modification even on complex three-dimensional thermoplastic parts. Plasmology4's systems can achieve surface energy increases from typical 30-40 dyne/cm to over 72 dyne/cm on various thermoplastics including polyolefins, polyesters, and engineering plastics [5]. The company has developed specialized treatment protocols for medical-grade thermoplastics that enhance biocompatibility and cell adhesion properties without introducing cytotoxic residues. Recent innovations include their "PlasmaSync" technology that automatically adjusts treatment parameters based on real-time feedback from the thermoplastic substrate [2][8].

Strengths: Atmospheric pressure operation reducing equipment complexity and cost; high-throughput capabilities suitable for industrial production; specialized expertise in medical and packaging applications. Weaknesses: Limited treatment depth compared to vacuum plasma systems; less effective for highly complex geometries with deep recesses; relatively newer company with less established industry presence compared to larger competitors.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has developed advanced plasma treatment systems specifically designed for thermoplastic modification. Their technology utilizes capacitively coupled plasma (CCP) and inductively coupled plasma (ICP) configurations to achieve precise surface modifications of thermoplastics. The company's plasma treatment solutions operate at various pressure ranges (from atmospheric to high vacuum) with controlled gas chemistry to target specific surface properties. Their systems incorporate real-time monitoring capabilities that adjust plasma parameters based on material feedback, ensuring consistent treatment quality across different thermoplastic compositions. Tokyo Electron's cold plasma technology can modify surface energy, improve adhesion properties, and enhance printability of thermoplastics without affecting bulk material properties. Recent innovations include multi-stage plasma treatment processes that can sequentially functionalize surfaces with different chemical groups, allowing for customized surface engineering of complex thermoplastic components used in semiconductor packaging and electronic devices [1][3].

Strengths: Precise control over plasma parameters enabling customized surface modifications; advanced monitoring systems ensuring treatment uniformity; extensive experience in semiconductor applications providing technical expertise. Weaknesses: Systems typically require significant capital investment; primarily focused on electronics industry applications rather than broader thermoplastic markets; complex operation requiring specialized technical knowledge.

Key Patents in Thermoplastic Surface Activation

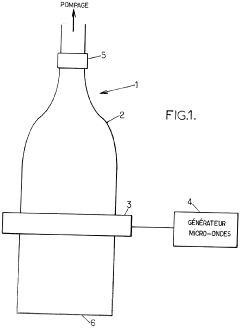

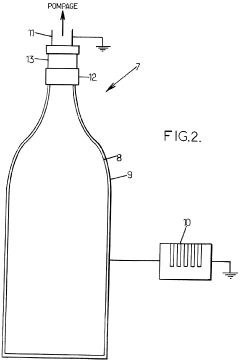

Method for cold plasma treatment of plastic bottles and device for implementing same

PatentWO2008015358A2

Innovation

- A process utilizing cold plasma, generated by surface wave field applicators or hollow cathode systems, to provide a high-density, spatially uniform flow of radicals and non-thermal energy for sterilization and barrier layer deposition, reducing sterilization and deposition times while avoiding chemical contaminants and multiple transfer steps.

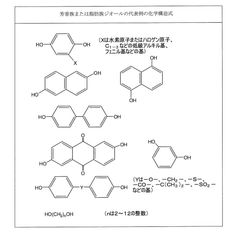

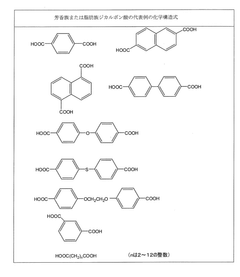

Thermoplastic liquid crystal polymer molded body and method for producing same

PatentWO2021039769A1

Innovation

- A method involving plasma treatment of the thermoplastic liquid crystal polymer surfaces with a direct method at high output and short duration, followed by vacuum drying or heat degassing, to modify the surface chemical bonds and enhance adhesion, including the use of nitrogen-containing and oxygen-containing gases in the plasma treatment.

Environmental Impact Assessment

The environmental impact of cold plasma treatment for thermoplastics represents a critical consideration in the broader adoption of this technology across industries. When compared to conventional thermoplastic surface modification techniques such as chemical treatments, mechanical abrasion, or thermal processes, cold plasma offers significant environmental advantages. The process operates at ambient temperatures with minimal energy consumption, substantially reducing the carbon footprint associated with surface modification operations.

Cold plasma technology eliminates the need for environmentally harmful solvents and chemicals commonly used in traditional surface treatments. This reduction in hazardous chemical usage translates to decreased environmental pollution, reduced waste management requirements, and improved workplace safety conditions. The process generates minimal waste streams, with most byproducts being non-toxic gases that can be safely released or captured through standard ventilation systems.

Water consumption represents another important environmental metric where cold plasma demonstrates superior performance. Unlike wet chemical processes that may require significant volumes of water for processing and rinsing, plasma treatment is essentially a dry process. This characteristic makes it particularly valuable in regions facing water scarcity challenges and for industries seeking to minimize their water footprint.

Life cycle assessment (LCA) studies comparing cold plasma to conventional treatments indicate potential reductions in environmental impact categories including global warming potential, acidification, and resource depletion. However, comprehensive LCA data specific to thermoplastic applications remains limited, highlighting a need for further research in this area.

The scalability of cold plasma systems presents both opportunities and challenges from an environmental perspective. While larger industrial systems may consume more energy, they typically offer improved efficiency per unit of treated material. Recent technological advances have focused on optimizing power consumption through pulsed plasma systems and precise control mechanisms, further enhancing environmental performance.

Regulatory frameworks increasingly favor technologies with reduced environmental impacts. Cold plasma treatment aligns well with initiatives such as the European Union's REACH regulations and various green manufacturing certifications, potentially offering compliance advantages for manufacturers. This regulatory alignment may accelerate adoption as environmental standards continue to tighten globally.

Future research directions should focus on quantifying environmental benefits through standardized metrics, optimizing energy efficiency of plasma generation systems, and developing closed-loop implementations that capture and reuse process gases. These advancements would further strengthen the environmental case for cold plasma treatment of thermoplastics across diverse industrial applications.

Cold plasma technology eliminates the need for environmentally harmful solvents and chemicals commonly used in traditional surface treatments. This reduction in hazardous chemical usage translates to decreased environmental pollution, reduced waste management requirements, and improved workplace safety conditions. The process generates minimal waste streams, with most byproducts being non-toxic gases that can be safely released or captured through standard ventilation systems.

Water consumption represents another important environmental metric where cold plasma demonstrates superior performance. Unlike wet chemical processes that may require significant volumes of water for processing and rinsing, plasma treatment is essentially a dry process. This characteristic makes it particularly valuable in regions facing water scarcity challenges and for industries seeking to minimize their water footprint.

Life cycle assessment (LCA) studies comparing cold plasma to conventional treatments indicate potential reductions in environmental impact categories including global warming potential, acidification, and resource depletion. However, comprehensive LCA data specific to thermoplastic applications remains limited, highlighting a need for further research in this area.

The scalability of cold plasma systems presents both opportunities and challenges from an environmental perspective. While larger industrial systems may consume more energy, they typically offer improved efficiency per unit of treated material. Recent technological advances have focused on optimizing power consumption through pulsed plasma systems and precise control mechanisms, further enhancing environmental performance.

Regulatory frameworks increasingly favor technologies with reduced environmental impacts. Cold plasma treatment aligns well with initiatives such as the European Union's REACH regulations and various green manufacturing certifications, potentially offering compliance advantages for manufacturers. This regulatory alignment may accelerate adoption as environmental standards continue to tighten globally.

Future research directions should focus on quantifying environmental benefits through standardized metrics, optimizing energy efficiency of plasma generation systems, and developing closed-loop implementations that capture and reuse process gases. These advancements would further strengthen the environmental case for cold plasma treatment of thermoplastics across diverse industrial applications.

Industry Standards and Quality Control

The cold plasma treatment of thermoplastics requires stringent quality control measures and adherence to established industry standards to ensure consistent and reliable outcomes. Currently, several international organizations have developed standards specifically addressing plasma treatment processes, including ISO 10993-1 for biocompatibility assessment of plasma-treated medical devices and ASTM D5946 for standard test methods for corona-treated polymer films.

Quality control in plasma treatment processes typically involves monitoring key parameters such as plasma power density, exposure time, gas composition, and pressure. These parameters must be precisely controlled within specified ranges to achieve desired surface modifications without compromising the bulk properties of thermoplastics. Many manufacturers implement statistical process control (SPC) methods to track these variables and ensure process stability over time.

Surface characterization techniques play a crucial role in quality assurance protocols. Contact angle measurements serve as a primary quality indicator, with most industries requiring specific ranges depending on the application. For adhesion-critical applications, values between 40-60 degrees are typically specified, while medical applications often require more stringent controls with narrower acceptable ranges.

XPS (X-ray Photoelectron Spectroscopy) and FTIR (Fourier Transform Infrared Spectroscopy) analyses are increasingly becoming standard requirements for high-precision applications, particularly in aerospace and medical industries. These techniques provide quantitative data on surface chemical composition and functional group formation, enabling more precise quality control than traditional methods.

Traceability requirements have become more rigorous in recent years, with regulatory bodies demanding comprehensive documentation of plasma treatment parameters, equipment calibration records, and validation studies. The FDA's Quality System Regulation (21 CFR Part 820) specifically addresses process validation requirements for medical device manufacturers utilizing plasma treatment, mandating thorough documentation and periodic revalidation.

Industry-specific standards vary significantly, with automotive applications following VDA standards, electronics manufacturers adhering to IPC guidelines, and medical device producers complying with ISO 13485. These standards often specify not only the quality control methods but also the frequency of testing and acceptable tolerance ranges for various surface properties.

Emerging trends in quality control include the implementation of real-time monitoring systems that utilize spectroscopic techniques to analyze plasma characteristics during processing, allowing for immediate adjustments to maintain optimal treatment conditions. Additionally, machine learning algorithms are being developed to predict treatment outcomes based on process parameters, potentially revolutionizing quality control approaches in plasma treatment facilities.

Quality control in plasma treatment processes typically involves monitoring key parameters such as plasma power density, exposure time, gas composition, and pressure. These parameters must be precisely controlled within specified ranges to achieve desired surface modifications without compromising the bulk properties of thermoplastics. Many manufacturers implement statistical process control (SPC) methods to track these variables and ensure process stability over time.

Surface characterization techniques play a crucial role in quality assurance protocols. Contact angle measurements serve as a primary quality indicator, with most industries requiring specific ranges depending on the application. For adhesion-critical applications, values between 40-60 degrees are typically specified, while medical applications often require more stringent controls with narrower acceptable ranges.

XPS (X-ray Photoelectron Spectroscopy) and FTIR (Fourier Transform Infrared Spectroscopy) analyses are increasingly becoming standard requirements for high-precision applications, particularly in aerospace and medical industries. These techniques provide quantitative data on surface chemical composition and functional group formation, enabling more precise quality control than traditional methods.

Traceability requirements have become more rigorous in recent years, with regulatory bodies demanding comprehensive documentation of plasma treatment parameters, equipment calibration records, and validation studies. The FDA's Quality System Regulation (21 CFR Part 820) specifically addresses process validation requirements for medical device manufacturers utilizing plasma treatment, mandating thorough documentation and periodic revalidation.

Industry-specific standards vary significantly, with automotive applications following VDA standards, electronics manufacturers adhering to IPC guidelines, and medical device producers complying with ISO 13485. These standards often specify not only the quality control methods but also the frequency of testing and acceptable tolerance ranges for various surface properties.

Emerging trends in quality control include the implementation of real-time monitoring systems that utilize spectroscopic techniques to analyze plasma characteristics during processing, allowing for immediate adjustments to maintain optimal treatment conditions. Additionally, machine learning algorithms are being developed to predict treatment outcomes based on process parameters, potentially revolutionizing quality control approaches in plasma treatment facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!