Cold Plasma Treatment in Food Processing: Mechanistic Insights

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Evolution and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from a niche scientific curiosity to a promising non-thermal food processing method. Initially developed in the early 20th century for industrial applications, plasma science found its way into food processing research in the late 1990s when researchers began exploring its potential for microbial decontamination. The technology's evolution accelerated in the 2000s with the development of atmospheric pressure plasma systems that eliminated the need for vacuum chambers, making practical food applications more feasible.

The fundamental principle behind cold plasma involves the generation of reactive species through the ionization of gases at near-ambient temperatures. This characteristic distinguishes it from thermal plasma technologies and makes it particularly suitable for heat-sensitive food products. Early applications focused primarily on surface decontamination, but research has progressively expanded to explore effects on food quality attributes, nutritional components, and functional properties.

Recent technological advancements have led to the development of various cold plasma generation methods, including dielectric barrier discharge (DBD), atmospheric pressure plasma jets (APPJ), and microwave-induced plasma systems. Each configuration offers distinct advantages in terms of treatment uniformity, scalability, and energy efficiency. The evolution of these systems has been driven by the need to address specific food processing challenges while maintaining product integrity.

The primary objectives of cold plasma technology in food processing center around enhancing food safety through microbial inactivation while preserving or enhancing quality attributes. Researchers aim to elucidate the complex mechanisms by which reactive plasma species interact with microbial cells, food matrices, and bioactive compounds. Understanding these interactions at the molecular level represents a critical research goal that would enable more targeted and efficient applications.

Additional objectives include optimizing treatment parameters for specific food products, developing cost-effective and energy-efficient plasma generation systems suitable for industrial implementation, and establishing standardized protocols for treatment validation. Researchers also seek to address regulatory considerations by generating comprehensive safety data on treated products and potential chemical residues.

Looking forward, the technology aims to move beyond laboratory demonstrations toward commercial implementation. This transition requires addressing challenges related to treatment uniformity for irregularly shaped products, scaling up plasma systems for industrial throughput requirements, and integrating plasma technology into existing processing lines. The ultimate goal is to position cold plasma as a sustainable alternative to conventional processing methods, offering reduced energy consumption, minimal water usage, and elimination of chemical residues.

The fundamental principle behind cold plasma involves the generation of reactive species through the ionization of gases at near-ambient temperatures. This characteristic distinguishes it from thermal plasma technologies and makes it particularly suitable for heat-sensitive food products. Early applications focused primarily on surface decontamination, but research has progressively expanded to explore effects on food quality attributes, nutritional components, and functional properties.

Recent technological advancements have led to the development of various cold plasma generation methods, including dielectric barrier discharge (DBD), atmospheric pressure plasma jets (APPJ), and microwave-induced plasma systems. Each configuration offers distinct advantages in terms of treatment uniformity, scalability, and energy efficiency. The evolution of these systems has been driven by the need to address specific food processing challenges while maintaining product integrity.

The primary objectives of cold plasma technology in food processing center around enhancing food safety through microbial inactivation while preserving or enhancing quality attributes. Researchers aim to elucidate the complex mechanisms by which reactive plasma species interact with microbial cells, food matrices, and bioactive compounds. Understanding these interactions at the molecular level represents a critical research goal that would enable more targeted and efficient applications.

Additional objectives include optimizing treatment parameters for specific food products, developing cost-effective and energy-efficient plasma generation systems suitable for industrial implementation, and establishing standardized protocols for treatment validation. Researchers also seek to address regulatory considerations by generating comprehensive safety data on treated products and potential chemical residues.

Looking forward, the technology aims to move beyond laboratory demonstrations toward commercial implementation. This transition requires addressing challenges related to treatment uniformity for irregularly shaped products, scaling up plasma systems for industrial throughput requirements, and integrating plasma technology into existing processing lines. The ultimate goal is to position cold plasma as a sustainable alternative to conventional processing methods, offering reduced energy consumption, minimal water usage, and elimination of chemical residues.

Food Industry Market Demand for Non-thermal Processing

The global food industry is experiencing a significant shift towards non-thermal processing technologies, driven by increasing consumer demand for minimally processed foods that retain nutritional value, sensory qualities, and freshness while ensuring safety. Cold plasma treatment has emerged as a promising non-thermal technology that addresses these market needs effectively.

Consumer preferences have evolved dramatically over the past decade, with a growing emphasis on "clean label" products free from chemical preservatives and additives. Market research indicates that approximately 75% of consumers now regularly check food labels for artificial ingredients, and 68% are willing to pay premium prices for foods they perceive as more natural. This trend has created substantial market pressure on food manufacturers to adopt alternative processing technologies.

Food safety concerns continue to drive innovation in processing methods. With foodborne illnesses affecting millions globally each year and causing significant economic losses, the industry faces mounting pressure to implement effective microbial control measures that don't rely on heat or chemicals. Cold plasma offers a solution by effectively inactivating pathogens while maintaining product integrity.

The shelf-life extension capabilities of non-thermal technologies represent another significant market driver. The global food waste problem—with roughly one-third of all food produced being discarded—has economic and environmental implications that non-thermal processing can help address. Technologies that can extend product shelf life without compromising quality create substantial value throughout the supply chain.

Regulatory frameworks worldwide are increasingly supportive of novel non-thermal technologies. The FDA and European Food Safety Authority have established pathways for validating new processing methods, creating a more favorable environment for commercial adoption of cold plasma and similar technologies.

Market analysis projects the global non-thermal food processing equipment market to grow at a compound annual growth rate of 6.2% through 2027, with particularly strong growth in regions with developed economies and sophisticated consumer markets like North America, Europe, and parts of Asia-Pacific.

Specific food sectors showing the highest demand for non-thermal processing include fresh produce, where cold plasma can reduce microbial loads without affecting texture or nutritional content; meat and seafood products, where maintaining color and flavor is critical; and packaged foods, where extended shelf life creates significant economic benefits.

The beverage industry has also shown increasing interest in cold plasma technology for applications in juice processing and water treatment, where maintaining nutritional compounds and flavor profiles is essential while ensuring microbial safety.

Consumer preferences have evolved dramatically over the past decade, with a growing emphasis on "clean label" products free from chemical preservatives and additives. Market research indicates that approximately 75% of consumers now regularly check food labels for artificial ingredients, and 68% are willing to pay premium prices for foods they perceive as more natural. This trend has created substantial market pressure on food manufacturers to adopt alternative processing technologies.

Food safety concerns continue to drive innovation in processing methods. With foodborne illnesses affecting millions globally each year and causing significant economic losses, the industry faces mounting pressure to implement effective microbial control measures that don't rely on heat or chemicals. Cold plasma offers a solution by effectively inactivating pathogens while maintaining product integrity.

The shelf-life extension capabilities of non-thermal technologies represent another significant market driver. The global food waste problem—with roughly one-third of all food produced being discarded—has economic and environmental implications that non-thermal processing can help address. Technologies that can extend product shelf life without compromising quality create substantial value throughout the supply chain.

Regulatory frameworks worldwide are increasingly supportive of novel non-thermal technologies. The FDA and European Food Safety Authority have established pathways for validating new processing methods, creating a more favorable environment for commercial adoption of cold plasma and similar technologies.

Market analysis projects the global non-thermal food processing equipment market to grow at a compound annual growth rate of 6.2% through 2027, with particularly strong growth in regions with developed economies and sophisticated consumer markets like North America, Europe, and parts of Asia-Pacific.

Specific food sectors showing the highest demand for non-thermal processing include fresh produce, where cold plasma can reduce microbial loads without affecting texture or nutritional content; meat and seafood products, where maintaining color and flavor is critical; and packaged foods, where extended shelf life creates significant economic benefits.

The beverage industry has also shown increasing interest in cold plasma technology for applications in juice processing and water treatment, where maintaining nutritional compounds and flavor profiles is essential while ensuring microbial safety.

Current Status and Technical Barriers in Cold Plasma Applications

Cold plasma technology in food processing has gained significant attention in recent years due to its potential as a non-thermal preservation method. Currently, cold plasma applications in food industry are primarily focused on microbial decontamination, enzyme inactivation, and modification of food properties. Laboratory-scale studies have demonstrated efficacy against a wide range of foodborne pathogens including Escherichia coli, Salmonella, Listeria monocytogenes, and various spoilage microorganisms on different food matrices.

Despite promising research outcomes, industrial implementation remains limited. Most applications are still at the research and development phase, with only a few commercial systems available for specific food products. Countries leading research in this field include the United States, Germany, Ireland, South Korea, and China, with significant contributions from research institutions rather than industry players.

The primary technical barriers hindering widespread adoption include scalability challenges and process standardization. Current plasma generation systems are designed for small-scale applications and face difficulties in treating large volumes of food products continuously. The non-uniform treatment resulting from plasma's line-of-sight nature presents a significant obstacle for irregularly shaped food items.

Another critical barrier is the lack of comprehensive understanding of plasma-food interactions. While antimicrobial effects are well-documented, the complex mechanisms behind these effects and potential impacts on nutritional and sensory qualities require further elucidation. The generation of reactive species during plasma treatment may lead to undesirable chemical changes in food components, particularly in lipid and protein-rich products.

Regulatory hurdles also present significant challenges. The novel nature of cold plasma technology means that regulatory frameworks for its application in food processing are still evolving. In many regions, cold plasma treatments require extensive safety validations before receiving approval for commercial food applications.

Equipment design limitations constitute another barrier. Current plasma generation systems often lack robustness for industrial food processing environments. Issues such as electrode deterioration, control of treatment parameters, and integration with existing processing lines need addressing before widespread implementation becomes feasible.

Energy efficiency remains a concern, particularly for scaled-up operations. The power requirements for generating and maintaining stable plasma discharges can be substantial, potentially offsetting the technology's environmental benefits compared to conventional thermal processing methods.

Despite promising research outcomes, industrial implementation remains limited. Most applications are still at the research and development phase, with only a few commercial systems available for specific food products. Countries leading research in this field include the United States, Germany, Ireland, South Korea, and China, with significant contributions from research institutions rather than industry players.

The primary technical barriers hindering widespread adoption include scalability challenges and process standardization. Current plasma generation systems are designed for small-scale applications and face difficulties in treating large volumes of food products continuously. The non-uniform treatment resulting from plasma's line-of-sight nature presents a significant obstacle for irregularly shaped food items.

Another critical barrier is the lack of comprehensive understanding of plasma-food interactions. While antimicrobial effects are well-documented, the complex mechanisms behind these effects and potential impacts on nutritional and sensory qualities require further elucidation. The generation of reactive species during plasma treatment may lead to undesirable chemical changes in food components, particularly in lipid and protein-rich products.

Regulatory hurdles also present significant challenges. The novel nature of cold plasma technology means that regulatory frameworks for its application in food processing are still evolving. In many regions, cold plasma treatments require extensive safety validations before receiving approval for commercial food applications.

Equipment design limitations constitute another barrier. Current plasma generation systems often lack robustness for industrial food processing environments. Issues such as electrode deterioration, control of treatment parameters, and integration with existing processing lines need addressing before widespread implementation becomes feasible.

Energy efficiency remains a concern, particularly for scaled-up operations. The power requirements for generating and maintaining stable plasma discharges can be substantial, potentially offsetting the technology's environmental benefits compared to conventional thermal processing methods.

Current Cold Plasma Treatment Mechanisms and Systems

01 Reactive species generation mechanisms in cold plasma

Cold plasma treatment generates various reactive species including reactive oxygen species (ROS) and reactive nitrogen species (RNS) that are key to its therapeutic effects. The mechanisms involve ionization of gas molecules, electron impact reactions, and photochemical processes. These reactive species can penetrate biological tissues to different depths depending on their stability and reactivity, creating cascading biochemical reactions that contribute to the treatment efficacy.- Reactive species generation mechanisms in cold plasma treatment: Cold plasma treatments generate various reactive species including reactive oxygen species (ROS) and reactive nitrogen species (RNS) that are key to their therapeutic effects. These species are formed through complex ionization processes when electrical energy is applied to gas molecules. The mechanisms involve electron impact ionization, dissociation, and excitation of gas molecules, leading to the formation of free radicals, ions, and excited species that can interact with biological tissues and surfaces. Understanding these generation mechanisms is crucial for optimizing plasma treatments for specific applications.

- Cellular interaction pathways of cold plasma: Cold plasma interacts with cells through multiple pathways, including direct plasma-cell contact, transfer of reactive species, and electromagnetic field effects. These interactions can trigger various cellular responses such as changes in membrane permeability, activation of signaling pathways, and modulation of gene expression. The plasma-induced oxidative stress can selectively target certain cell types, particularly cancer cells, while potentially preserving healthy cells. The mechanistic insights into these cellular interactions help explain the observed effects in wound healing, cancer treatment, and antimicrobial applications.

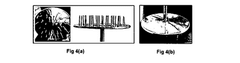

- Antimicrobial mechanisms of cold plasma: Cold plasma exhibits strong antimicrobial properties through multiple mechanisms. The generated reactive species can damage microbial cell membranes, denature proteins, and cause DNA damage. Plasma treatment can also disrupt biofilm formation and penetrate existing biofilms. The mechanistic insights reveal that plasma can be effective against a wide range of pathogens including bacteria, fungi, and viruses, including drug-resistant strains. These antimicrobial mechanisms are particularly valuable for medical device sterilization, wound disinfection, and treatment of infections.

- Tissue regeneration and wound healing mechanisms: Cold plasma promotes tissue regeneration and wound healing through several mechanisms. It stimulates angiogenesis, enhances fibroblast proliferation, and modulates inflammatory responses. The plasma-generated reactive species can activate growth factors and signaling pathways involved in tissue repair. Additionally, plasma treatment can improve blood circulation in the treated area and accelerate the formation of granulation tissue. These mechanistic insights explain why cold plasma therapy has shown promise for chronic wounds, diabetic ulcers, and other difficult-to-heal tissue injuries.

- Plasma-surface modification mechanisms: Cold plasma treatment can modify surface properties through various mechanisms including etching, deposition, cross-linking, and functionalization. These processes alter the physical and chemical characteristics of treated surfaces, affecting properties such as wettability, adhesion, and biocompatibility. The mechanistic insights reveal how plasma parameters (power, treatment time, gas composition) influence the surface modification outcomes. Understanding these mechanisms is essential for applications in biomaterials development, medical implants, and tissue engineering scaffolds where controlled surface properties are crucial for biological integration.

02 Cellular response mechanisms to cold plasma exposure

Cold plasma treatment induces specific cellular responses including changes in membrane permeability, activation of intracellular signaling pathways, and modulation of gene expression. The mechanistic insights reveal that plasma-generated species can trigger controlled oxidative stress, leading to cellular adaptation or selective apoptosis depending on dose and cell type. These mechanisms explain the differential effects observed between healthy and diseased cells during therapeutic applications.Expand Specific Solutions03 Plasma-tissue interaction mechanisms

The interaction between cold plasma and biological tissues involves complex physical and chemical processes. When plasma contacts tissue, it creates a unique microenvironment where charged particles, electric fields, and reactive species interact with biomolecules. This interaction can modify protein structures, affect cell membrane functions, and alter extracellular matrix components. Understanding these mechanisms helps optimize treatment parameters for specific therapeutic outcomes in wound healing, cancer treatment, and antimicrobial applications.Expand Specific Solutions04 Antimicrobial mechanisms of cold plasma

Cold plasma exhibits strong antimicrobial effects through multiple mechanisms. These include direct damage to microbial cell walls and membranes by charged particles and electric fields, oxidative damage to intracellular components by reactive species, and DNA damage leading to inhibition of replication. The mechanistic insights reveal synergistic effects between different plasma components that can overcome microbial resistance mechanisms, making cold plasma effective against a broad spectrum of pathogens including antibiotic-resistant strains.Expand Specific Solutions05 Plasma delivery systems and parameter optimization

The mechanisms by which cold plasma exerts its effects are highly dependent on the delivery system design and treatment parameters. Different plasma sources (dielectric barrier discharge, plasma jets, surface micro-discharge) generate distinct plasma compositions and characteristics. The mechanistic insights into how parameters such as gas composition, power input, treatment duration, and distance affect the generation and delivery of therapeutic plasma components are crucial for optimizing treatment protocols and developing standardized approaches for clinical applications.Expand Specific Solutions

Leading Companies and Research Institutions in Cold Plasma Technology

Cold plasma treatment in food processing is emerging as a promising non-thermal technology, currently transitioning from research to early commercial adoption. The market is experiencing rapid growth, estimated to reach $2-3 billion by 2025, driven by increasing demand for minimal processing technologies that maintain food quality while ensuring safety. Technologically, the field shows varying maturity levels across applications, with companies at different development stages. Leading players include Plasmapp Co. Ltd., pioneering processed-meat applications, and Clean Crop Technologies focusing on contaminant removal from seeds and foods. Research institutions like Zhejiang University, Tohoku University, and China Agricultural University are advancing fundamental understanding, while established corporations such as L'Oréal, Mars, Inc., and Air Liquide are exploring specialized applications. Equipment manufacturers including Tokyo Electron, NAURA Microelectronics, and Lam Research are developing scalable plasma generation systems, indicating growing industrial interest in this technology.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed a proprietary cold plasma treatment platform specifically engineered for food processing applications. Their PlasmaSafe™ technology utilizes a modified dielectric barrier discharge (DBD) system that generates atmospheric non-thermal plasma with precisely controlled reactive species composition. The company's approach focuses on optimizing the generation of specific reactive oxygen and nitrogen species that target microbial contaminants while minimizing interactions with sensitive food components. Their system incorporates patented electrode designs that create uniform plasma fields capable of treating irregular food surfaces with consistent efficacy[3][9]. Plasmology4's technology operates at ambient temperatures and pressures, eliminating thermal damage to heat-sensitive foods while achieving significant pathogen reduction. The company has documented 3-5 log reductions in common foodborne pathogens including Listeria, Salmonella, and E. coli on various food substrates including fresh produce, nuts, seeds, and meat products[5]. Their research has elucidated specific mechanisms of microbial inactivation, including cell membrane disruption, protein denaturation, and DNA damage pathways induced by plasma-generated reactive species.

Strengths: Highly effective pathogen reduction without thermal damage; minimal impact on nutritional and sensory qualities; adaptable to various food matrices through parameter optimization; relatively low energy consumption compared to other plasma systems. Weaknesses: Requires careful calibration for different food types; limited penetration depth restricts applications primarily to surface treatments; higher initial capital investment compared to conventional methods.

Mars, Inc.

Technical Solution: Mars, Inc. has pioneered advanced cold plasma treatment systems for food safety and preservation, particularly focused on dry foods like chocolate, confectionery, and pet food ingredients. Their proprietary Plasma Food Protection Technology (PFPT) utilizes a combination of direct and indirect plasma application methods to achieve comprehensive microbial control. The system generates cold plasma through a modified atmospheric pressure plasma jet (APPJ) configuration that creates a controlled mixture of reactive oxygen and nitrogen species. Mars has developed specialized electrode configurations and gas mixtures that optimize antimicrobial efficacy while minimizing impact on sensitive food components[2]. Their research has demonstrated significant reductions in Salmonella, Listeria and mycotoxin-producing fungi on cocoa beans and nuts, with minimal changes to flavor compounds and bioactive ingredients[4]. Mars has integrated real-time monitoring systems that adjust plasma parameters based on food characteristics and contamination levels.

Strengths: Highly effective against both bacterial and fungal contaminants; preserves heat-sensitive ingredients; adaptable to various food matrices through parameter optimization; integrated into existing processing lines. Weaknesses: Treatment uniformity challenges with complex food geometries; requires careful control of moisture content for optimal efficacy; higher energy consumption compared to some conventional methods.

Key Patents and Scientific Breakthroughs in Cold Plasma Food Processing

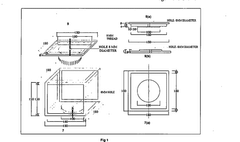

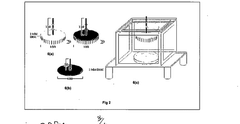

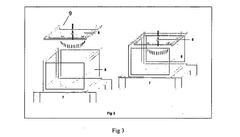

A cold plasma system and its method for preservation of food

PatentPendingIN202441030833A

Innovation

- A cost-effective cold plasma system using a dielectric barrier discharge (DBD) configuration with a flyback transformer, zero voltage switching (ZVS) circuit, and Cockcroft Walton Voltage Multiplier (CWVM) to generate atmospheric pressure cold plasma, effectively decontaminating food surfaces and extending shelf life without compromising quality.

Food Safety Regulations and Compliance for Novel Processing Technologies

The regulatory landscape for novel food processing technologies like cold plasma treatment is complex and continuously evolving. In the United States, the FDA oversees novel food processing technologies under the Federal Food, Drug, and Cosmetic Act, requiring manufacturers to demonstrate that these technologies are "generally recognized as safe" (GRAS). For cold plasma specifically, this necessitates comprehensive safety assessments focusing on potential chemical changes in treated foods and the formation of reactive species.

The European Union applies more stringent regulations through the Novel Foods Regulation (EU) 2015/2283, which mandates thorough safety evaluations before market approval. Cold plasma treatments must undergo rigorous assessment by the European Food Safety Authority (EFSA), with particular attention to potential alterations in nutritional composition and the generation of undesirable compounds during treatment.

International standards organizations, including Codex Alimentarius and ISO, are developing specific guidelines for emerging non-thermal technologies. These frameworks aim to standardize validation protocols and establish acceptable parameters for cold plasma applications in food processing. Currently, ISO 22000 provides general food safety management principles that manufacturers must adapt for cold plasma implementation.

Compliance challenges specific to cold plasma technology include the standardization of treatment parameters across different food matrices. The variability in plasma generation methods, gas compositions, and exposure times creates difficulties in establishing universal safety protocols. Manufacturers must validate that their specific cold plasma configurations consistently achieve the intended antimicrobial efficacy without compromising food quality or safety.

Documentation requirements for regulatory approval typically include detailed process validation studies demonstrating consistent pathogen reduction, analyses of potential chemical changes in treated foods, and comprehensive risk assessments addressing both known and potential hazards. These must account for the unique reactive species generated during plasma treatment and their interactions with different food components.

Looking forward, regulatory frameworks are expected to evolve as scientific understanding of cold plasma mechanisms deepens. Several jurisdictions are developing specialized guidelines for non-thermal technologies, with some regulatory bodies establishing expert committees specifically focused on novel processing methods. Industry stakeholders are encouraged to engage proactively with regulators through pre-submission consultations and participation in standards development to facilitate smoother approval processes.

The European Union applies more stringent regulations through the Novel Foods Regulation (EU) 2015/2283, which mandates thorough safety evaluations before market approval. Cold plasma treatments must undergo rigorous assessment by the European Food Safety Authority (EFSA), with particular attention to potential alterations in nutritional composition and the generation of undesirable compounds during treatment.

International standards organizations, including Codex Alimentarius and ISO, are developing specific guidelines for emerging non-thermal technologies. These frameworks aim to standardize validation protocols and establish acceptable parameters for cold plasma applications in food processing. Currently, ISO 22000 provides general food safety management principles that manufacturers must adapt for cold plasma implementation.

Compliance challenges specific to cold plasma technology include the standardization of treatment parameters across different food matrices. The variability in plasma generation methods, gas compositions, and exposure times creates difficulties in establishing universal safety protocols. Manufacturers must validate that their specific cold plasma configurations consistently achieve the intended antimicrobial efficacy without compromising food quality or safety.

Documentation requirements for regulatory approval typically include detailed process validation studies demonstrating consistent pathogen reduction, analyses of potential chemical changes in treated foods, and comprehensive risk assessments addressing both known and potential hazards. These must account for the unique reactive species generated during plasma treatment and their interactions with different food components.

Looking forward, regulatory frameworks are expected to evolve as scientific understanding of cold plasma mechanisms deepens. Several jurisdictions are developing specialized guidelines for non-thermal technologies, with some regulatory bodies establishing expert committees specifically focused on novel processing methods. Industry stakeholders are encouraged to engage proactively with regulators through pre-submission consultations and participation in standards development to facilitate smoother approval processes.

Sustainability Impact of Cold Plasma Treatment in Food Industry

Cold plasma treatment represents a significant advancement in sustainable food processing technologies, offering numerous environmental benefits compared to conventional methods. The non-thermal nature of cold plasma substantially reduces energy consumption, with studies indicating up to 70% less energy usage than traditional thermal processing techniques. This energy efficiency directly translates to reduced greenhouse gas emissions across the food production chain.

Water conservation constitutes another critical sustainability advantage of cold plasma applications. Unlike conventional washing and sanitizing processes that may require large volumes of water, cold plasma treatments operate in dry or semi-dry conditions, potentially reducing water usage by 40-60% in certain applications. This aspect is particularly valuable in regions facing water scarcity challenges.

The technology also minimizes chemical inputs in food processing. By generating reactive species in situ from ambient air or other gases, cold plasma reduces or eliminates the need for chemical sanitizers and preservatives. Research demonstrates that facilities implementing cold plasma systems have decreased their chemical usage by 30-50%, significantly reducing the environmental burden associated with chemical production, transportation, and disposal.

Waste reduction represents another sustainability dimension of cold plasma treatment. By extending shelf life and reducing spoilage, this technology helps combat food waste throughout the supply chain. Studies indicate potential food waste reductions of 15-25% for certain perishable products treated with cold plasma, addressing a major global sustainability challenge.

From a lifecycle perspective, cold plasma equipment demonstrates favorable environmental metrics. Modern systems are increasingly compact and energy-efficient, with operational lifespans exceeding 10 years when properly maintained. The environmental payback period for such systems typically ranges from 2-4 years, depending on application intensity and regional energy sources.

Additionally, cold plasma technology supports circular economy principles by enabling the valorization of food industry by-products. Treatment can enhance the functional properties of agricultural residues, facilitating their conversion into value-added products rather than waste streams.

As regulatory frameworks increasingly emphasize sustainability metrics, cold plasma's reduced environmental footprint positions it advantageously for future food processing requirements. Industry adoption continues to accelerate as manufacturers recognize both the operational and environmental benefits of this innovative technology.

Water conservation constitutes another critical sustainability advantage of cold plasma applications. Unlike conventional washing and sanitizing processes that may require large volumes of water, cold plasma treatments operate in dry or semi-dry conditions, potentially reducing water usage by 40-60% in certain applications. This aspect is particularly valuable in regions facing water scarcity challenges.

The technology also minimizes chemical inputs in food processing. By generating reactive species in situ from ambient air or other gases, cold plasma reduces or eliminates the need for chemical sanitizers and preservatives. Research demonstrates that facilities implementing cold plasma systems have decreased their chemical usage by 30-50%, significantly reducing the environmental burden associated with chemical production, transportation, and disposal.

Waste reduction represents another sustainability dimension of cold plasma treatment. By extending shelf life and reducing spoilage, this technology helps combat food waste throughout the supply chain. Studies indicate potential food waste reductions of 15-25% for certain perishable products treated with cold plasma, addressing a major global sustainability challenge.

From a lifecycle perspective, cold plasma equipment demonstrates favorable environmental metrics. Modern systems are increasingly compact and energy-efficient, with operational lifespans exceeding 10 years when properly maintained. The environmental payback period for such systems typically ranges from 2-4 years, depending on application intensity and regional energy sources.

Additionally, cold plasma technology supports circular economy principles by enabling the valorization of food industry by-products. Treatment can enhance the functional properties of agricultural residues, facilitating their conversion into value-added products rather than waste streams.

As regulatory frameworks increasingly emphasize sustainability metrics, cold plasma's reduced environmental footprint positions it advantageously for future food processing requirements. Industry adoption continues to accelerate as manufacturers recognize both the operational and environmental benefits of this innovative technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!