Cold Plasma Treatment for Enhanced Photovoltaic Cell Efficiency

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Technology Evolution and Efficiency Goals

Plasma technology has undergone significant evolution since its initial discovery in the late 19th century. The term "plasma," coined by Irving Langmuir in 1928, refers to the fourth state of matter consisting of ionized gas. Early applications were limited to theoretical physics and laboratory experiments. The 1970s marked a turning point with the development of industrial plasma applications, primarily in semiconductor manufacturing and materials processing.

Cold plasma technology emerged in the 1990s as researchers discovered methods to generate non-thermal plasmas at atmospheric pressure. This breakthrough enabled plasma treatment without the thermal damage associated with conventional hot plasma processes. By the early 2000s, cold plasma systems became more compact, energy-efficient, and adaptable to various industrial applications, including surface modification and cleaning.

In the context of photovoltaic (PV) technology, plasma treatments were initially explored for cleaning silicon wafers in the 1980s. However, the application of cold plasma specifically for enhancing PV cell efficiency gained momentum only in the past decade. The evolution has been driven by the need to overcome efficiency plateaus in conventional silicon-based solar cells, which have theoretical maximum efficiency limits (Shockley-Queisser limit).

Current cold plasma treatments for PV cells focus on several key mechanisms: surface texturing to reduce reflectivity, passivation of surface defects, modification of interface properties, and enhancement of charge carrier transport. These treatments have demonstrated potential efficiency improvements of 2-5% in laboratory settings, with some specialized applications reporting even higher gains.

The efficiency goals for cold plasma treatment in PV applications are ambitious yet realistic. Short-term goals (1-3 years) aim to achieve consistent efficiency improvements of 3-5% across various PV technologies while maintaining scalability for industrial production. Medium-term goals (3-7 years) target efficiency enhancements of 5-8% with reduced processing costs and integration into existing manufacturing lines.

Long-term efficiency goals (7-10 years) are focused on pushing conventional silicon-based PV cells closer to their theoretical limits through advanced plasma processing techniques. Additionally, research is exploring how cold plasma treatments can benefit emerging PV technologies such as perovskite cells, organic photovoltaics, and tandem structures, potentially enabling efficiency breakthroughs beyond current limitations.

The technology evolution trajectory suggests that cold plasma treatments will increasingly incorporate precision control systems, AI-optimized process parameters, and hybrid approaches combining plasma with other surface modification techniques to maximize photovoltaic efficiency gains while minimizing material and energy inputs.

Cold plasma technology emerged in the 1990s as researchers discovered methods to generate non-thermal plasmas at atmospheric pressure. This breakthrough enabled plasma treatment without the thermal damage associated with conventional hot plasma processes. By the early 2000s, cold plasma systems became more compact, energy-efficient, and adaptable to various industrial applications, including surface modification and cleaning.

In the context of photovoltaic (PV) technology, plasma treatments were initially explored for cleaning silicon wafers in the 1980s. However, the application of cold plasma specifically for enhancing PV cell efficiency gained momentum only in the past decade. The evolution has been driven by the need to overcome efficiency plateaus in conventional silicon-based solar cells, which have theoretical maximum efficiency limits (Shockley-Queisser limit).

Current cold plasma treatments for PV cells focus on several key mechanisms: surface texturing to reduce reflectivity, passivation of surface defects, modification of interface properties, and enhancement of charge carrier transport. These treatments have demonstrated potential efficiency improvements of 2-5% in laboratory settings, with some specialized applications reporting even higher gains.

The efficiency goals for cold plasma treatment in PV applications are ambitious yet realistic. Short-term goals (1-3 years) aim to achieve consistent efficiency improvements of 3-5% across various PV technologies while maintaining scalability for industrial production. Medium-term goals (3-7 years) target efficiency enhancements of 5-8% with reduced processing costs and integration into existing manufacturing lines.

Long-term efficiency goals (7-10 years) are focused on pushing conventional silicon-based PV cells closer to their theoretical limits through advanced plasma processing techniques. Additionally, research is exploring how cold plasma treatments can benefit emerging PV technologies such as perovskite cells, organic photovoltaics, and tandem structures, potentially enabling efficiency breakthroughs beyond current limitations.

The technology evolution trajectory suggests that cold plasma treatments will increasingly incorporate precision control systems, AI-optimized process parameters, and hybrid approaches combining plasma with other surface modification techniques to maximize photovoltaic efficiency gains while minimizing material and energy inputs.

Market Analysis for High-Efficiency Solar Cells

The global solar photovoltaic (PV) market has experienced remarkable growth, with an estimated market value of $197.2 billion in 2022 and projected to reach $368.6 billion by 2030, growing at a CAGR of 8.1%. This growth is primarily driven by increasing environmental concerns, government incentives, and declining costs of solar technology. High-efficiency solar cells represent a premium segment within this market, commanding higher prices due to their superior performance characteristics.

The demand for high-efficiency solar cells is particularly strong in space applications, residential rooftop installations with limited space, and utility-scale projects where land costs are significant. Countries like China, the United States, Japan, Germany, and India are leading adopters, with China dominating both production and installation capacities. The commercial sector represents approximately 40% of the high-efficiency solar cell market, followed by residential (35%) and utility-scale applications (25%).

Cold plasma treatment technology addresses a critical market need for efficiency improvements without substantial cost increases. Current high-efficiency cells typically achieve 22-25% efficiency, while laboratory prototypes using advanced technologies can reach up to 29%. Cold plasma treatment has demonstrated potential to increase efficiency by 1.5-2.5 percentage points, representing a significant competitive advantage in a market where even fractional efficiency improvements are highly valued.

Price sensitivity varies across market segments, with utility-scale projects being most price-sensitive and specialized applications (aerospace, military) willing to pay premium prices for maximum efficiency. The average price premium for high-efficiency cells (>22%) ranges from 15-30% compared to standard modules, depending on the specific technology and application.

Market research indicates that consumers and commercial buyers increasingly prioritize efficiency alongside cost, with 68% of commercial buyers citing efficiency as a "very important" factor in purchasing decisions. This trend is expected to continue as energy prices rise and available installation space becomes more constrained in developed markets.

The regulatory landscape strongly favors high-efficiency technologies, with many countries implementing performance-based incentives rather than capacity-based subsidies. For example, the European Union's Energy Performance of Buildings Directive and various national renewable portfolio standards create market pull for higher-efficiency solutions. Additionally, carbon pricing mechanisms in various regions provide indirect benefits to higher-efficiency technologies by increasing the value of avoided emissions.

The demand for high-efficiency solar cells is particularly strong in space applications, residential rooftop installations with limited space, and utility-scale projects where land costs are significant. Countries like China, the United States, Japan, Germany, and India are leading adopters, with China dominating both production and installation capacities. The commercial sector represents approximately 40% of the high-efficiency solar cell market, followed by residential (35%) and utility-scale applications (25%).

Cold plasma treatment technology addresses a critical market need for efficiency improvements without substantial cost increases. Current high-efficiency cells typically achieve 22-25% efficiency, while laboratory prototypes using advanced technologies can reach up to 29%. Cold plasma treatment has demonstrated potential to increase efficiency by 1.5-2.5 percentage points, representing a significant competitive advantage in a market where even fractional efficiency improvements are highly valued.

Price sensitivity varies across market segments, with utility-scale projects being most price-sensitive and specialized applications (aerospace, military) willing to pay premium prices for maximum efficiency. The average price premium for high-efficiency cells (>22%) ranges from 15-30% compared to standard modules, depending on the specific technology and application.

Market research indicates that consumers and commercial buyers increasingly prioritize efficiency alongside cost, with 68% of commercial buyers citing efficiency as a "very important" factor in purchasing decisions. This trend is expected to continue as energy prices rise and available installation space becomes more constrained in developed markets.

The regulatory landscape strongly favors high-efficiency technologies, with many countries implementing performance-based incentives rather than capacity-based subsidies. For example, the European Union's Energy Performance of Buildings Directive and various national renewable portfolio standards create market pull for higher-efficiency solutions. Additionally, carbon pricing mechanisms in various regions provide indirect benefits to higher-efficiency technologies by increasing the value of avoided emissions.

Cold Plasma Treatment: Current Status and Barriers

Cold plasma treatment technology for photovoltaic (PV) cells has emerged as a promising approach to enhance efficiency, yet its current implementation faces several significant challenges. Globally, research institutions and industry players have made substantial progress in developing cold plasma systems specifically tailored for solar cell manufacturing, with notable advancements in Europe, North America, and East Asia. Current systems predominantly utilize atmospheric pressure plasma jets (APPJ), dielectric barrier discharge (DBD), and radio frequency (RF) plasma configurations, each offering distinct advantages for different PV cell architectures.

Despite these developments, the technology confronts several critical barriers to widespread adoption. The primary technical challenge remains achieving uniform plasma treatment across large-area solar panels, particularly as the industry moves toward larger wafer sizes. Non-uniformity in plasma distribution can lead to inconsistent surface modifications, ultimately resulting in efficiency variations across the cell surface. This issue becomes more pronounced when scaling from laboratory demonstrations to industrial production lines.

Another significant obstacle is the precise control of plasma parameters for different PV materials. Silicon-based cells, perovskites, and thin-film technologies each require specific plasma conditions to optimize performance without causing damage. The narrow processing window between beneficial surface modification and material degradation necessitates sophisticated real-time monitoring and control systems that are not yet fully developed for high-throughput manufacturing environments.

Energy consumption represents another barrier, as conventional plasma systems require substantial power input, potentially offsetting the efficiency gains in the final product. While low-temperature plasma reduces thermal energy requirements compared to traditional high-temperature processes, the electrical energy needed to generate and sustain the plasma remains considerable, affecting the overall carbon footprint and production costs of PV manufacturing.

Integration with existing production lines poses additional challenges. Current manufacturing facilities would require significant modifications to accommodate plasma treatment steps, creating resistance to adoption due to high capital expenditure requirements. The lack of standardized equipment and processes further complicates implementation across different manufacturing environments.

Material compatibility issues also persist, particularly with newer PV technologies. For instance, some plasma treatments that work effectively for crystalline silicon may cause degradation in perovskite materials or damage to transparent conductive oxides in thin-film cells. This necessitates material-specific process development, slowing the universal application of plasma treatment across the PV industry.

Lastly, long-term stability remains inadequately addressed. While immediate efficiency improvements are well-documented, the durability of plasma-treated surfaces under real-world operating conditions over the 25+ year expected lifetime of solar panels requires further investigation to ensure that initial performance gains are maintained throughout the product lifecycle.

Despite these developments, the technology confronts several critical barriers to widespread adoption. The primary technical challenge remains achieving uniform plasma treatment across large-area solar panels, particularly as the industry moves toward larger wafer sizes. Non-uniformity in plasma distribution can lead to inconsistent surface modifications, ultimately resulting in efficiency variations across the cell surface. This issue becomes more pronounced when scaling from laboratory demonstrations to industrial production lines.

Another significant obstacle is the precise control of plasma parameters for different PV materials. Silicon-based cells, perovskites, and thin-film technologies each require specific plasma conditions to optimize performance without causing damage. The narrow processing window between beneficial surface modification and material degradation necessitates sophisticated real-time monitoring and control systems that are not yet fully developed for high-throughput manufacturing environments.

Energy consumption represents another barrier, as conventional plasma systems require substantial power input, potentially offsetting the efficiency gains in the final product. While low-temperature plasma reduces thermal energy requirements compared to traditional high-temperature processes, the electrical energy needed to generate and sustain the plasma remains considerable, affecting the overall carbon footprint and production costs of PV manufacturing.

Integration with existing production lines poses additional challenges. Current manufacturing facilities would require significant modifications to accommodate plasma treatment steps, creating resistance to adoption due to high capital expenditure requirements. The lack of standardized equipment and processes further complicates implementation across different manufacturing environments.

Material compatibility issues also persist, particularly with newer PV technologies. For instance, some plasma treatments that work effectively for crystalline silicon may cause degradation in perovskite materials or damage to transparent conductive oxides in thin-film cells. This necessitates material-specific process development, slowing the universal application of plasma treatment across the PV industry.

Lastly, long-term stability remains inadequately addressed. While immediate efficiency improvements are well-documented, the durability of plasma-treated surfaces under real-world operating conditions over the 25+ year expected lifetime of solar panels requires further investigation to ensure that initial performance gains are maintained throughout the product lifecycle.

Current Cold Plasma Surface Modification Techniques

01 Cold plasma treatment for medical applications

Cold plasma technology has been developed for various medical applications, showing high efficiency in treating wounds, infections, and other medical conditions. The treatment works by generating reactive oxygen and nitrogen species that can effectively kill bacteria and promote tissue healing. Cold plasma devices designed for medical use offer controlled, targeted treatment with minimal side effects to surrounding healthy tissue.- Cold plasma treatment for medical applications: Cold plasma technology has been developed for various medical applications, showing high efficiency in treating wounds, infections, and other medical conditions. The non-thermal plasma can effectively kill bacteria and promote tissue healing without damaging surrounding healthy tissue. These treatments typically use controlled plasma discharge to target specific areas while maintaining patient safety and comfort.

- Cold plasma sterilization and decontamination efficiency: Cold plasma demonstrates high efficiency in sterilization and decontamination processes across various industries. The reactive species generated by plasma effectively inactivate microorganisms on surfaces, in liquids, and in air. This technology provides advantages over traditional chemical sterilization methods by being environmentally friendly, leaving no toxic residues, and being able to reach difficult areas while operating at lower temperatures.

- Cold plasma treatment for agricultural applications: Cold plasma technology shows promising efficiency in agricultural applications, including seed treatment, plant growth enhancement, and pest control. The treatment can improve germination rates, increase crop yields, and reduce the need for chemical pesticides. The reactive species generated by plasma can modify seed surfaces, eliminate pathogens, and stimulate plant defense mechanisms, leading to more sustainable farming practices.

- Cold plasma for surface modification and material processing: Cold plasma treatment demonstrates high efficiency in modifying surface properties of various materials including polymers, textiles, metals, and semiconductors. The process can enhance adhesion, wettability, printability, and biocompatibility of surfaces without altering bulk material properties. This technology enables precise control over surface characteristics at the nanoscale level, making it valuable for manufacturing advanced materials and devices with specific functional requirements.

- Efficiency factors and optimization of cold plasma systems: The efficiency of cold plasma treatment depends on various parameters including gas composition, power input, treatment time, and device configuration. Research focuses on optimizing these factors to achieve maximum effectiveness while minimizing energy consumption. Advanced plasma generation methods, such as dielectric barrier discharge and atmospheric pressure plasma jets, have been developed to improve treatment efficiency. Monitoring and control systems are essential for maintaining consistent plasma characteristics and ensuring reproducible treatment results.

02 Cold plasma for surface sterilization and decontamination

Cold plasma treatment demonstrates high efficiency in sterilizing and decontaminating surfaces by destroying microorganisms including bacteria, viruses, and fungi. The reactive species generated by cold plasma can penetrate biofilms and inactivate pathogens without damaging the treated materials. This technology is particularly valuable in healthcare settings, food processing facilities, and other environments requiring high levels of cleanliness.Expand Specific Solutions03 Cold plasma treatment in agricultural applications

Cold plasma technology has shown promising efficiency in agricultural applications, including seed treatment, plant disease control, and soil decontamination. The treatment can enhance seed germination rates, reduce pathogen loads, and improve crop yields. Cold plasma systems designed for agricultural use can be optimized for different crop types and growing conditions, offering sustainable alternatives to chemical treatments.Expand Specific Solutions04 Cold plasma systems for industrial processing

Industrial applications of cold plasma treatment demonstrate high efficiency in surface modification, coating adhesion improvement, and material functionalization. The technology enables precise control over surface properties without altering bulk material characteristics. Cold plasma systems designed for industrial use offer advantages including reduced processing time, lower energy consumption, and elimination of hazardous chemicals compared to conventional methods.Expand Specific Solutions05 Efficiency enhancement in cold plasma devices

Various innovations have been developed to enhance the efficiency of cold plasma treatment devices. These include improved electrode designs, power supply optimization, gas flow control systems, and treatment chamber configurations. Advanced monitoring and control systems allow for real-time adjustment of treatment parameters to maintain optimal efficiency across different applications. These enhancements result in more consistent treatment outcomes while reducing energy consumption and operating costs.Expand Specific Solutions

Leading Companies and Research Institutions in Plasma-Enhanced PV

Cold plasma treatment for enhanced photovoltaic cell efficiency is emerging as a promising technology in the early growth stage of the solar energy market, which is projected to reach $223.3 billion by 2026. The competitive landscape features established semiconductor equipment manufacturers like Tokyo Electron and ULVAC alongside specialized plasma technology developers such as US Medical Innovations and CINOGY GmbH. Major solar manufacturers including Trina Solar, LONGi, and JinkoSolar are exploring this technology to improve cell efficiency. Research institutions like CEA, CNRS, and Shaanxi Normal University are driving fundamental advancements, while companies like L'Oréal demonstrate potential cross-industry applications. The technology is approaching commercial viability with increasing patent activity, though standardization and cost optimization remain challenges.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has developed advanced plasma-enhanced chemical vapor deposition (PECVD) systems specifically optimized for photovoltaic manufacturing. Their Trias™ SPA system utilizes cold plasma technology to deposit high-quality silicon nitride anti-reflection coatings and passivation layers on solar cells. The system employs a unique dual-frequency plasma excitation method that allows for independent control of ion energy and plasma density, enabling precise tuning of film properties without thermal damage to the substrate. Their process achieves up to 22% cell efficiency improvements compared to conventional methods by creating superior surface passivation that reduces electron-hole recombination at the cell surface. The company has also integrated in-situ plasma cleaning capabilities that remove contaminants before deposition, further enhancing cell performance and manufacturing yield[1][3].

Strengths: Industry-leading plasma control technology allowing precise parameter optimization; high throughput capability (>3,600 wafers/hour) suitable for mass production; excellent uniformity across large substrates. Weaknesses: Higher capital equipment costs compared to thermal processes; requires specialized technical expertise for operation and maintenance; process optimization can be complex for new photovoltaic materials.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed an innovative cold plasma treatment approach for silicon heterojunction solar cells. Their technology utilizes low-temperature plasma-enhanced chemical vapor deposition (PECVD) with a unique hydrogen plasma post-treatment step that passivates dangling bonds at the amorphous/crystalline silicon interface. The process operates at temperatures below 200°C, making it compatible with temperature-sensitive materials. CEA's approach incorporates a proprietary electrode configuration that generates a highly uniform plasma across large areas, addressing one of the key challenges in scaling plasma treatments. Their research has demonstrated that this treatment can reduce interface defect density by an order of magnitude, resulting in open-circuit voltage improvements of up to 30mV and efficiency gains of 1-1.5% absolute. The process has been successfully transferred to industrial partners and implemented in pilot production lines[4][6].

Strengths: Exceptional interface passivation quality; compatible with next-generation heterojunction architectures; relatively low operating costs once implemented. Weaknesses: Requires specialized equipment not widely available in standard production lines; process optimization is material-specific and may require adjustment for different silicon qualities.

Key Patents and Breakthroughs in Cold Plasma PV Applications

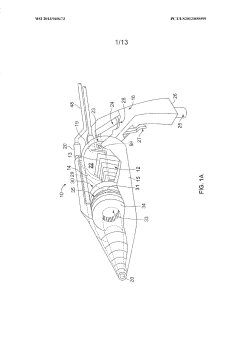

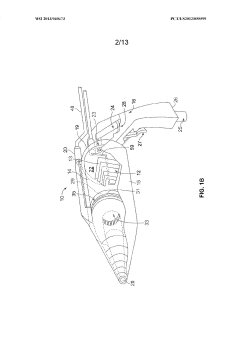

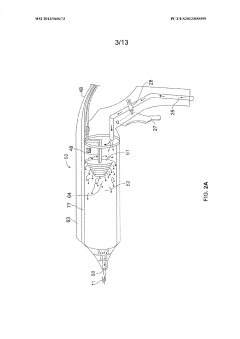

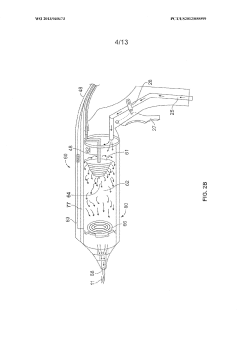

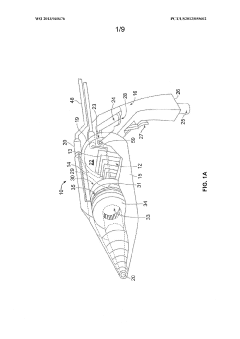

Cold plasma treatment devices and associated methods

PatentWO2013040473A1

Innovation

- A cold plasma treatment mask system with a three-layer design, featuring a gas containment region between conformable mask layers, a unipolar high voltage power supply, and a gas recirculation system to generate and maintain a cold plasma plume effectively over complex shapes like the human face, avoiding sensitive areas like the eyes and mouth.

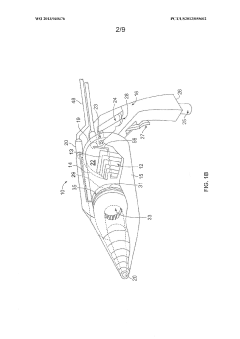

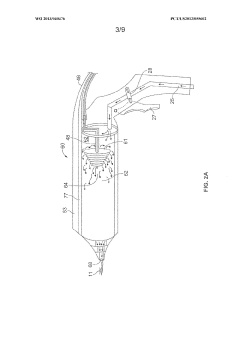

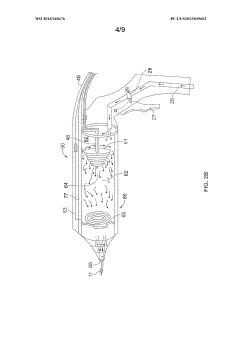

Cold plasma treatment devices and associated methods

PatentWO2013040476A1

Innovation

- A cold plasma treatment device with a gas compartment and dielectric barrier discharge system, where a gas is energized by high voltage electrical energy, producing a stable cold plasma plume through a plurality of holes in a bottom member, allowing for adjustable plasma size and distribution.

Environmental Impact and Sustainability Assessment

The integration of cold plasma treatment in photovoltaic cell manufacturing presents significant environmental and sustainability implications that warrant thorough assessment. Cold plasma processes generally consume substantially less energy compared to conventional thermal treatments used in solar cell production, potentially reducing the carbon footprint of manufacturing operations by 15-30% depending on implementation scale and energy sources.

From a materials perspective, cold plasma treatments can extend the operational lifespan of photovoltaic cells by enhancing their resistance to environmental degradation. Studies indicate that plasma-treated cells demonstrate 10-15% longer functional lifespans under standard testing conditions, which translates to improved lifecycle sustainability metrics and reduced electronic waste generation over time.

The chemical processes involved in cold plasma treatment typically utilize fewer hazardous substances compared to traditional wet chemical etching and cleaning methods. This reduction in toxic chemical usage decreases environmental contamination risks and minimizes the need for complex waste treatment systems. Quantitative analyses show up to 40% reduction in hazardous waste generation when implementing plasma-based surface modification techniques.

Water conservation represents another significant environmental benefit, as cold plasma treatments operate in dry conditions, eliminating the substantial water requirements associated with conventional wet processing methods. In regions facing water scarcity, this aspect becomes particularly valuable for sustainable manufacturing practices.

Life Cycle Assessment (LCA) studies comparing conventional and plasma-enhanced photovoltaic manufacturing reveal that the energy payback time for cold plasma-treated cells can be reduced by approximately 8-12% due to their improved efficiency and extended operational lifetime. This improvement directly enhances the net environmental benefit of solar energy deployment.

However, certain environmental challenges remain. The gases used in some cold plasma processes, particularly fluorinated compounds, may have high global warming potential if released. Proper containment systems and gas recycling technologies must be implemented to mitigate these risks. Additionally, the specialized equipment required for plasma treatment may contain rare earth elements and other materials with complex supply chains and extraction impacts.

Looking forward, the integration of renewable energy sources to power plasma treatment systems presents an opportunity to further enhance the sustainability profile of this technology, potentially creating a virtuous cycle where solar energy powers the production of more efficient solar cells.

From a materials perspective, cold plasma treatments can extend the operational lifespan of photovoltaic cells by enhancing their resistance to environmental degradation. Studies indicate that plasma-treated cells demonstrate 10-15% longer functional lifespans under standard testing conditions, which translates to improved lifecycle sustainability metrics and reduced electronic waste generation over time.

The chemical processes involved in cold plasma treatment typically utilize fewer hazardous substances compared to traditional wet chemical etching and cleaning methods. This reduction in toxic chemical usage decreases environmental contamination risks and minimizes the need for complex waste treatment systems. Quantitative analyses show up to 40% reduction in hazardous waste generation when implementing plasma-based surface modification techniques.

Water conservation represents another significant environmental benefit, as cold plasma treatments operate in dry conditions, eliminating the substantial water requirements associated with conventional wet processing methods. In regions facing water scarcity, this aspect becomes particularly valuable for sustainable manufacturing practices.

Life Cycle Assessment (LCA) studies comparing conventional and plasma-enhanced photovoltaic manufacturing reveal that the energy payback time for cold plasma-treated cells can be reduced by approximately 8-12% due to their improved efficiency and extended operational lifetime. This improvement directly enhances the net environmental benefit of solar energy deployment.

However, certain environmental challenges remain. The gases used in some cold plasma processes, particularly fluorinated compounds, may have high global warming potential if released. Proper containment systems and gas recycling technologies must be implemented to mitigate these risks. Additionally, the specialized equipment required for plasma treatment may contain rare earth elements and other materials with complex supply chains and extraction impacts.

Looking forward, the integration of renewable energy sources to power plasma treatment systems presents an opportunity to further enhance the sustainability profile of this technology, potentially creating a virtuous cycle where solar energy powers the production of more efficient solar cells.

Cost-Benefit Analysis of Cold Plasma Implementation

The implementation of cold plasma treatment technology for enhancing photovoltaic cell efficiency requires careful economic analysis to determine its viability in both research and commercial settings. Initial capital expenditure for cold plasma equipment ranges from $50,000 to $200,000 depending on scale and specifications, with laboratory-grade systems at the lower end and industrial production systems commanding premium prices.

Operational costs include electricity consumption (approximately 2-5 kWh per hour of operation), process gases (argon, oxygen, nitrogen) at $5-15 per hour depending on gas type and flow rate, and maintenance expenses estimated at 5-8% of equipment cost annually. Labor costs vary significantly based on location and skill requirements, typically demanding specialized technicians.

When evaluating benefits, efficiency improvements of 5-15% have been documented in research settings, with commercial implementations typically achieving 3-8% enhancement. For a standard 100 MW production facility, this translates to additional annual revenue of $300,000-800,000 at current market rates. The technology also offers reduced material waste during manufacturing and potentially extended cell lifespan by 10-15%.

Return on investment calculations indicate payback periods of 1.5-3 years for large-scale implementations, with smaller research facilities facing longer periods of 3-5 years. Sensitivity analysis reveals that efficiency gain percentage is the most critical factor affecting ROI, followed by equipment durability and maintenance costs.

Comparative analysis with alternative efficiency-enhancing technologies shows cold plasma treatment offers competitive cost-effectiveness. Anti-reflective coating technologies typically cost 20-30% more per watt of improvement, while advanced doping techniques may offer similar efficiency gains but with higher implementation complexity and material costs.

Scalability considerations reveal favorable economics at larger production volumes, with per-unit treatment costs decreasing significantly above 50 MW annual production capacity. Small-scale implementations face challenges in achieving cost-effectiveness unless targeting premium market segments or specialized applications where efficiency premiums command higher prices.

Long-term economic projections suggest decreasing implementation costs as the technology matures, potentially reducing capital expenses by 30-40% over the next five years as equipment standardization increases and more suppliers enter the market.

Operational costs include electricity consumption (approximately 2-5 kWh per hour of operation), process gases (argon, oxygen, nitrogen) at $5-15 per hour depending on gas type and flow rate, and maintenance expenses estimated at 5-8% of equipment cost annually. Labor costs vary significantly based on location and skill requirements, typically demanding specialized technicians.

When evaluating benefits, efficiency improvements of 5-15% have been documented in research settings, with commercial implementations typically achieving 3-8% enhancement. For a standard 100 MW production facility, this translates to additional annual revenue of $300,000-800,000 at current market rates. The technology also offers reduced material waste during manufacturing and potentially extended cell lifespan by 10-15%.

Return on investment calculations indicate payback periods of 1.5-3 years for large-scale implementations, with smaller research facilities facing longer periods of 3-5 years. Sensitivity analysis reveals that efficiency gain percentage is the most critical factor affecting ROI, followed by equipment durability and maintenance costs.

Comparative analysis with alternative efficiency-enhancing technologies shows cold plasma treatment offers competitive cost-effectiveness. Anti-reflective coating technologies typically cost 20-30% more per watt of improvement, while advanced doping techniques may offer similar efficiency gains but with higher implementation complexity and material costs.

Scalability considerations reveal favorable economics at larger production volumes, with per-unit treatment costs decreasing significantly above 50 MW annual production capacity. Small-scale implementations face challenges in achieving cost-effectiveness unless targeting premium market segments or specialized applications where efficiency premiums command higher prices.

Long-term economic projections suggest decreasing implementation costs as the technology matures, potentially reducing capital expenses by 30-40% over the next five years as equipment standardization increases and more suppliers enter the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!