How Does Cold Plasma Treatment Alter Nanoscale Surface Textures?

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology, also known as non-thermal plasma or low-temperature plasma, has evolved significantly over the past several decades from a niche scientific curiosity to a versatile industrial tool. This technology operates by creating a partially ionized gas containing reactive species, electrons, ions, and UV photons while maintaining temperatures close to ambient conditions, making it suitable for treating heat-sensitive materials including polymers, textiles, and biological tissues.

The evolution of cold plasma technology began in the 1970s with basic research applications, progressing through the 1990s when semiconductor manufacturing adopted plasma etching processes. The early 2000s marked a turning point with the development of atmospheric pressure plasma systems that eliminated the need for vacuum chambers, dramatically reducing operational costs and expanding potential applications across industries.

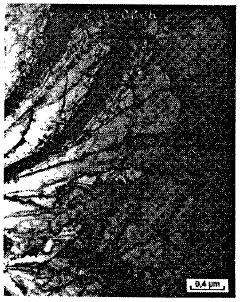

Recent technological advancements have focused on precise control of plasma parameters, enabling targeted surface modifications at the nanoscale level. Modern cold plasma systems can selectively alter surface properties without affecting bulk material characteristics, creating unprecedented opportunities for nanoscale engineering of surfaces. This capability has revolutionized fields ranging from biomedical implants to advanced electronics manufacturing.

The primary objective of cold plasma treatment for nanoscale surface texturing is to achieve controlled modification of surface topography and chemistry at the 1-100 nm scale. This includes creating specific surface roughness patterns, introducing functional groups, and developing hierarchical surface structures that can dramatically alter material properties such as wettability, adhesion, and biocompatibility.

Current research aims to establish quantitative relationships between plasma treatment parameters (power density, treatment time, gas composition, pressure) and resulting nanoscale surface modifications. Understanding these relationships is crucial for developing predictable, reproducible processes that can be scaled for industrial applications while maintaining nanometer-level precision.

Another key objective is to develop in-situ monitoring techniques that allow real-time observation and control of nanoscale surface changes during plasma treatment. This represents a significant challenge due to the dynamic nature of plasma-surface interactions and the microscopic scale at which these changes occur.

Looking forward, the field is moving toward multi-functional surface engineering, where cold plasma treatments are designed to simultaneously impart multiple desired properties to surfaces through precisely controlled nanoscale texturing. The ultimate goal is to develop comprehensive models that can predict plasma-surface interactions across different material systems, enabling design-driven approaches to nanoscale surface engineering rather than empirical trial-and-error methodologies.

The evolution of cold plasma technology began in the 1970s with basic research applications, progressing through the 1990s when semiconductor manufacturing adopted plasma etching processes. The early 2000s marked a turning point with the development of atmospheric pressure plasma systems that eliminated the need for vacuum chambers, dramatically reducing operational costs and expanding potential applications across industries.

Recent technological advancements have focused on precise control of plasma parameters, enabling targeted surface modifications at the nanoscale level. Modern cold plasma systems can selectively alter surface properties without affecting bulk material characteristics, creating unprecedented opportunities for nanoscale engineering of surfaces. This capability has revolutionized fields ranging from biomedical implants to advanced electronics manufacturing.

The primary objective of cold plasma treatment for nanoscale surface texturing is to achieve controlled modification of surface topography and chemistry at the 1-100 nm scale. This includes creating specific surface roughness patterns, introducing functional groups, and developing hierarchical surface structures that can dramatically alter material properties such as wettability, adhesion, and biocompatibility.

Current research aims to establish quantitative relationships between plasma treatment parameters (power density, treatment time, gas composition, pressure) and resulting nanoscale surface modifications. Understanding these relationships is crucial for developing predictable, reproducible processes that can be scaled for industrial applications while maintaining nanometer-level precision.

Another key objective is to develop in-situ monitoring techniques that allow real-time observation and control of nanoscale surface changes during plasma treatment. This represents a significant challenge due to the dynamic nature of plasma-surface interactions and the microscopic scale at which these changes occur.

Looking forward, the field is moving toward multi-functional surface engineering, where cold plasma treatments are designed to simultaneously impart multiple desired properties to surfaces through precisely controlled nanoscale texturing. The ultimate goal is to develop comprehensive models that can predict plasma-surface interactions across different material systems, enabling design-driven approaches to nanoscale surface engineering rather than empirical trial-and-error methodologies.

Market Applications for Plasma-Modified Surfaces

Cold plasma surface modification technology has revolutionized numerous industries by enabling precise control over material surface properties at the nanoscale. The market applications for plasma-modified surfaces span across diverse sectors, with healthcare and biomedical industries representing significant adoption areas. Plasma-treated medical implants demonstrate enhanced biocompatibility, reduced infection risks, and improved tissue integration. The global medical implant market, heavily influenced by plasma surface technologies, continues to expand as aging populations drive demand for orthopedic, dental, and cardiovascular implants with optimized surface characteristics.

The electronics industry represents another major application domain, where plasma-modified surfaces enable critical advancements in semiconductor manufacturing, printed circuit boards, and display technologies. Plasma treatments create precisely controlled hydrophilic or hydrophobic surfaces essential for miniaturization trends in consumer electronics. These treatments facilitate improved adhesion properties for subsequent manufacturing processes while enhancing product durability and performance characteristics.

Automotive and aerospace sectors utilize plasma-modified surfaces to address challenges in lightweight material integration, coating adhesion, and fuel efficiency. Plasma treatments enable effective bonding between dissimilar materials in composite structures while providing enhanced corrosion resistance and wear properties. The growing emphasis on fuel efficiency and emissions reduction has accelerated adoption of plasma surface technologies for reducing friction coefficients and improving aerodynamic properties.

The packaging industry has embraced plasma surface modification to enhance printability, sealability, and barrier properties of polymeric materials. Food packaging applications benefit particularly from antimicrobial plasma treatments that extend shelf life without chemical additives. The technology enables sustainable packaging solutions by improving recyclability and reducing material requirements through enhanced functional properties.

Textile and consumer goods manufacturers increasingly implement plasma treatments to create functional fabrics with water-repellent, oil-resistant, or antimicrobial properties. The ability to modify surface characteristics without altering bulk material properties allows manufacturers to develop premium products with enhanced performance characteristics while maintaining cost-effectiveness in production processes.

Emerging applications include environmental technologies where plasma-modified surfaces facilitate advanced filtration systems, catalytic converters, and energy storage solutions. The renewable energy sector utilizes plasma treatments to enhance solar panel efficiency through optimized light absorption and self-cleaning properties. Water treatment applications benefit from plasma-modified membranes with tailored selectivity and fouling resistance characteristics.

The market trajectory for plasma-modified surfaces continues to expand as industries recognize the competitive advantages offered by nanoscale surface engineering. The technology's versatility, relatively low environmental impact, and ability to create unique surface properties without chemical waste position it as a sustainable manufacturing approach aligned with global trends toward greener production methods.

The electronics industry represents another major application domain, where plasma-modified surfaces enable critical advancements in semiconductor manufacturing, printed circuit boards, and display technologies. Plasma treatments create precisely controlled hydrophilic or hydrophobic surfaces essential for miniaturization trends in consumer electronics. These treatments facilitate improved adhesion properties for subsequent manufacturing processes while enhancing product durability and performance characteristics.

Automotive and aerospace sectors utilize plasma-modified surfaces to address challenges in lightweight material integration, coating adhesion, and fuel efficiency. Plasma treatments enable effective bonding between dissimilar materials in composite structures while providing enhanced corrosion resistance and wear properties. The growing emphasis on fuel efficiency and emissions reduction has accelerated adoption of plasma surface technologies for reducing friction coefficients and improving aerodynamic properties.

The packaging industry has embraced plasma surface modification to enhance printability, sealability, and barrier properties of polymeric materials. Food packaging applications benefit particularly from antimicrobial plasma treatments that extend shelf life without chemical additives. The technology enables sustainable packaging solutions by improving recyclability and reducing material requirements through enhanced functional properties.

Textile and consumer goods manufacturers increasingly implement plasma treatments to create functional fabrics with water-repellent, oil-resistant, or antimicrobial properties. The ability to modify surface characteristics without altering bulk material properties allows manufacturers to develop premium products with enhanced performance characteristics while maintaining cost-effectiveness in production processes.

Emerging applications include environmental technologies where plasma-modified surfaces facilitate advanced filtration systems, catalytic converters, and energy storage solutions. The renewable energy sector utilizes plasma treatments to enhance solar panel efficiency through optimized light absorption and self-cleaning properties. Water treatment applications benefit from plasma-modified membranes with tailored selectivity and fouling resistance characteristics.

The market trajectory for plasma-modified surfaces continues to expand as industries recognize the competitive advantages offered by nanoscale surface engineering. The technology's versatility, relatively low environmental impact, and ability to create unique surface properties without chemical waste position it as a sustainable manufacturing approach aligned with global trends toward greener production methods.

Current Challenges in Nanoscale Surface Modification

Despite significant advancements in nanoscale surface modification techniques, several critical challenges persist in the field, particularly when examining cold plasma treatment effects on nanoscale surface textures. The primary technical obstacle remains achieving precise control over plasma parameters to produce consistent and reproducible surface modifications. Researchers continue to struggle with maintaining uniform plasma density across larger substrate areas, resulting in heterogeneous surface textures that compromise functional performance in advanced applications.

The complex plasma-surface interactions present another formidable challenge. The mechanisms by which cold plasma alters nanoscale surface textures involve multiple simultaneous processes including ion bombardment, radical reactions, and thermal effects. These interactions are highly dependent on substrate material properties, making it difficult to develop universal treatment protocols across different material systems. Furthermore, the transient nature of plasma species complicates real-time monitoring and control of the modification process.

Scale-up challenges represent a significant barrier to industrial implementation. Laboratory-scale plasma systems often demonstrate excellent results that become difficult to replicate in industrial settings where larger surface areas require treatment. The physics of plasma generation and containment fundamentally changes at larger scales, creating new technical hurdles for maintaining nanoscale precision across production-scale components.

Characterization limitations further impede progress in this field. Current analytical techniques often provide incomplete information about plasma-modified surfaces, particularly regarding the three-dimensional aspects of nanoscale textures. The dynamic nature of plasma-treated surfaces, which may continue evolving post-treatment due to relaxation phenomena or environmental interactions, requires advanced in-situ characterization methods that are still under development.

Energy efficiency and environmental considerations pose additional challenges. Many plasma systems require significant power input and sometimes utilize environmentally problematic process gases. Developing more sustainable approaches while maintaining treatment effectiveness represents an ongoing technical dilemma for researchers and engineers in this field.

Interdisciplinary knowledge gaps also hinder advancement. The field requires expertise spanning plasma physics, materials science, surface chemistry, and application-specific engineering. This multidisciplinary nature creates communication barriers and knowledge silos that slow innovation and practical implementation of new techniques for controlling nanoscale surface textures through cold plasma treatment.

The complex plasma-surface interactions present another formidable challenge. The mechanisms by which cold plasma alters nanoscale surface textures involve multiple simultaneous processes including ion bombardment, radical reactions, and thermal effects. These interactions are highly dependent on substrate material properties, making it difficult to develop universal treatment protocols across different material systems. Furthermore, the transient nature of plasma species complicates real-time monitoring and control of the modification process.

Scale-up challenges represent a significant barrier to industrial implementation. Laboratory-scale plasma systems often demonstrate excellent results that become difficult to replicate in industrial settings where larger surface areas require treatment. The physics of plasma generation and containment fundamentally changes at larger scales, creating new technical hurdles for maintaining nanoscale precision across production-scale components.

Characterization limitations further impede progress in this field. Current analytical techniques often provide incomplete information about plasma-modified surfaces, particularly regarding the three-dimensional aspects of nanoscale textures. The dynamic nature of plasma-treated surfaces, which may continue evolving post-treatment due to relaxation phenomena or environmental interactions, requires advanced in-situ characterization methods that are still under development.

Energy efficiency and environmental considerations pose additional challenges. Many plasma systems require significant power input and sometimes utilize environmentally problematic process gases. Developing more sustainable approaches while maintaining treatment effectiveness represents an ongoing technical dilemma for researchers and engineers in this field.

Interdisciplinary knowledge gaps also hinder advancement. The field requires expertise spanning plasma physics, materials science, surface chemistry, and application-specific engineering. This multidisciplinary nature creates communication barriers and knowledge silos that slow innovation and practical implementation of new techniques for controlling nanoscale surface textures through cold plasma treatment.

Established Cold Plasma Surface Modification Methods

01 Cold plasma treatment for surface modification of medical devices

Cold plasma treatment can be used to modify the surface properties of medical devices, such as implants and catheters, to improve biocompatibility and reduce infection risks. The treatment creates specific surface textures that can enhance cell adhesion, promote tissue integration, and prevent bacterial colonization. This technique allows for precise control of surface characteristics without affecting the bulk properties of the materials.- Cold plasma treatment for surface modification of medical devices: Cold plasma treatment can be used to modify the surface properties of medical devices, such as implants and catheters, to enhance biocompatibility, reduce bacterial adhesion, and improve integration with biological tissues. The treatment creates specific surface textures and chemical modifications that can control cell attachment and prevent infections. This technology enables precise surface engineering without affecting the bulk properties of the medical materials.

- Plasma-induced micro and nano texturing for enhanced surface properties: Cold plasma treatments can create controlled micro and nano-scale surface textures that modify the physical and chemical properties of materials. These textured surfaces can exhibit enhanced characteristics such as improved wettability, adhesion, and friction properties. The plasma process parameters can be adjusted to achieve specific texture patterns, depths, and distributions, allowing for customized surface engineering solutions across various industrial applications.

- Cold plasma treatment for biological and medical applications: Cold plasma technology is utilized in various biological and medical applications to create specific surface textures that enhance therapeutic outcomes. The treatment can be applied to create antimicrobial surfaces, improve wound healing, sterilize medical equipment, and modify tissue engineering scaffolds. The non-thermal nature of cold plasma allows for treatment of heat-sensitive biological materials while still achieving the desired surface modifications and texturing effects.

- Industrial applications of plasma-textured surfaces: Cold plasma treatment is employed in various industrial applications to create functional surface textures that enhance product performance. These applications include improving adhesion properties for coatings and bonding, creating self-cleaning surfaces, enhancing wear resistance, and modifying optical properties. The plasma-induced textures can be tailored to specific industrial requirements by controlling treatment parameters such as gas composition, power, and exposure time.

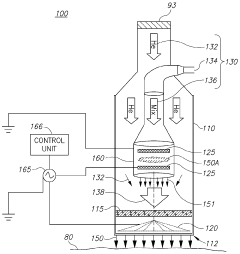

- Advanced plasma technologies for controlled surface texturing: Advanced cold plasma technologies have been developed to achieve precise control over surface texturing processes. These include atmospheric pressure plasma systems, plasma jet arrays, and pulsed plasma treatments that allow for selective modification of surfaces with complex geometries. The technologies enable the creation of gradient textures, patterned surfaces, and localized treatment areas, expanding the possibilities for surface engineering across medical, electronic, and manufacturing industries.

02 Plasma-induced micro and nano texturing for enhanced material properties

Cold plasma treatment can create controlled micro and nano-scale textures on material surfaces, resulting in enhanced physical and chemical properties. These textured surfaces can exhibit improved wettability, adhesion, and friction characteristics. The process parameters, such as plasma power, treatment time, and gas composition, can be adjusted to achieve specific surface morphologies tailored for different applications.Expand Specific Solutions03 Cold plasma surface treatment for biomedical applications

Cold plasma treatment creates bioactive surface textures on medical implants and devices that can promote cell growth, enhance tissue integration, and reduce inflammatory responses. The modified surfaces can be designed to have antimicrobial properties, preventing biofilm formation and reducing infection risks. This technology is particularly valuable for orthopedic implants, dental materials, and tissue engineering scaffolds.Expand Specific Solutions04 Plasma treatment for surface texturing of polymers and composites

Cold plasma technology can be used to create specific surface textures on polymers and composite materials, improving their adhesion properties, printability, and coating performance. The treatment modifies the surface chemistry and topography without affecting the bulk properties of the materials. This approach is particularly useful for enhancing the bonding strength in composite structures and improving the performance of polymer-based products.Expand Specific Solutions05 Cold plasma texturing for electronic and semiconductor applications

Cold plasma treatment can create precise surface textures on electronic components and semiconductor materials to enhance their performance. The textured surfaces can improve thermal management, electrical conductivity, and optical properties. This technique allows for nanoscale modification of surfaces with high precision and reproducibility, making it valuable for advanced electronic devices, sensors, and photovoltaic applications.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Cold plasma treatment for nanoscale surface modification is currently in a growth phase, with the market expanding rapidly due to increasing applications in biomedical, electronics, and materials science sectors. The global market size for plasma surface treatment technologies is projected to reach significant value as industries recognize its advantages in enhancing surface properties without altering bulk characteristics. Technologically, the field shows varying maturity levels across applications, with established players like Applied Materials, Lam Research, and Fraunhofer-Gesellschaft leading industrial implementations. Academic institutions including Shanghai Jiao Tong University, Zhejiang University, and Swiss Federal Institute of Technology are advancing fundamental research, while specialized companies such as US Medical Innovations and Nanjing Suman Plasma Technology are developing niche applications. L'Oréal and F. Hoffmann-La Roche represent growing interest from consumer products and pharmaceutical sectors, indicating cross-industry adoption potential.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative cold plasma treatment technologies focused on creating biomimetic nanoscale surface textures. Their research team has pioneered a multi-stage plasma processing approach that combines plasma etching, deposition, and functionalization to create hierarchical surface structures with controlled features at the nano, micro, and macro scales. Their cold plasma systems utilize a unique dual-frequency capacitively coupled plasma (CCP) configuration that allows independent control of ion energy and plasma density, enabling precise manipulation of surface morphology. The university has demonstrated particular expertise in creating superhydrophobic surfaces through plasma-induced nanoscale roughening combined with plasma-deposited fluorocarbon films, achieving water contact angles exceeding 170°. Their research has shown that cold plasma treatments can create nanopillars, nanopores, and nanocones with dimensions as small as 20nm and aspect ratios up to 10:1. Additionally, they have developed plasma-based methods for creating gradient surface properties where nanoscale texture gradually changes across a surface, enabling unique functional behaviors.

Strengths: Strong focus on biomimetic surface designs with exceptional control over wettability properties; innovative approaches to creating gradient and hierarchical surface structures. Weaknesses: Some technologies still at laboratory scale rather than industrial implementation; less emphasis on high-throughput processing compared to commercial entities.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed comprehensive cold plasma treatment technologies for nanoscale surface modification across diverse materials. Their approach combines atmospheric pressure plasma jets (APPJ) with precisely controlled gas chemistry to achieve targeted surface functionalization. Fraunhofer's systems utilize a modular design that allows for customization of plasma parameters including gas composition, power density, and treatment duration to optimize surface modification for specific applications. Their research has demonstrated that cold plasma treatments can create nanoscale surface textures with controlled roughness ranging from 5-200nm while simultaneously introducing specific chemical functional groups. Particularly innovative is their development of spatially selective plasma treatment techniques that can create patterned surface modifications without requiring masks or templates. Fraunhofer has also pioneered plasma polymerization processes that deposit ultra-thin (1-100nm) functional coatings with precisely controlled chemical composition and nanoscale topography.

Strengths: Exceptional versatility across material types including polymers, metals, ceramics, and composites; strong focus on industrial scalability and technology transfer. Weaknesses: Less specialized in high-precision semiconductor applications compared to dedicated semiconductor equipment manufacturers; some technologies still in development phase for commercial implementation.

Key Mechanisms of Plasma-Surface Interactions

Process for incorporating material into the surface of a solid body and altering it, in particular the surface of a material

PatentWO1995029274A1

Innovation

- A method involving a high-energy plasma pulse is directed onto the material surface, melting and rapidly solidifying the surface layer, allowing for the introduction of additives like carbon, which creates metastable phases and a finely crystalline structure, increasing microhardness through non-equilibrium states and rapid solidification processes.

Cold plasma treatment

PatentWO2015059702A1

Innovation

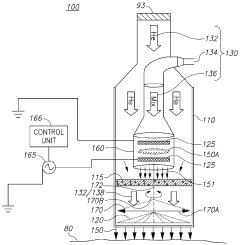

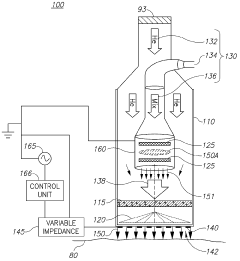

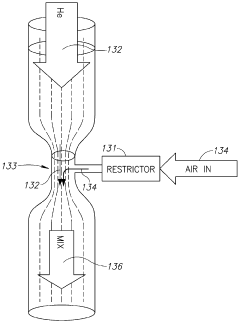

- A plasma treatment device with a nozzle configured to receive a first gas and an auxiliary gas, and at least one electrode applying a radiofrequency electromagnetic field to ionize the gases, emitting plasma uniformly over a large treatment area, using a rotating or vibrating electrode configuration to prevent hot spots and ensure even plasma distribution.

Environmental Impact and Sustainability Considerations

Cold plasma treatment of nanoscale surfaces presents significant environmental and sustainability implications that warrant careful consideration. The process itself offers several environmental advantages compared to traditional surface modification techniques. Notably, cold plasma treatments typically operate at ambient temperatures and pressures, substantially reducing energy consumption compared to thermal or chemical processes that require high temperatures or energy-intensive conditions.

The chemical efficiency of cold plasma represents another environmental benefit. These systems often utilize minimal chemical inputs, primarily relying on gases like oxygen, nitrogen, or argon that have relatively low environmental impacts. This reduction in chemical usage translates to decreased waste generation and fewer hazardous byproducts requiring specialized disposal procedures, thereby minimizing the environmental footprint of manufacturing processes.

From a sustainability perspective, cold plasma treatment enables the development of more durable and functional surfaces. By enhancing properties such as corrosion resistance, wear resistance, and adhesion characteristics, plasma-treated materials typically exhibit extended service lifespans. This longevity directly contributes to resource conservation and waste reduction across various industrial applications.

The technology also supports the principles of green chemistry through its precision and efficiency. Cold plasma treatments can be precisely controlled to modify only the outermost nanometers of a surface without altering bulk material properties. This targeted approach minimizes resource utilization while maximizing functional benefits, aligning with sustainable manufacturing principles.

However, certain environmental challenges remain. The gases used in plasma generation, particularly fluorinated compounds sometimes employed for specific applications, may have significant global warming potential if released. Additionally, the generation of plasma requires electrical energy, which depending on the source, may contribute to carbon emissions and other environmental impacts associated with power generation.

The scalability of cold plasma technologies presents both opportunities and challenges for sustainability. While laboratory-scale systems demonstrate excellent environmental performance, industrial-scale implementation may face efficiency losses and increased resource requirements. Research into optimizing large-scale plasma systems is essential to maintain the environmental benefits observed at smaller scales.

Looking forward, integration of renewable energy sources for plasma generation and development of closed-loop systems that recapture and reuse process gases represent promising avenues for further enhancing the environmental profile of cold plasma surface modification technologies. These advancements could position cold plasma treatment as a cornerstone technology in sustainable manufacturing paradigms.

The chemical efficiency of cold plasma represents another environmental benefit. These systems often utilize minimal chemical inputs, primarily relying on gases like oxygen, nitrogen, or argon that have relatively low environmental impacts. This reduction in chemical usage translates to decreased waste generation and fewer hazardous byproducts requiring specialized disposal procedures, thereby minimizing the environmental footprint of manufacturing processes.

From a sustainability perspective, cold plasma treatment enables the development of more durable and functional surfaces. By enhancing properties such as corrosion resistance, wear resistance, and adhesion characteristics, plasma-treated materials typically exhibit extended service lifespans. This longevity directly contributes to resource conservation and waste reduction across various industrial applications.

The technology also supports the principles of green chemistry through its precision and efficiency. Cold plasma treatments can be precisely controlled to modify only the outermost nanometers of a surface without altering bulk material properties. This targeted approach minimizes resource utilization while maximizing functional benefits, aligning with sustainable manufacturing principles.

However, certain environmental challenges remain. The gases used in plasma generation, particularly fluorinated compounds sometimes employed for specific applications, may have significant global warming potential if released. Additionally, the generation of plasma requires electrical energy, which depending on the source, may contribute to carbon emissions and other environmental impacts associated with power generation.

The scalability of cold plasma technologies presents both opportunities and challenges for sustainability. While laboratory-scale systems demonstrate excellent environmental performance, industrial-scale implementation may face efficiency losses and increased resource requirements. Research into optimizing large-scale plasma systems is essential to maintain the environmental benefits observed at smaller scales.

Looking forward, integration of renewable energy sources for plasma generation and development of closed-loop systems that recapture and reuse process gases represent promising avenues for further enhancing the environmental profile of cold plasma surface modification technologies. These advancements could position cold plasma treatment as a cornerstone technology in sustainable manufacturing paradigms.

Scalability and Industrial Implementation Challenges

The scaling of cold plasma treatment from laboratory to industrial applications presents significant challenges that must be addressed for widespread commercial adoption. Current laboratory-scale plasma systems typically process small samples under highly controlled conditions, while industrial implementation requires treatment of large surface areas with consistent results. The throughput limitations of existing plasma systems represent a primary bottleneck, as most configurations can only treat limited surface areas simultaneously, making them impractical for high-volume manufacturing environments.

Energy consumption poses another critical challenge for industrial scaling. Cold plasma processes require substantial power input to generate and maintain plasma states, particularly when treating larger surface areas. This energy requirement directly impacts operational costs and environmental footprint, potentially offsetting some of the sustainability benefits that plasma treatments offer compared to conventional chemical processes.

Process uniformity becomes increasingly difficult to maintain as treatment areas expand. Industrial applications demand consistent nanoscale surface modifications across entire components or continuous production lines. Variations in plasma density, gas flow dynamics, and electric field distribution can lead to non-uniform treatment results, compromising product quality and performance reliability. These uniformity challenges are particularly pronounced when treating complex three-dimensional geometries or textured surfaces.

Integration with existing manufacturing lines presents additional implementation hurdles. Cold plasma systems must be compatible with current production workflows, including handling systems, quality control processes, and throughput requirements. Retrofitting plasma treatment stations into established manufacturing environments often requires significant engineering adaptations and process modifications.

Cost considerations ultimately determine commercial viability. The capital expenditure for industrial-scale plasma equipment, combined with operational expenses and potential production line modifications, must be justified by measurable improvements in product performance or manufacturing efficiency. Many potential adopters remain hesitant due to uncertain return on investment calculations, particularly in industries with thin profit margins.

Regulatory compliance and safety standards further complicate industrial implementation. Plasma systems generate electromagnetic fields, potentially hazardous gases, and UV radiation that must be properly contained and monitored in production environments. Meeting workplace safety regulations while maintaining treatment effectiveness requires sophisticated engineering solutions and robust safety protocols.

Energy consumption poses another critical challenge for industrial scaling. Cold plasma processes require substantial power input to generate and maintain plasma states, particularly when treating larger surface areas. This energy requirement directly impacts operational costs and environmental footprint, potentially offsetting some of the sustainability benefits that plasma treatments offer compared to conventional chemical processes.

Process uniformity becomes increasingly difficult to maintain as treatment areas expand. Industrial applications demand consistent nanoscale surface modifications across entire components or continuous production lines. Variations in plasma density, gas flow dynamics, and electric field distribution can lead to non-uniform treatment results, compromising product quality and performance reliability. These uniformity challenges are particularly pronounced when treating complex three-dimensional geometries or textured surfaces.

Integration with existing manufacturing lines presents additional implementation hurdles. Cold plasma systems must be compatible with current production workflows, including handling systems, quality control processes, and throughput requirements. Retrofitting plasma treatment stations into established manufacturing environments often requires significant engineering adaptations and process modifications.

Cost considerations ultimately determine commercial viability. The capital expenditure for industrial-scale plasma equipment, combined with operational expenses and potential production line modifications, must be justified by measurable improvements in product performance or manufacturing efficiency. Many potential adopters remain hesitant due to uncertain return on investment calculations, particularly in industries with thin profit margins.

Regulatory compliance and safety standards further complicate industrial implementation. Plasma systems generate electromagnetic fields, potentially hazardous gases, and UV radiation that must be properly contained and monitored in production environments. Meeting workplace safety regulations while maintaining treatment effectiveness requires sophisticated engineering solutions and robust safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!