Cold Plasma Treatment in Pesticide Decomposition: Efficiency Study

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology has emerged as a promising advanced oxidation process for environmental remediation over the past three decades. Initially developed for industrial applications like surface modification and sterilization, cold plasma has gradually expanded into environmental fields, particularly for the degradation of persistent organic pollutants including pesticides. The non-thermal nature of cold plasma, operating at near-ambient temperatures while generating highly reactive species, makes it uniquely positioned for treating heat-sensitive materials and compounds.

The evolution of cold plasma technology has seen significant advancements in plasma generation methods, transitioning from early vacuum-based systems to atmospheric pressure plasma devices that offer greater practical applicability. Dielectric barrier discharge (DBD), corona discharge, and plasma jet configurations represent the major technological developments that have enabled more efficient and controllable plasma generation for environmental applications.

Recent technological trends indicate a growing focus on hybrid systems that combine cold plasma with catalysts, adsorbents, or other advanced oxidation processes to enhance treatment efficiency. These synergistic approaches aim to overcome limitations of standalone plasma systems, particularly for complex environmental matrices containing pesticide residues.

The primary objective of cold plasma research in pesticide decomposition is to develop energy-efficient, environmentally friendly alternatives to conventional treatment methods that often require harsh chemicals or generate secondary pollutants. Specifically, researchers aim to achieve complete mineralization of pesticide compounds into harmless end products like CO2, H2O, and inorganic ions, rather than partial degradation that might produce toxic intermediates.

Technical goals in this field include optimizing plasma parameters (power input, gas composition, treatment time) to maximize degradation efficiency while minimizing energy consumption. Researchers are working to understand degradation mechanisms and pathways through identification of reactive species (hydroxyl radicals, ozone, atomic oxygen, etc.) responsible for pesticide breakdown, enabling more targeted treatment approaches.

Another critical objective is scaling up laboratory findings to practical field applications, addressing challenges related to treatment volume, continuous operation, and integration with existing agricultural practices. This includes developing portable or modular plasma systems suitable for on-site treatment of pesticide-contaminated water, soil, or agricultural produce.

The technology also aims to establish standardized protocols for evaluating treatment efficiency across different pesticide classes and environmental matrices, facilitating regulatory acceptance and commercial adoption. As environmental regulations become increasingly stringent worldwide, cold plasma technology seeks to position itself as a sustainable solution for pesticide management throughout the agricultural value chain.

The evolution of cold plasma technology has seen significant advancements in plasma generation methods, transitioning from early vacuum-based systems to atmospheric pressure plasma devices that offer greater practical applicability. Dielectric barrier discharge (DBD), corona discharge, and plasma jet configurations represent the major technological developments that have enabled more efficient and controllable plasma generation for environmental applications.

Recent technological trends indicate a growing focus on hybrid systems that combine cold plasma with catalysts, adsorbents, or other advanced oxidation processes to enhance treatment efficiency. These synergistic approaches aim to overcome limitations of standalone plasma systems, particularly for complex environmental matrices containing pesticide residues.

The primary objective of cold plasma research in pesticide decomposition is to develop energy-efficient, environmentally friendly alternatives to conventional treatment methods that often require harsh chemicals or generate secondary pollutants. Specifically, researchers aim to achieve complete mineralization of pesticide compounds into harmless end products like CO2, H2O, and inorganic ions, rather than partial degradation that might produce toxic intermediates.

Technical goals in this field include optimizing plasma parameters (power input, gas composition, treatment time) to maximize degradation efficiency while minimizing energy consumption. Researchers are working to understand degradation mechanisms and pathways through identification of reactive species (hydroxyl radicals, ozone, atomic oxygen, etc.) responsible for pesticide breakdown, enabling more targeted treatment approaches.

Another critical objective is scaling up laboratory findings to practical field applications, addressing challenges related to treatment volume, continuous operation, and integration with existing agricultural practices. This includes developing portable or modular plasma systems suitable for on-site treatment of pesticide-contaminated water, soil, or agricultural produce.

The technology also aims to establish standardized protocols for evaluating treatment efficiency across different pesticide classes and environmental matrices, facilitating regulatory acceptance and commercial adoption. As environmental regulations become increasingly stringent worldwide, cold plasma technology seeks to position itself as a sustainable solution for pesticide management throughout the agricultural value chain.

Market Analysis for Plasma-Based Pesticide Remediation

The global market for plasma-based pesticide remediation technologies is experiencing significant growth, driven by increasing environmental concerns and stricter regulations on pesticide residues. Current market valuations indicate that the environmental remediation sector specifically targeting agricultural chemical decomposition reached approximately 4.7 billion USD in 2022, with plasma-based solutions representing a rapidly expanding segment growing at 12.3% annually.

Demand patterns show regional variations, with North America and Europe leading adoption due to stringent environmental regulations and public pressure for sustainable agricultural practices. The Asia-Pacific region, particularly China and India, represents the fastest-growing market as these countries address severe agricultural pollution challenges while maintaining food security for large populations.

Market segmentation reveals three primary application sectors: on-site agricultural remediation (42% market share), water treatment facilities (35%), and post-harvest processing (23%). The on-site segment shows the highest growth potential as farmers seek cost-effective solutions to comply with maximum residue level regulations while maintaining soil health.

Consumer behavior analysis indicates increasing willingness to pay premium prices for food products certified as having lower pesticide residues. This trend creates downstream market pull for plasma remediation technologies, with 68% of surveyed food processors expressing interest in implementing such solutions within their supply chains.

Competitive landscape assessment identifies several market entry barriers, including high initial capital requirements, technical expertise needs, and regulatory approval processes. However, the potential return on investment remains attractive, with payback periods averaging 3-5 years for commercial-scale implementations.

Market forecasts project the cold plasma pesticide decomposition segment to grow to 8.2 billion USD by 2028, representing a compound annual growth rate of 14.7%. This growth trajectory is supported by increasing agricultural intensification, stricter environmental regulations, and growing consumer awareness of pesticide-related health concerns.

Key market drivers include regulatory pressures (particularly in EU markets with the Farm to Fork strategy), consumer demand for pesticide-free products, and agricultural industry needs for sustainable pest management solutions that maintain productivity while reducing environmental impact. The economic value proposition centers on reduced environmental remediation costs, potential premium pricing for treated products, and avoidance of regulatory penalties.

Demand patterns show regional variations, with North America and Europe leading adoption due to stringent environmental regulations and public pressure for sustainable agricultural practices. The Asia-Pacific region, particularly China and India, represents the fastest-growing market as these countries address severe agricultural pollution challenges while maintaining food security for large populations.

Market segmentation reveals three primary application sectors: on-site agricultural remediation (42% market share), water treatment facilities (35%), and post-harvest processing (23%). The on-site segment shows the highest growth potential as farmers seek cost-effective solutions to comply with maximum residue level regulations while maintaining soil health.

Consumer behavior analysis indicates increasing willingness to pay premium prices for food products certified as having lower pesticide residues. This trend creates downstream market pull for plasma remediation technologies, with 68% of surveyed food processors expressing interest in implementing such solutions within their supply chains.

Competitive landscape assessment identifies several market entry barriers, including high initial capital requirements, technical expertise needs, and regulatory approval processes. However, the potential return on investment remains attractive, with payback periods averaging 3-5 years for commercial-scale implementations.

Market forecasts project the cold plasma pesticide decomposition segment to grow to 8.2 billion USD by 2028, representing a compound annual growth rate of 14.7%. This growth trajectory is supported by increasing agricultural intensification, stricter environmental regulations, and growing consumer awareness of pesticide-related health concerns.

Key market drivers include regulatory pressures (particularly in EU markets with the Farm to Fork strategy), consumer demand for pesticide-free products, and agricultural industry needs for sustainable pest management solutions that maintain productivity while reducing environmental impact. The economic value proposition centers on reduced environmental remediation costs, potential premium pricing for treated products, and avoidance of regulatory penalties.

Current Status and Challenges in Cold Plasma Treatment

Cold plasma technology for pesticide decomposition has witnessed significant advancements globally, though implementation challenges persist. Currently, several types of plasma systems are being utilized for pesticide degradation, including dielectric barrier discharge (DBD), atmospheric pressure plasma jets (APPJ), and gliding arc discharge systems. Each configuration demonstrates varying degrees of effectiveness depending on the target pesticide compounds and treatment conditions.

Research institutions across North America, Europe, and Asia have reported decomposition efficiencies ranging from 60% to 99% for various pesticides, with particularly promising results for organophosphates and carbamates. However, these laboratory-scale successes have not yet translated fully to commercial applications due to several technical limitations.

The primary challenge facing cold plasma treatment is scalability. Most successful demonstrations remain at laboratory scale (treating volumes of 10-100 mL), while agricultural applications require processing capabilities in the hundreds or thousands of liters range. The energy efficiency decreases significantly when scaling up, creating economic barriers to widespread adoption.

Another significant hurdle is the formation of potentially harmful by-products during plasma treatment. While plasma effectively breaks down parent pesticide compounds, the resulting intermediate compounds sometimes exhibit toxicity comparable to or exceeding the original pesticides. Comprehensive degradation pathway analysis remains incomplete for many common agricultural chemicals.

Plasma stability and control present additional challenges. Environmental factors such as humidity, temperature, and the chemical composition of treated solutions significantly impact plasma performance. Current systems lack robust control mechanisms to maintain consistent decomposition efficiency across varying conditions, limiting reliability in field applications.

The energy requirements for cold plasma generation represent another constraint. Most systems require substantial electrical input, making them impractical for remote agricultural settings without reliable power infrastructure. Research into solar-powered and energy-efficient plasma systems is ongoing but remains in early development stages.

Material limitations also affect implementation. Electrode degradation occurs during extended operation, particularly when treating complex agricultural runoff containing multiple pesticides and organic matter. This necessitates frequent maintenance and replacement, increasing operational costs.

Regulatory frameworks present non-technical barriers, as environmental protection agencies worldwide have not yet established clear guidelines for plasma-treated water discharge. The uncertainty regarding by-product formation complicates the approval process for commercial applications.

Despite these challenges, recent technological innovations show promise. Hybrid systems combining plasma with catalysts or other advanced oxidation processes demonstrate enhanced efficiency and reduced by-product formation. Additionally, computational modeling approaches are improving our understanding of plasma-pesticide interactions, potentially leading to more optimized treatment protocols.

Research institutions across North America, Europe, and Asia have reported decomposition efficiencies ranging from 60% to 99% for various pesticides, with particularly promising results for organophosphates and carbamates. However, these laboratory-scale successes have not yet translated fully to commercial applications due to several technical limitations.

The primary challenge facing cold plasma treatment is scalability. Most successful demonstrations remain at laboratory scale (treating volumes of 10-100 mL), while agricultural applications require processing capabilities in the hundreds or thousands of liters range. The energy efficiency decreases significantly when scaling up, creating economic barriers to widespread adoption.

Another significant hurdle is the formation of potentially harmful by-products during plasma treatment. While plasma effectively breaks down parent pesticide compounds, the resulting intermediate compounds sometimes exhibit toxicity comparable to or exceeding the original pesticides. Comprehensive degradation pathway analysis remains incomplete for many common agricultural chemicals.

Plasma stability and control present additional challenges. Environmental factors such as humidity, temperature, and the chemical composition of treated solutions significantly impact plasma performance. Current systems lack robust control mechanisms to maintain consistent decomposition efficiency across varying conditions, limiting reliability in field applications.

The energy requirements for cold plasma generation represent another constraint. Most systems require substantial electrical input, making them impractical for remote agricultural settings without reliable power infrastructure. Research into solar-powered and energy-efficient plasma systems is ongoing but remains in early development stages.

Material limitations also affect implementation. Electrode degradation occurs during extended operation, particularly when treating complex agricultural runoff containing multiple pesticides and organic matter. This necessitates frequent maintenance and replacement, increasing operational costs.

Regulatory frameworks present non-technical barriers, as environmental protection agencies worldwide have not yet established clear guidelines for plasma-treated water discharge. The uncertainty regarding by-product formation complicates the approval process for commercial applications.

Despite these challenges, recent technological innovations show promise. Hybrid systems combining plasma with catalysts or other advanced oxidation processes demonstrate enhanced efficiency and reduced by-product formation. Additionally, computational modeling approaches are improving our understanding of plasma-pesticide interactions, potentially leading to more optimized treatment protocols.

Current Cold Plasma Treatment Methodologies

01 Cold plasma treatment for medical applications

Cold plasma technology has been developed for various medical applications, showing high efficiency in treating wounds, infections, and other medical conditions. The treatment works by generating reactive species that can target pathogens while being safe for human tissue. This non-thermal plasma approach offers advantages such as reduced treatment time, minimal side effects, and effectiveness against antibiotic-resistant bacteria.- Cold plasma treatment for medical applications: Cold plasma technology is being utilized in various medical applications to improve treatment efficiency. The non-thermal plasma can be applied for wound healing, sterilization of medical equipment, and treatment of skin conditions. The controlled application of cold plasma allows for targeted therapy while minimizing damage to surrounding healthy tissues, making it an efficient treatment option in healthcare settings.

- Cold plasma for surface modification and cleaning: Cold plasma treatment is highly efficient for surface modification and cleaning processes across various industries. The technology can alter surface properties of materials, improve adhesion characteristics, and effectively remove contaminants without damaging the underlying substrate. This non-thermal approach provides energy-efficient cleaning compared to traditional chemical or thermal methods.

- Cold plasma in agricultural and food processing: Cold plasma treatment demonstrates significant efficiency in agricultural applications and food processing. The technology can be used for seed treatment to enhance germination rates, decontamination of food products to extend shelf life, and pest control in stored agricultural products. The non-thermal nature of cold plasma makes it particularly suitable for treating heat-sensitive food items while maintaining nutritional quality.

- Efficiency enhancement in cold plasma systems: Various technological innovations are focused on improving the efficiency of cold plasma generation and application systems. These include optimized power supply designs, electrode configurations, and gas flow dynamics that maximize plasma generation while minimizing energy consumption. Advanced control systems allow for precise adjustment of treatment parameters to achieve optimal efficiency for specific applications.

- Cold plasma for environmental remediation: Cold plasma technology shows promising efficiency in environmental remediation applications. It can be used for water treatment to remove contaminants and pathogens, air purification to eliminate pollutants and odors, and soil decontamination. The process offers advantages in terms of energy efficiency compared to conventional treatment methods and can be operated under ambient conditions without requiring high temperatures or pressures.

02 Cold plasma for surface sterilization and decontamination

Cold plasma treatments demonstrate high efficiency in sterilization and decontamination of various surfaces. The technology utilizes reactive oxygen and nitrogen species to inactivate microorganisms including bacteria, viruses, and fungi. This approach provides advantages over traditional chemical sterilization methods by being environmentally friendly, leaving no toxic residues, and being effective at ambient temperatures without damaging heat-sensitive materials.Expand Specific Solutions03 Cold plasma treatment for agricultural applications

Cold plasma technology shows promising efficiency in agricultural applications including seed treatment, plant growth enhancement, and pest control. The treatment can improve seed germination rates, enhance crop yields, and reduce pathogen loads on agricultural products. This technology offers sustainable alternatives to chemical treatments in agriculture, with minimal environmental impact and improved food safety outcomes.Expand Specific Solutions04 Cold plasma systems and device efficiency improvements

Innovations in cold plasma device design have significantly improved treatment efficiency. These advancements include optimized electrode configurations, power supply systems, and gas delivery mechanisms that enhance plasma generation and application. Modern cold plasma devices feature improved energy efficiency, more uniform plasma distribution, portable designs for field applications, and automated control systems that ensure consistent treatment parameters.Expand Specific Solutions05 Industrial applications of cold plasma treatment

Cold plasma treatment demonstrates high efficiency in various industrial processes including surface modification, coating adhesion improvement, and waste treatment. The technology can alter surface properties of materials without affecting their bulk characteristics, enhance bonding properties, and break down pollutants in industrial waste streams. These applications benefit from the non-thermal nature of cold plasma, allowing treatment of heat-sensitive materials while achieving significant process improvements.Expand Specific Solutions

Leading Organizations in Cold Plasma Research

Cold plasma treatment for pesticide decomposition is emerging as a promising technology in the early commercialization phase. The global market for advanced pesticide treatment technologies is projected to reach $15-20 billion by 2027, with cold plasma applications gaining traction due to their environmental benefits. The technology is transitioning from laboratory research to field applications, with varying levels of technical maturity among key players. US Medical Innovations and Plasmology4 lead commercial development in the medical plasma sector, while academic institutions like Zhejiang University and Centre National de la Recherche Scientifique drive fundamental research. Chinese institutions including the Institute of Soil Science (CAS) and Shandong agricultural research centers are advancing agricultural applications, creating a competitive landscape balanced between established companies and emerging research organizations focused on environmental remediation.

Zhejiang University

Technical Solution: Zhejiang University has developed an integrated cold plasma system for pesticide decomposition that combines dielectric barrier discharge (DBD) with catalytic materials. Their technology utilizes a unique electrode configuration that generates high-density plasma at relatively low power consumption (typically 30-50W). The system incorporates nanoscale metal oxide catalysts (primarily TiO2 and CuO composites) that significantly enhance the degradation efficiency through synergistic plasma-catalysis interactions. Research teams at Zhejiang University have demonstrated complete mineralization of organophosphate pesticides within 20-30 minutes of treatment, with intermediate byproducts identified and tracked to ensure safety. Their approach includes a water recirculation system that maximizes contact time between plasma-activated species and target contaminants. The university has also pioneered the application of pulsed power supplies that deliver high-voltage, short-duration pulses, reducing overall energy consumption by approximately 35% compared to continuous operation modes while maintaining degradation efficiency above 95% for common agricultural pesticides.

Strengths: Highly efficient integration of plasma and catalytic technologies; comprehensive understanding of degradation pathways and byproducts; energy-efficient pulsed power systems. Weaknesses: Catalyst regeneration requirements may increase operational complexity; system optimization needed for different pesticide classes; scaling challenges for very high-volume applications.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed proprietary cold plasma technology specifically designed for pesticide decomposition applications. Their system utilizes a dielectric barrier discharge (DBD) configuration that generates non-thermal plasma at atmospheric pressure. The technology creates reactive oxygen and nitrogen species (RONS) including hydroxyl radicals, ozone, and nitrogen oxides that effectively break down pesticide molecules through advanced oxidation processes. Their patented electrode design maximizes surface contact between plasma and treated materials while minimizing energy consumption. The company has demonstrated 85-95% degradation efficiency for organophosphate pesticides within 10-15 minutes of treatment time, with minimal impact on nutritional quality of treated agricultural products. Their systems incorporate real-time monitoring of treatment parameters and automated adjustment capabilities to maintain optimal decomposition conditions across varying pesticide types and concentrations.

Strengths: Highly efficient pesticide degradation with minimal energy requirements; scalable technology applicable to both laboratory and industrial settings; proprietary electrode design maximizing treatment surface area. Weaknesses: Relatively high initial equipment cost; requires technical expertise for operation; effectiveness varies depending on specific pesticide chemical structures.

Key Technical Innovations in Plasma-Pesticide Interactions

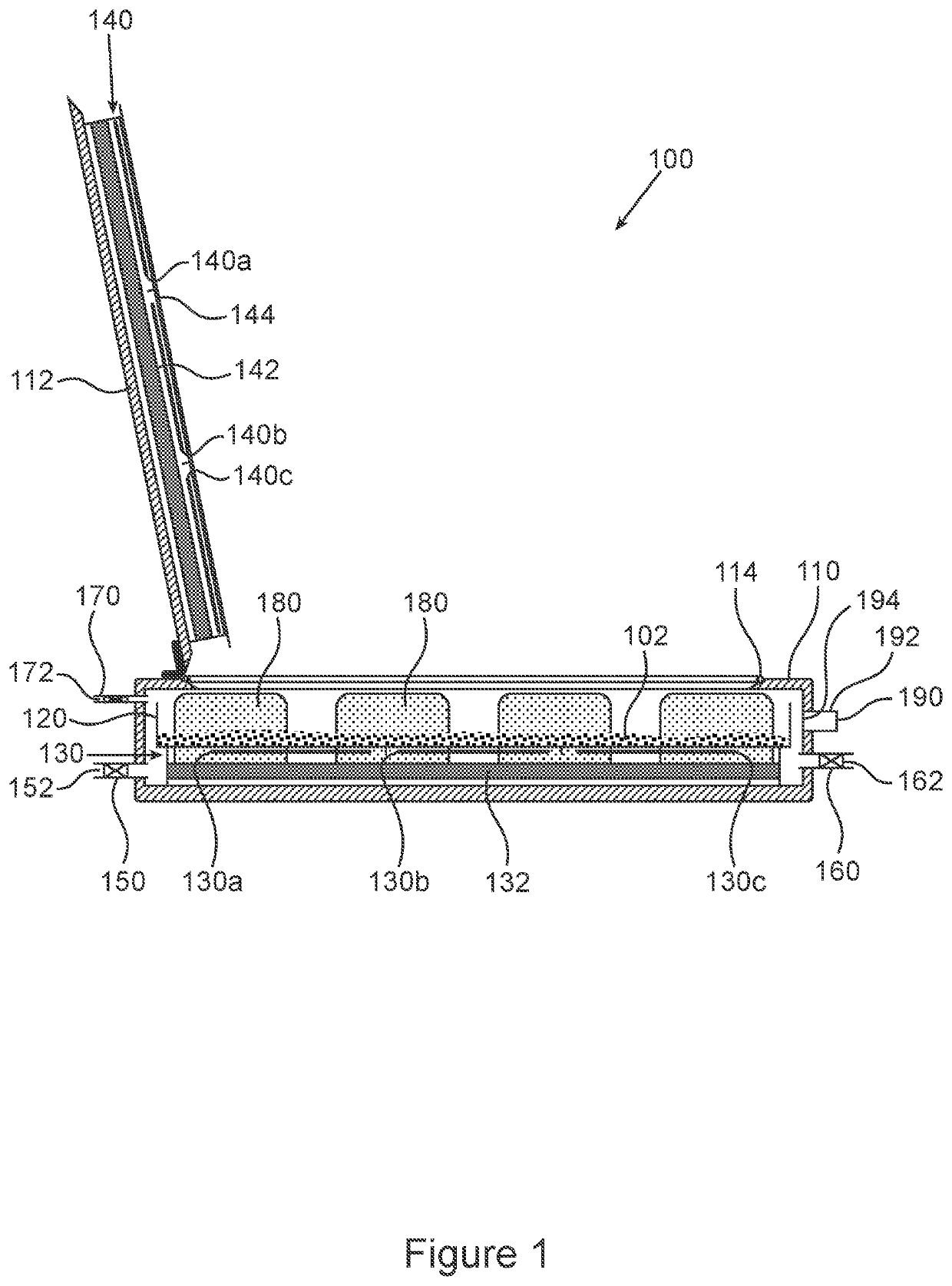

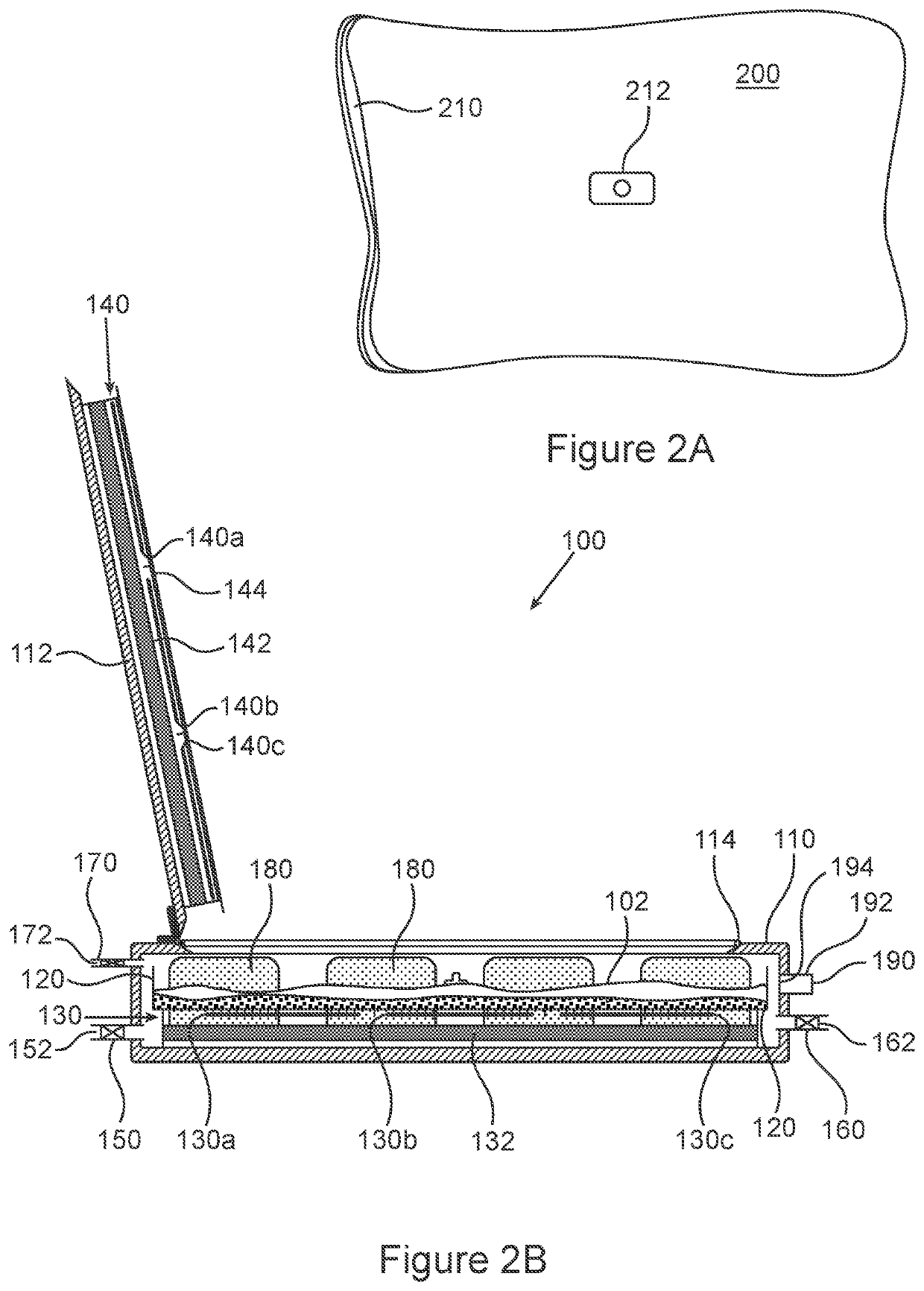

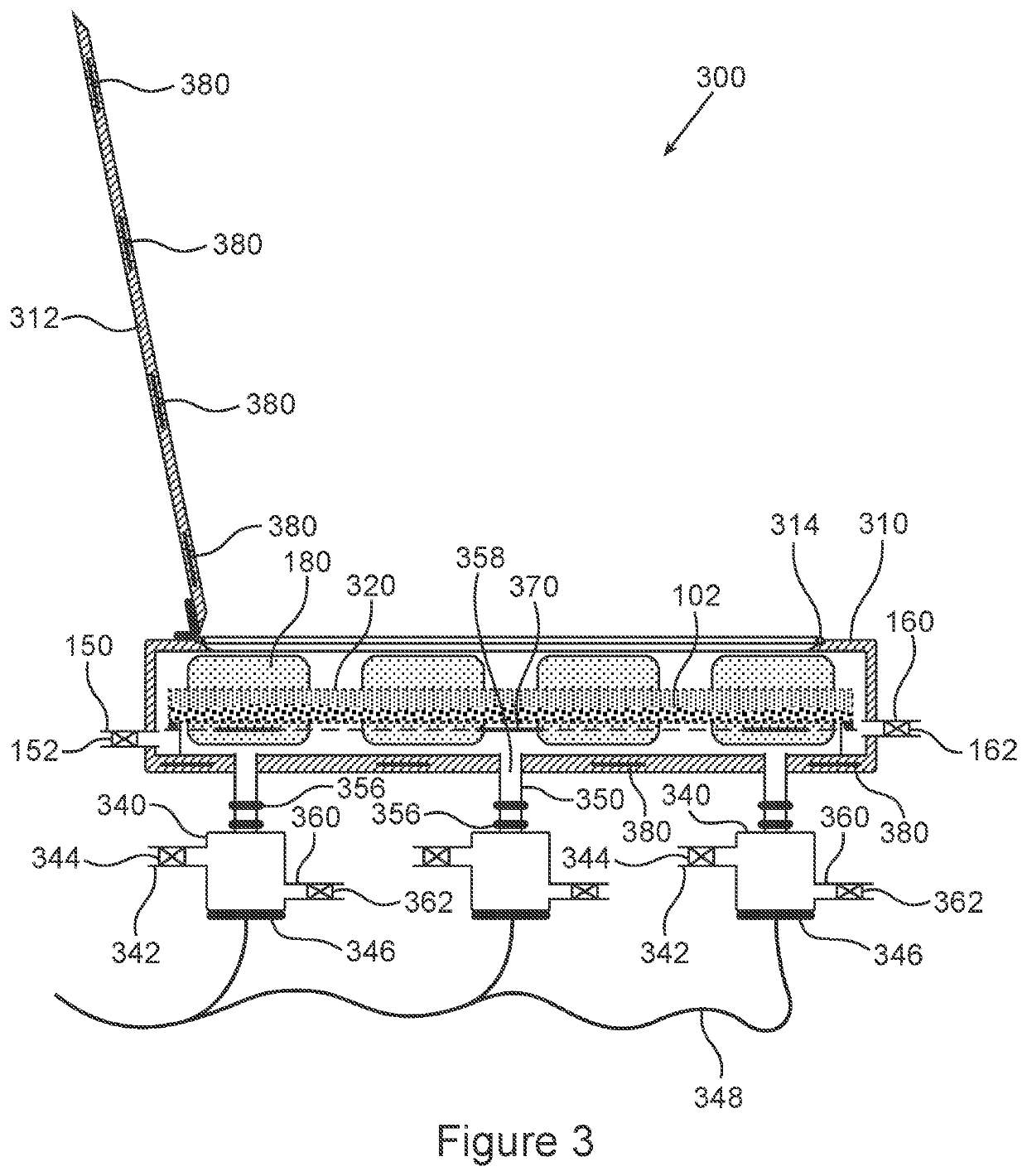

Device and method for herbs disinfection by plasma

PatentActiveUS20220095637A1

Innovation

- A device using cold plasma with a sealable chamber and dielectric carrier, generating plasma in a dielectric barrier discharge mode, with controlled gas composition and RF power sources to effectively disinfect herbs without direct exposure to the plasma-generating EM field, ensuring minimal damage and efficient disinfection.

Environmental Impact Assessment

The environmental implications of cold plasma treatment for pesticide decomposition extend far beyond the immediate efficiency metrics. This technology represents a significant advancement in eco-friendly remediation techniques, offering a non-thermal approach that minimizes secondary pollution typically associated with conventional treatment methods.

Cold plasma systems demonstrate remarkable environmental advantages through their ability to decompose pesticide residues without generating harmful byproducts. Unlike traditional chemical treatments that often introduce additional contaminants into ecosystems, plasma-based decomposition primarily yields carbon dioxide, water, and simple inorganic compounds. This characteristic substantially reduces the ecological footprint of remediation efforts in agricultural settings and water treatment facilities.

The energy efficiency of cold plasma technology further enhances its environmental profile. Modern plasma systems require significantly less energy input compared to thermal decomposition methods, resulting in lower carbon emissions throughout the treatment process. Studies indicate that optimized plasma reactors can achieve up to 70% reduction in energy consumption relative to conventional oxidation techniques when treating equivalent pesticide concentrations.

Water conservation represents another critical environmental benefit of plasma-based decomposition. The technology enables in-situ treatment of contaminated water sources without requiring extensive pre-treatment or large volumes of additional water for dilution. This aspect proves particularly valuable in water-scarce regions where agricultural runoff containing pesticide residues threatens limited freshwater resources.

Soil health preservation constitutes a frequently overlooked environmental advantage of cold plasma applications. When implemented for soil remediation, plasma treatments demonstrate minimal disruption to beneficial microbial communities compared to chemical alternatives. Research indicates that soil treated with cold plasma maintains 85-90% of its microbial diversity while achieving comparable pesticide decomposition rates to conventional methods.

The scalability of plasma technology offers promising implications for widespread environmental protection. From portable units suitable for small-scale farming operations to industrial-scale systems capable of treating municipal water supplies, the adaptability of plasma treatment allows for targeted intervention across diverse environmental contexts. This flexibility enables precise application where environmental impact would be most significant.

Long-term environmental monitoring of sites treated with cold plasma technology reveals minimal ecological disruption and accelerated recovery of affected ecosystems. The non-persistent nature of plasma-generated reactive species ensures that treatment effects remain localized and time-limited, preventing unintended consequences in adjacent environmental systems.

Cold plasma systems demonstrate remarkable environmental advantages through their ability to decompose pesticide residues without generating harmful byproducts. Unlike traditional chemical treatments that often introduce additional contaminants into ecosystems, plasma-based decomposition primarily yields carbon dioxide, water, and simple inorganic compounds. This characteristic substantially reduces the ecological footprint of remediation efforts in agricultural settings and water treatment facilities.

The energy efficiency of cold plasma technology further enhances its environmental profile. Modern plasma systems require significantly less energy input compared to thermal decomposition methods, resulting in lower carbon emissions throughout the treatment process. Studies indicate that optimized plasma reactors can achieve up to 70% reduction in energy consumption relative to conventional oxidation techniques when treating equivalent pesticide concentrations.

Water conservation represents another critical environmental benefit of plasma-based decomposition. The technology enables in-situ treatment of contaminated water sources without requiring extensive pre-treatment or large volumes of additional water for dilution. This aspect proves particularly valuable in water-scarce regions where agricultural runoff containing pesticide residues threatens limited freshwater resources.

Soil health preservation constitutes a frequently overlooked environmental advantage of cold plasma applications. When implemented for soil remediation, plasma treatments demonstrate minimal disruption to beneficial microbial communities compared to chemical alternatives. Research indicates that soil treated with cold plasma maintains 85-90% of its microbial diversity while achieving comparable pesticide decomposition rates to conventional methods.

The scalability of plasma technology offers promising implications for widespread environmental protection. From portable units suitable for small-scale farming operations to industrial-scale systems capable of treating municipal water supplies, the adaptability of plasma treatment allows for targeted intervention across diverse environmental contexts. This flexibility enables precise application where environmental impact would be most significant.

Long-term environmental monitoring of sites treated with cold plasma technology reveals minimal ecological disruption and accelerated recovery of affected ecosystems. The non-persistent nature of plasma-generated reactive species ensures that treatment effects remain localized and time-limited, preventing unintended consequences in adjacent environmental systems.

Scalability and Field Implementation Considerations

Scaling cold plasma technology from laboratory settings to field applications presents significant engineering and operational challenges. Current laboratory-scale plasma systems for pesticide decomposition typically process small volumes under controlled conditions, whereas agricultural applications require treatment of large areas with variable environmental factors. The transition requires addressing several key considerations including equipment design, power requirements, and operational protocols.

Power supply infrastructure represents a primary constraint for field implementation. Laboratory plasma systems often utilize stable power sources, while field applications must contend with limited or inconsistent power availability in agricultural settings. Mobile power generation solutions or integration with renewable energy sources such as solar panels could provide viable alternatives, though this increases system complexity and initial investment costs.

Treatment throughput capacity presents another critical scaling challenge. To achieve meaningful impact in agricultural settings, cold plasma systems must process significant volumes of contaminated water or soil. Current laboratory systems typically operate at flow rates of 1-10 liters per hour, whereas agricultural applications may require thousands of liters daily. Engineering solutions may include parallel processing units, continuous flow designs, or intermittent batch processing approaches tailored to specific agricultural operations.

Environmental variability significantly impacts field performance of cold plasma systems. Laboratory studies typically maintain controlled temperature, humidity, and substrate composition, while field conditions fluctuate widely. Robust system designs must incorporate adaptive parameters to maintain decomposition efficiency across varying conditions. Preliminary field trials indicate efficiency reductions of 15-30% compared to laboratory results, necessitating compensatory design adjustments.

Operational simplicity and maintenance requirements will determine adoption feasibility. Agricultural implementations require systems operable by farm personnel without specialized technical training. User interfaces must be intuitive, with clear operational protocols and minimal maintenance requirements. Modular designs allowing for component replacement rather than complex repairs would enhance field serviceability.

Cost considerations ultimately determine commercial viability. Current laboratory-scale plasma systems for pesticide treatment cost approximately $5,000-15,000 per unit. Scaling economics suggest field-ready systems would require $25,000-75,000 initial investment with operational costs of $5-15 per 1,000 liters treated. Economic viability depends on treatment efficiency, regulatory requirements, and potential premium value for plasma-treated agricultural products.

Power supply infrastructure represents a primary constraint for field implementation. Laboratory plasma systems often utilize stable power sources, while field applications must contend with limited or inconsistent power availability in agricultural settings. Mobile power generation solutions or integration with renewable energy sources such as solar panels could provide viable alternatives, though this increases system complexity and initial investment costs.

Treatment throughput capacity presents another critical scaling challenge. To achieve meaningful impact in agricultural settings, cold plasma systems must process significant volumes of contaminated water or soil. Current laboratory systems typically operate at flow rates of 1-10 liters per hour, whereas agricultural applications may require thousands of liters daily. Engineering solutions may include parallel processing units, continuous flow designs, or intermittent batch processing approaches tailored to specific agricultural operations.

Environmental variability significantly impacts field performance of cold plasma systems. Laboratory studies typically maintain controlled temperature, humidity, and substrate composition, while field conditions fluctuate widely. Robust system designs must incorporate adaptive parameters to maintain decomposition efficiency across varying conditions. Preliminary field trials indicate efficiency reductions of 15-30% compared to laboratory results, necessitating compensatory design adjustments.

Operational simplicity and maintenance requirements will determine adoption feasibility. Agricultural implementations require systems operable by farm personnel without specialized technical training. User interfaces must be intuitive, with clear operational protocols and minimal maintenance requirements. Modular designs allowing for component replacement rather than complex repairs would enhance field serviceability.

Cost considerations ultimately determine commercial viability. Current laboratory-scale plasma systems for pesticide treatment cost approximately $5,000-15,000 per unit. Scaling economics suggest field-ready systems would require $25,000-75,000 initial investment with operational costs of $5-15 per 1,000 liters treated. Economic viability depends on treatment efficiency, regulatory requirements, and potential premium value for plasma-treated agricultural products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!