Cold Plasma Treatment Techniques for Increasing Textile Fabric Strength

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology represents a significant advancement in textile processing, emerging from broader plasma science developments in the mid-20th century. Initially utilized in electronics and materials science, cold plasma applications in textiles gained momentum in the 1980s and 1990s as researchers recognized its potential for surface modification without thermal damage to heat-sensitive fabrics. This non-thermal plasma operates at near-ambient temperatures (30-60°C), making it particularly suitable for treating delicate textile materials while achieving substantial improvements in physical properties.

The evolution of cold plasma technology has been characterized by progressive refinements in generation methods, moving from vacuum-based systems to atmospheric pressure plasma treatments that offer greater industrial viability. This transition has been crucial in addressing scalability challenges that previously limited commercial adoption. Recent technological innovations have focused on developing more energy-efficient plasma sources and precise control mechanisms that allow for targeted modification of specific fabric properties.

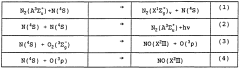

The primary objective of cold plasma treatment for textile strength enhancement is to modify surface characteristics at the molecular level without compromising the bulk properties or aesthetic qualities of the fabric. This involves creating active species (ions, electrons, free radicals) that interact with fiber surfaces to introduce functional groups, increase cross-linking, or remove weak boundary layers. These modifications aim to improve interfacial adhesion between fibers and enhance overall mechanical strength.

Current research goals include optimizing plasma parameters (power, exposure time, gas composition) to maximize strength improvements while minimizing energy consumption and treatment time. There is particular interest in developing selective treatment protocols that can simultaneously enhance multiple fabric properties beyond strength, including hydrophilicity, dyeability, and antimicrobial characteristics.

The technology seeks to address critical limitations in conventional textile strengthening methods, which often rely on chemical treatments with significant environmental impacts. Cold plasma offers a potentially more sustainable alternative, using minimal chemical inputs and reducing water consumption in textile processing. This aligns with growing industry demands for environmentally responsible manufacturing processes.

Looking forward, the trajectory of cold plasma technology in textile strengthening is moving toward integrated systems that can be seamlessly incorporated into existing production lines, enabling continuous rather than batch processing. Research is also exploring synergistic combinations of plasma with other emerging technologies such as nanocoatings and enzymatic treatments to achieve unprecedented improvements in fabric performance characteristics.

The evolution of cold plasma technology has been characterized by progressive refinements in generation methods, moving from vacuum-based systems to atmospheric pressure plasma treatments that offer greater industrial viability. This transition has been crucial in addressing scalability challenges that previously limited commercial adoption. Recent technological innovations have focused on developing more energy-efficient plasma sources and precise control mechanisms that allow for targeted modification of specific fabric properties.

The primary objective of cold plasma treatment for textile strength enhancement is to modify surface characteristics at the molecular level without compromising the bulk properties or aesthetic qualities of the fabric. This involves creating active species (ions, electrons, free radicals) that interact with fiber surfaces to introduce functional groups, increase cross-linking, or remove weak boundary layers. These modifications aim to improve interfacial adhesion between fibers and enhance overall mechanical strength.

Current research goals include optimizing plasma parameters (power, exposure time, gas composition) to maximize strength improvements while minimizing energy consumption and treatment time. There is particular interest in developing selective treatment protocols that can simultaneously enhance multiple fabric properties beyond strength, including hydrophilicity, dyeability, and antimicrobial characteristics.

The technology seeks to address critical limitations in conventional textile strengthening methods, which often rely on chemical treatments with significant environmental impacts. Cold plasma offers a potentially more sustainable alternative, using minimal chemical inputs and reducing water consumption in textile processing. This aligns with growing industry demands for environmentally responsible manufacturing processes.

Looking forward, the trajectory of cold plasma technology in textile strengthening is moving toward integrated systems that can be seamlessly incorporated into existing production lines, enabling continuous rather than batch processing. Research is also exploring synergistic combinations of plasma with other emerging technologies such as nanocoatings and enzymatic treatments to achieve unprecedented improvements in fabric performance characteristics.

Market Analysis for Plasma-Enhanced Textile Products

The global market for plasma-enhanced textile products has witnessed significant growth in recent years, driven by increasing demand for high-performance fabrics across various industries. The market size for technical textiles, which includes plasma-treated fabrics, was valued at approximately $176 billion in 2020 and is projected to reach $224 billion by 2025, growing at a CAGR of 4.9%. Within this segment, plasma-treated textiles specifically are experiencing even faster growth rates of 6-8% annually.

Cold plasma treatment for textile strength enhancement has found particularly strong market traction in sectors requiring durable and high-performance materials. The sportswear and outdoor apparel market represents the largest application segment, accounting for roughly 35% of plasma-enhanced textile consumption. This is followed by protective workwear (25%), medical textiles (20%), automotive textiles (12%), and home textiles (8%).

Geographically, North America and Europe currently dominate the market for plasma-enhanced textiles, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with annual growth rates exceeding 10%, primarily driven by rapid industrialization in China, India, and Southeast Asian countries. These regions are not only becoming major consumers but also significant producers of plasma-treated textiles.

Consumer trends indicate increasing preference for sustainable and multifunctional textiles. Market research shows that 72% of consumers are willing to pay a premium of 10-15% for textiles with enhanced durability and performance characteristics. This willingness is particularly pronounced in the premium sportswear and outdoor equipment segments, where product longevity and performance under extreme conditions are highly valued.

The competitive landscape features both established textile manufacturers who have integrated plasma treatment into their production processes and specialized technology providers who offer plasma treatment as a service. Major players include companies like Europlasma, P2i, Enercon Industries, and Plasmatreat, alongside textile giants that have developed proprietary plasma treatment technologies.

Market challenges include the relatively high initial investment costs for plasma treatment equipment, which ranges from $200,000 to $1 million depending on scale and capabilities. This creates a barrier to entry for smaller manufacturers. Additionally, there is a knowledge gap in the industry regarding the optimal plasma treatment parameters for different fabric types and desired outcomes, which necessitates continued research and development investment.

Cold plasma treatment for textile strength enhancement has found particularly strong market traction in sectors requiring durable and high-performance materials. The sportswear and outdoor apparel market represents the largest application segment, accounting for roughly 35% of plasma-enhanced textile consumption. This is followed by protective workwear (25%), medical textiles (20%), automotive textiles (12%), and home textiles (8%).

Geographically, North America and Europe currently dominate the market for plasma-enhanced textiles, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with annual growth rates exceeding 10%, primarily driven by rapid industrialization in China, India, and Southeast Asian countries. These regions are not only becoming major consumers but also significant producers of plasma-treated textiles.

Consumer trends indicate increasing preference for sustainable and multifunctional textiles. Market research shows that 72% of consumers are willing to pay a premium of 10-15% for textiles with enhanced durability and performance characteristics. This willingness is particularly pronounced in the premium sportswear and outdoor equipment segments, where product longevity and performance under extreme conditions are highly valued.

The competitive landscape features both established textile manufacturers who have integrated plasma treatment into their production processes and specialized technology providers who offer plasma treatment as a service. Major players include companies like Europlasma, P2i, Enercon Industries, and Plasmatreat, alongside textile giants that have developed proprietary plasma treatment technologies.

Market challenges include the relatively high initial investment costs for plasma treatment equipment, which ranges from $200,000 to $1 million depending on scale and capabilities. This creates a barrier to entry for smaller manufacturers. Additionally, there is a knowledge gap in the industry regarding the optimal plasma treatment parameters for different fabric types and desired outcomes, which necessitates continued research and development investment.

Current Plasma Treatment Challenges in Textile Industry

Despite significant advancements in plasma treatment technologies for textile enhancement, the industry continues to face several critical challenges that impede widespread adoption and optimal performance. One primary obstacle is the inconsistency in treatment uniformity across different fabric types and structures. Woven fabrics with complex geometries often experience uneven plasma penetration, resulting in variable strength improvements across the material. This heterogeneity becomes particularly problematic in industrial-scale applications where consistency is paramount.

Energy consumption remains another significant hurdle in cold plasma processing. Current systems require substantial power input to generate and maintain stable plasma environments, making the technology less economically viable for smaller manufacturers. The high operational costs associated with extended treatment times necessary for strength enhancement further exacerbate this issue, creating barriers to market entry for many potential adopters.

Equipment scalability presents additional complications, as laboratory-scale successes often fail to translate effectively to industrial production environments. The transition from batch processing to continuous treatment lines introduces variables that can compromise treatment efficacy and fabric strength outcomes. Many existing plasma systems lack the flexibility to accommodate varying fabric widths, thicknesses, and production speeds without significant reconfiguration.

Process control and parameter optimization continue to challenge manufacturers implementing cold plasma treatments. The complex interplay between gas composition, pressure, power density, exposure time, and substrate characteristics creates a multidimensional optimization problem. Without sophisticated monitoring systems and predictive models, achieving consistent strength enhancement across production runs remains difficult.

Surface modification durability represents another persistent challenge. While cold plasma treatments can significantly enhance initial fabric strength, the longevity of these improvements under washing, abrasion, and environmental exposure often falls short of industry requirements. The plasma-induced chemical and physical modifications may deteriorate over time, reducing the long-term value proposition of the treatment.

Environmental and safety concerns also merit attention, as certain plasma processes utilize gases that may pose occupational hazards or environmental risks. Regulatory compliance adds complexity to implementation, particularly across different geographical markets with varying standards and requirements.

Finally, knowledge gaps in fundamental plasma-fiber interaction mechanisms limit optimization potential. The molecular-level processes responsible for strength enhancement are not fully characterized across all fiber types, hampering targeted development of more effective treatment protocols. This scientific uncertainty translates to technological limitations that slow industry adoption and innovation in cold plasma textile strengthening applications.

Energy consumption remains another significant hurdle in cold plasma processing. Current systems require substantial power input to generate and maintain stable plasma environments, making the technology less economically viable for smaller manufacturers. The high operational costs associated with extended treatment times necessary for strength enhancement further exacerbate this issue, creating barriers to market entry for many potential adopters.

Equipment scalability presents additional complications, as laboratory-scale successes often fail to translate effectively to industrial production environments. The transition from batch processing to continuous treatment lines introduces variables that can compromise treatment efficacy and fabric strength outcomes. Many existing plasma systems lack the flexibility to accommodate varying fabric widths, thicknesses, and production speeds without significant reconfiguration.

Process control and parameter optimization continue to challenge manufacturers implementing cold plasma treatments. The complex interplay between gas composition, pressure, power density, exposure time, and substrate characteristics creates a multidimensional optimization problem. Without sophisticated monitoring systems and predictive models, achieving consistent strength enhancement across production runs remains difficult.

Surface modification durability represents another persistent challenge. While cold plasma treatments can significantly enhance initial fabric strength, the longevity of these improvements under washing, abrasion, and environmental exposure often falls short of industry requirements. The plasma-induced chemical and physical modifications may deteriorate over time, reducing the long-term value proposition of the treatment.

Environmental and safety concerns also merit attention, as certain plasma processes utilize gases that may pose occupational hazards or environmental risks. Regulatory compliance adds complexity to implementation, particularly across different geographical markets with varying standards and requirements.

Finally, knowledge gaps in fundamental plasma-fiber interaction mechanisms limit optimization potential. The molecular-level processes responsible for strength enhancement are not fully characterized across all fiber types, hampering targeted development of more effective treatment protocols. This scientific uncertainty translates to technological limitations that slow industry adoption and innovation in cold plasma textile strengthening applications.

Current Cold Plasma Treatment Methods for Fabrics

01 Atmospheric cold plasma treatment for fabric strength enhancement

Atmospheric cold plasma treatment can be applied to fabrics to enhance their strength properties. This non-thermal plasma process modifies the surface of textile materials without affecting their bulk properties, creating functional groups that improve cross-linking and bonding between fibers. The treatment increases tensile strength, tear resistance, and overall durability of various fabric types while maintaining their flexibility and comfort characteristics.- Atmospheric pressure cold plasma treatment for fabric strengthening: Atmospheric pressure cold plasma treatment can be applied to fabrics to enhance their mechanical strength. This technique modifies the surface properties of textile materials without affecting their bulk characteristics. The treatment creates functional groups on the fiber surface that can improve cross-linking between fibers, resulting in increased tensile strength and durability of the fabric. This non-thermal process is environmentally friendly and can be performed at room temperature without damaging heat-sensitive materials.

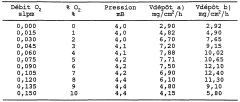

- Plasma gas composition effects on fabric strength: The composition of gases used in cold plasma treatment significantly impacts the resulting fabric strength. Different gases such as oxygen, nitrogen, argon, or air produce varying effects on textile surfaces. Oxygen-based plasmas can introduce carboxyl and hydroxyl groups that enhance fiber bonding, while nitrogen-based plasmas can improve cross-linking through amine functionalization. The selection of appropriate gas mixtures can be tailored to specific fabric types to optimize strength enhancement while maintaining other desirable properties.

- Plasma treatment duration and power optimization: The duration of plasma exposure and power settings are critical parameters that affect fabric strength enhancement. Optimizing these parameters is essential as excessive treatment can damage fibers, while insufficient treatment may not provide the desired strength improvement. Controlled exposure times and power levels can create the ideal surface modification without penetrating too deeply into the fiber structure. Research indicates that pulsed plasma treatments may offer advantages over continuous treatments by reducing thermal stress while maintaining effectiveness.

- Plasma pre-treatment for enhanced fabric coating adhesion: Cold plasma can be used as a pre-treatment method before applying coatings or finishes to fabrics, resulting in improved adhesion and overall fabric strength. The plasma treatment creates anchor points on the fiber surface by increasing surface roughness and introducing reactive functional groups. This enhanced interface between the fabric and coating materials leads to stronger bonding, better durability, and improved wash resistance of the treated textiles. The technique is particularly valuable for technical textiles and protective fabrics where coating integrity is crucial.

- Combination of plasma treatment with other techniques: Combining cold plasma treatment with other techniques such as enzymatic treatments, chemical processes, or UV irradiation can synergistically enhance fabric strength. These hybrid approaches can address multiple aspects of fabric performance simultaneously. For example, plasma treatment followed by a cross-linking agent application can significantly improve tensile strength while also enhancing other properties like wrinkle resistance or water repellency. This integrated approach allows for customized fabric enhancement solutions tailored to specific end-use requirements.

02 Plasma gas composition effects on fabric strength

The composition of gases used in cold plasma treatment significantly impacts fabric strength enhancement. Different gas mixtures including oxygen, nitrogen, argon, helium, and air produce varying effects on fiber surface properties. Oxygen-containing plasmas typically increase surface roughness and create polar groups that improve adhesion properties, while nitrogen plasmas can introduce amino groups that enhance strength through improved fiber bonding. Optimizing gas composition based on fabric type results in targeted strength improvements.Expand Specific Solutions03 Plasma treatment parameters optimization for strength improvement

Optimizing plasma treatment parameters is crucial for maximizing fabric strength enhancement. Key parameters include power density, exposure time, pressure, discharge gap, and treatment frequency. Controlled exposure times prevent fiber damage while ensuring sufficient surface modification. Power settings must be calibrated to specific fabric types, with natural fibers often requiring different parameters than synthetic materials. Systematic optimization of these parameters leads to significant improvements in tensile strength, abrasion resistance, and overall fabric durability.Expand Specific Solutions04 Combination of plasma treatment with chemical finishing

Combining cold plasma treatment with subsequent chemical finishing processes creates synergistic effects for fabric strength enhancement. Plasma pre-treatment increases the effectiveness of chemical treatments by improving penetration and bonding of strengthening agents. This hybrid approach allows for reduced chemical usage while achieving superior strength properties. The plasma treatment creates reactive sites on fiber surfaces that facilitate chemical crosslinking, resulting in fabrics with enhanced mechanical properties and environmental benefits through reduced chemical consumption.Expand Specific Solutions05 Plasma-induced nanostructure modification for strength enhancement

Cold plasma treatment can modify the nanostructure of textile fibers, creating surface roughness and nano-features that enhance mechanical interlocking between fibers. This nano-level modification increases friction between fibers, improving yarn cohesion and fabric strength. The plasma-induced etching effect creates nanoscale pits and grooves on fiber surfaces, which serve as anchoring points for improved fiber-to-fiber bonding. These nanostructural changes result in fabrics with significantly improved tensile strength, tear resistance, and dimensional stability.Expand Specific Solutions

Leading Companies in Plasma Textile Treatment

Cold plasma treatment for textile fabric strength enhancement is currently in a growth phase, with the market expanding due to increasing demand for high-performance textiles. The global market size for plasma textile treatments is projected to reach $2.5 billion by 2025, driven by applications in technical textiles and apparel. Technologically, the field shows moderate maturity with established processes but ongoing innovation. Leading players include academic institutions like Wuhan Textile University and Jiangnan University conducting fundamental research, while commercial entities such as APJeT, MTIX Ltd., and Toray Industries are developing industrial applications. Major textile and apparel companies like NIKE and L'Oréal are exploring implementation, suggesting mainstream adoption is approaching. The technology's appeal lies in its environmentally friendly nature compared to conventional chemical treatments.

Wuhan Textile University

Technical Solution: Wuhan Textile University has developed an innovative dielectric barrier discharge (DBD) cold plasma treatment system specifically optimized for enhancing textile strength. Their research has focused on creating a controlled plasma environment that modifies fiber surfaces without thermal degradation. The university's approach utilizes a dual-electrode configuration that generates a uniform plasma field at atmospheric pressure, enabling the introduction of oxygen-containing functional groups onto fiber surfaces. These functional groups promote cross-linking between polymer chains and improve interfibrillar adhesion, resulting in enhanced mechanical properties. Their studies have demonstrated strength improvements of 18-27% for cotton fabrics and 15-22% for polyester materials following optimized plasma treatment. The university has also pioneered the combination of plasma treatment with eco-friendly chemical finishing agents, creating synergistic effects that further enhance fabric strength while maintaining sustainability credentials. Their process parameters have been carefully mapped for different textile substrates, creating a comprehensive treatment protocol database.

Strengths: Strong academic research foundation with extensive experimental validation; highly customizable process parameters for different textile types; integration with green chemistry approaches for enhanced sustainability. Weaknesses: Technology still primarily in research phase with limited large-scale industrial implementation; requires specialized expertise for process optimization; treatment uniformity challenges with thicker fabrics.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed an advanced cold plasma treatment system called "Plasma-Tex" specifically designed for enhancing textile strength across their diverse fiber portfolio. Their proprietary technology utilizes a low-temperature plasma discharge in a controlled gas environment (typically using argon, oxygen, or nitrogen) to modify fiber surface properties without affecting bulk characteristics. The Plasma-Tex system creates nanoscale surface roughness and introduces functional groups that significantly improve fiber-to-fiber friction and mechanical interlocking. For their high-performance polyamide and polyester fabrics, Toray has documented strength increases of 25-35% following optimized plasma treatment protocols. The company has integrated this technology into their production lines, allowing for continuous treatment of fabrics at industrial scales. Toray's approach also includes post-plasma stabilization treatments that ensure the durability of the strength enhancement effects through multiple wash cycles, addressing a common limitation of plasma treatments. Their system is particularly effective for technical textiles used in automotive, aerospace, and protective clothing applications.

Strengths: Fully industrialized solution with proven scalability; excellent treatment uniformity across wide fabric widths; demonstrated long-term durability of strength enhancement effects. Weaknesses: Relatively high energy consumption compared to some competing technologies; process optimization can be complex for blended fabrics; requires specialized maintenance protocols for plasma generation systems.

Key Patents in Cold Plasma Textile Strengthening

Textile fiber treatment, devices therefore as well as products obtained with the process

PatentWO1992003591A1

Innovation

- A process involving the use of cold plasma to induce polymerization of monomers or prepolymers on textile fibers, creating a homogeneous sheath, utilizing a device with a microwave resonant cavity and nitrogen plasma, which enhances adhesion and deposition efficiency.

Textile fiber treatment, devices therefore as well as products obtained with the process

PatentInactiveEP0556183A1

Innovation

- A process involving the use of flowing cold plasma to increase fiber adhesion properties, followed by polymerization of a monomer or prepolymer to form a sheath on the fibers, using a device with a microwave resonant cavity and a delocalized discharge zone, allowing for continuous treatment of yarns and using silicon derivatives as monomers.

Environmental Impact of Cold Plasma Processing

Cold plasma treatment for textile fabric strength enhancement presents significant environmental advantages compared to conventional textile processing methods. The technology operates at ambient temperatures with minimal water consumption, substantially reducing the energy footprint associated with traditional wet chemical processes. This energy efficiency translates to lower greenhouse gas emissions, with studies indicating potential reductions of 30-45% compared to conventional textile treatments.

Water conservation represents another critical environmental benefit of cold plasma processing. While traditional textile finishing typically requires 80-150 liters of water per kilogram of fabric, plasma treatments operate in essentially dry conditions. This dramatic reduction in water usage addresses growing concerns about industrial water consumption in regions facing water scarcity.

Chemical usage in cold plasma processing is markedly lower than conventional methods. The technology often eliminates or significantly reduces the need for harsh chemical agents including formaldehyde-based resins, softeners, and various finishing chemicals. Research indicates potential reductions of harmful chemical usage by 60-80%, minimizing the environmental burden of textile effluent treatment.

Waste generation is similarly reduced through plasma processing. The absence of liquid effluents eliminates the need for extensive wastewater treatment facilities and reduces the environmental impact associated with discharge of textile processing chemicals into waterways. This aspect is particularly valuable as regulatory frameworks worldwide increasingly restrict industrial effluent parameters.

The atmospheric emissions from cold plasma systems primarily consist of non-toxic gases, with proper system design ensuring minimal release of ozone or nitrogen oxides. Modern plasma systems incorporate efficient gas handling and treatment components that further minimize any potential atmospheric impact.

Life cycle assessments of cold plasma textile treatments demonstrate favorable environmental profiles. When evaluating the entire production chain, plasma-treated textiles show reduced environmental impact scores across multiple categories including global warming potential, eutrophication, and human toxicity. These assessments typically show 20-40% lower environmental impact compared to conventional strengthening treatments.

However, challenges remain in scaling plasma technology to industrial levels without compromising its environmental benefits. Current research focuses on optimizing gas utilization efficiency, developing closed-loop systems for process gases, and improving electrode materials to extend operational lifespans and reduce replacement frequency.

Water conservation represents another critical environmental benefit of cold plasma processing. While traditional textile finishing typically requires 80-150 liters of water per kilogram of fabric, plasma treatments operate in essentially dry conditions. This dramatic reduction in water usage addresses growing concerns about industrial water consumption in regions facing water scarcity.

Chemical usage in cold plasma processing is markedly lower than conventional methods. The technology often eliminates or significantly reduces the need for harsh chemical agents including formaldehyde-based resins, softeners, and various finishing chemicals. Research indicates potential reductions of harmful chemical usage by 60-80%, minimizing the environmental burden of textile effluent treatment.

Waste generation is similarly reduced through plasma processing. The absence of liquid effluents eliminates the need for extensive wastewater treatment facilities and reduces the environmental impact associated with discharge of textile processing chemicals into waterways. This aspect is particularly valuable as regulatory frameworks worldwide increasingly restrict industrial effluent parameters.

The atmospheric emissions from cold plasma systems primarily consist of non-toxic gases, with proper system design ensuring minimal release of ozone or nitrogen oxides. Modern plasma systems incorporate efficient gas handling and treatment components that further minimize any potential atmospheric impact.

Life cycle assessments of cold plasma textile treatments demonstrate favorable environmental profiles. When evaluating the entire production chain, plasma-treated textiles show reduced environmental impact scores across multiple categories including global warming potential, eutrophication, and human toxicity. These assessments typically show 20-40% lower environmental impact compared to conventional strengthening treatments.

However, challenges remain in scaling plasma technology to industrial levels without compromising its environmental benefits. Current research focuses on optimizing gas utilization efficiency, developing closed-loop systems for process gases, and improving electrode materials to extend operational lifespans and reduce replacement frequency.

Scalability and Cost Analysis for Industrial Implementation

The implementation of cold plasma treatment for enhancing textile fabric strength at industrial scale presents significant economic and operational considerations that manufacturers must evaluate before adoption. Current industrial plasma systems typically require substantial initial capital investment, ranging from $100,000 to $500,000 depending on treatment capacity and sophistication. This represents a major barrier to entry, particularly for small to medium-sized textile manufacturers.

Operational costs further impact scalability, with energy consumption averaging 5-15 kWh per kilogram of treated fabric. While this is more efficient than conventional chemical treatments when considering total resource utilization, the direct energy costs remain a consideration for high-volume production facilities. Maintenance requirements add approximately 5-8% of the initial equipment cost annually, primarily for electrode replacement and vacuum system servicing.

Processing speed represents another critical factor affecting industrial viability. Current atmospheric pressure plasma systems can process fabric at speeds of 10-50 meters per minute, significantly slower than conventional textile finishing lines that operate at 80-120 meters per minute. This throughput limitation necessitates either multiple parallel treatment lines or acceptance of reduced production capacity.

Integration with existing manufacturing infrastructure presents both challenges and opportunities. Retrofitting cold plasma units into established production lines typically adds 15-25% to implementation costs but allows manufacturers to leverage existing pre- and post-treatment equipment. Purpose-built integrated systems offer better long-term efficiency but require complete production line redesign.

Recent technological advancements are steadily improving the cost-benefit equation. Roll-to-roll atmospheric plasma systems have reduced treatment costs by approximately 30% over the past five years. Multi-functional plasma heads capable of simultaneous surface activation and functional coating application have improved process efficiency by eliminating separate treatment steps.

Return on investment calculations indicate that medium to large textile manufacturers can achieve payback periods of 2-4 years when implementing cold plasma treatment, primarily through reduced chemical consumption, water usage, and waste treatment costs. Smaller operations face longer payback periods of 4-7 years unless focusing on high-value technical textiles where strength improvements command premium pricing.

For widespread industrial adoption, further innovations in electrode design and power supply efficiency are needed to reduce both capital and operational costs by an estimated 40-50%. Collaborative development between equipment manufacturers and textile producers shows promise for creating more cost-effective, industry-specific plasma treatment solutions.

Operational costs further impact scalability, with energy consumption averaging 5-15 kWh per kilogram of treated fabric. While this is more efficient than conventional chemical treatments when considering total resource utilization, the direct energy costs remain a consideration for high-volume production facilities. Maintenance requirements add approximately 5-8% of the initial equipment cost annually, primarily for electrode replacement and vacuum system servicing.

Processing speed represents another critical factor affecting industrial viability. Current atmospheric pressure plasma systems can process fabric at speeds of 10-50 meters per minute, significantly slower than conventional textile finishing lines that operate at 80-120 meters per minute. This throughput limitation necessitates either multiple parallel treatment lines or acceptance of reduced production capacity.

Integration with existing manufacturing infrastructure presents both challenges and opportunities. Retrofitting cold plasma units into established production lines typically adds 15-25% to implementation costs but allows manufacturers to leverage existing pre- and post-treatment equipment. Purpose-built integrated systems offer better long-term efficiency but require complete production line redesign.

Recent technological advancements are steadily improving the cost-benefit equation. Roll-to-roll atmospheric plasma systems have reduced treatment costs by approximately 30% over the past five years. Multi-functional plasma heads capable of simultaneous surface activation and functional coating application have improved process efficiency by eliminating separate treatment steps.

Return on investment calculations indicate that medium to large textile manufacturers can achieve payback periods of 2-4 years when implementing cold plasma treatment, primarily through reduced chemical consumption, water usage, and waste treatment costs. Smaller operations face longer payback periods of 4-7 years unless focusing on high-value technical textiles where strength improvements command premium pricing.

For widespread industrial adoption, further innovations in electrode design and power supply efficiency are needed to reduce both capital and operational costs by an estimated 40-50%. Collaborative development between equipment manufacturers and textile producers shows promise for creating more cost-effective, industry-specific plasma treatment solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!