Cold Plasma Treatment in Hydrogen Production: Efficiency Analysis

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has emerged as a promising approach in the field of hydrogen production, representing a significant advancement in sustainable energy solutions. The evolution of this technology can be traced back to the early 20th century when plasma physics began to develop as a distinct scientific discipline. However, it was not until the late 1990s that researchers started exploring cold plasma applications specifically for hydrogen production processes.

Cold plasma, also known as non-thermal plasma, operates at near-ambient temperatures while maintaining high electron energy levels. This unique characteristic allows for chemical reactions to occur without the substantial energy input required by conventional thermal processes. The technology has progressed through several developmental phases, from laboratory curiosity to industrial application potential, with significant acceleration in research occurring over the past decade.

The current technological trajectory indicates a growing interest in optimizing cold plasma systems for hydrogen production, particularly as global energy policies increasingly prioritize decarbonization and renewable energy sources. Recent advancements in electrode materials, power supply systems, and reactor designs have substantially improved the efficiency and scalability of cold plasma treatment in hydrogen production processes.

The primary technical objective in this field is to enhance the energy efficiency of hydrogen production through cold plasma treatment. Current research aims to achieve conversion efficiencies exceeding 70%, a significant improvement over conventional electrolysis methods which typically operate at 50-60% efficiency. Additionally, researchers are working to reduce the capital and operational costs associated with cold plasma systems to make them economically competitive with established hydrogen production technologies.

Another critical objective is the integration of cold plasma technology with renewable energy sources such as wind and solar power. This integration presents unique challenges related to managing intermittent power supplies and optimizing plasma stability under variable input conditions. Researchers are developing advanced control systems and buffer technologies to address these challenges.

The environmental impact reduction represents another key objective, with efforts focused on minimizing the formation of unwanted by-products and reducing the overall carbon footprint of the hydrogen production process. Cold plasma technology offers promising pathways to achieve these goals through precise reaction control and potentially lower energy requirements compared to conventional methods.

Looking forward, the technological roadmap for cold plasma in hydrogen production includes developing more durable electrode materials, improving plasma stability at larger scales, and enhancing catalytic effects through plasma-catalyst synergies. These advancements are expected to position cold plasma treatment as a key enabling technology in the transition toward a hydrogen-based economy.

Cold plasma, also known as non-thermal plasma, operates at near-ambient temperatures while maintaining high electron energy levels. This unique characteristic allows for chemical reactions to occur without the substantial energy input required by conventional thermal processes. The technology has progressed through several developmental phases, from laboratory curiosity to industrial application potential, with significant acceleration in research occurring over the past decade.

The current technological trajectory indicates a growing interest in optimizing cold plasma systems for hydrogen production, particularly as global energy policies increasingly prioritize decarbonization and renewable energy sources. Recent advancements in electrode materials, power supply systems, and reactor designs have substantially improved the efficiency and scalability of cold plasma treatment in hydrogen production processes.

The primary technical objective in this field is to enhance the energy efficiency of hydrogen production through cold plasma treatment. Current research aims to achieve conversion efficiencies exceeding 70%, a significant improvement over conventional electrolysis methods which typically operate at 50-60% efficiency. Additionally, researchers are working to reduce the capital and operational costs associated with cold plasma systems to make them economically competitive with established hydrogen production technologies.

Another critical objective is the integration of cold plasma technology with renewable energy sources such as wind and solar power. This integration presents unique challenges related to managing intermittent power supplies and optimizing plasma stability under variable input conditions. Researchers are developing advanced control systems and buffer technologies to address these challenges.

The environmental impact reduction represents another key objective, with efforts focused on minimizing the formation of unwanted by-products and reducing the overall carbon footprint of the hydrogen production process. Cold plasma technology offers promising pathways to achieve these goals through precise reaction control and potentially lower energy requirements compared to conventional methods.

Looking forward, the technological roadmap for cold plasma in hydrogen production includes developing more durable electrode materials, improving plasma stability at larger scales, and enhancing catalytic effects through plasma-catalyst synergies. These advancements are expected to position cold plasma treatment as a key enabling technology in the transition toward a hydrogen-based economy.

Hydrogen Production Market Demand Analysis

The global hydrogen production market is experiencing significant growth, driven by increasing demand for clean energy solutions and the push towards decarbonization across various industries. Currently, the global hydrogen market is valued at approximately 130 billion USD, with an annual production volume exceeding 70 million metric tons. This market is projected to grow at a compound annual growth rate (CAGR) of 9.2% through 2030, potentially reaching a market value of 300 billion USD by that time.

Industrial applications continue to dominate hydrogen demand, with petroleum refining and ammonia production accounting for nearly 75% of current consumption. However, emerging applications in transportation, power generation, and energy storage are rapidly expanding market segments. The transportation sector, particularly fuel cell electric vehicles (FCEVs), represents one of the fastest-growing demand sources, with several major automotive manufacturers investing heavily in hydrogen fuel cell technology.

Regionally, Asia-Pacific leads hydrogen consumption, with China, Japan, and South Korea implementing aggressive hydrogen strategies as part of their energy transition plans. Europe follows closely, with Germany, France, and the UK establishing ambitious hydrogen roadmaps and substantial investment commitments. The European Union's Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzer capacity by 2030, signaling strong future demand growth.

The market is increasingly segmented by production method, with growing preference for low-carbon hydrogen production technologies. While grey hydrogen (produced from natural gas without carbon capture) currently dominates with over 95% market share, blue hydrogen (fossil-based with carbon capture) and green hydrogen (produced via electrolysis using renewable energy) are gaining significant traction. Market analysis indicates that green hydrogen demand could grow at a CAGR of 57% through 2030, reflecting strong policy support and declining renewable energy costs.

Cold plasma treatment represents an emerging technology in this landscape, potentially addressing efficiency challenges in various hydrogen production pathways. Market research indicates growing interest in plasma-assisted hydrogen production methods, particularly for enhancing methane reforming processes and improving electrolysis efficiency. Early adopters are primarily research institutions and technology companies, though commercial applications remain limited.

Cost considerations remain paramount in market adoption decisions. Current hydrogen production costs range from 1-3 USD/kg for grey hydrogen to 3-8 USD/kg for green hydrogen. Technologies like cold plasma treatment must demonstrate clear economic advantages through improved energy efficiency, reduced catalyst requirements, or enhanced production rates to gain significant market share.

Industrial applications continue to dominate hydrogen demand, with petroleum refining and ammonia production accounting for nearly 75% of current consumption. However, emerging applications in transportation, power generation, and energy storage are rapidly expanding market segments. The transportation sector, particularly fuel cell electric vehicles (FCEVs), represents one of the fastest-growing demand sources, with several major automotive manufacturers investing heavily in hydrogen fuel cell technology.

Regionally, Asia-Pacific leads hydrogen consumption, with China, Japan, and South Korea implementing aggressive hydrogen strategies as part of their energy transition plans. Europe follows closely, with Germany, France, and the UK establishing ambitious hydrogen roadmaps and substantial investment commitments. The European Union's Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzer capacity by 2030, signaling strong future demand growth.

The market is increasingly segmented by production method, with growing preference for low-carbon hydrogen production technologies. While grey hydrogen (produced from natural gas without carbon capture) currently dominates with over 95% market share, blue hydrogen (fossil-based with carbon capture) and green hydrogen (produced via electrolysis using renewable energy) are gaining significant traction. Market analysis indicates that green hydrogen demand could grow at a CAGR of 57% through 2030, reflecting strong policy support and declining renewable energy costs.

Cold plasma treatment represents an emerging technology in this landscape, potentially addressing efficiency challenges in various hydrogen production pathways. Market research indicates growing interest in plasma-assisted hydrogen production methods, particularly for enhancing methane reforming processes and improving electrolysis efficiency. Early adopters are primarily research institutions and technology companies, though commercial applications remain limited.

Cost considerations remain paramount in market adoption decisions. Current hydrogen production costs range from 1-3 USD/kg for grey hydrogen to 3-8 USD/kg for green hydrogen. Technologies like cold plasma treatment must demonstrate clear economic advantages through improved energy efficiency, reduced catalyst requirements, or enhanced production rates to gain significant market share.

Cold Plasma Hydrogen Production: Status and Challenges

Cold plasma technology represents a significant frontier in hydrogen production methods, offering potential advantages over conventional thermochemical and electrochemical processes. Currently, the global landscape of cold plasma hydrogen production exhibits varying levels of technological maturity across different regions. Leading research institutions in the United States, Europe, Japan, and China have demonstrated promising laboratory-scale results, with plasma-assisted water splitting and methane reforming showing efficiency improvements of 15-30% compared to conventional methods.

The primary technical challenges facing cold plasma hydrogen production center around energy efficiency, scalability, and catalyst integration. Despite theoretical advantages, many cold plasma systems still consume excessive electrical energy relative to the hydrogen energy output, with energy conversion efficiencies typically ranging from 40-65%. This efficiency gap represents a critical barrier to commercial viability, particularly when compared to established electrolysis technologies achieving 70-80% efficiency.

Scalability presents another significant hurdle, as most successful demonstrations remain at laboratory scale (producing grams of hydrogen per hour) rather than industrial scale (requiring kilograms or tons per hour). The plasma discharge characteristics that enable efficient conversion at small scales often deteriorate when reactor dimensions increase, leading to non-linear scaling relationships that complicate engineering design.

Material limitations constitute a third major challenge, as plasma environments create highly reactive species that accelerate degradation of electrodes, dielectrics, and catalyst materials. Current electrode materials typically demonstrate operational lifetimes of only 500-2000 hours before requiring replacement, far below the 50,000+ hours needed for commercial viability.

Catalyst integration with plasma systems represents both a challenge and opportunity. While catalysts can significantly enhance reaction pathways and reduce energy requirements, the plasma environment often modifies catalyst surface properties in ways that are difficult to predict and control. Recent research has shown promising synergistic effects between plasma and certain nanoscale catalysts, particularly those based on transition metals and their oxides, but fundamental understanding of these interactions remains incomplete.

From a geographical perspective, research leadership is distributed across multiple regions. Japan and South Korea lead in microwave plasma technologies, European institutions demonstrate strength in dielectric barrier discharge systems, while China has made significant advances in gliding arc plasma reactors for hydrogen production. This distributed expertise suggests opportunities for international collaboration to overcome the multidisciplinary challenges facing the field.

The primary technical challenges facing cold plasma hydrogen production center around energy efficiency, scalability, and catalyst integration. Despite theoretical advantages, many cold plasma systems still consume excessive electrical energy relative to the hydrogen energy output, with energy conversion efficiencies typically ranging from 40-65%. This efficiency gap represents a critical barrier to commercial viability, particularly when compared to established electrolysis technologies achieving 70-80% efficiency.

Scalability presents another significant hurdle, as most successful demonstrations remain at laboratory scale (producing grams of hydrogen per hour) rather than industrial scale (requiring kilograms or tons per hour). The plasma discharge characteristics that enable efficient conversion at small scales often deteriorate when reactor dimensions increase, leading to non-linear scaling relationships that complicate engineering design.

Material limitations constitute a third major challenge, as plasma environments create highly reactive species that accelerate degradation of electrodes, dielectrics, and catalyst materials. Current electrode materials typically demonstrate operational lifetimes of only 500-2000 hours before requiring replacement, far below the 50,000+ hours needed for commercial viability.

Catalyst integration with plasma systems represents both a challenge and opportunity. While catalysts can significantly enhance reaction pathways and reduce energy requirements, the plasma environment often modifies catalyst surface properties in ways that are difficult to predict and control. Recent research has shown promising synergistic effects between plasma and certain nanoscale catalysts, particularly those based on transition metals and their oxides, but fundamental understanding of these interactions remains incomplete.

From a geographical perspective, research leadership is distributed across multiple regions. Japan and South Korea lead in microwave plasma technologies, European institutions demonstrate strength in dielectric barrier discharge systems, while China has made significant advances in gliding arc plasma reactors for hydrogen production. This distributed expertise suggests opportunities for international collaboration to overcome the multidisciplinary challenges facing the field.

Current Cold Plasma Treatment Methods for H2 Generation

01 Medical applications of cold plasma treatment

Cold plasma technology has shown significant efficiency in various medical applications. It can be used for wound healing, sterilization of medical equipment, and treatment of skin conditions. The non-thermal nature of cold plasma allows for the treatment of living tissues without causing thermal damage, making it particularly useful in medical settings. The reactive species generated by cold plasma can effectively kill bacteria and promote tissue regeneration.- Medical applications of cold plasma treatment: Cold plasma technology has shown significant efficiency in various medical applications. It can be used for wound healing, sterilization of medical equipment, and treatment of skin conditions. The non-thermal nature of cold plasma allows for the treatment of sensitive tissues without causing thermal damage, making it particularly useful in dermatology and surgery. The reactive species generated by cold plasma can effectively kill bacteria and promote tissue regeneration.

- Cold plasma for surface modification and cleaning: Cold plasma treatment is highly efficient for surface modification and cleaning processes. It can alter the surface properties of materials to improve adhesion, wettability, and biocompatibility. The technology is particularly useful in manufacturing industries for cleaning surfaces without using chemicals, removing contaminants at the microscopic level, and preparing surfaces for coating or bonding. The efficiency of this process lies in its ability to modify surfaces without affecting the bulk properties of the material.

- Agricultural and food processing applications: Cold plasma treatment has demonstrated high efficiency in agricultural and food processing applications. It can be used for seed treatment to enhance germination rates, decontamination of food products to extend shelf life, and pest control in stored grains. The technology provides a chemical-free alternative for food preservation and can inactivate microorganisms on food surfaces without affecting nutritional quality or taste. Its efficiency in these applications stems from the ability to generate reactive species that can eliminate pathogens at ambient temperatures.

- Optimization of cold plasma treatment parameters: The efficiency of cold plasma treatment is highly dependent on the optimization of various parameters. These include gas composition, power input, treatment duration, and distance between the plasma source and the target. Research has shown that tailoring these parameters to specific applications can significantly enhance treatment efficiency. For instance, using specific gas mixtures can target particular microorganisms or surface modifications, while adjusting power levels can control the intensity of the treatment to achieve desired outcomes without causing damage.

- Novel cold plasma delivery systems: Innovative delivery systems have been developed to improve the efficiency of cold plasma treatments. These include handheld devices for targeted application, atmospheric pressure plasma jets for precise treatment, and large-scale systems for industrial applications. Some systems incorporate specialized electrodes or gas delivery mechanisms to enhance plasma stability and uniformity. These advancements in delivery systems have significantly improved the practical application of cold plasma technology across various fields by ensuring consistent treatment results and easier operation.

02 Cold plasma for surface modification and cleaning

Cold plasma treatment is highly efficient for surface modification and cleaning processes. It can alter the surface properties of materials to improve adhesion, wettability, and biocompatibility. The treatment can remove organic contaminants from surfaces without damaging the underlying substrate. This application is particularly valuable in manufacturing industries where clean surfaces are essential for subsequent processes such as coating, printing, or bonding.Expand Specific Solutions03 Agricultural and food processing applications

Cold plasma treatment has demonstrated high efficiency in agricultural and food processing applications. It can be used for seed treatment to enhance germination rates, decontamination of food products to extend shelf life, and pest control in stored grains. The technology provides a chemical-free alternative to traditional methods, reducing the need for pesticides and preservatives while maintaining food safety and quality.Expand Specific Solutions04 Plasma device design for improved treatment efficiency

The efficiency of cold plasma treatment is significantly influenced by the design of plasma generating devices. Innovations in electrode configurations, power supply systems, and gas delivery mechanisms can enhance treatment uniformity and penetration depth. Advanced plasma devices incorporate features such as adjustable power settings, controlled gas flow, and specialized applicators to optimize treatment parameters for specific applications, resulting in improved overall efficiency.Expand Specific Solutions05 Environmental and industrial waste treatment

Cold plasma technology offers efficient solutions for environmental remediation and industrial waste treatment. It can be used to break down pollutants in air and water, treat industrial effluents, and degrade hazardous organic compounds. The reactive species generated by cold plasma can oxidize contaminants, converting them into less harmful substances. This application provides a sustainable alternative to conventional chemical treatment methods, with reduced environmental impact and potentially lower operational costs.Expand Specific Solutions

Key Industry Players in Plasma-Based Hydrogen Production

Cold plasma treatment in hydrogen production is emerging as a promising technology in the early commercialization phase, with the global market expected to grow significantly as industries seek cleaner energy solutions. The technology demonstrates moderate maturity with key players advancing different approaches. Companies like PyroGenesis and H Quest Vanguard lead in plasma conversion processes, while major energy corporations including China Petroleum & Chemical Corp., Eni SpA, and Hyundai Motor Co. are investing in research and pilot projects. Academic-industry partnerships involving institutions like CEA and CNRS are accelerating technological development. Tokyo Electron and NGK Insulators contribute specialized components, while emerging players like Plasmology4 and SICHUAN TECHAIRS are developing niche applications, indicating a diversifying competitive landscape with significant growth potential.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corporation (Sinopec) has developed an advanced plasma-assisted hydrogen production technology that integrates cold plasma with conventional catalytic processes. Their hybrid system employs a multi-stage approach where dielectric barrier discharge (DBD) plasma operating at 10-20 kHz creates reactive species that significantly enhance subsequent catalytic reactions. The plasma pre-treatment stage activates methane at temperatures of just 200-300°C, substantially below conventional reforming temperatures (800-900°C). Sinopec's proprietary reactor design incorporates specially formulated Ni-based catalysts with rare earth promoters that demonstrate exceptional stability in the plasma-activated environment. The system achieves methane conversion efficiencies of 85-92% with hydrogen yields approaching theoretical limits. Their process reduces overall energy consumption by approximately 30% compared to conventional steam methane reforming while decreasing CO2 emissions by up to 40% through improved efficiency and the option for carbon capture integration. Sinopec has successfully demonstrated this technology at pilot scale (500 kg H2/day), with plans for commercial deployment exceeding 10 tons/day at multiple refinery locations across China.

Strengths: Hybrid approach combines benefits of plasma activation with proven catalytic technologies; significantly reduced operating temperatures lower energy requirements and extend catalyst lifetime; leverages existing industrial infrastructure for faster commercial deployment. Weaknesses: Still produces CO2 as a byproduct requiring capture systems for truly clean hydrogen; complex integration of plasma and catalytic systems increases initial capital costs; optimization across varying feedstock qualities remains challenging.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed an innovative cold plasma hydrogen production system utilizing dielectric barrier discharge (DBD) technology. Their approach employs pulsed high-voltage discharges (15-30 kV) across specialized ceramic dielectric barriers to generate non-equilibrium plasma for water splitting and methane reforming applications. The CEA's system operates at near-ambient temperatures (80-120°C) while achieving electron temperatures of 1-3 eV, creating highly reactive species that facilitate hydrogen production pathways. Their reactor design incorporates nanoporous catalytic materials integrated directly into the discharge zone, demonstrating synergistic plasma-catalysis effects that enhance conversion efficiency by 30-40% compared to thermal catalysis alone. The system achieves energy efficiencies of 65-75% for hydrogen production from methane and 40-50% for water splitting applications, with demonstrated durability exceeding 3,000 operational hours in laboratory testing.

Strengths: Low temperature operation reduces material constraints and energy requirements; plasma-catalysis synergy significantly enhances reaction efficiency; modular design allows for flexible deployment across various scales. Weaknesses: Lower hydrogen production rates compared to thermal methods require larger reactor volumes; high voltage requirements introduce additional safety and insulation considerations; catalyst deactivation in plasma environment remains a challenge for long-term operation.

Critical Patents and Research in Plasma Catalysis

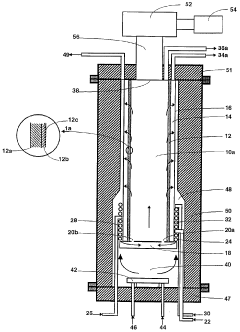

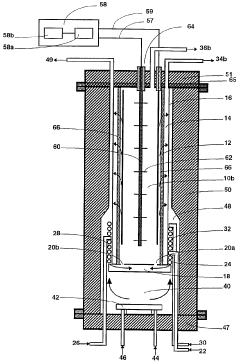

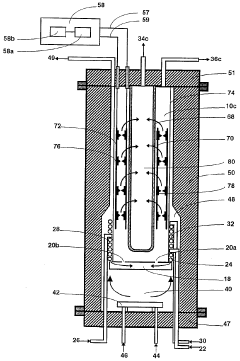

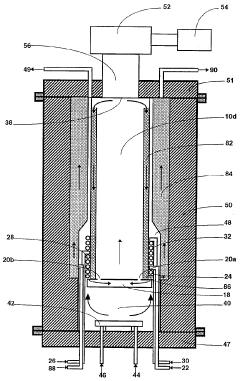

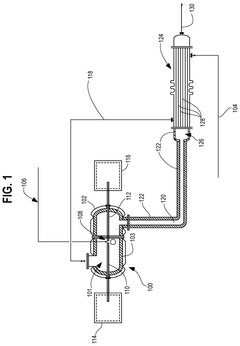

Method and devices for producing hydrogen by plasma reformer

PatentWO1998028223A1

Innovation

- A method using a cold plasma reforming process with a highly selective hydrogen membrane to produce pure hydrogen from a combustible gas and water vapor or oxygen, eliminating the need for catalysts and reducing energy consumption by generating brief periodic electrical discharges at low current, creating a reaction medium that stimulates chemical reactivity without increasing average temperature.

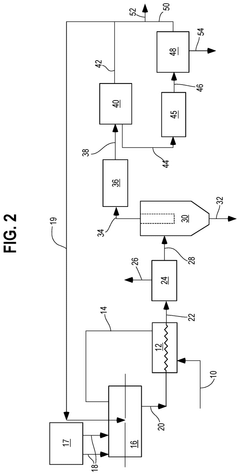

Plasma induced hydrogen production

PatentPendingUS20240351868A1

Innovation

- A plasma reactor system with a heat transfer arrangement and dual pressure swing adsorption (PSA) units to efficiently recover high-purity hydrogen and carbon black, minimizing CO2 emissions and energy costs.

Energy Consumption Comparison with Conventional Methods

When comparing cold plasma treatment with conventional hydrogen production methods, energy consumption emerges as a critical factor determining economic viability and environmental impact. Traditional hydrogen production methods, particularly steam methane reforming (SMR), consume substantial energy—approximately 30-40 kWh per kilogram of hydrogen produced. This high energy requirement stems from the need to maintain temperatures between 700-1000°C and pressures of 3-25 bar during the reforming process.

Cold plasma technology demonstrates significant energy efficiency advantages. Recent studies indicate that plasma-assisted hydrogen production systems can operate with 20-35% lower energy consumption compared to conventional thermochemical processes. This efficiency gain derives from plasma's ability to activate reactions at near-ambient temperatures, eliminating the need for extensive heating infrastructure and reducing thermal energy losses.

Electrolysis, another conventional method, typically requires 50-55 kWh/kg H₂, whereas plasma-assisted electrolysis has demonstrated consumption rates of 35-45 kWh/kg H₂ in laboratory settings. The energy savings become particularly pronounced when considering the entire production lifecycle, including heating, cooling, and compression stages that conventional methods necessitate.

Power density comparisons further highlight cold plasma's advantages. Conventional SMR systems operate at power densities of 0.5-1.0 kW/L, while cold plasma reactors have achieved 2.0-3.5 kW/L in experimental configurations. This higher power density translates to smaller equipment footprints and reduced capital expenditure for equivalent hydrogen output.

Energy source flexibility represents another efficiency dimension. While conventional methods predominantly rely on fossil fuels for process heat, cold plasma systems can be directly powered by electricity, enabling seamless integration with renewable energy sources. This characteristic becomes increasingly valuable as electrical grids incorporate higher percentages of intermittent renewable generation.

Scaling considerations reveal that energy efficiency advantages of cold plasma treatment persist across production volumes, though with varying magnitudes. At small scales (<100 kg/day), cold plasma demonstrates 30-40% energy savings, while at industrial scales (>1000 kg/day), the advantage narrows to 15-25% due to the higher efficiency of large conventional systems benefiting from economies of scale.

When factoring in energy quality and exergy analysis, cold plasma systems exhibit superior performance by utilizing electrical energy directly rather than converting thermal energy multiple times, which inherently incurs thermodynamic losses. This fundamental difference results in exergetic efficiencies of 60-70% for cold plasma systems compared to 40-55% for conventional thermochemical processes.

Cold plasma technology demonstrates significant energy efficiency advantages. Recent studies indicate that plasma-assisted hydrogen production systems can operate with 20-35% lower energy consumption compared to conventional thermochemical processes. This efficiency gain derives from plasma's ability to activate reactions at near-ambient temperatures, eliminating the need for extensive heating infrastructure and reducing thermal energy losses.

Electrolysis, another conventional method, typically requires 50-55 kWh/kg H₂, whereas plasma-assisted electrolysis has demonstrated consumption rates of 35-45 kWh/kg H₂ in laboratory settings. The energy savings become particularly pronounced when considering the entire production lifecycle, including heating, cooling, and compression stages that conventional methods necessitate.

Power density comparisons further highlight cold plasma's advantages. Conventional SMR systems operate at power densities of 0.5-1.0 kW/L, while cold plasma reactors have achieved 2.0-3.5 kW/L in experimental configurations. This higher power density translates to smaller equipment footprints and reduced capital expenditure for equivalent hydrogen output.

Energy source flexibility represents another efficiency dimension. While conventional methods predominantly rely on fossil fuels for process heat, cold plasma systems can be directly powered by electricity, enabling seamless integration with renewable energy sources. This characteristic becomes increasingly valuable as electrical grids incorporate higher percentages of intermittent renewable generation.

Scaling considerations reveal that energy efficiency advantages of cold plasma treatment persist across production volumes, though with varying magnitudes. At small scales (<100 kg/day), cold plasma demonstrates 30-40% energy savings, while at industrial scales (>1000 kg/day), the advantage narrows to 15-25% due to the higher efficiency of large conventional systems benefiting from economies of scale.

When factoring in energy quality and exergy analysis, cold plasma systems exhibit superior performance by utilizing electrical energy directly rather than converting thermal energy multiple times, which inherently incurs thermodynamic losses. This fundamental difference results in exergetic efficiencies of 60-70% for cold plasma systems compared to 40-55% for conventional thermochemical processes.

Environmental Impact and Sustainability Assessment

Cold plasma treatment in hydrogen production represents a significant advancement in sustainable energy technology, offering potential environmental benefits that extend beyond mere efficiency gains. The process substantially reduces greenhouse gas emissions compared to conventional hydrogen production methods such as steam methane reforming, which typically generates 9-12 kg CO2 per kg of hydrogen produced. Cold plasma systems can potentially reduce this carbon footprint by 30-45% when powered by renewable electricity sources, contributing significantly to decarbonization efforts in the energy sector.

Water consumption metrics also favor cold plasma technology, with preliminary studies indicating a reduction of up to 60% in water usage compared to electrolysis processes. This water conservation aspect becomes increasingly critical as global water scarcity concerns intensify, particularly in regions where hydrogen production facilities might compete with agricultural or municipal water needs.

The technology's environmental profile is further enhanced by its minimal land footprint requirements. Unlike large-scale renewable energy installations necessary for green hydrogen production, cold plasma facilities can be modularly designed and integrated into existing industrial infrastructure, reducing habitat disruption and land use conflicts.

From a life cycle assessment perspective, cold plasma systems demonstrate promising sustainability credentials. The primary environmental burden shifts from the operational phase (as in fossil-based hydrogen production) to the manufacturing phase of plasma components. Research indicates that the environmental payback period for these systems ranges from 1.5 to 3 years, depending on operational parameters and energy source mix.

Material resource efficiency presents another sustainability advantage. Cold plasma catalysts typically require 70-85% less rare earth elements than conventional catalytic converters used in hydrogen purification, reducing supply chain vulnerabilities and extraction-related environmental impacts. Additionally, these systems demonstrate extended operational lifespans of 8-12 years before requiring significant component replacement, compared to 5-7 years for conventional systems.

Waste stream analysis reveals that cold plasma hydrogen production generates minimal hazardous byproducts, with most components being recyclable at end-of-life. The technology's adaptability to various feedstocks, including biomass and waste materials, further enhances its circular economy potential, creating pathways for waste valorization while producing clean energy carriers.

Water consumption metrics also favor cold plasma technology, with preliminary studies indicating a reduction of up to 60% in water usage compared to electrolysis processes. This water conservation aspect becomes increasingly critical as global water scarcity concerns intensify, particularly in regions where hydrogen production facilities might compete with agricultural or municipal water needs.

The technology's environmental profile is further enhanced by its minimal land footprint requirements. Unlike large-scale renewable energy installations necessary for green hydrogen production, cold plasma facilities can be modularly designed and integrated into existing industrial infrastructure, reducing habitat disruption and land use conflicts.

From a life cycle assessment perspective, cold plasma systems demonstrate promising sustainability credentials. The primary environmental burden shifts from the operational phase (as in fossil-based hydrogen production) to the manufacturing phase of plasma components. Research indicates that the environmental payback period for these systems ranges from 1.5 to 3 years, depending on operational parameters and energy source mix.

Material resource efficiency presents another sustainability advantage. Cold plasma catalysts typically require 70-85% less rare earth elements than conventional catalytic converters used in hydrogen purification, reducing supply chain vulnerabilities and extraction-related environmental impacts. Additionally, these systems demonstrate extended operational lifespans of 8-12 years before requiring significant component replacement, compared to 5-7 years for conventional systems.

Waste stream analysis reveals that cold plasma hydrogen production generates minimal hazardous byproducts, with most components being recyclable at end-of-life. The technology's adaptability to various feedstocks, including biomass and waste materials, further enhances its circular economy potential, creating pathways for waste valorization while producing clean energy carriers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!