Impact of Cold Plasma Treatment on Surface Energy of Polymers

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has evolved significantly since its initial discovery in the early 20th century. Originally observed as an electrical discharge phenomenon, plasma—often referred to as the fourth state of matter—has transformed from a laboratory curiosity into a versatile industrial tool. The development trajectory accelerated notably in the 1960s and 1970s when researchers began exploring its potential for surface modification applications, particularly for polymeric materials.

The fundamental principle behind cold plasma technology involves the generation of reactive species (ions, electrons, free radicals) in a gas through electrical discharge while maintaining near-ambient temperatures. This characteristic distinguishes cold plasma from thermal plasma, making it particularly suitable for treating heat-sensitive materials like polymers without causing thermal degradation.

Over the past two decades, cold plasma treatment has emerged as a powerful technique for modifying surface properties of polymers without altering their bulk characteristics. The technology has demonstrated remarkable versatility across diverse industries including medical device manufacturing, packaging, automotive components, and electronics, where surface energy manipulation is critical for adhesion, printing, and coating processes.

Current technological trends indicate a shift toward atmospheric pressure plasma systems, which eliminate the need for vacuum equipment, thereby reducing operational complexity and costs compared to traditional low-pressure plasma systems. Additionally, there is growing interest in developing selective surface modification techniques that can create spatially controlled surface energy patterns on polymeric substrates.

The primary objective of cold plasma treatment for polymer surface modification is to enhance surface energy characteristics through the introduction of specific functional groups. This process aims to improve wettability, adhesion properties, and biocompatibility without compromising the mechanical integrity or bulk properties of the polymer substrate.

Research goals in this field include developing more energy-efficient plasma generation methods, creating more precise control mechanisms for functional group attachment, and establishing standardized protocols for treatment parameters across different polymer types. There is also significant interest in understanding the long-term stability of plasma-induced surface modifications and developing treatments that provide durable surface energy alterations.

The convergence of plasma physics, materials science, and surface chemistry continues to drive innovation in this field, with particular emphasis on environmentally friendly processes that minimize chemical waste compared to conventional wet chemical treatments. As sustainability becomes increasingly important in manufacturing processes, cold plasma technology represents a promising approach for eco-friendly surface modification of polymeric materials.

The fundamental principle behind cold plasma technology involves the generation of reactive species (ions, electrons, free radicals) in a gas through electrical discharge while maintaining near-ambient temperatures. This characteristic distinguishes cold plasma from thermal plasma, making it particularly suitable for treating heat-sensitive materials like polymers without causing thermal degradation.

Over the past two decades, cold plasma treatment has emerged as a powerful technique for modifying surface properties of polymers without altering their bulk characteristics. The technology has demonstrated remarkable versatility across diverse industries including medical device manufacturing, packaging, automotive components, and electronics, where surface energy manipulation is critical for adhesion, printing, and coating processes.

Current technological trends indicate a shift toward atmospheric pressure plasma systems, which eliminate the need for vacuum equipment, thereby reducing operational complexity and costs compared to traditional low-pressure plasma systems. Additionally, there is growing interest in developing selective surface modification techniques that can create spatially controlled surface energy patterns on polymeric substrates.

The primary objective of cold plasma treatment for polymer surface modification is to enhance surface energy characteristics through the introduction of specific functional groups. This process aims to improve wettability, adhesion properties, and biocompatibility without compromising the mechanical integrity or bulk properties of the polymer substrate.

Research goals in this field include developing more energy-efficient plasma generation methods, creating more precise control mechanisms for functional group attachment, and establishing standardized protocols for treatment parameters across different polymer types. There is also significant interest in understanding the long-term stability of plasma-induced surface modifications and developing treatments that provide durable surface energy alterations.

The convergence of plasma physics, materials science, and surface chemistry continues to drive innovation in this field, with particular emphasis on environmentally friendly processes that minimize chemical waste compared to conventional wet chemical treatments. As sustainability becomes increasingly important in manufacturing processes, cold plasma technology represents a promising approach for eco-friendly surface modification of polymeric materials.

Market Applications Analysis

Cold plasma treatment of polymers has gained significant traction across multiple industries due to its ability to modify surface energy without altering bulk properties. The market applications span diverse sectors, with packaging being one of the most prominent. In the food and beverage packaging industry, plasma-treated polymers demonstrate enhanced printability, adhesion properties, and barrier characteristics, leading to extended shelf life and improved product presentation. Major packaging companies have reported 30-40% improvement in print quality and adhesion strength after implementing cold plasma surface treatments.

The medical device sector represents another high-value application area, where plasma-treated polymers are utilized for catheters, implants, and diagnostic equipment. The improved surface energy facilitates better biocompatibility and cell adhesion while reducing bacterial attachment. This market segment has shown consistent growth rates of 7-9% annually, with plasma surface modification technologies contributing significantly to this expansion.

Automotive and aerospace industries leverage plasma-treated polymers for composite bonding applications, where the enhanced surface energy enables stronger adhesion between dissimilar materials. This has resulted in weight reduction while maintaining structural integrity, with some manufacturers reporting up to 15% weight savings in specific components. The improved bonding strength has also extended the service life of these components by 20-25%.

The electronics sector utilizes cold plasma treatment for circuit boards, display panels, and semiconductor packaging. The precise control of surface energy allows for finer circuit patterns and improved component adhesion. As electronic devices continue to miniaturize, the demand for plasma-treated polymers with precisely controlled surface properties has grown by approximately 12% annually.

Textile and nonwoven industries have adopted cold plasma technology to enhance wettability, dyeability, and functional coating adhesion. This has enabled the development of advanced technical textiles with properties such as water repellency, antimicrobial characteristics, and improved comfort. The market for such functional textiles has expanded at 8-10% annually, with plasma treatment being a key enabling technology.

Environmental considerations are driving further market growth, as cold plasma treatments offer a solvent-free alternative to traditional chemical surface modifications. This aligns with increasingly stringent regulations on volatile organic compounds (VOCs) and hazardous chemicals. Companies implementing plasma technologies have reported reductions in chemical waste by 50-70% compared to conventional surface treatment methods.

The medical device sector represents another high-value application area, where plasma-treated polymers are utilized for catheters, implants, and diagnostic equipment. The improved surface energy facilitates better biocompatibility and cell adhesion while reducing bacterial attachment. This market segment has shown consistent growth rates of 7-9% annually, with plasma surface modification technologies contributing significantly to this expansion.

Automotive and aerospace industries leverage plasma-treated polymers for composite bonding applications, where the enhanced surface energy enables stronger adhesion between dissimilar materials. This has resulted in weight reduction while maintaining structural integrity, with some manufacturers reporting up to 15% weight savings in specific components. The improved bonding strength has also extended the service life of these components by 20-25%.

The electronics sector utilizes cold plasma treatment for circuit boards, display panels, and semiconductor packaging. The precise control of surface energy allows for finer circuit patterns and improved component adhesion. As electronic devices continue to miniaturize, the demand for plasma-treated polymers with precisely controlled surface properties has grown by approximately 12% annually.

Textile and nonwoven industries have adopted cold plasma technology to enhance wettability, dyeability, and functional coating adhesion. This has enabled the development of advanced technical textiles with properties such as water repellency, antimicrobial characteristics, and improved comfort. The market for such functional textiles has expanded at 8-10% annually, with plasma treatment being a key enabling technology.

Environmental considerations are driving further market growth, as cold plasma treatments offer a solvent-free alternative to traditional chemical surface modifications. This aligns with increasingly stringent regulations on volatile organic compounds (VOCs) and hazardous chemicals. Companies implementing plasma technologies have reported reductions in chemical waste by 50-70% compared to conventional surface treatment methods.

Current Challenges in Polymer Surface Modification

Despite significant advancements in polymer surface modification techniques, several persistent challenges continue to impede the widespread industrial adoption of cold plasma treatment for enhancing polymer surface energy. The inherent hydrophobic nature of most polymers presents a fundamental obstacle, requiring sophisticated modification approaches to achieve desired wettability and adhesion properties. This hydrophobicity stems from low surface energy, typically ranging from 20-40 mJ/m², significantly lower than the optimal range needed for many applications.

A critical challenge lies in the aging effect or hydrophobic recovery phenomenon, where plasma-treated polymer surfaces gradually revert to their original hydrophobic state. This recovery occurs through various mechanisms including the reorientation of polar groups away from the surface, diffusion of low molecular weight oxidized materials into the bulk, and the migration of untreated chains from the bulk to the surface. The time scale of this recovery varies from hours to months depending on polymer type, storage conditions, and treatment parameters.

The heterogeneity of treatment across complex geometries represents another significant hurdle. Plasma treatment efficacy can vary substantially across curved surfaces, recessed areas, and intricate structures, leading to inconsistent surface energy modifications. This non-uniformity becomes particularly problematic in applications requiring precise control over surface properties across the entire component.

Process scalability presents considerable difficulties when transitioning from laboratory to industrial settings. While atmospheric pressure plasma systems offer potential solutions, they often struggle to maintain the same level of treatment uniformity and effectiveness as vacuum-based systems when processing large volumes or continuous production lines.

The sensitivity of plasma treatment outcomes to processing parameters creates reproducibility challenges. Minor variations in power input, gas composition, exposure time, or substrate temperature can significantly alter surface energy outcomes. This sensitivity necessitates sophisticated process control systems that many manufacturing facilities find difficult to implement and maintain.

Environmental factors during and after treatment, including ambient humidity, temperature fluctuations, and contamination, can dramatically influence treatment effectiveness and longevity. These variables introduce additional complexity to process validation and quality control protocols.

Furthermore, the industry faces a knowledge gap regarding the precise correlation between plasma treatment parameters and resulting surface energy characteristics for specific polymer types. This deficiency hampers the development of standardized treatment protocols and predictive models that could facilitate broader industrial implementation.

A critical challenge lies in the aging effect or hydrophobic recovery phenomenon, where plasma-treated polymer surfaces gradually revert to their original hydrophobic state. This recovery occurs through various mechanisms including the reorientation of polar groups away from the surface, diffusion of low molecular weight oxidized materials into the bulk, and the migration of untreated chains from the bulk to the surface. The time scale of this recovery varies from hours to months depending on polymer type, storage conditions, and treatment parameters.

The heterogeneity of treatment across complex geometries represents another significant hurdle. Plasma treatment efficacy can vary substantially across curved surfaces, recessed areas, and intricate structures, leading to inconsistent surface energy modifications. This non-uniformity becomes particularly problematic in applications requiring precise control over surface properties across the entire component.

Process scalability presents considerable difficulties when transitioning from laboratory to industrial settings. While atmospheric pressure plasma systems offer potential solutions, they often struggle to maintain the same level of treatment uniformity and effectiveness as vacuum-based systems when processing large volumes or continuous production lines.

The sensitivity of plasma treatment outcomes to processing parameters creates reproducibility challenges. Minor variations in power input, gas composition, exposure time, or substrate temperature can significantly alter surface energy outcomes. This sensitivity necessitates sophisticated process control systems that many manufacturing facilities find difficult to implement and maintain.

Environmental factors during and after treatment, including ambient humidity, temperature fluctuations, and contamination, can dramatically influence treatment effectiveness and longevity. These variables introduce additional complexity to process validation and quality control protocols.

Furthermore, the industry faces a knowledge gap regarding the precise correlation between plasma treatment parameters and resulting surface energy characteristics for specific polymer types. This deficiency hampers the development of standardized treatment protocols and predictive models that could facilitate broader industrial implementation.

Current Plasma Treatment Methods for Polymers

01 Surface energy modification using cold plasma treatment

Cold plasma treatment can be used to modify the surface energy of materials, making them more hydrophilic or hydrophobic depending on the treatment parameters. This modification alters the wettability and adhesion properties of the surface, which is beneficial for various applications including medical devices, textiles, and industrial components. The treatment creates functional groups on the surface that change its chemical and physical properties without affecting the bulk material characteristics.- Surface energy modification using cold plasma treatment: Cold plasma treatment can be used to modify the surface energy of various materials. This process involves exposing the material surface to ionized gas, which can alter the surface properties without affecting the bulk material. The treatment can increase surface energy, improving wettability and adhesion properties, which is particularly useful for materials that are naturally hydrophobic. The modified surface energy can enhance bonding capabilities and improve coating adhesion.

- Medical device surface treatment with cold plasma: Cold plasma treatment is utilized to modify the surface properties of medical devices to enhance biocompatibility, sterilization, and functionality. The treatment can create specific surface characteristics that promote cell adhesion, reduce bacterial colonization, or improve integration with biological tissues. This approach is particularly valuable for implantable devices, catheters, and surgical instruments where surface properties directly impact clinical outcomes and patient safety.

- Cold plasma for surface cleaning and activation: Cold plasma treatment serves as an effective method for cleaning surfaces by removing organic contaminants and activating surfaces prior to bonding or coating processes. The energetic species in plasma can break down and remove contaminants at the molecular level without damaging the underlying material. This surface activation creates reactive sites that enhance adhesion properties, making it particularly valuable in manufacturing processes requiring high-quality surface preparation.

- Controlled surface modification parameters in cold plasma treatment: The effectiveness of cold plasma treatment for surface energy modification depends on carefully controlled parameters such as gas composition, power settings, exposure time, and pressure. These parameters can be adjusted to achieve specific surface energy levels and functional properties. Advanced systems incorporate real-time monitoring and feedback control to ensure consistent treatment results across different materials and applications, allowing for precise tailoring of surface properties.

- Industrial applications of cold plasma surface treatment: Cold plasma treatment for surface energy modification has diverse industrial applications including electronics manufacturing, textile processing, packaging, automotive components, and aerospace materials. The technology enables improved adhesion for coatings, paints, and adhesives, enhances printability on polymers, and can create functional surfaces with specific properties such as hydrophilicity or hydrophobicity. These treatments can be integrated into production lines for continuous or batch processing of materials.

02 Medical device surface treatment with cold plasma

Cold plasma treatment is applied to medical devices to enhance biocompatibility, sterilization, and surface functionality. The treatment increases surface energy to improve cell adhesion, protein binding, and integration with biological tissues. This is particularly important for implantable devices, catheters, and surgical instruments where surface properties directly impact clinical outcomes. The controlled modification of surface energy through plasma treatment helps reduce infection risks and improve device performance in medical applications.Expand Specific Solutions03 Cold plasma for surface cleaning and activation

Cold plasma treatment serves as an effective method for cleaning surfaces by removing organic contaminants and activating the surface through increased surface energy. The process breaks down organic compounds on the surface, leaving it clean at the molecular level. Surface activation increases reactivity, making subsequent processes like coating, printing, or bonding more effective. This environmentally friendly technique requires no chemicals and leaves no residues, making it suitable for sensitive applications in electronics, optics, and precision manufacturing.Expand Specific Solutions04 Controlled surface energy modification for adhesion improvement

Cold plasma treatment allows precise control over surface energy to optimize adhesion properties for bonding, coating, and printing applications. By adjusting plasma parameters such as gas composition, power, and exposure time, the surface energy can be tailored to specific requirements. This controlled modification enhances adhesion strength between dissimilar materials, improves coating uniformity, and increases durability of the bonded interfaces. The treatment creates chemical functional groups that form stronger bonds with adhesives and coatings.Expand Specific Solutions05 Atmospheric pressure cold plasma for industrial surface treatment

Atmospheric pressure cold plasma systems enable industrial-scale surface energy modification without vacuum chambers, making the technology more accessible and cost-effective for manufacturing processes. These systems can be integrated into production lines for continuous treatment of materials including polymers, metals, glass, and textiles. The technology allows for high-throughput processing while maintaining precise control over surface properties. Applications include automotive components, packaging materials, textiles, and consumer electronics where modified surface energy improves product performance and manufacturing efficiency.Expand Specific Solutions

Leading Companies in Plasma Processing Industry

The cold plasma treatment for polymer surface energy modification is in a growth phase, with an estimated market size of $2-3 billion and expanding at 15% annually. The technology has reached moderate maturity, with established players like Tokyo Electron, Air Liquide, and BASF leading industrial applications, while research institutions such as Wisconsin Alumni Research Foundation and Dalian University of Technology drive innovation. Companies like L'Oréal and Honda represent diverse application sectors. The competitive landscape shows a mix of specialized plasma technology providers (US Patent Innovations, Softal Electronic) and large corporations integrating plasma treatments into manufacturing processes. Regional clusters in Asia, Europe, and North America indicate global technology adoption, with increasing focus on sustainable applications and integration with advanced manufacturing.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has developed advanced plasma treatment systems specifically designed for polymer surface modification. Their technology utilizes low-temperature plasma to alter surface energy properties without affecting bulk material characteristics. The company's PlasmaProTM series employs controlled atmospheric pressure plasma that generates reactive species which interact with polymer surfaces to introduce functional groups like hydroxyl, carboxyl, and amine groups[1]. Their systems feature precise control over plasma parameters including power density, treatment time, and gas composition, allowing customization of surface energy from hydrophobic to hydrophilic states depending on application requirements[3]. Tokyo Electron's cold plasma technology achieves surface energy increases from typical 30-40 mJ/m² to over 72 mJ/m² for polymers like polyethylene and polypropylene, significantly enhancing adhesion properties for subsequent coating or bonding processes[5].

Strengths: Precise control over plasma parameters enables customized surface energy modification; non-thermal process preserves bulk material properties; environmentally friendly compared to chemical treatments. Weaknesses: Higher initial equipment investment compared to chemical treatments; requires technical expertise for optimal parameter selection; treatment effects may diminish over time requiring process optimization.

Air Liquide SA

Technical Solution: Air Liquide has pioneered atmospheric pressure cold plasma technology for polymer surface modification through their ACXYS product line. Their systems utilize a proprietary electrode design that generates uniform plasma discharge at atmospheric pressure, eliminating the need for vacuum chambers. The technology employs precisely controlled gas mixtures (typically helium, argon, oxygen, or nitrogen) to create reactive plasma species that interact with polymer surfaces[2]. Air Liquide's cold plasma treatment increases polymer surface energy by introducing polar functional groups, with documented improvements from 30-40 mJ/m² to 65-78 mJ/m² depending on the polymer type and treatment parameters[4]. Their systems feature real-time monitoring capabilities that adjust plasma parameters to maintain consistent surface energy results across varying production conditions. The company has developed specialized applications for medical device polymers, packaging materials, and automotive components, demonstrating surface energy stability for up to 6 months post-treatment under controlled storage conditions[7].

Strengths: Atmospheric pressure operation eliminates vacuum requirements, enabling in-line processing; modular design allows integration into existing production lines; real-time monitoring ensures consistent treatment quality. Weaknesses: Process requires specialized gas mixtures increasing operational costs; treatment uniformity can be challenging for complex 3D geometries; higher energy consumption compared to some competing technologies.

Key Scientific Advances in Cold Plasma-Polymer Interactions

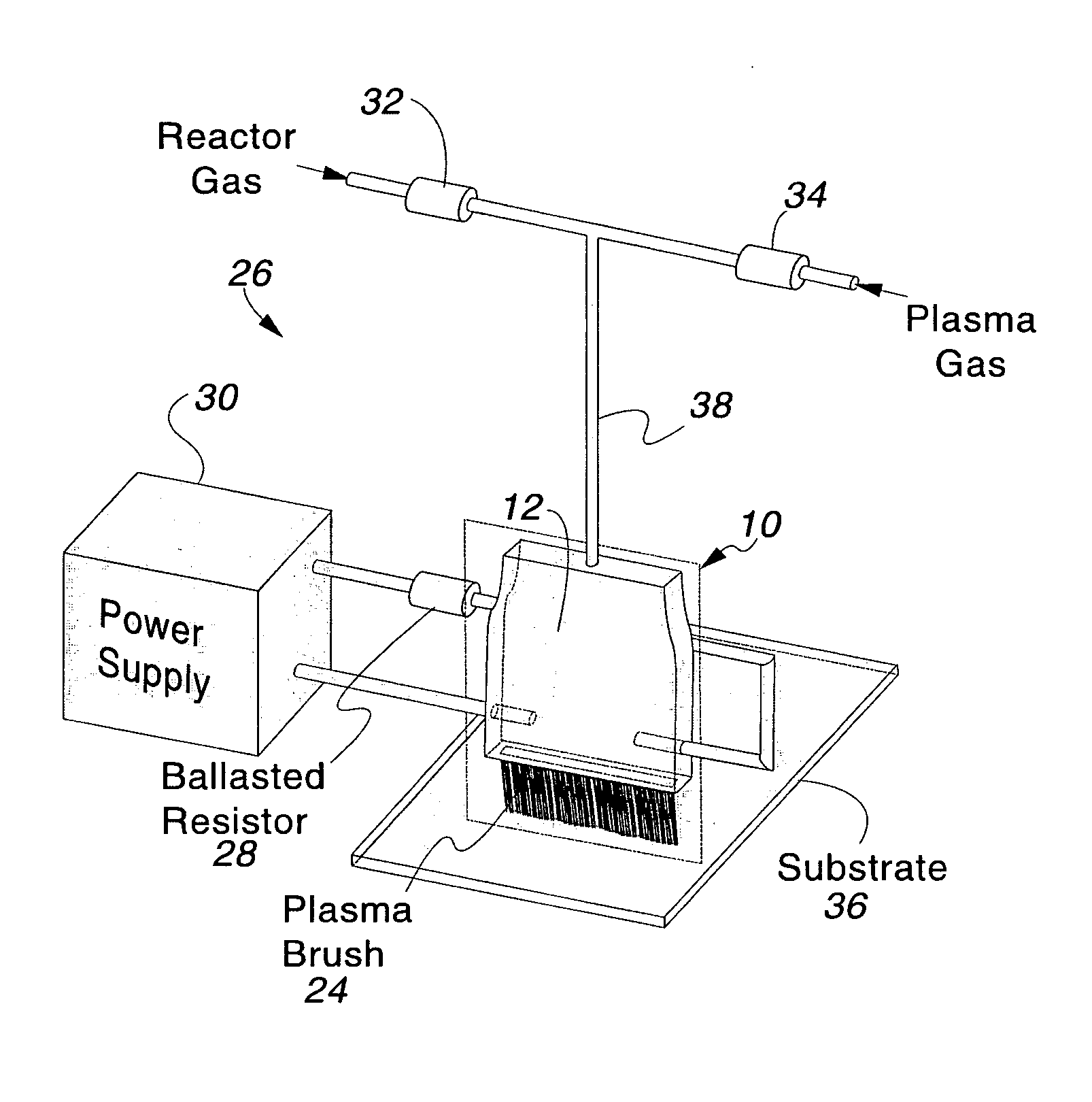

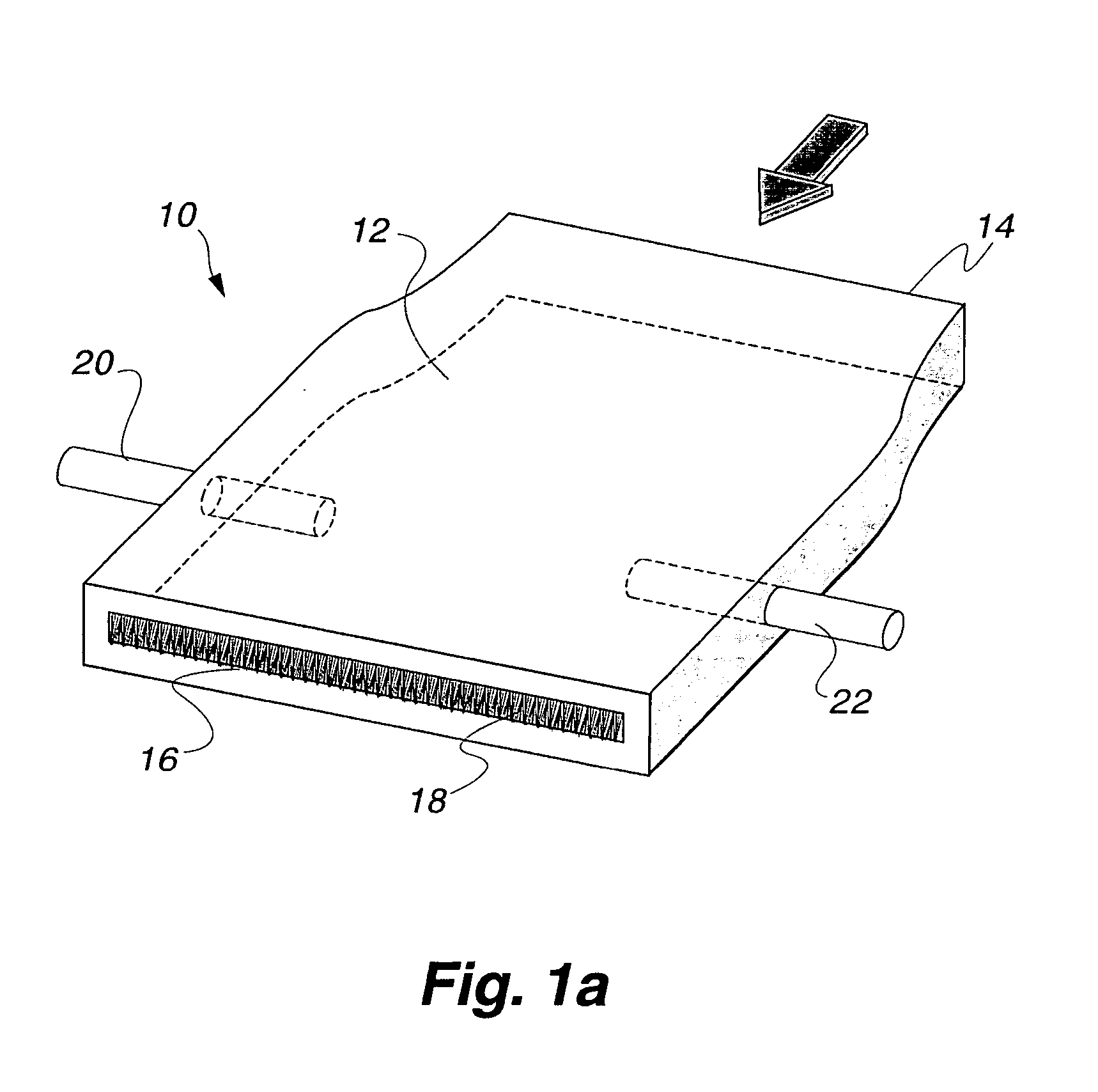

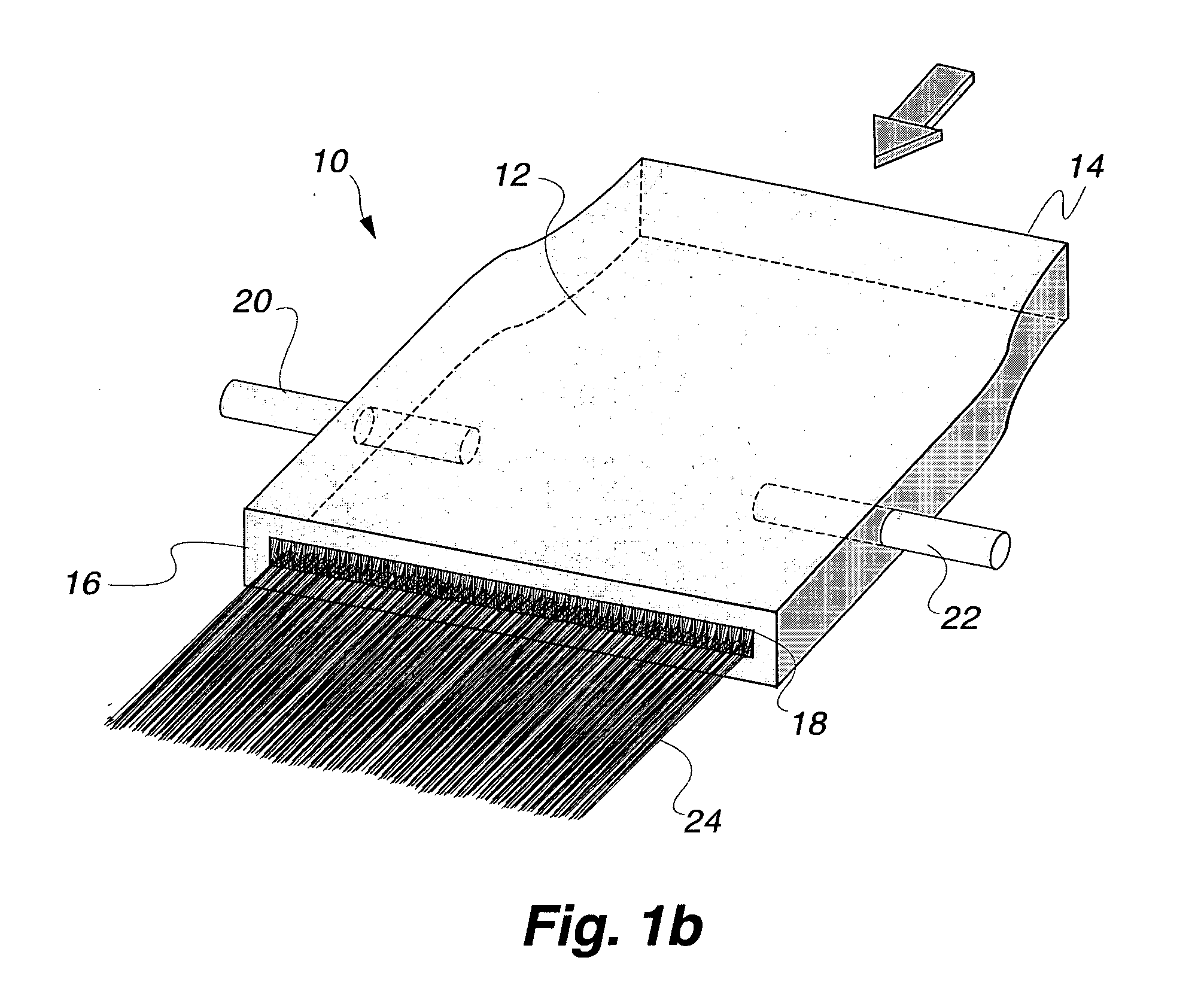

Polymer treatment using a plasma brush

PatentInactiveUS20070113867A1

Innovation

- A method and apparatus for generating a stable, low-temperature atmospheric pressure plasma brush that exposes polymer surfaces to change wettability, using a narrow slit gas chamber and electrodes with controlled gas flow and electrical power to create a plasma brush at temperatures less than 300 degrees Celsius.

Environmental Impact Assessment

Cold plasma treatment of polymers, while offering significant benefits for surface modification, necessitates careful consideration of its environmental implications. The energy consumption associated with plasma generation represents a primary environmental concern. Traditional plasma systems require substantial electrical power, contributing to carbon emissions when powered by non-renewable energy sources. However, recent advancements in cold plasma technology have yielded more energy-efficient systems, with some modern atmospheric pressure plasma devices consuming up to 70% less energy than their predecessors.

Waste generation from plasma processes presents another environmental consideration. Unlike conventional chemical surface treatments that produce significant liquid waste requiring specialized disposal, cold plasma treatments generate minimal waste streams. The primary byproducts are typically exhaust gases containing low concentrations of reaction products. These emissions generally include ozone, nitrogen oxides, and volatile organic compounds (VOCs) depending on the process gas and polymer substrate.

The chemical inputs for cold plasma treatment demonstrate favorable environmental profiles compared to alternative surface modification techniques. Most processes utilize inert gases like argon, helium, or reactive gases such as oxygen and nitrogen, which pose minimal environmental hazards. This represents a significant improvement over solvent-based chemical treatments that often involve environmentally persistent compounds and hazardous chemicals requiring stringent handling protocols.

Life cycle assessment (LCA) studies comparing cold plasma treatment to conventional polymer surface modification methods indicate potential environmental benefits. Research published in the Journal of Cleaner Production (2019) demonstrated that plasma-treated polyethylene components exhibited 30-45% lower environmental impact scores across categories including global warming potential, acidification, and resource depletion when compared to chemical priming methods.

The scalability of cold plasma technology also influences its environmental footprint. Industrial implementation requires consideration of treatment throughput versus energy consumption. Roll-to-roll atmospheric plasma systems have emerged as particularly promising, offering continuous processing capabilities while maintaining relatively low environmental impact per unit area treated.

Regulatory frameworks increasingly recognize the environmental advantages of plasma technologies. The European Union's REACH regulations and similar global initiatives have accelerated industry transition toward less chemically intensive processes, positioning cold plasma treatment as an environmentally preferable alternative for polymer surface modification in numerous applications including medical devices, packaging, and automotive components.

Waste generation from plasma processes presents another environmental consideration. Unlike conventional chemical surface treatments that produce significant liquid waste requiring specialized disposal, cold plasma treatments generate minimal waste streams. The primary byproducts are typically exhaust gases containing low concentrations of reaction products. These emissions generally include ozone, nitrogen oxides, and volatile organic compounds (VOCs) depending on the process gas and polymer substrate.

The chemical inputs for cold plasma treatment demonstrate favorable environmental profiles compared to alternative surface modification techniques. Most processes utilize inert gases like argon, helium, or reactive gases such as oxygen and nitrogen, which pose minimal environmental hazards. This represents a significant improvement over solvent-based chemical treatments that often involve environmentally persistent compounds and hazardous chemicals requiring stringent handling protocols.

Life cycle assessment (LCA) studies comparing cold plasma treatment to conventional polymer surface modification methods indicate potential environmental benefits. Research published in the Journal of Cleaner Production (2019) demonstrated that plasma-treated polyethylene components exhibited 30-45% lower environmental impact scores across categories including global warming potential, acidification, and resource depletion when compared to chemical priming methods.

The scalability of cold plasma technology also influences its environmental footprint. Industrial implementation requires consideration of treatment throughput versus energy consumption. Roll-to-roll atmospheric plasma systems have emerged as particularly promising, offering continuous processing capabilities while maintaining relatively low environmental impact per unit area treated.

Regulatory frameworks increasingly recognize the environmental advantages of plasma technologies. The European Union's REACH regulations and similar global initiatives have accelerated industry transition toward less chemically intensive processes, positioning cold plasma treatment as an environmentally preferable alternative for polymer surface modification in numerous applications including medical devices, packaging, and automotive components.

Cost-Benefit Analysis of Implementation

The implementation of cold plasma treatment for polymer surface modification requires careful cost-benefit analysis to determine its economic viability in industrial applications. Initial capital investment for cold plasma equipment ranges from $50,000 to $500,000 depending on scale, complexity, and processing capacity. This includes vacuum chambers, power supplies, gas handling systems, and control interfaces. For large-scale manufacturing operations, customized systems may exceed $1 million.

Operational costs comprise several components: electricity consumption (typically 5-15 kW per treatment unit), process gases (argon, oxygen, nitrogen) at $2-10 per treatment cycle, maintenance (approximately 5-8% of capital cost annually), and skilled operator wages. These recurring expenses must be weighed against the tangible benefits.

The economic advantages of cold plasma treatment are substantial. Enhanced adhesion properties can reduce adhesive consumption by 15-30%, resulting in material cost savings. Product rejection rates typically decrease by 10-25% due to improved bonding reliability, directly impacting manufacturing efficiency. The treatment also enables the use of less expensive base polymers while maintaining performance specifications, potentially reducing raw material costs by 8-15%.

Environmental and regulatory benefits provide additional economic value. Cold plasma treatments generally reduce VOC emissions by eliminating solvent-based surface preparation methods, potentially saving $5,000-20,000 annually in regulatory compliance costs. The process's dry nature eliminates wastewater treatment requirements, saving an additional $3,000-15,000 annually depending on facility size.

Return on investment calculations indicate that most industrial implementations achieve payback within 12-24 months. Small-scale operations focusing on high-value products may see ROI in as little as 8 months, while larger installations with higher capital costs typically require 18-30 months to break even. Industries producing medical devices, aerospace components, and automotive parts generally experience the fastest returns due to the high cost of failure in these sectors.

Long-term economic sustainability is enhanced through reduced energy consumption compared to thermal or chemical treatments, with savings of 30-60% possible. The scalability of plasma systems allows for gradual capacity expansion without proportional cost increases, improving long-term capital efficiency as production volumes grow.

Operational costs comprise several components: electricity consumption (typically 5-15 kW per treatment unit), process gases (argon, oxygen, nitrogen) at $2-10 per treatment cycle, maintenance (approximately 5-8% of capital cost annually), and skilled operator wages. These recurring expenses must be weighed against the tangible benefits.

The economic advantages of cold plasma treatment are substantial. Enhanced adhesion properties can reduce adhesive consumption by 15-30%, resulting in material cost savings. Product rejection rates typically decrease by 10-25% due to improved bonding reliability, directly impacting manufacturing efficiency. The treatment also enables the use of less expensive base polymers while maintaining performance specifications, potentially reducing raw material costs by 8-15%.

Environmental and regulatory benefits provide additional economic value. Cold plasma treatments generally reduce VOC emissions by eliminating solvent-based surface preparation methods, potentially saving $5,000-20,000 annually in regulatory compliance costs. The process's dry nature eliminates wastewater treatment requirements, saving an additional $3,000-15,000 annually depending on facility size.

Return on investment calculations indicate that most industrial implementations achieve payback within 12-24 months. Small-scale operations focusing on high-value products may see ROI in as little as 8 months, while larger installations with higher capital costs typically require 18-30 months to break even. Industries producing medical devices, aerospace components, and automotive parts generally experience the fastest returns due to the high cost of failure in these sectors.

Long-term economic sustainability is enhanced through reduced energy consumption compared to thermal or chemical treatments, with savings of 30-60% possible. The scalability of plasma systems allows for gradual capacity expansion without proportional cost increases, improving long-term capital efficiency as production volumes grow.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!