Cold Plasma Treatment of Agricultural Products: Safety and Standards

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Evolution and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from primarily industrial applications to emerging agricultural uses. Initially developed in the early 20th century for material surface modifications, cold plasma technology has undergone substantial refinement since the 1990s with the development of atmospheric pressure plasma systems that eliminated the need for vacuum chambers, making the technology more accessible and cost-effective for broader applications.

The evolution of cold plasma in agricultural applications began in earnest during the early 2000s, when researchers first explored its potential for seed germination enhancement and pathogen reduction on food surfaces. By 2010, significant advancements in plasma source miniaturization and energy efficiency enabled more targeted applications in food processing. The period between 2015 and 2020 marked a critical transition, with cold plasma technology demonstrating promising results in extending shelf life, reducing pesticide residues, and improving the microbiological safety of various agricultural products without compromising nutritional quality.

Recent technological developments have focused on optimizing plasma parameters (gas composition, power input, treatment time) specifically for agricultural applications, moving beyond the one-size-fits-all approach borrowed from industrial applications. The integration of cold plasma with other preservation technologies, such as modified atmosphere packaging and bioactive coatings, represents the current frontier of innovation in this field.

The primary objectives of cold plasma technology in agricultural applications center around enhancing food safety through microbial inactivation while maintaining product quality. Specifically, researchers aim to develop standardized treatment protocols that can achieve consistent 5-log reductions in pathogenic microorganisms across diverse agricultural products. Another critical objective involves establishing clear safety parameters that address concerns about potential chemical residues, particularly reactive nitrogen and oxygen species that may form during plasma treatment.

Long-term technological goals include developing energy-efficient, scalable plasma systems suitable for commercial implementation across the agricultural supply chain. This encompasses portable units for on-farm applications, in-line systems for processing facilities, and even consumer-level devices. Additionally, researchers are working toward comprehensive understanding of plasma-food interactions at the molecular level to enable precise control of treatment outcomes.

The convergence of cold plasma technology with digital monitoring systems and artificial intelligence represents an emerging trend, with objectives focused on real-time adjustment of plasma parameters based on product characteristics and contamination levels. This adaptive approach aims to optimize treatment efficiency while minimizing energy consumption and potential negative effects on product quality.

The evolution of cold plasma in agricultural applications began in earnest during the early 2000s, when researchers first explored its potential for seed germination enhancement and pathogen reduction on food surfaces. By 2010, significant advancements in plasma source miniaturization and energy efficiency enabled more targeted applications in food processing. The period between 2015 and 2020 marked a critical transition, with cold plasma technology demonstrating promising results in extending shelf life, reducing pesticide residues, and improving the microbiological safety of various agricultural products without compromising nutritional quality.

Recent technological developments have focused on optimizing plasma parameters (gas composition, power input, treatment time) specifically for agricultural applications, moving beyond the one-size-fits-all approach borrowed from industrial applications. The integration of cold plasma with other preservation technologies, such as modified atmosphere packaging and bioactive coatings, represents the current frontier of innovation in this field.

The primary objectives of cold plasma technology in agricultural applications center around enhancing food safety through microbial inactivation while maintaining product quality. Specifically, researchers aim to develop standardized treatment protocols that can achieve consistent 5-log reductions in pathogenic microorganisms across diverse agricultural products. Another critical objective involves establishing clear safety parameters that address concerns about potential chemical residues, particularly reactive nitrogen and oxygen species that may form during plasma treatment.

Long-term technological goals include developing energy-efficient, scalable plasma systems suitable for commercial implementation across the agricultural supply chain. This encompasses portable units for on-farm applications, in-line systems for processing facilities, and even consumer-level devices. Additionally, researchers are working toward comprehensive understanding of plasma-food interactions at the molecular level to enable precise control of treatment outcomes.

The convergence of cold plasma technology with digital monitoring systems and artificial intelligence represents an emerging trend, with objectives focused on real-time adjustment of plasma parameters based on product characteristics and contamination levels. This adaptive approach aims to optimize treatment efficiency while minimizing energy consumption and potential negative effects on product quality.

Agricultural Market Demand for Cold Plasma Applications

The global agricultural market is experiencing a significant shift towards sustainable and environmentally friendly technologies, creating a fertile ground for cold plasma applications. Current market analysis indicates that the agricultural sector is increasingly receptive to cold plasma technology due to its potential to address critical challenges in food safety, shelf-life extension, and reduction of chemical inputs. The market demand is primarily driven by consumer preferences for minimally processed foods with fewer chemical residues, alongside stringent regulatory requirements for food safety across international markets.

Cold plasma technology's versatility in agricultural applications has created multiple market segments with distinct growth trajectories. The post-harvest treatment segment currently represents the largest market share, with applications in decontamination of fruits, vegetables, grains, and seeds showing particular promise. Industry reports suggest that the cold plasma agricultural market is projected to grow at a compound annual growth rate exceeding 10% through 2030, with the post-harvest segment maintaining its dominant position.

Geographically, North America and Europe lead in adoption rates, primarily due to advanced regulatory frameworks supporting novel food technologies and higher consumer awareness regarding food safety. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by increasing food safety concerns, rapid industrialization of agriculture, and growing export requirements for agricultural products meeting international standards.

The seed treatment segment represents another rapidly expanding market opportunity, with cold plasma demonstrating efficacy in improving germination rates, enhancing seedling vigor, and reducing pathogen loads. This application is particularly attractive to the organic farming sector, which faces limited options for seed treatments that align with organic certification requirements.

Market research indicates that large-scale commercial adoption faces several barriers, including high initial investment costs, lack of standardized equipment for different agricultural applications, and limited awareness among potential end-users. However, these barriers are gradually diminishing as technology providers develop more cost-effective and application-specific solutions.

The economic value proposition of cold plasma technology is increasingly recognized by stakeholders across the agricultural value chain. Food processors value its potential to reduce food waste and extend shelf life, while producers appreciate its capacity to meet export requirements without chemical residues. Additionally, retailers are responding to consumer demand for safer food products with minimal processing, creating pull-through demand for cold plasma-treated agricultural products.

Cold plasma technology's versatility in agricultural applications has created multiple market segments with distinct growth trajectories. The post-harvest treatment segment currently represents the largest market share, with applications in decontamination of fruits, vegetables, grains, and seeds showing particular promise. Industry reports suggest that the cold plasma agricultural market is projected to grow at a compound annual growth rate exceeding 10% through 2030, with the post-harvest segment maintaining its dominant position.

Geographically, North America and Europe lead in adoption rates, primarily due to advanced regulatory frameworks supporting novel food technologies and higher consumer awareness regarding food safety. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by increasing food safety concerns, rapid industrialization of agriculture, and growing export requirements for agricultural products meeting international standards.

The seed treatment segment represents another rapidly expanding market opportunity, with cold plasma demonstrating efficacy in improving germination rates, enhancing seedling vigor, and reducing pathogen loads. This application is particularly attractive to the organic farming sector, which faces limited options for seed treatments that align with organic certification requirements.

Market research indicates that large-scale commercial adoption faces several barriers, including high initial investment costs, lack of standardized equipment for different agricultural applications, and limited awareness among potential end-users. However, these barriers are gradually diminishing as technology providers develop more cost-effective and application-specific solutions.

The economic value proposition of cold plasma technology is increasingly recognized by stakeholders across the agricultural value chain. Food processors value its potential to reduce food waste and extend shelf life, while producers appreciate its capacity to meet export requirements without chemical residues. Additionally, retailers are responding to consumer demand for safer food products with minimal processing, creating pull-through demand for cold plasma-treated agricultural products.

Current Status and Barriers in Cold Plasma Treatment

Cold plasma treatment for agricultural products has gained significant attention globally, yet its widespread implementation faces several technical and regulatory challenges. Currently, the technology has reached a stage where laboratory-scale applications have demonstrated promising results for microbial decontamination, shelf-life extension, and quality preservation of various agricultural products. However, the transition from laboratory to commercial scale remains limited, with only a few countries like the United States, Japan, and several European nations having operational industrial-scale cold plasma systems for food processing.

The primary technical barriers include scalability issues, where laboratory successes have proven difficult to replicate at industrial scales. The non-uniform treatment effect across different product surfaces, particularly for irregularly shaped agricultural products, presents a significant challenge. Additionally, the optimization of plasma parameters (gas composition, power input, exposure time) varies substantially across different agricultural products, requiring product-specific protocols that complicate standardization efforts.

Equipment design represents another substantial barrier, as current cold plasma generators often lack the robustness needed for continuous operation in agricultural processing environments. The integration of cold plasma systems into existing processing lines without disrupting established workflows remains problematic, requiring significant engineering modifications that increase implementation costs.

From a regulatory perspective, cold plasma treatment faces a complex landscape of varying standards across different regions. The absence of harmonized international standards specifically addressing cold plasma applications in agriculture creates uncertainty for technology developers and potential adopters. In many jurisdictions, cold plasma is still considered a novel food processing technology, requiring extensive safety validation before approval.

Safety concerns constitute another significant barrier, particularly regarding the potential formation of reactive species that might affect the nutritional and toxicological profiles of treated products. Limited long-term studies on the effects of plasma-treated agricultural products on human health have created hesitation among regulatory bodies to grant broad approvals.

Economic barriers also impede adoption, with high initial investment costs for cold plasma equipment and uncertain return on investment timelines deterring many potential users. The technology's energy efficiency at industrial scales remains suboptimal, contributing to operational cost concerns.

Knowledge gaps in the fundamental mechanisms of plasma-food interactions further complicate progress. The complex chemical reactions occurring at the plasma-product interface are not fully understood, making it difficult to predict treatment outcomes across different agricultural matrices and limiting the development of predictive models for quality and safety assurance.

The primary technical barriers include scalability issues, where laboratory successes have proven difficult to replicate at industrial scales. The non-uniform treatment effect across different product surfaces, particularly for irregularly shaped agricultural products, presents a significant challenge. Additionally, the optimization of plasma parameters (gas composition, power input, exposure time) varies substantially across different agricultural products, requiring product-specific protocols that complicate standardization efforts.

Equipment design represents another substantial barrier, as current cold plasma generators often lack the robustness needed for continuous operation in agricultural processing environments. The integration of cold plasma systems into existing processing lines without disrupting established workflows remains problematic, requiring significant engineering modifications that increase implementation costs.

From a regulatory perspective, cold plasma treatment faces a complex landscape of varying standards across different regions. The absence of harmonized international standards specifically addressing cold plasma applications in agriculture creates uncertainty for technology developers and potential adopters. In many jurisdictions, cold plasma is still considered a novel food processing technology, requiring extensive safety validation before approval.

Safety concerns constitute another significant barrier, particularly regarding the potential formation of reactive species that might affect the nutritional and toxicological profiles of treated products. Limited long-term studies on the effects of plasma-treated agricultural products on human health have created hesitation among regulatory bodies to grant broad approvals.

Economic barriers also impede adoption, with high initial investment costs for cold plasma equipment and uncertain return on investment timelines deterring many potential users. The technology's energy efficiency at industrial scales remains suboptimal, contributing to operational cost concerns.

Knowledge gaps in the fundamental mechanisms of plasma-food interactions further complicate progress. The complex chemical reactions occurring at the plasma-product interface are not fully understood, making it difficult to predict treatment outcomes across different agricultural matrices and limiting the development of predictive models for quality and safety assurance.

Existing Cold Plasma Treatment Protocols for Agriculture

01 Safety mechanisms in cold plasma devices

Cold plasma treatment devices incorporate various safety mechanisms to prevent harm to patients and operators. These include temperature monitoring systems, automatic shut-off features when unsafe conditions are detected, and protective shields to contain the plasma within the treatment area. Some devices also include power regulation systems that ensure the plasma remains at non-thermal levels, preventing tissue damage while maintaining therapeutic efficacy.- Safety mechanisms in cold plasma treatment devices: Cold plasma treatment devices incorporate various safety mechanisms to protect patients and operators. These include automatic shut-off systems, power monitoring circuits, and protective shields that prevent accidental exposure. Advanced devices feature real-time monitoring of treatment parameters to ensure that plasma intensity remains within safe therapeutic ranges. These safety features are designed to minimize risks while maximizing treatment efficacy.

- Biological safety assessments for cold plasma applications: Comprehensive biological safety assessments are conducted to evaluate the effects of cold plasma on living tissues. These assessments include cytotoxicity studies, genotoxicity evaluations, and tissue compatibility tests. Research indicates that when properly controlled, cold plasma treatments can be safely applied without causing significant damage to healthy cells or tissues. Parameters such as exposure time, plasma composition, and energy levels are carefully calibrated to ensure safety while maintaining therapeutic effectiveness.

- Patient-specific safety protocols: Customized safety protocols are developed for different patient populations to address specific vulnerabilities. These protocols consider factors such as age, medical conditions, skin sensitivity, and treatment areas. For patients with implanted electronic devices, special precautions are implemented to prevent electromagnetic interference. Treatment parameters are adjusted based on individual risk factors, and continuous monitoring during treatment ensures patient safety throughout the procedure.

- Environmental and operational safety considerations: Environmental and operational safety aspects of cold plasma treatments include proper ventilation systems to manage ozone and other byproducts, shielding to contain electromagnetic emissions, and ergonomic design features to ensure operator safety. Treatment rooms are equipped with appropriate safety infrastructure, and standardized operating procedures are established to minimize risks. Regular maintenance and calibration of equipment are essential components of the safety framework for cold plasma applications.

- Regulatory compliance and safety standards: Cold plasma treatment devices must comply with stringent regulatory requirements and safety standards before clinical implementation. These standards govern aspects such as electrical safety, electromagnetic compatibility, biocompatibility, and risk management. Manufacturers conduct extensive testing and validation to demonstrate compliance with international standards. Documentation of safety measures, potential risks, and mitigation strategies is required for regulatory approval, ensuring that cold plasma technologies meet established safety benchmarks before entering medical practice.

02 Biocompatibility and tissue interaction safety

Cold plasma treatments are designed to interact with biological tissues without causing thermal damage. Research has focused on optimizing plasma parameters to ensure biocompatibility while achieving therapeutic effects. This includes controlling ion density, electron temperature, and reactive species generation to levels that are safe for human tissue exposure. Studies have demonstrated minimal adverse effects on healthy cells while effectively targeting pathogens or abnormal tissues.Expand Specific Solutions03 Medical application safety protocols

Specific safety protocols have been developed for medical applications of cold plasma, including wound healing, dermatological treatments, and cancer therapy. These protocols include treatment duration limits, appropriate distance maintenance between plasma source and tissue, and patient-specific parameter adjustments based on condition severity and tissue sensitivity. Medical-grade plasma devices undergo rigorous testing to ensure they meet safety standards for clinical use.Expand Specific Solutions04 Radiation and emission safety controls

Cold plasma devices are designed to minimize harmful radiation and emissions. Engineering controls limit UV radiation, ozone production, and electromagnetic interference to safe levels. Some devices incorporate filtration systems to capture potentially harmful byproducts or use noble gases that produce minimal toxic compounds. Regular calibration and monitoring ensure that emission levels remain within safety thresholds throughout the device's operational life.Expand Specific Solutions05 Safety certification and regulatory compliance

Cold plasma treatment devices undergo extensive safety certification processes to meet regulatory requirements. This includes electrical safety testing, biocompatibility assessments, and clinical validation studies. Manufacturers must demonstrate compliance with standards such as IEC 60601 for medical electrical equipment and ISO 10993 for biocompatibility. Documentation of safety features, risk assessments, and mitigation strategies are required for market approval in different jurisdictions.Expand Specific Solutions

Leading Companies and Research Institutions in Cold Plasma

Cold plasma treatment for agricultural products is emerging as a promising technology in the early growth phase. The market is expanding rapidly, with projections suggesting significant growth as food safety concerns increase globally. Technologically, the field shows varying maturity levels across applications. Academic institutions like Zhejiang University, North Carolina State University, and Nanjing Agricultural University are driving fundamental research, while companies demonstrate different specialization levels. Plasmology4 and Clean Crop Technologies focus specifically on cold plasma applications for agriculture, whereas larger corporations like Bühler AG and L'Oréal are exploring broader implementations. Plasmapp and SinnovaTek represent the growing commercial equipment sector. The technology's standardization remains underdeveloped, with safety protocols still evolving through collaborations between research institutions and regulatory bodies.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed a proprietary cold plasma technology platform specifically designed for agricultural applications. Their system utilizes a non-thermal atmospheric pressure plasma that can be applied directly to agricultural products without causing thermal damage. The technology creates reactive oxygen and nitrogen species that effectively eliminate pathogens while preserving the nutritional quality and sensory attributes of treated foods. Their approach includes specialized plasma delivery systems that can be integrated into existing processing lines, allowing for continuous treatment of agricultural products. Plasmology4's technology operates at ambient temperatures and pressure, making it energy-efficient and suitable for heat-sensitive products. The company has conducted extensive safety testing to ensure their plasma treatments meet FDA and USDA standards, with particular attention to preventing the formation of harmful byproducts during treatment.

Strengths: Highly specialized in agricultural applications with systems designed specifically for food processing environments; technology preserves nutritional and sensory qualities while achieving microbial reduction. Weaknesses: As a specialized company, may have limited resources compared to larger corporations; technology may require significant capital investment for implementation in existing processing facilities.

Bühler AG

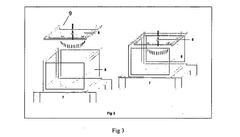

Technical Solution: Bühler AG has integrated cold plasma technology into their comprehensive food processing solutions, focusing on grain, nut, and seed decontamination. Their approach combines cold plasma with their existing processing equipment to create multi-hurdle preservation systems. Bühler's cold plasma technology utilizes dielectric barrier discharge (DBD) systems that generate plasma at atmospheric pressure, allowing for continuous processing of agricultural commodities. The company has developed specialized treatment chambers that ensure uniform plasma exposure across product surfaces while maintaining strict temperature control to prevent quality degradation. Their systems are designed with food safety compliance in mind, incorporating HACCP principles and meeting international food safety standards. Bühler has conducted extensive validation studies demonstrating 3-5 log reductions in pathogenic microorganisms while maintaining product quality and shelf life. Their technology is particularly notable for its integration capabilities with existing processing lines, minimizing implementation barriers.

Strengths: Extensive experience in food processing equipment allows for seamless integration of plasma technology into existing production lines; global presence provides strong distribution and service network. Weaknesses: Cold plasma represents only one segment of their diverse portfolio, potentially limiting dedicated R&D resources compared to plasma-focused companies; solutions may be optimized for specific commodity types rather than all agricultural products.

Key Patents and Research in Agricultural Cold Plasma

Method and system using cold plasma for removal of processing contaminants in processed agricultural products

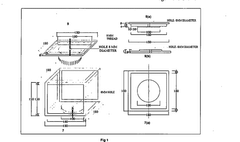

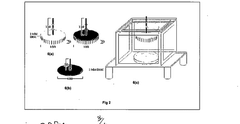

PatentWO2020242011A2

Innovation

- The use of low-temperature plasma technology to treat processed agricultural products, employing methods such as reduced pressure discharge plasma, dielectric barrier discharge plasma, corona discharge plasma jet, and intermittent corona discharge plasma jet to decompose and reduce benzopyrene and acrylamide through oxidation reactions and electron bombardment.

A cold plasma system and its method for preservation of food

PatentPendingIN202441030833A

Innovation

- A cost-effective cold plasma system using a dielectric barrier discharge (DBD) configuration with a flyback transformer, zero voltage switching (ZVS) circuit, and Cockcroft Walton Voltage Multiplier (CWVM) to generate atmospheric pressure cold plasma, effectively decontaminating food surfaces and extending shelf life without compromising quality.

Regulatory Framework for Cold Plasma in Food Processing

The regulatory landscape for cold plasma technology in food processing remains in a developmental stage, with significant variations across different regions and jurisdictions. In the United States, the Food and Drug Administration (FDA) has not yet established specific regulations for cold plasma applications in food processing, though it falls under the broader regulatory framework of novel food processing technologies. The FDA typically requires comprehensive safety assessments and validation studies before approving new food processing technologies.

The European Food Safety Authority (EFSA) has taken steps toward establishing guidelines for cold plasma applications, considering it under the Novel Food Regulation (EU) 2015/2283. This regulation requires thorough safety evaluations before market authorization. Additionally, the European Commission has funded research initiatives to develop standardized protocols for cold plasma applications in food processing, aiming to establish harmonized regulatory approaches across member states.

In Asia, regulatory frameworks vary significantly. Japan's Ministry of Health, Labour and Welfare has shown interest in cold plasma technology but maintains stringent requirements for safety validation. China's National Food Safety Standard system is gradually incorporating provisions for novel food processing technologies, including potential applications of cold plasma treatment.

International organizations such as the Codex Alimentarius Commission are working toward developing global standards for emerging food processing technologies. The International Organization for Standardization (ISO) has established technical committees focused on standardizing plasma technology applications, though specific standards for agricultural applications remain under development.

Key regulatory considerations include efficacy validation protocols, safety assessment methodologies, and equipment standardization requirements. Regulatory bodies typically require evidence demonstrating that cold plasma treatment does not introduce harmful chemical residues, alter nutritional profiles negatively, or create toxic compounds through interaction with food matrices.

The absence of a unified regulatory framework presents challenges for technology developers and food processors seeking to implement cold plasma solutions. Industry stakeholders are actively engaging with regulatory authorities to establish clear guidelines and standards that balance innovation with consumer safety. Several industry consortia have formed to develop self-regulatory practices and standardized protocols while formal regulations evolve.

Moving forward, the development of internationally recognized standards will be crucial for the widespread adoption of cold plasma technology in food processing. Regulatory harmonization efforts will likely focus on establishing treatment parameters, validation methodologies, and safety assessment protocols that can be universally applied across different food categories and processing environments.

The European Food Safety Authority (EFSA) has taken steps toward establishing guidelines for cold plasma applications, considering it under the Novel Food Regulation (EU) 2015/2283. This regulation requires thorough safety evaluations before market authorization. Additionally, the European Commission has funded research initiatives to develop standardized protocols for cold plasma applications in food processing, aiming to establish harmonized regulatory approaches across member states.

In Asia, regulatory frameworks vary significantly. Japan's Ministry of Health, Labour and Welfare has shown interest in cold plasma technology but maintains stringent requirements for safety validation. China's National Food Safety Standard system is gradually incorporating provisions for novel food processing technologies, including potential applications of cold plasma treatment.

International organizations such as the Codex Alimentarius Commission are working toward developing global standards for emerging food processing technologies. The International Organization for Standardization (ISO) has established technical committees focused on standardizing plasma technology applications, though specific standards for agricultural applications remain under development.

Key regulatory considerations include efficacy validation protocols, safety assessment methodologies, and equipment standardization requirements. Regulatory bodies typically require evidence demonstrating that cold plasma treatment does not introduce harmful chemical residues, alter nutritional profiles negatively, or create toxic compounds through interaction with food matrices.

The absence of a unified regulatory framework presents challenges for technology developers and food processors seeking to implement cold plasma solutions. Industry stakeholders are actively engaging with regulatory authorities to establish clear guidelines and standards that balance innovation with consumer safety. Several industry consortia have formed to develop self-regulatory practices and standardized protocols while formal regulations evolve.

Moving forward, the development of internationally recognized standards will be crucial for the widespread adoption of cold plasma technology in food processing. Regulatory harmonization efforts will likely focus on establishing treatment parameters, validation methodologies, and safety assessment protocols that can be universally applied across different food categories and processing environments.

Environmental Impact Assessment of Cold Plasma Technology

Cold plasma technology, while offering significant benefits for agricultural product treatment, must be evaluated for its environmental impacts to ensure sustainable implementation. The environmental footprint of cold plasma systems begins with energy consumption, which varies significantly depending on system design and operational parameters. Modern cold plasma generators have demonstrated improved energy efficiency compared to traditional thermal processing methods, with some systems achieving energy reductions of 30-45% when optimized for specific agricultural applications.

Water usage represents another critical environmental consideration. Unlike conventional washing and sanitizing processes that may consume 5-8 gallons of water per pound of produce, cold plasma treatments operate in dry or semi-dry conditions, potentially reducing water consumption by 70-90% in post-harvest processing facilities. This water conservation aspect becomes increasingly valuable in regions facing water scarcity challenges.

Regarding atmospheric emissions, cold plasma systems generate reactive species that typically revert to harmless components after treatment. Research indicates that properly designed systems produce minimal ozone and nitrogen oxide emissions, with concentrations well below regulatory thresholds. Studies conducted at agricultural research facilities have demonstrated that emissions from cold plasma treatments dissipate rapidly, with measurements showing 95% reduction within 2-3 meters from the treatment source.

Waste generation from cold plasma technology is substantially lower than chemical treatment alternatives. The process eliminates the need for chemical sanitizers, reducing chemical waste streams by up to 80% according to comparative studies. Additionally, the absence of chemical residues on treated products minimizes downstream environmental contamination through agricultural runoff.

Life cycle assessments of cold plasma systems reveal favorable environmental profiles when considering manufacturing, operation, and end-of-life disposal. The primary environmental concern relates to the production of electronic components and specialized materials used in plasma generators. However, the extended operational lifespan of modern systems (typically 8-10 years) distributes this impact over a significant period of productive use.

Integration of renewable energy sources with cold plasma systems presents a promising pathway for further reducing environmental impacts. Pilot projects utilizing solar-powered plasma generators have demonstrated technical feasibility, though economic viability remains challenging in some contexts. These hybrid systems could potentially achieve carbon-neutral operation, aligning with agricultural sustainability goals and regulatory trends toward reduced environmental footprints in food processing.

Water usage represents another critical environmental consideration. Unlike conventional washing and sanitizing processes that may consume 5-8 gallons of water per pound of produce, cold plasma treatments operate in dry or semi-dry conditions, potentially reducing water consumption by 70-90% in post-harvest processing facilities. This water conservation aspect becomes increasingly valuable in regions facing water scarcity challenges.

Regarding atmospheric emissions, cold plasma systems generate reactive species that typically revert to harmless components after treatment. Research indicates that properly designed systems produce minimal ozone and nitrogen oxide emissions, with concentrations well below regulatory thresholds. Studies conducted at agricultural research facilities have demonstrated that emissions from cold plasma treatments dissipate rapidly, with measurements showing 95% reduction within 2-3 meters from the treatment source.

Waste generation from cold plasma technology is substantially lower than chemical treatment alternatives. The process eliminates the need for chemical sanitizers, reducing chemical waste streams by up to 80% according to comparative studies. Additionally, the absence of chemical residues on treated products minimizes downstream environmental contamination through agricultural runoff.

Life cycle assessments of cold plasma systems reveal favorable environmental profiles when considering manufacturing, operation, and end-of-life disposal. The primary environmental concern relates to the production of electronic components and specialized materials used in plasma generators. However, the extended operational lifespan of modern systems (typically 8-10 years) distributes this impact over a significant period of productive use.

Integration of renewable energy sources with cold plasma systems presents a promising pathway for further reducing environmental impacts. Pilot projects utilizing solar-powered plasma generators have demonstrated technical feasibility, though economic viability remains challenging in some contexts. These hybrid systems could potentially achieve carbon-neutral operation, aligning with agricultural sustainability goals and regulatory trends toward reduced environmental footprints in food processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!