Cold Plasma Treatment Influence on Adhesive Bonding Strength

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from a purely scientific curiosity to a versatile industrial tool with diverse applications. Initially developed in the early 20th century, plasma science gained substantial momentum in the 1960s with the advancement of vacuum technology and power electronics. Cold plasma, specifically, emerged as a distinct field in the 1980s when researchers discovered methods to generate non-equilibrium plasmas at atmospheric pressure and near-ambient temperatures.

The fundamental principle behind cold plasma involves the partial ionization of gas molecules without significant thermal heating, creating a reactive environment rich in electrons, ions, free radicals, and excited species. This unique characteristic allows for surface modification and activation without thermal damage to heat-sensitive materials, making it particularly valuable for adhesive bonding applications across various industries.

Recent technological advancements have significantly expanded cold plasma capabilities, with developments in atmospheric pressure plasma jets (APPJ), dielectric barrier discharge (DBD) systems, and corona discharge technologies. These innovations have democratized plasma technology, reducing equipment costs and complexity while increasing accessibility for industrial applications, particularly in adhesive bonding processes.

In the context of adhesive bonding, cold plasma treatment addresses a critical challenge in modern manufacturing: creating strong, durable bonds between dissimilar or difficult-to-bond materials. Traditional bonding methods often struggle with materials like advanced polymers, composites, and certain metals due to their inherently low surface energy or chemical inertness. Cold plasma offers a solution by modifying surface properties without altering bulk characteristics.

The primary objectives of cold plasma technology in adhesive bonding applications include enhancing surface wettability, increasing surface energy, creating functional groups for chemical bonding, removing surface contaminants, and improving overall bond strength and durability. These objectives align with broader industrial trends toward lightweight construction, multi-material assemblies, and environmentally friendly joining processes that reduce or eliminate mechanical fasteners and solvent-based adhesives.

Current research aims to optimize plasma parameters for specific material combinations, develop more energy-efficient and compact plasma systems, establish standardized treatment protocols, and quantify the long-term stability of plasma-activated surfaces. Additionally, there is growing interest in combining cold plasma with other surface preparation techniques to create synergistic effects and further enhance bonding performance across diverse manufacturing environments.

The fundamental principle behind cold plasma involves the partial ionization of gas molecules without significant thermal heating, creating a reactive environment rich in electrons, ions, free radicals, and excited species. This unique characteristic allows for surface modification and activation without thermal damage to heat-sensitive materials, making it particularly valuable for adhesive bonding applications across various industries.

Recent technological advancements have significantly expanded cold plasma capabilities, with developments in atmospheric pressure plasma jets (APPJ), dielectric barrier discharge (DBD) systems, and corona discharge technologies. These innovations have democratized plasma technology, reducing equipment costs and complexity while increasing accessibility for industrial applications, particularly in adhesive bonding processes.

In the context of adhesive bonding, cold plasma treatment addresses a critical challenge in modern manufacturing: creating strong, durable bonds between dissimilar or difficult-to-bond materials. Traditional bonding methods often struggle with materials like advanced polymers, composites, and certain metals due to their inherently low surface energy or chemical inertness. Cold plasma offers a solution by modifying surface properties without altering bulk characteristics.

The primary objectives of cold plasma technology in adhesive bonding applications include enhancing surface wettability, increasing surface energy, creating functional groups for chemical bonding, removing surface contaminants, and improving overall bond strength and durability. These objectives align with broader industrial trends toward lightweight construction, multi-material assemblies, and environmentally friendly joining processes that reduce or eliminate mechanical fasteners and solvent-based adhesives.

Current research aims to optimize plasma parameters for specific material combinations, develop more energy-efficient and compact plasma systems, establish standardized treatment protocols, and quantify the long-term stability of plasma-activated surfaces. Additionally, there is growing interest in combining cold plasma with other surface preparation techniques to create synergistic effects and further enhance bonding performance across diverse manufacturing environments.

Market Analysis for Plasma-Enhanced Adhesive Applications

The global market for plasma-enhanced adhesive applications has experienced significant growth over the past decade, driven primarily by increasing demand for high-performance bonding solutions across multiple industries. The market size for plasma surface treatment technologies was valued at approximately $2.1 billion in 2022 and is projected to reach $3.4 billion by 2028, representing a compound annual growth rate of 8.3% during the forecast period.

Automotive and aerospace sectors currently dominate the market demand, collectively accounting for over 45% of the total market share. These industries require exceptional bonding strength for critical components where mechanical failure could lead to catastrophic consequences. The electronics industry follows closely, representing about 22% of market share, with particular emphasis on microelectronics assembly where traditional adhesive methods often prove inadequate.

Regional analysis reveals that North America and Europe currently lead the market with combined market share exceeding 60%, primarily due to the concentration of aerospace, automotive, and medical device manufacturing in these regions. However, the Asia-Pacific region is demonstrating the fastest growth rate at approximately 10.5% annually, driven by rapid industrialization in China, South Korea, and India, particularly in electronics manufacturing.

Consumer demand trends indicate a growing preference for environmentally friendly bonding solutions, with cold plasma treatment offering significant advantages over chemical-based surface preparation methods. This shift is particularly evident in medical device manufacturing, where regulatory requirements increasingly favor non-toxic processing methods. Market research indicates that approximately 68% of medical device manufacturers are actively exploring plasma treatment alternatives to chemical primers.

Economic analysis of implementation costs versus performance benefits reveals that while initial capital investment for cold plasma equipment remains relatively high, operational costs are significantly lower than traditional chemical treatment processes. The return on investment typically occurs within 18-24 months for high-volume manufacturing operations, primarily through reduced material waste, improved production efficiency, and decreased environmental compliance costs.

Market forecasts suggest that portable and flexible plasma treatment systems will experience the highest growth rate within the sector, as manufacturers seek adaptable solutions for diverse production environments. Additionally, integration of plasma treatment into automated production lines represents a key market opportunity, with potential to increase adoption rates across small and medium-sized manufacturing enterprises previously deterred by implementation complexity.

Automotive and aerospace sectors currently dominate the market demand, collectively accounting for over 45% of the total market share. These industries require exceptional bonding strength for critical components where mechanical failure could lead to catastrophic consequences. The electronics industry follows closely, representing about 22% of market share, with particular emphasis on microelectronics assembly where traditional adhesive methods often prove inadequate.

Regional analysis reveals that North America and Europe currently lead the market with combined market share exceeding 60%, primarily due to the concentration of aerospace, automotive, and medical device manufacturing in these regions. However, the Asia-Pacific region is demonstrating the fastest growth rate at approximately 10.5% annually, driven by rapid industrialization in China, South Korea, and India, particularly in electronics manufacturing.

Consumer demand trends indicate a growing preference for environmentally friendly bonding solutions, with cold plasma treatment offering significant advantages over chemical-based surface preparation methods. This shift is particularly evident in medical device manufacturing, where regulatory requirements increasingly favor non-toxic processing methods. Market research indicates that approximately 68% of medical device manufacturers are actively exploring plasma treatment alternatives to chemical primers.

Economic analysis of implementation costs versus performance benefits reveals that while initial capital investment for cold plasma equipment remains relatively high, operational costs are significantly lower than traditional chemical treatment processes. The return on investment typically occurs within 18-24 months for high-volume manufacturing operations, primarily through reduced material waste, improved production efficiency, and decreased environmental compliance costs.

Market forecasts suggest that portable and flexible plasma treatment systems will experience the highest growth rate within the sector, as manufacturers seek adaptable solutions for diverse production environments. Additionally, integration of plasma treatment into automated production lines represents a key market opportunity, with potential to increase adoption rates across small and medium-sized manufacturing enterprises previously deterred by implementation complexity.

Current Challenges in Plasma Surface Modification

Despite significant advancements in plasma surface modification technologies, several critical challenges persist that limit the full potential of cold plasma treatment for enhancing adhesive bonding strength. The primary obstacle remains the lack of standardization across different plasma treatment processes, making it difficult to establish consistent protocols that can be universally applied across various substrate materials and adhesive systems.

Surface chemistry complexity presents another significant challenge, as plasma-induced modifications create highly dynamic surfaces whose properties can change rapidly over time. This phenomenon, known as hydrophobic recovery or aging effect, causes treated surfaces to gradually revert to their original state, diminishing the effectiveness of the plasma treatment. The time-dependent nature of these modifications necessitates precise timing between treatment and bonding processes, creating logistical complications in manufacturing environments.

Parameter optimization continues to be problematic due to the multitude of variables involved in plasma treatment, including gas composition, power settings, exposure time, pressure conditions, and substrate characteristics. The interdependence of these parameters creates a vast experimental space that is difficult to navigate efficiently, often requiring extensive trial-and-error approaches that consume significant resources.

Scale-up challenges represent a major hurdle when transitioning from laboratory-scale plasma treatments to industrial applications. Maintaining uniform plasma distribution across large or geometrically complex surfaces remains technically demanding, with edge effects and shadowing phenomena causing inconsistent surface modification that leads to variable bonding performance.

Energy efficiency concerns persist as conventional plasma systems often require substantial power input, particularly for atmospheric pressure plasma treatments. This high energy consumption impacts both operational costs and environmental sustainability, creating barriers to widespread industrial adoption.

Material compatibility issues arise when plasma treatments interact with sensitive substrates, potentially causing thermal damage, surface degradation, or undesired chemical modifications that compromise the material's integrity. This is particularly problematic for temperature-sensitive polymers, composites with heterogeneous surfaces, and biological materials.

Characterization and quality control methods remain inadequate for real-time monitoring of plasma treatment effectiveness. Current analytical techniques often provide limited information about the actual surface state and potential bonding performance, making it difficult to implement robust quality assurance protocols in production environments.

Surface chemistry complexity presents another significant challenge, as plasma-induced modifications create highly dynamic surfaces whose properties can change rapidly over time. This phenomenon, known as hydrophobic recovery or aging effect, causes treated surfaces to gradually revert to their original state, diminishing the effectiveness of the plasma treatment. The time-dependent nature of these modifications necessitates precise timing between treatment and bonding processes, creating logistical complications in manufacturing environments.

Parameter optimization continues to be problematic due to the multitude of variables involved in plasma treatment, including gas composition, power settings, exposure time, pressure conditions, and substrate characteristics. The interdependence of these parameters creates a vast experimental space that is difficult to navigate efficiently, often requiring extensive trial-and-error approaches that consume significant resources.

Scale-up challenges represent a major hurdle when transitioning from laboratory-scale plasma treatments to industrial applications. Maintaining uniform plasma distribution across large or geometrically complex surfaces remains technically demanding, with edge effects and shadowing phenomena causing inconsistent surface modification that leads to variable bonding performance.

Energy efficiency concerns persist as conventional plasma systems often require substantial power input, particularly for atmospheric pressure plasma treatments. This high energy consumption impacts both operational costs and environmental sustainability, creating barriers to widespread industrial adoption.

Material compatibility issues arise when plasma treatments interact with sensitive substrates, potentially causing thermal damage, surface degradation, or undesired chemical modifications that compromise the material's integrity. This is particularly problematic for temperature-sensitive polymers, composites with heterogeneous surfaces, and biological materials.

Characterization and quality control methods remain inadequate for real-time monitoring of plasma treatment effectiveness. Current analytical techniques often provide limited information about the actual surface state and potential bonding performance, making it difficult to implement robust quality assurance protocols in production environments.

Existing Plasma Treatment Methods for Adhesion Enhancement

01 Surface activation by cold plasma for improved adhesion

Cold plasma treatment can be used to activate material surfaces by introducing functional groups, removing contaminants, and increasing surface energy. This activation process significantly enhances the wettability of surfaces and creates more bonding sites, resulting in stronger adhesive bonds between materials. The treatment is particularly effective for polymers, composites, and other materials that traditionally have poor adhesion properties.- Surface activation by cold plasma for improved adhesion: Cold plasma treatment can be used to activate material surfaces by creating functional groups and increasing surface energy, which significantly enhances adhesive bonding strength. This process removes contaminants and modifies the surface chemistry, allowing for better wetting and interaction with adhesives. The treatment can be applied to various materials including polymers, metals, and composites, resulting in stronger and more durable bonds without altering the bulk properties of the materials.

- Plasma parameter optimization for adhesive bonding: The effectiveness of cold plasma treatment on adhesive bonding strength depends on optimizing various parameters such as power level, treatment time, gas composition, and pressure. Controlling these parameters allows for customized surface modifications that match specific adhesive requirements. Proper optimization can lead to significant improvements in bond strength, with some studies showing increases of over 200% compared to untreated surfaces. The process can be tailored for different material combinations and adhesive types.

- Plasma-induced nanostructuring for mechanical interlocking: Cold plasma treatment can create nanoscale surface roughness and texturing that promotes mechanical interlocking between the adhesive and substrate. This physical modification works in conjunction with chemical activation to further enhance bonding strength. The controlled etching effect creates an increased surface area and anchoring points for the adhesive to penetrate and grip, resulting in bonds that resist both shear and tensile forces more effectively than those on smooth surfaces.

- Atmospheric pressure cold plasma for industrial applications: Atmospheric pressure cold plasma systems offer advantages for industrial adhesive bonding applications by eliminating the need for vacuum chambers. These systems can be integrated into production lines for continuous processing, making them suitable for high-volume manufacturing. The technology enables in-line surface treatment immediately before adhesive application, preventing recontamination and ensuring optimal bonding conditions. This approach is particularly valuable for large components or when vacuum processing is impractical.

- Material-specific plasma treatments for specialized bonding: Different materials require specialized cold plasma treatment approaches to maximize adhesive bonding strength. For example, fluoropolymers may need specific gas mixtures to defluorinate the surface, while silicone-based materials benefit from oxygen plasma to create silanol groups. Composite materials often require treatments that selectively modify both matrix and reinforcement components. These tailored approaches consider the unique surface chemistry of each material to create optimal conditions for adhesive interaction and long-term bond stability.

02 Cold plasma parameters optimization for adhesive strength

The effectiveness of cold plasma treatment on adhesive bonding strength depends on various operational parameters such as plasma power, treatment time, gas composition, and pressure. Optimizing these parameters is crucial for achieving maximum adhesion improvement. Research shows that controlled plasma exposure can increase bond strength by up to several hundred percent compared to untreated surfaces, with specific parameter combinations yielding optimal results for different material combinations.Expand Specific Solutions03 Material-specific cold plasma treatments for adhesive bonding

Different materials require specific cold plasma treatment approaches to maximize adhesive bonding strength. For instance, treatments for metals often focus on oxide layer modification and contaminant removal, while polymer treatments typically target surface energy enhancement and chemical functionalization. Specialized plasma treatments have been developed for difficult-to-bond materials such as polytetrafluoroethylene (PTFE), silicones, and high-performance composites, enabling previously impossible or weak bonding applications.Expand Specific Solutions04 Atmospheric pressure cold plasma for adhesive bonding

Atmospheric pressure cold plasma systems offer advantages for adhesive bonding applications by eliminating the need for vacuum chambers, enabling continuous processing, and allowing treatment of larger components. These systems can be integrated into production lines for real-time surface activation before adhesive application. The technology has shown comparable or superior bonding strength improvements to vacuum-based plasma treatments while offering greater flexibility and lower operational costs for industrial applications.Expand Specific Solutions05 Durability and aging of plasma-enhanced adhesive bonds

Cold plasma treatment not only increases initial adhesive bond strength but also improves the long-term durability of bonds under environmental stresses such as humidity, temperature cycling, and chemical exposure. Research indicates that properly optimized plasma treatments can prevent interfacial failure modes and extend bond lifetime. The enhanced durability is attributed to stronger chemical bonding at the interface and improved resistance to moisture ingress, making plasma treatment particularly valuable for applications in harsh environments.Expand Specific Solutions

Leading Companies in Plasma Processing Industry

Cold plasma treatment for adhesive bonding is currently in a growth phase, with increasing adoption across industries due to its effectiveness in enhancing surface adhesion properties. The global market for plasma surface treatment systems is expanding steadily, projected to reach significant value as industries seek environmentally friendly surface modification techniques. Technologically, the field shows varying maturity levels among key players. Companies like tesa SE, Sika Technology AG, and 3M Innovative Properties demonstrate advanced capabilities in adhesive applications, while Applied Materials, Tokyo Electron, and Resonac Corp lead in plasma technology development. Research institutions such as Delft University of Technology and Central South University contribute fundamental advancements, while manufacturers like Robert Bosch GmbH and Panasonic Holdings implement these technologies in production environments.

tesa SE

Technical Solution: tesa SE has developed a sophisticated cold plasma treatment technology called PlasmaBond™ specifically designed to enhance adhesive tape performance on difficult-to-bond surfaces. Their approach utilizes a controlled low-temperature plasma discharge that modifies surface properties without thermal damage to heat-sensitive substrates. The technology creates nanoscale surface modifications that significantly increase surface energy and wettability while introducing polar functional groups that form strong chemical bonds with adhesive components[2]. tesa's system employs a unique electrode configuration that enables uniform treatment of flexible materials in roll-to-roll processing, making it particularly suitable for tape manufacturing applications. Their research demonstrates adhesion improvements of 200-350% on low surface energy polymers like polyethylene and polypropylene. The company has developed specialized plasma recipes for different substrate combinations, with particular focus on automotive, electronics, and medical applications where reliable bonding is critical[5]. The technology operates at atmospheric pressure, eliminating the need for vacuum chambers and enabling integration into existing production lines.

Strengths: Specialized expertise in adhesive tape applications; roll-to-roll processing capability enables high-volume manufacturing; extensive experience with diverse substrate materials relevant to tape applications. Weaknesses: Technology primarily optimized for flat or slightly curved surfaces; may require additional process steps for certain substrate combinations; effectiveness can vary with ambient humidity conditions.

Sika Technology AG

Technical Solution: Sika Technology has developed an innovative cold plasma treatment system called PlasmaPrep™ specifically designed to enhance adhesive bonding strength for challenging substrates in construction and industrial applications. Their technology utilizes a controlled atmospheric pressure plasma discharge that creates a highly reactive environment at the material surface without generating excessive heat. The process introduces oxygen-containing functional groups while simultaneously cleaning and micro-etching surfaces to create ideal conditions for adhesive bonding[1]. Sika's approach combines precise plasma parameter control with proprietary gas mixtures optimized for different substrate types. Their research demonstrates significant improvements in adhesion strength, with increases of up to 250% on polyolefins and up to 180% on various engineering plastics. The company has integrated this technology with their comprehensive adhesive portfolio, creating complete bonding solutions that address surface preparation, primer application, and adhesive selection as an integrated system[3]. Sika's plasma treatment can be applied to metals, composites, ceramics, and various polymers, making it versatile across multiple industries.

Strengths: Comprehensive approach integrating surface treatment with adhesive formulation expertise; robust process parameters suitable for industrial environments; excellent compatibility with existing manufacturing workflows. Weaknesses: Requires careful optimization for each substrate combination; effectiveness can be influenced by ambient conditions; may require additional surface preparation steps for heavily contaminated materials.

Key Mechanisms of Plasma-Surface Interactions

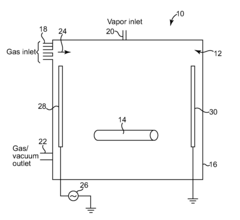

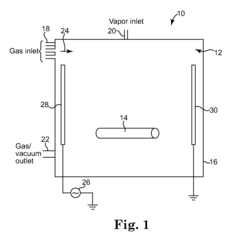

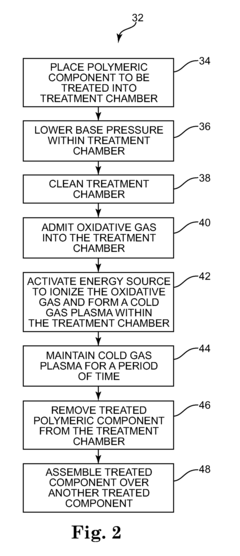

Cold plasma bonding of polymeric tubing in implantable medical devices

PatentInactiveUS20100125318A1

Innovation

- The use of a cold gas plasma bonding process to form an oxygen-rich layer on silicone tubular members, allowing for direct bonding without external forces or adhesives, by subjecting the inner and outer surfaces of the members to oxidative cold gas plasma treatments and assembling them in an interference fit.

Environmental Impact of Cold Plasma Processing

Cold plasma treatment for adhesive bonding offers significant environmental advantages compared to traditional surface preparation methods. The process operates at ambient temperatures and atmospheric pressure, substantially reducing energy consumption compared to thermal or chemical treatments. This energy efficiency translates to lower carbon emissions, particularly when implemented at industrial scales where traditional heating processes would otherwise consume considerable power.

The elimination or reduction of chemical solvents represents perhaps the most significant environmental benefit. Conventional adhesive bonding preparation often relies on solvent-based cleaning and etching processes that release volatile organic compounds (VOCs) and hazardous air pollutants. Cold plasma treatments require no such chemicals, operating instead with environmentally benign working gases like air, oxygen, nitrogen, or argon, thereby eliminating toxic waste streams and reducing workplace exposure to harmful substances.

Water consumption is another critical environmental factor where cold plasma demonstrates advantages. Unlike wet chemical processes that may require substantial volumes of water for processing and rinsing, plasma treatment is essentially a dry process. This characteristic becomes particularly valuable in regions facing water scarcity issues and helps manufacturers comply with increasingly stringent wastewater discharge regulations.

The technology's waste profile is remarkably minimal. Cold plasma systems generate negligible solid waste and produce few byproducts beyond trace amounts of ozone in oxygen-containing plasmas, which can be easily managed with proper ventilation. The equipment itself has a relatively long operational lifespan, reducing the environmental impact associated with manufacturing and disposing of processing equipment.

From a life cycle perspective, plasma-treated adhesive bonds often demonstrate enhanced durability and aging resistance, potentially extending product lifespans and reducing replacement frequency. This longevity effect multiplies the environmental benefits across the entire product lifecycle, from raw material extraction to end-of-life disposal.

Regulatory compliance represents another environmental advantage, as cold plasma technologies align well with global environmental initiatives like the European Union's REACH regulations and various national programs aimed at reducing industrial emissions and hazardous waste. As environmental regulations continue to tighten worldwide, the inherently cleaner nature of cold plasma processing positions it as an increasingly attractive option for forward-thinking manufacturers.

The elimination or reduction of chemical solvents represents perhaps the most significant environmental benefit. Conventional adhesive bonding preparation often relies on solvent-based cleaning and etching processes that release volatile organic compounds (VOCs) and hazardous air pollutants. Cold plasma treatments require no such chemicals, operating instead with environmentally benign working gases like air, oxygen, nitrogen, or argon, thereby eliminating toxic waste streams and reducing workplace exposure to harmful substances.

Water consumption is another critical environmental factor where cold plasma demonstrates advantages. Unlike wet chemical processes that may require substantial volumes of water for processing and rinsing, plasma treatment is essentially a dry process. This characteristic becomes particularly valuable in regions facing water scarcity issues and helps manufacturers comply with increasingly stringent wastewater discharge regulations.

The technology's waste profile is remarkably minimal. Cold plasma systems generate negligible solid waste and produce few byproducts beyond trace amounts of ozone in oxygen-containing plasmas, which can be easily managed with proper ventilation. The equipment itself has a relatively long operational lifespan, reducing the environmental impact associated with manufacturing and disposing of processing equipment.

From a life cycle perspective, plasma-treated adhesive bonds often demonstrate enhanced durability and aging resistance, potentially extending product lifespans and reducing replacement frequency. This longevity effect multiplies the environmental benefits across the entire product lifecycle, from raw material extraction to end-of-life disposal.

Regulatory compliance represents another environmental advantage, as cold plasma technologies align well with global environmental initiatives like the European Union's REACH regulations and various national programs aimed at reducing industrial emissions and hazardous waste. As environmental regulations continue to tighten worldwide, the inherently cleaner nature of cold plasma processing positions it as an increasingly attractive option for forward-thinking manufacturers.

Quality Control Standards for Plasma-Treated Surfaces

Quality control standards for plasma-treated surfaces are essential to ensure consistent adhesive bonding strength in industrial applications. These standards typically encompass multiple parameters that must be monitored and controlled throughout the plasma treatment process. The cornerstone of these standards is surface energy measurement, commonly performed using contact angle analysis, which provides quantitative data on wettability improvements after plasma treatment.

Process parameter documentation forms another critical component of quality control standards. This includes maintaining detailed records of plasma power settings, exposure time, gas composition, pressure levels, and distance between the plasma source and substrate. These parameters directly influence the effectiveness of surface activation and must be standardized to achieve reproducible bonding results.

Surface cleanliness verification is mandated by most quality control protocols, often utilizing techniques such as X-ray photoelectron spectroscopy (XPS) or Fourier-transform infrared spectroscopy (FTIR) to detect contaminants that could compromise adhesion. Additionally, surface roughness measurements using profilometry or atomic force microscopy help ensure that plasma treatment creates the optimal surface topography for mechanical interlocking with adhesives.

Aging effect monitoring represents another crucial standard, as plasma-treated surfaces can experience hydrophobic recovery over time. Quality control protocols typically specify maximum allowable time intervals between treatment and bonding, along with storage conditions for treated components. Some standards require periodic retesting of surface properties if components cannot be bonded immediately after treatment.

Bond strength testing serves as the ultimate validation method in quality control standards. This commonly involves lap shear tests, peel tests, or pull-off tests performed according to international standards such as ASTM D1002 or ISO 4587. Statistical process control methods are applied to these test results to identify trends and ensure consistency in bonding performance.

Documentation and traceability requirements complete the quality control framework. These standards mandate comprehensive record-keeping of all treatment parameters, test results, and process deviations. Many industries, particularly aerospace and automotive, require full traceability of plasma-treated components throughout their lifecycle, with unique identifiers linking each component to its specific treatment parameters and quality test results.

Process parameter documentation forms another critical component of quality control standards. This includes maintaining detailed records of plasma power settings, exposure time, gas composition, pressure levels, and distance between the plasma source and substrate. These parameters directly influence the effectiveness of surface activation and must be standardized to achieve reproducible bonding results.

Surface cleanliness verification is mandated by most quality control protocols, often utilizing techniques such as X-ray photoelectron spectroscopy (XPS) or Fourier-transform infrared spectroscopy (FTIR) to detect contaminants that could compromise adhesion. Additionally, surface roughness measurements using profilometry or atomic force microscopy help ensure that plasma treatment creates the optimal surface topography for mechanical interlocking with adhesives.

Aging effect monitoring represents another crucial standard, as plasma-treated surfaces can experience hydrophobic recovery over time. Quality control protocols typically specify maximum allowable time intervals between treatment and bonding, along with storage conditions for treated components. Some standards require periodic retesting of surface properties if components cannot be bonded immediately after treatment.

Bond strength testing serves as the ultimate validation method in quality control standards. This commonly involves lap shear tests, peel tests, or pull-off tests performed according to international standards such as ASTM D1002 or ISO 4587. Statistical process control methods are applied to these test results to identify trends and ensure consistency in bonding performance.

Documentation and traceability requirements complete the quality control framework. These standards mandate comprehensive record-keeping of all treatment parameters, test results, and process deviations. Many industries, particularly aerospace and automotive, require full traceability of plasma-treated components throughout their lifecycle, with unique identifiers linking each component to its specific treatment parameters and quality test results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!