Cold Plasma Treatment for Enhanced Coating Adhesion in Aerospace

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from laboratory curiosity to industrial application. Initially developed in the mid-20th century, plasma science gained momentum in the 1970s and 1980s with the advancement of vacuum technology and power electronics. The aerospace industry began exploring cold plasma applications in the 1990s, primarily for surface cleaning operations, before recognizing its potential for adhesion enhancement.

The fundamental principle behind cold plasma treatment involves the generation of a partially ionized gas containing reactive species, electrons, ions, and UV radiation while maintaining near-ambient temperatures. This unique characteristic allows for surface modification without thermal damage to heat-sensitive aerospace materials such as composites and lightweight alloys. The non-equilibrium nature of cold plasma enables selective surface chemistry modifications without affecting bulk material properties.

Current technological developments focus on atmospheric pressure cold plasma systems, which represent a significant advancement over traditional vacuum-based approaches. These systems offer greater flexibility, reduced operational costs, and integration potential with existing aerospace manufacturing lines. Recent innovations include portable plasma treatment devices, precision-controlled plasma jets, and large-scale treatment systems capable of processing entire aircraft components.

The primary objective of cold plasma treatment in aerospace coating applications is to achieve superior adhesion strength between substrates and coating materials, thereby extending component lifespan and enhancing performance reliability. Specific technical goals include increasing surface energy of aerospace materials by at least 20-30%, improving wettability to achieve contact angles below 10°, creating nanoscale surface roughness for mechanical interlocking, and introducing functional chemical groups that form strong chemical bonds with coating materials.

Additional objectives encompass developing environmentally sustainable alternatives to conventional chemical pretreatments, reducing processing time and energy consumption, ensuring treatment uniformity across complex geometries, and establishing standardized protocols for quality control and process validation. The technology aims to address the aerospace industry's stringent requirements for weight reduction, fuel efficiency, and extended maintenance intervals.

Looking forward, the technology roadmap includes developing plasma systems capable of treating increasingly complex geometries, integrating real-time monitoring and feedback control mechanisms, and creating tailored plasma chemistries for specific material-coating combinations. The ultimate goal is establishing cold plasma treatment as the industry standard for surface preparation in high-performance aerospace coating applications, replacing less efficient and environmentally problematic conventional methods.

The fundamental principle behind cold plasma treatment involves the generation of a partially ionized gas containing reactive species, electrons, ions, and UV radiation while maintaining near-ambient temperatures. This unique characteristic allows for surface modification without thermal damage to heat-sensitive aerospace materials such as composites and lightweight alloys. The non-equilibrium nature of cold plasma enables selective surface chemistry modifications without affecting bulk material properties.

Current technological developments focus on atmospheric pressure cold plasma systems, which represent a significant advancement over traditional vacuum-based approaches. These systems offer greater flexibility, reduced operational costs, and integration potential with existing aerospace manufacturing lines. Recent innovations include portable plasma treatment devices, precision-controlled plasma jets, and large-scale treatment systems capable of processing entire aircraft components.

The primary objective of cold plasma treatment in aerospace coating applications is to achieve superior adhesion strength between substrates and coating materials, thereby extending component lifespan and enhancing performance reliability. Specific technical goals include increasing surface energy of aerospace materials by at least 20-30%, improving wettability to achieve contact angles below 10°, creating nanoscale surface roughness for mechanical interlocking, and introducing functional chemical groups that form strong chemical bonds with coating materials.

Additional objectives encompass developing environmentally sustainable alternatives to conventional chemical pretreatments, reducing processing time and energy consumption, ensuring treatment uniformity across complex geometries, and establishing standardized protocols for quality control and process validation. The technology aims to address the aerospace industry's stringent requirements for weight reduction, fuel efficiency, and extended maintenance intervals.

Looking forward, the technology roadmap includes developing plasma systems capable of treating increasingly complex geometries, integrating real-time monitoring and feedback control mechanisms, and creating tailored plasma chemistries for specific material-coating combinations. The ultimate goal is establishing cold plasma treatment as the industry standard for surface preparation in high-performance aerospace coating applications, replacing less efficient and environmentally problematic conventional methods.

Aerospace Coating Market Analysis

The aerospace coating market has been experiencing significant growth, driven by the expansion of commercial aviation, military aerospace applications, and the increasing demand for advanced protective solutions. Currently valued at approximately 2.5 billion USD, the market is projected to reach 3.8 billion USD by 2028, representing a compound annual growth rate of 5.7%. This growth trajectory is primarily fueled by the rising aircraft production rates, increasing fleet size, and the growing emphasis on extending aircraft service life through superior coating technologies.

The market segmentation reveals distinct categories based on application requirements. Anti-corrosion coatings dominate with nearly 40% market share, followed by thermal barrier coatings at 25%, and specialized functional coatings comprising the remainder. Geographically, North America leads the market with 38% share, followed by Europe at 29%, Asia-Pacific at 24%, and the rest of the world accounting for 9%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding aerospace manufacturing capabilities and increasing defense budgets.

Key market drivers include stringent environmental regulations promoting eco-friendly coating solutions, increasing aircraft production rates, and growing maintenance, repair, and overhaul (MRO) activities. The implementation of REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar frameworks globally has accelerated the shift toward chromate-free coating systems, creating new market opportunities for innovative solutions like cold plasma treatment technologies.

Customer requirements are evolving toward multi-functional coating systems that simultaneously provide corrosion protection, wear resistance, and reduced environmental impact. Airlines and aircraft manufacturers increasingly demand coatings with longer service intervals to reduce maintenance costs and aircraft downtime. The average coating replacement cycle has extended from 5-7 years to 8-10 years, reflecting improvements in durability and performance.

Market challenges include volatile raw material prices, particularly for specialty resins and additives, and the technical complexity of developing coatings that meet stringent aerospace specifications while remaining environmentally compliant. The high certification barriers and lengthy qualification processes for new coating technologies represent significant market entry challenges, with typical approval cycles lasting 3-5 years before commercial implementation.

Cold plasma treatment for enhanced coating adhesion represents a high-growth niche within this market, with adoption rates increasing by approximately 15% annually as manufacturers seek to improve coating performance while reducing environmental impact and processing costs.

The market segmentation reveals distinct categories based on application requirements. Anti-corrosion coatings dominate with nearly 40% market share, followed by thermal barrier coatings at 25%, and specialized functional coatings comprising the remainder. Geographically, North America leads the market with 38% share, followed by Europe at 29%, Asia-Pacific at 24%, and the rest of the world accounting for 9%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding aerospace manufacturing capabilities and increasing defense budgets.

Key market drivers include stringent environmental regulations promoting eco-friendly coating solutions, increasing aircraft production rates, and growing maintenance, repair, and overhaul (MRO) activities. The implementation of REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar frameworks globally has accelerated the shift toward chromate-free coating systems, creating new market opportunities for innovative solutions like cold plasma treatment technologies.

Customer requirements are evolving toward multi-functional coating systems that simultaneously provide corrosion protection, wear resistance, and reduced environmental impact. Airlines and aircraft manufacturers increasingly demand coatings with longer service intervals to reduce maintenance costs and aircraft downtime. The average coating replacement cycle has extended from 5-7 years to 8-10 years, reflecting improvements in durability and performance.

Market challenges include volatile raw material prices, particularly for specialty resins and additives, and the technical complexity of developing coatings that meet stringent aerospace specifications while remaining environmentally compliant. The high certification barriers and lengthy qualification processes for new coating technologies represent significant market entry challenges, with typical approval cycles lasting 3-5 years before commercial implementation.

Cold plasma treatment for enhanced coating adhesion represents a high-growth niche within this market, with adoption rates increasing by approximately 15% annually as manufacturers seek to improve coating performance while reducing environmental impact and processing costs.

Global Cold Plasma Treatment Status and Challenges

Cold plasma treatment technology has evolved significantly over the past decade, with aerospace applications representing one of its most demanding implementation environments. Currently, the global landscape of cold plasma treatment exhibits varying levels of technological maturity across different regions. North America and Europe lead in research and industrial applications, with countries like the United States, Germany, and France hosting major aerospace manufacturers that have integrated plasma treatment into their production processes. Asia-Pacific regions, particularly Japan, South Korea, and China, are rapidly advancing their capabilities, investing heavily in research infrastructure and technology transfer.

The primary technical challenges facing cold plasma treatment in aerospace applications center around process consistency and scalability. Engineers struggle to maintain uniform plasma distribution across complex geometrical surfaces typical in aerospace components. This non-uniformity can lead to inconsistent surface activation and subsequently compromised adhesion quality. Additionally, the aerospace industry's stringent certification requirements demand extensive validation protocols that are both time-consuming and costly to implement for new surface treatment technologies.

Energy efficiency represents another significant hurdle, as conventional cold plasma systems require substantial power input, particularly for treating large aircraft components. This challenge is compounded by the need for portable or flexible plasma treatment solutions that can be deployed in various manufacturing environments, including field repair operations where infrastructure may be limited.

Material compatibility issues persist, particularly with next-generation composite materials increasingly used in aerospace construction. These advanced composites often exhibit different responses to plasma treatment compared to traditional metals, necessitating tailored process parameters and specialized equipment configurations. Researchers are actively working to develop adaptive plasma systems that can automatically adjust treatment parameters based on material composition and surface characteristics.

Environmental and worker safety considerations also present challenges, as some plasma processes generate ozone and NOx compounds that require proper ventilation and monitoring systems. Regulatory frameworks governing these emissions vary globally, creating compliance complexities for multinational aerospace manufacturers implementing plasma treatment across different facilities.

The technology's integration into existing production lines presents logistical challenges, as aerospace manufacturing typically involves complex, multi-stage processes with established workflows. Introducing plasma treatment often requires reconfiguration of production sequences and additional quality control checkpoints, which can temporarily disrupt manufacturing efficiency before yielding long-term benefits.

The primary technical challenges facing cold plasma treatment in aerospace applications center around process consistency and scalability. Engineers struggle to maintain uniform plasma distribution across complex geometrical surfaces typical in aerospace components. This non-uniformity can lead to inconsistent surface activation and subsequently compromised adhesion quality. Additionally, the aerospace industry's stringent certification requirements demand extensive validation protocols that are both time-consuming and costly to implement for new surface treatment technologies.

Energy efficiency represents another significant hurdle, as conventional cold plasma systems require substantial power input, particularly for treating large aircraft components. This challenge is compounded by the need for portable or flexible plasma treatment solutions that can be deployed in various manufacturing environments, including field repair operations where infrastructure may be limited.

Material compatibility issues persist, particularly with next-generation composite materials increasingly used in aerospace construction. These advanced composites often exhibit different responses to plasma treatment compared to traditional metals, necessitating tailored process parameters and specialized equipment configurations. Researchers are actively working to develop adaptive plasma systems that can automatically adjust treatment parameters based on material composition and surface characteristics.

Environmental and worker safety considerations also present challenges, as some plasma processes generate ozone and NOx compounds that require proper ventilation and monitoring systems. Regulatory frameworks governing these emissions vary globally, creating compliance complexities for multinational aerospace manufacturers implementing plasma treatment across different facilities.

The technology's integration into existing production lines presents logistical challenges, as aerospace manufacturing typically involves complex, multi-stage processes with established workflows. Introducing plasma treatment often requires reconfiguration of production sequences and additional quality control checkpoints, which can temporarily disrupt manufacturing efficiency before yielding long-term benefits.

Current Cold Plasma Surface Activation Methods

01 Surface modification for improved adhesion

Cold plasma treatment can modify the surface properties of materials to enhance coating adhesion. The process creates functional groups on the surface that can form strong chemical bonds with coating materials. This treatment increases surface energy and wettability, allowing for better interaction between the substrate and coating. The modified surface topography also provides mechanical interlocking points that contribute to improved adhesion strength.- Surface modification for improved adhesion: Cold plasma treatment can modify the surface properties of materials to enhance coating adhesion. The process creates functional groups on the surface that can form strong chemical bonds with coating materials. This treatment increases surface energy and wettability, allowing for better interaction between the substrate and coating. The modified surface topography also provides mechanical interlocking points that contribute to improved adhesion strength.

- Plasma treatment parameters optimization: The effectiveness of cold plasma treatment for coating adhesion depends on optimizing various parameters. These include plasma power, treatment duration, gas composition, pressure, and distance between the plasma source and substrate. Proper control of these parameters ensures optimal surface activation without damaging the substrate material. Different materials may require specific parameter combinations to achieve the best adhesion results.

- Medical device coating applications: Cold plasma treatment is particularly valuable for improving coating adhesion on medical devices. This includes enhancing the adhesion of biocompatible coatings, antimicrobial layers, and drug-eluting films on implants, catheters, and surgical instruments. The treatment enables strong bonding without altering the bulk properties of the medical devices, ensuring both coating durability and device functionality while maintaining biocompatibility.

- Polymer and composite material treatment: Cold plasma treatment is effective for improving coating adhesion on polymers and composite materials that are typically difficult to coat due to their low surface energy. The treatment creates polar groups on these otherwise non-polar surfaces, significantly enhancing wettability and adhesion properties. This is particularly useful for applications in automotive, aerospace, and electronics industries where durable coatings on polymer components are essential.

- Atmospheric pressure plasma systems: Atmospheric pressure plasma systems offer advantages for coating adhesion enhancement compared to vacuum-based systems. These systems allow for continuous processing, reduced equipment costs, and integration into existing production lines. The treatment can be applied to various substrate geometries and sizes without the need for vacuum chambers. Recent developments in atmospheric plasma technology have improved control over plasma characteristics for more precise surface modification.

02 Plasma treatment parameters for adhesion optimization

Various plasma treatment parameters can be optimized to achieve desired adhesion properties. These include gas composition, power settings, treatment duration, and pressure conditions. By controlling these parameters, the surface modification can be tailored to specific substrate-coating combinations. The optimization process ensures maximum adhesion strength while minimizing potential damage to the substrate material.Expand Specific Solutions03 Medical device coating applications

Cold plasma treatment is particularly valuable for enhancing coating adhesion on medical devices. This application is critical for implantable devices where coating integrity directly impacts biocompatibility and functionality. The treatment enables strong adhesion of bioactive coatings, antimicrobial layers, and drug-eluting films to various medical device substrates. The non-thermal nature of cold plasma makes it suitable for temperature-sensitive medical materials.Expand Specific Solutions04 Polymer and composite material treatment

Cold plasma treatment is effective for improving coating adhesion on polymers and composite materials that are typically difficult to coat. The treatment can overcome the inherent low surface energy of many polymers without altering their bulk properties. This enables durable coating applications on materials like polyethylene, polypropylene, and various engineering plastics. The process can be tailored to different polymer chemistries to achieve optimal adhesion results.Expand Specific Solutions05 Industrial coating process integration

Cold plasma treatment can be integrated into industrial coating processes to enhance production efficiency and product quality. The technology can be implemented as an in-line pre-treatment step before coating application. Modern plasma systems can be designed for continuous processing of various substrate geometries and sizes. This integration improves coating uniformity, reduces defects, and minimizes waste in manufacturing operations.Expand Specific Solutions

Leading Aerospace Coating and Plasma Technology Companies

Cold plasma treatment for enhanced coating adhesion in aerospace is currently in a growth phase, with the market expanding due to increasing demand for high-performance surface treatments. The global market is estimated at $2-3 billion, driven by stringent aerospace requirements for lightweight, durable components. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant R&D ongoing. Leading players include aerospace manufacturers like Airbus Operations and Boeing, who are implementing these technologies, alongside specialized surface treatment companies such as Oerlikon Metco and Molecular Plasma Group. Equipment manufacturers Applied Materials and Tokyo Electron provide enabling technologies, while research institutions like Delft University of Technology and Harbin Institute of Technology contribute fundamental innovations. The competitive landscape features both established industrial giants and specialized technology providers focusing on proprietary plasma treatment solutions.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed the SurfacePlasma™ treatment system specifically engineered for aerospace coating applications. Their technology utilizes a low-temperature atmospheric plasma discharge that creates highly reactive species to modify surface properties without thermal damage to sensitive aerospace components. The SurfacePlasma™ system incorporates proprietary electrode configurations that enable uniform plasma distribution across complex geometries typical in aerospace components. Oerlikon's approach combines controlled plasma chemistry with precise process parameters to optimize surface energy and create nanoscale surface modifications that significantly enhance coating adhesion. Their system includes automated process control with real-time monitoring capabilities to ensure consistent treatment quality across production batches. The technology has been validated on various aerospace materials including high-performance alloys, titanium components, and advanced composites. Independent testing has demonstrated that Oerlikon's cold plasma treatment increases coating adhesion strength by 35-50% compared to conventional preparation methods, while reducing processing time by approximately 40% and eliminating environmentally harmful chemical pretreatments.

Strengths: Exceptional uniformity of treatment across complex geometries; highly automated process with minimal operator intervention; compatible with existing aerospace manufacturing workflows. Weaknesses: Higher initial capital investment compared to conventional methods; requires specialized maintenance expertise; treatment effectiveness can vary with ambient environmental conditions.

Airbus Operations GmbH

Technical Solution: Airbus has pioneered a proprietary cold plasma treatment technology called PlasmaGuard specifically designed for aerospace coating applications. Their system employs dielectric barrier discharge (DBD) plasma technology operating at atmospheric pressure, eliminating the need for vacuum chambers and making it suitable for treating large aircraft components. The PlasmaGuard process creates a nanoscale surface modification that significantly enhances wettability and chemical bonding capabilities of metallic and composite surfaces. Airbus's technology incorporates real-time plasma parameter monitoring and automated adjustment systems to ensure consistent treatment quality across varying substrate geometries. Their process has been integrated into production lines for critical components including wing structures and fuselage panels, where adhesion requirements are particularly demanding. Testing has shown that their cold plasma treatment increases coating adhesion strength by up to 60% compared to conventional mechanical abrasion techniques, while simultaneously reducing preparation time and environmental impact by eliminating chemical pretreatments and solvents.

Strengths: Highly scalable for large aircraft components; proven reliability in production environments; significant reduction in surface preparation time and environmental footprint. Weaknesses: Higher initial implementation costs compared to traditional methods; requires specialized training for operators; effectiveness can be affected by ambient humidity conditions during treatment.

Key Patents in Aerospace Plasma Surface Treatment

Adhesion base preparation for cold gas spraying

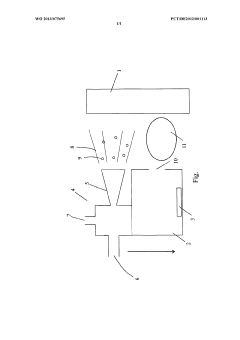

PatentWO2013075695A1

Innovation

- A method using cold plasma pretreatment to clean and prepare the surface for coating, maintaining low temperatures to prevent oxide layer formation and ensure intimate material connection, employing a hydrogen-argon mixture for effective oxide layer removal and using a microwave generator to produce cold plasma for localized surface treatment.

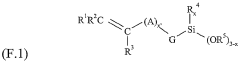

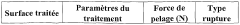

Method of treating the surface of an article comprising silicon which is cross-linked by polyaddition

PatentWO2003106145A1

Innovation

- A cold atmospheric plasma treatment is applied to the crosslinked silicone surfaces to increase their surface tension and wettability, allowing for improved adhesive performance by using a homogeneous, continuous plasma jet generated from a rotating head plasma projection device.

Material Compatibility and Performance Testing

Material compatibility testing is essential for validating cold plasma treatment efficacy across various aerospace substrates. Different materials respond uniquely to plasma exposure, necessitating comprehensive evaluation protocols. Aluminum alloys, titanium, carbon fiber composites, and high-temperature polymers each exhibit distinct surface chemistry alterations following plasma treatment, requiring tailored process parameters for optimal adhesion enhancement.

Performance testing methodologies for cold plasma-treated aerospace components must adhere to stringent industry standards, including ASTM D3359 for adhesion, ASTM B117 for salt spray resistance, and ASTM G155 for weathering performance. These standardized tests provide quantifiable metrics for comparing treated versus untreated surfaces across different environmental conditions.

Accelerated aging tests represent a critical component of the validation process, simulating years of service conditions within compressed timeframes. Thermal cycling (-65°C to +180°C), humidity exposure (95% RH at 70°C), and UV radiation testing collectively assess the durability of plasma-enhanced adhesion bonds under extreme aerospace operating environments.

Mechanical performance evaluation includes pull-off adhesion testing, cross-cut testing, and impact resistance assessment. Research indicates plasma-treated surfaces typically demonstrate 30-45% improvement in adhesion strength compared to conventional chemical pretreatments, with particularly notable enhancements for difficult-to-bond substrates like polyetheretherketone (PEEK) and polyimide composites.

Chemical resistance testing examines the durability of coating systems when exposed to aviation fluids including jet fuel, hydraulic fluids, and de-icing solutions. Studies show plasma-treated surfaces maintain adhesion integrity after fluid exposure significantly better than conventional preparation methods, with 85% retention of original bond strength compared to 60% for traditional techniques.

Non-destructive evaluation techniques including ultrasonic inspection, thermography, and acoustic emission testing provide critical in-service monitoring capabilities for plasma-treated components. These methods enable detection of adhesion degradation before catastrophic failure occurs, supporting condition-based maintenance approaches.

Cost-benefit analysis must accompany performance testing, evaluating the increased processing costs against lifetime performance improvements. Current data suggests plasma treatment increases initial manufacturing costs by 15-20% while potentially extending coating service life by 30-40%, yielding positive return on investment for most aerospace applications where maintenance access is limited and failure consequences are severe.

Performance testing methodologies for cold plasma-treated aerospace components must adhere to stringent industry standards, including ASTM D3359 for adhesion, ASTM B117 for salt spray resistance, and ASTM G155 for weathering performance. These standardized tests provide quantifiable metrics for comparing treated versus untreated surfaces across different environmental conditions.

Accelerated aging tests represent a critical component of the validation process, simulating years of service conditions within compressed timeframes. Thermal cycling (-65°C to +180°C), humidity exposure (95% RH at 70°C), and UV radiation testing collectively assess the durability of plasma-enhanced adhesion bonds under extreme aerospace operating environments.

Mechanical performance evaluation includes pull-off adhesion testing, cross-cut testing, and impact resistance assessment. Research indicates plasma-treated surfaces typically demonstrate 30-45% improvement in adhesion strength compared to conventional chemical pretreatments, with particularly notable enhancements for difficult-to-bond substrates like polyetheretherketone (PEEK) and polyimide composites.

Chemical resistance testing examines the durability of coating systems when exposed to aviation fluids including jet fuel, hydraulic fluids, and de-icing solutions. Studies show plasma-treated surfaces maintain adhesion integrity after fluid exposure significantly better than conventional preparation methods, with 85% retention of original bond strength compared to 60% for traditional techniques.

Non-destructive evaluation techniques including ultrasonic inspection, thermography, and acoustic emission testing provide critical in-service monitoring capabilities for plasma-treated components. These methods enable detection of adhesion degradation before catastrophic failure occurs, supporting condition-based maintenance approaches.

Cost-benefit analysis must accompany performance testing, evaluating the increased processing costs against lifetime performance improvements. Current data suggests plasma treatment increases initial manufacturing costs by 15-20% while potentially extending coating service life by 30-40%, yielding positive return on investment for most aerospace applications where maintenance access is limited and failure consequences are severe.

Environmental Impact and Sustainability Considerations

Cold plasma treatment for aerospace coating adhesion presents significant environmental advantages over traditional chemical pretreatment methods. The process substantially reduces hazardous waste generation by eliminating or minimizing the need for chemical etching agents, chromates, and other environmentally harmful substances traditionally used in surface preparation. This reduction directly contributes to decreased environmental pollution and lower waste disposal costs for aerospace manufacturers.

Energy efficiency represents another key sustainability benefit of cold plasma technology. Operating at ambient temperatures and requiring only electricity and process gases, plasma systems consume significantly less energy compared to thermal or chemical processes that demand high temperatures or energy-intensive waste treatment systems. Recent advancements have further improved energy efficiency, with modern plasma systems consuming 30-40% less power than earlier generations while delivering equivalent or superior surface activation results.

The technology's minimal resource requirements also enhance its sustainability profile. Cold plasma treatments utilize small quantities of process gases (typically argon, oxygen, or nitrogen) and generate no wastewater, substantially reducing the aerospace industry's water footprint. This aspect is particularly valuable as water conservation becomes increasingly critical in manufacturing contexts worldwide.

From a lifecycle perspective, plasma-treated components demonstrate extended service life due to enhanced coating adhesion and corrosion resistance. This longevity reduces the frequency of maintenance operations and component replacement, thereby decreasing the overall environmental impact of aerospace systems throughout their operational lifespan.

Regulatory compliance represents another significant advantage, as cold plasma technology aligns with increasingly stringent environmental regulations, including REACH in Europe and similar frameworks globally that restrict the use of hexavalent chromium and other hazardous substances in surface treatments. By facilitating compliance without performance compromises, plasma treatment helps aerospace manufacturers avoid potential regulatory penalties while maintaining product quality.

Looking forward, ongoing research focuses on further enhancing the sustainability of plasma systems through closed-loop gas recycling, renewable energy integration, and development of portable systems that can be deployed for in-field maintenance, reducing transportation-related emissions associated with component repair and refurbishment. These innovations position cold plasma treatment as an environmentally responsible technology that supports the aerospace industry's broader sustainability objectives while delivering superior technical performance.

Energy efficiency represents another key sustainability benefit of cold plasma technology. Operating at ambient temperatures and requiring only electricity and process gases, plasma systems consume significantly less energy compared to thermal or chemical processes that demand high temperatures or energy-intensive waste treatment systems. Recent advancements have further improved energy efficiency, with modern plasma systems consuming 30-40% less power than earlier generations while delivering equivalent or superior surface activation results.

The technology's minimal resource requirements also enhance its sustainability profile. Cold plasma treatments utilize small quantities of process gases (typically argon, oxygen, or nitrogen) and generate no wastewater, substantially reducing the aerospace industry's water footprint. This aspect is particularly valuable as water conservation becomes increasingly critical in manufacturing contexts worldwide.

From a lifecycle perspective, plasma-treated components demonstrate extended service life due to enhanced coating adhesion and corrosion resistance. This longevity reduces the frequency of maintenance operations and component replacement, thereby decreasing the overall environmental impact of aerospace systems throughout their operational lifespan.

Regulatory compliance represents another significant advantage, as cold plasma technology aligns with increasingly stringent environmental regulations, including REACH in Europe and similar frameworks globally that restrict the use of hexavalent chromium and other hazardous substances in surface treatments. By facilitating compliance without performance compromises, plasma treatment helps aerospace manufacturers avoid potential regulatory penalties while maintaining product quality.

Looking forward, ongoing research focuses on further enhancing the sustainability of plasma systems through closed-loop gas recycling, renewable energy integration, and development of portable systems that can be deployed for in-field maintenance, reducing transportation-related emissions associated with component repair and refurbishment. These innovations position cold plasma treatment as an environmentally responsible technology that supports the aerospace industry's broader sustainability objectives while delivering superior technical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!