Cold Plasma Treatment Impact on the Mechanical Properties of Metals

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Evolution and Objectives

Cold plasma technology has evolved significantly over the past several decades, transitioning from a niche scientific curiosity to a versatile industrial tool with applications across multiple sectors. The journey began in the early 20th century with fundamental research on electrical discharges in gases, but it wasn't until the 1970s that researchers started exploring cold plasma's potential for material surface modification. By the 1990s, cold plasma treatments were being investigated for their ability to enhance metal surface properties without the thermal damage associated with traditional heat treatments.

The evolution of cold plasma technology has been characterized by progressive improvements in plasma generation methods, from direct current (DC) discharges to radio frequency (RF) systems, and more recently to atmospheric pressure plasma jets (APPJ) that eliminate the need for vacuum chambers. These advancements have dramatically reduced equipment costs and expanded the range of practical applications, particularly in metal treatment processes.

A significant milestone occurred in the early 2000s when researchers demonstrated that cold plasma treatment could effectively modify the surface properties of various metals, including steel, aluminum, and titanium alloys, enhancing their hardness, wear resistance, and corrosion protection without altering their bulk properties. This breakthrough opened new possibilities for industries requiring high-performance metal components.

The primary objective of cold plasma treatment for metals is to enhance mechanical properties through surface modification rather than bulk material changes. This includes improving hardness, wear resistance, fatigue strength, and corrosion resistance while maintaining the desirable bulk properties of the metal. Additionally, cold plasma technology aims to provide these enhancements through an environmentally friendly process that consumes less energy than conventional heat treatments and eliminates the need for hazardous chemicals often used in traditional surface modification techniques.

Current research objectives focus on optimizing plasma parameters for specific metal alloys, developing more precise control systems for treatment uniformity, and scaling the technology for industrial implementation. There is particular interest in understanding the fundamental mechanisms by which plasma species interact with metal surfaces at the atomic level, as this knowledge could enable more targeted treatments with predictable outcomes.

Looking forward, the technology trajectory points toward the development of hybrid plasma systems that combine multiple treatment modalities, in-line process monitoring capabilities for quality control, and the integration of cold plasma treatments into advanced manufacturing processes such as additive manufacturing. These developments aim to position cold plasma as a key enabling technology for next-generation metal components with superior mechanical properties.

The evolution of cold plasma technology has been characterized by progressive improvements in plasma generation methods, from direct current (DC) discharges to radio frequency (RF) systems, and more recently to atmospheric pressure plasma jets (APPJ) that eliminate the need for vacuum chambers. These advancements have dramatically reduced equipment costs and expanded the range of practical applications, particularly in metal treatment processes.

A significant milestone occurred in the early 2000s when researchers demonstrated that cold plasma treatment could effectively modify the surface properties of various metals, including steel, aluminum, and titanium alloys, enhancing their hardness, wear resistance, and corrosion protection without altering their bulk properties. This breakthrough opened new possibilities for industries requiring high-performance metal components.

The primary objective of cold plasma treatment for metals is to enhance mechanical properties through surface modification rather than bulk material changes. This includes improving hardness, wear resistance, fatigue strength, and corrosion resistance while maintaining the desirable bulk properties of the metal. Additionally, cold plasma technology aims to provide these enhancements through an environmentally friendly process that consumes less energy than conventional heat treatments and eliminates the need for hazardous chemicals often used in traditional surface modification techniques.

Current research objectives focus on optimizing plasma parameters for specific metal alloys, developing more precise control systems for treatment uniformity, and scaling the technology for industrial implementation. There is particular interest in understanding the fundamental mechanisms by which plasma species interact with metal surfaces at the atomic level, as this knowledge could enable more targeted treatments with predictable outcomes.

Looking forward, the technology trajectory points toward the development of hybrid plasma systems that combine multiple treatment modalities, in-line process monitoring capabilities for quality control, and the integration of cold plasma treatments into advanced manufacturing processes such as additive manufacturing. These developments aim to position cold plasma as a key enabling technology for next-generation metal components with superior mechanical properties.

Market Applications for Plasma-Treated Metals

Cold plasma treatment of metals has opened significant market opportunities across multiple industrial sectors, transforming traditional manufacturing processes and enabling new applications. The aerospace industry represents one of the most valuable markets for plasma-treated metals, where enhanced surface properties contribute to improved fatigue resistance and corrosion protection for critical components. Commercial aircraft manufacturers increasingly specify plasma-treated aluminum alloys and titanium components to extend service life while reducing maintenance costs. The market value in aerospace applications alone is projected to grow substantially as manufacturers seek lightweight yet durable materials.

The automotive sector has emerged as another major application area, with plasma-treated metals finding use in engine components, body panels, and structural elements. The treatment's ability to improve wear resistance while maintaining or enhancing mechanical properties makes it particularly valuable for high-stress components. Leading automotive manufacturers have begun incorporating plasma-treated steel and aluminum alloys in premium vehicle lines, with adoption rates accelerating as production costs decrease.

Medical device manufacturing represents a high-value niche market where plasma-treated metals command premium pricing. The biocompatibility improvements achieved through cold plasma treatment make these materials ideal for implantable devices, surgical instruments, and diagnostic equipment. The orthopedic implant segment shows particularly strong growth potential as plasma treatments can enhance osseointegration while maintaining structural integrity.

The energy sector utilizes plasma-treated metals in both traditional and renewable energy applications. Power generation equipment benefits from improved corrosion resistance and mechanical properties, while wind turbine components gain extended operational lifespans through plasma-enhanced surface treatments. Solar energy infrastructure similarly benefits from plasma-treated mounting systems and structural components with improved environmental durability.

Consumer electronics manufacturers have begun exploring plasma-treated metals for device casings and internal components, valuing the combination of strength, weight reduction, and aesthetic qualities. The premium smartphone and laptop segments particularly benefit from these advanced materials, with consumers willing to pay premium prices for devices with superior durability and appearance.

Industrial machinery and equipment manufacturing represents perhaps the broadest application area, with plasma-treated metals finding use in cutting tools, forming dies, hydraulic components, and structural elements. The improved wear resistance and fatigue properties translate directly to extended service life and reduced maintenance costs, creating a compelling value proposition for industrial users across manufacturing sectors.

The automotive sector has emerged as another major application area, with plasma-treated metals finding use in engine components, body panels, and structural elements. The treatment's ability to improve wear resistance while maintaining or enhancing mechanical properties makes it particularly valuable for high-stress components. Leading automotive manufacturers have begun incorporating plasma-treated steel and aluminum alloys in premium vehicle lines, with adoption rates accelerating as production costs decrease.

Medical device manufacturing represents a high-value niche market where plasma-treated metals command premium pricing. The biocompatibility improvements achieved through cold plasma treatment make these materials ideal for implantable devices, surgical instruments, and diagnostic equipment. The orthopedic implant segment shows particularly strong growth potential as plasma treatments can enhance osseointegration while maintaining structural integrity.

The energy sector utilizes plasma-treated metals in both traditional and renewable energy applications. Power generation equipment benefits from improved corrosion resistance and mechanical properties, while wind turbine components gain extended operational lifespans through plasma-enhanced surface treatments. Solar energy infrastructure similarly benefits from plasma-treated mounting systems and structural components with improved environmental durability.

Consumer electronics manufacturers have begun exploring plasma-treated metals for device casings and internal components, valuing the combination of strength, weight reduction, and aesthetic qualities. The premium smartphone and laptop segments particularly benefit from these advanced materials, with consumers willing to pay premium prices for devices with superior durability and appearance.

Industrial machinery and equipment manufacturing represents perhaps the broadest application area, with plasma-treated metals finding use in cutting tools, forming dies, hydraulic components, and structural elements. The improved wear resistance and fatigue properties translate directly to extended service life and reduced maintenance costs, creating a compelling value proposition for industrial users across manufacturing sectors.

Current Limitations in Cold Plasma Metal Treatment

Despite the promising advancements in cold plasma treatment for metals, several significant limitations currently hinder its widespread industrial adoption and optimal performance. One of the primary constraints is the depth limitation of plasma treatment effects. Cold plasma typically modifies only the outermost surface layers of metals (typically 10-100 nm), making it challenging to enhance bulk mechanical properties in thicker components. This surface-limited effect restricts applications requiring deep material modification.

Process control and reproducibility present another major challenge. Current cold plasma systems often struggle with maintaining consistent plasma characteristics across large or complex-shaped metal components. Parameters such as plasma density, electron temperature, and reactive species concentration can fluctuate during treatment, leading to non-uniform surface modifications and inconsistent mechanical property improvements.

Energy efficiency remains a concern in existing cold plasma treatment systems. Many setups require significant power input while delivering relatively low treatment efficiency, particularly for metals with high thermal conductivity that rapidly dissipate the plasma energy. This inefficiency translates to higher operational costs and environmental impact, limiting commercial viability.

The relationship between plasma treatment parameters and resulting mechanical properties is not fully understood. Current research reveals complex, often non-linear correlations between plasma exposure time, gas composition, power density, and the resulting changes in hardness, fatigue resistance, and other mechanical properties. This knowledge gap complicates process optimization and predictive modeling.

Material-specific limitations further constrain applications. Certain metal alloys respond poorly to cold plasma treatment due to their chemical composition or microstructure. For instance, some aluminum alloys show minimal improvement in wear resistance after plasma treatment compared to steel alloys. Additionally, high-temperature resistant alloys may require specialized plasma conditions that current systems cannot efficiently deliver.

Scalability issues persist in transitioning from laboratory to industrial implementation. Most successful demonstrations have occurred on small specimens under carefully controlled laboratory conditions. Scaling these processes to accommodate industrial production volumes while maintaining quality and cost-effectiveness remains challenging.

Integration with existing manufacturing workflows presents additional hurdles. Cold plasma treatment often requires specialized equipment and processing steps that may not easily fit into established production lines. The need for vacuum conditions in many plasma systems further complicates integration into continuous manufacturing processes.

Process control and reproducibility present another major challenge. Current cold plasma systems often struggle with maintaining consistent plasma characteristics across large or complex-shaped metal components. Parameters such as plasma density, electron temperature, and reactive species concentration can fluctuate during treatment, leading to non-uniform surface modifications and inconsistent mechanical property improvements.

Energy efficiency remains a concern in existing cold plasma treatment systems. Many setups require significant power input while delivering relatively low treatment efficiency, particularly for metals with high thermal conductivity that rapidly dissipate the plasma energy. This inefficiency translates to higher operational costs and environmental impact, limiting commercial viability.

The relationship between plasma treatment parameters and resulting mechanical properties is not fully understood. Current research reveals complex, often non-linear correlations between plasma exposure time, gas composition, power density, and the resulting changes in hardness, fatigue resistance, and other mechanical properties. This knowledge gap complicates process optimization and predictive modeling.

Material-specific limitations further constrain applications. Certain metal alloys respond poorly to cold plasma treatment due to their chemical composition or microstructure. For instance, some aluminum alloys show minimal improvement in wear resistance after plasma treatment compared to steel alloys. Additionally, high-temperature resistant alloys may require specialized plasma conditions that current systems cannot efficiently deliver.

Scalability issues persist in transitioning from laboratory to industrial implementation. Most successful demonstrations have occurred on small specimens under carefully controlled laboratory conditions. Scaling these processes to accommodate industrial production volumes while maintaining quality and cost-effectiveness remains challenging.

Integration with existing manufacturing workflows presents additional hurdles. Cold plasma treatment often requires specialized equipment and processing steps that may not easily fit into established production lines. The need for vacuum conditions in many plasma systems further complicates integration into continuous manufacturing processes.

Established Cold Plasma Metal Treatment Methodologies

01 Cold plasma treatment for enhancing mechanical properties of materials

Cold plasma treatment can be used to enhance the mechanical properties of various materials. The treatment modifies the surface characteristics of materials, improving their strength, durability, and resistance to wear. This process involves exposing materials to ionized gas at low temperatures, which alters the surface structure without affecting the bulk properties. The treatment can be applied to metals, polymers, and composites to achieve improved mechanical performance.- Cold plasma treatment for enhancing mechanical properties of materials: Cold plasma treatment can be used to enhance the mechanical properties of various materials by modifying their surface characteristics. This process involves exposing materials to ionized gas at low temperatures, which can improve hardness, tensile strength, and wear resistance without affecting the bulk properties of the material. The treatment creates functional groups on the surface that can enhance adhesion and other mechanical properties.

- Cold plasma for medical device surface modification: Cold plasma technology is utilized to modify the surface properties of medical devices, improving their mechanical performance and biocompatibility. The treatment can enhance the adhesion of coatings, increase wear resistance, and create antimicrobial surfaces. This non-thermal plasma process allows for surface modification without altering the bulk properties of sensitive medical materials, resulting in devices with improved durability and functionality.

- Cold plasma treatment for polymer and composite materials: Cold plasma treatment is particularly effective for modifying the surface properties of polymers and composite materials. The treatment can increase surface energy, improve wettability, and enhance adhesion between layers in composites. This results in improved mechanical properties such as interfacial strength, impact resistance, and overall durability of the treated materials without degrading their bulk characteristics.

- Cold plasma for textile and fiber treatment: Cold plasma technology is applied to textiles and fibers to enhance their mechanical properties such as tensile strength, abrasion resistance, and dimensional stability. The treatment modifies the surface of the fibers without affecting their bulk properties, improving their durability and performance. Additionally, it can impart functional properties like water repellency or improved dye uptake while maintaining or enhancing the mechanical characteristics of the treated textiles.

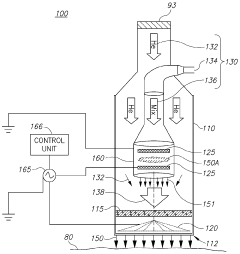

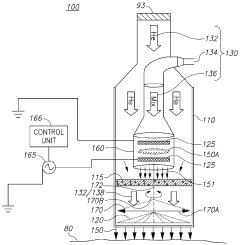

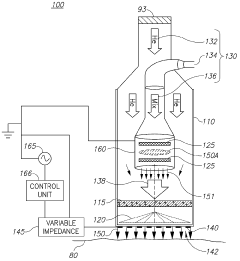

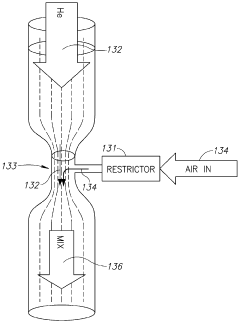

- Cold plasma systems and equipment for mechanical property enhancement: Specialized cold plasma systems and equipment have been developed specifically for enhancing the mechanical properties of materials. These systems control parameters such as gas composition, pressure, power, and treatment time to optimize the effect on mechanical properties. Advanced plasma generators, chambers, and electrodes are designed to ensure uniform treatment and consistent improvement in hardness, adhesion, and wear resistance across various substrate materials.

02 Cold plasma treatment for medical devices and implants

Cold plasma technology is utilized in the treatment of medical devices and implants to enhance their mechanical properties and biocompatibility. The treatment can modify surface characteristics to improve integration with biological tissues, reduce friction, and increase wear resistance. This application is particularly important for orthopedic implants, dental materials, and other medical devices where mechanical stability and tissue compatibility are crucial factors.Expand Specific Solutions03 Cold plasma treatment for textile and polymer materials

Cold plasma treatment can significantly improve the mechanical properties of textile and polymer materials. The process enhances adhesion properties, increases tensile strength, and improves durability without altering the bulk characteristics of the materials. This treatment method is particularly effective for modifying surface energy, creating functional groups, and improving the bonding capabilities of polymers and textiles, resulting in enhanced mechanical performance.Expand Specific Solutions04 Cold plasma systems and apparatus for mechanical property enhancement

Various cold plasma systems and apparatus have been developed specifically for enhancing mechanical properties of materials. These systems control parameters such as gas composition, pressure, power, and treatment time to achieve desired modifications to material surfaces. Advanced plasma generation technologies enable precise treatment of complex geometries and sensitive materials, allowing for targeted improvement of mechanical characteristics while maintaining the integrity of the treated objects.Expand Specific Solutions05 Cold plasma surface modification for adhesion improvement

Cold plasma treatment is effective for surface modification to improve adhesion properties between different materials. The treatment creates functional groups on material surfaces, increases surface energy, and removes contaminants, resulting in stronger bonds and improved mechanical interfaces. This application is particularly valuable in composite manufacturing, coating processes, and joining dissimilar materials where mechanical strength at the interface is critical for overall performance.Expand Specific Solutions

Leading Companies and Research Institutions in Plasma Technology

Cold plasma treatment for metals is currently in a growth phase, with increasing adoption across aerospace, automotive, and medical industries. The market is projected to reach significant scale due to the technology's ability to enhance surface properties without altering bulk characteristics. Leading companies demonstrate varying levels of technological maturity: Applied Materials and Praxair S.T. Technology have established commercial applications, while research institutions like Dalian University of Technology and Osaka University are advancing fundamental understanding. US Medical Innovations and Plasmology4 are developing specialized medical applications, while industrial players like NTN Corp and IMT Co. are implementing cold plasma for specific manufacturing processes. The competitive landscape shows a mix of established industrial giants and specialized technology providers, with ongoing collaboration between academic and commercial entities driving innovation.

US Patent Innovations LLC

Technical Solution: US Patent Innovations LLC has developed an innovative cold plasma technology specifically targeting the enhancement of mechanical properties in surgical-grade metals and alloys. Their proprietary Plasma Scalpel™ technology has been adapted for metal treatment applications, utilizing a controlled cold plasma jet that can be precisely directed to modify specific areas of metal components. The company's approach employs a unique gas mixture and electrode configuration that generates a stable, non-thermal plasma capable of surface modification without bulk heating. This technology creates a modified surface layer with enhanced hardness, wear resistance, and biocompatibility, particularly valuable for medical implants and surgical instruments. Their plasma treatment has been shown to increase the surface hardness of stainless steel by up to 35% while simultaneously improving corrosion resistance in biological environments. The process also creates nanoscale surface texturing that enhances adhesion properties for subsequent coatings or biological integration.

Strengths: Highly precise spatial control allowing selective treatment of complex geometries; minimal thermal impact making it suitable for heat-sensitive alloys; dual enhancement of both mechanical and biocompatibility properties. Weaknesses: Limited scalability for large industrial applications; relatively high operational costs; technology primarily optimized for medical-grade metals rather than general industrial applications.

Plasmology4, Inc.

Technical Solution: Plasmology4 has developed a proprietary cold atmospheric plasma (CAP) technology specifically designed for metal surface modification to enhance mechanical properties. Their system, known as PLASMA4™, utilizes a unique electrode configuration that generates a stable, uniform plasma discharge at atmospheric pressure without requiring vacuum chambers. This technology creates reactive species that interact with metal surfaces to form nanoscale oxide layers and modified microstructures in the near-surface region. The treatment process increases surface hardness by up to 25% while simultaneously improving corrosion resistance. Plasmology4's approach is particularly effective for aluminum alloys, where their plasma treatment has demonstrated a significant increase in fatigue strength and wear resistance without altering the bulk properties or dimensional specifications of the treated components. The company has also developed specialized treatment protocols for various metal types, including titanium medical implants where their plasma treatment enhances osseointegration while maintaining mechanical integrity.

Strengths: Atmospheric pressure operation eliminates need for vacuum equipment, reducing operational costs; rapid processing times suitable for high-volume manufacturing; environmentally friendly process with no hazardous waste. Weaknesses: Treatment depth limited to near-surface regions (typically <100μm); less effective on certain high-carbon steel alloys; requires precise control of treatment parameters to avoid surface damage.

Key Scientific Breakthroughs in Plasma-Metal Interaction

Process for improving the corrosion resistance of metallic materials

PatentWO1989010424A1

Innovation

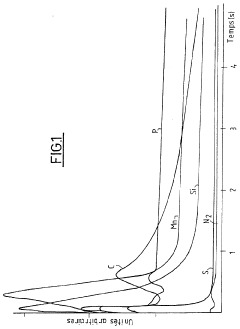

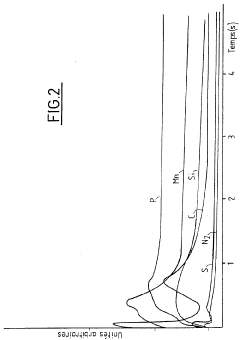

- A low-temperature plasma surface treatment using molecular gases like oxygen, ozone, nitrogen, hydrogen, and their mixtures with inert gases at pressures of 1 to 10 Pa, which maintains the material at a temperature below 100°C, enhances corrosion resistance without altering surface roughness.

Cold plasma treatment

PatentWO2015059702A1

Innovation

- A plasma treatment device with a nozzle configured to receive a first gas and an auxiliary gas, and at least one electrode applying a radiofrequency electromagnetic field to ionize the gases, emitting plasma uniformly over a large treatment area, using a rotating or vibrating electrode configuration to prevent hot spots and ensure even plasma distribution.

Environmental Impact of Cold Plasma Processing

Cold plasma processing offers significant environmental advantages over traditional metal treatment methods, positioning it as a more sustainable alternative in industrial applications. The technology operates at ambient temperatures with minimal energy consumption compared to conventional thermal processes, resulting in a substantially reduced carbon footprint. Studies indicate energy savings of 40-60% when replacing heat-intensive metal treatments with cold plasma alternatives.

Water conservation represents another critical environmental benefit, as cold plasma treatments typically require little to no water usage. This stands in stark contrast to chemical etching and cleaning processes that may consume thousands of gallons of water per production cycle and generate contaminated wastewater requiring extensive treatment.

The elimination or significant reduction of hazardous chemicals constitutes perhaps the most important environmental advantage. Traditional metal surface treatments often rely on acids, solvents, and heavy metal compounds that pose serious environmental and health risks. Cold plasma processing substitutes these harmful substances with environmentally benign working gases like argon, oxygen, or nitrogen, dramatically reducing toxic waste generation and associated disposal challenges.

Emissions from cold plasma systems primarily consist of non-toxic gases, with negligible production of volatile organic compounds (VOCs) or other air pollutants common in conventional metal processing. This contributes to improved air quality both within manufacturing facilities and surrounding communities.

Life cycle assessments of cold plasma metal treatment technologies demonstrate 30-70% lower environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion when compared to conventional alternatives. These environmental benefits translate to reduced regulatory compliance costs and potential qualification for green manufacturing incentives.

However, certain environmental considerations remain. The production of reactive species during plasma generation must be properly managed, particularly when using gases that could potentially form ozone or nitrogen oxides. Additionally, while the direct environmental impact is minimal, the manufacturing of sophisticated plasma generation equipment involves complex electronics that present their own sustainability challenges regarding resource extraction and end-of-life disposal.

As industries increasingly prioritize sustainable manufacturing practices, cold plasma's environmental advantages position it as a key technology for meeting stringent environmental regulations while simultaneously improving metal performance characteristics.

Water conservation represents another critical environmental benefit, as cold plasma treatments typically require little to no water usage. This stands in stark contrast to chemical etching and cleaning processes that may consume thousands of gallons of water per production cycle and generate contaminated wastewater requiring extensive treatment.

The elimination or significant reduction of hazardous chemicals constitutes perhaps the most important environmental advantage. Traditional metal surface treatments often rely on acids, solvents, and heavy metal compounds that pose serious environmental and health risks. Cold plasma processing substitutes these harmful substances with environmentally benign working gases like argon, oxygen, or nitrogen, dramatically reducing toxic waste generation and associated disposal challenges.

Emissions from cold plasma systems primarily consist of non-toxic gases, with negligible production of volatile organic compounds (VOCs) or other air pollutants common in conventional metal processing. This contributes to improved air quality both within manufacturing facilities and surrounding communities.

Life cycle assessments of cold plasma metal treatment technologies demonstrate 30-70% lower environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion when compared to conventional alternatives. These environmental benefits translate to reduced regulatory compliance costs and potential qualification for green manufacturing incentives.

However, certain environmental considerations remain. The production of reactive species during plasma generation must be properly managed, particularly when using gases that could potentially form ozone or nitrogen oxides. Additionally, while the direct environmental impact is minimal, the manufacturing of sophisticated plasma generation equipment involves complex electronics that present their own sustainability challenges regarding resource extraction and end-of-life disposal.

As industries increasingly prioritize sustainable manufacturing practices, cold plasma's environmental advantages position it as a key technology for meeting stringent environmental regulations while simultaneously improving metal performance characteristics.

Cost-Benefit Analysis of Plasma Treatment Implementation

Implementing cold plasma treatment technology for metal processing requires careful financial analysis to determine its economic viability. Initial capital expenditure for plasma treatment equipment ranges from $50,000 to $500,000 depending on scale, complexity, and processing capabilities. This investment includes vacuum chambers, plasma generators, control systems, and safety equipment. Additionally, facility modifications may be necessary to accommodate the new equipment, potentially adding 10-20% to initial costs.

Operational expenses must be considered, including electricity consumption (typically 5-15 kW per treatment unit), process gases (argon, nitrogen, oxygen), maintenance (estimated at 5-8% of equipment cost annually), and specialized personnel training. These recurring costs generally range from $10,000 to $50,000 annually depending on production volume and treatment parameters.

The financial benefits of plasma treatment manifest in several ways. Enhanced surface properties lead to extended component lifespans, with treated parts demonstrating 30-200% longer service life depending on application. This translates to reduced replacement frequency and associated maintenance costs. Improved wear resistance can decrease downtime in manufacturing operations by 15-25%, while enhanced corrosion resistance reduces protective coating requirements by up to 40%.

Manufacturing efficiency improvements include reduced chemical consumption (60-80% less than traditional chemical treatments), decreased water usage, and lower waste disposal costs. The environmentally friendly nature of plasma treatment also mitigates regulatory compliance expenses and potential environmental liabilities.

Return on investment typically occurs within 1-3 years for high-volume applications. Industries with high-value components such as aerospace, medical devices, and precision engineering tend to realize faster payback periods due to the significant impact on component performance and reliability. Small-batch manufacturers may experience longer ROI periods unless focusing on high-margin specialty products.

Sensitivity analysis indicates that treatment throughput is the most critical factor affecting economic viability. Operations processing at least 1,000 parts monthly typically achieve favorable economics. The technology becomes increasingly cost-effective as energy prices rise and environmental regulations tighten, positioning plasma treatment as a forward-looking investment that hedges against future regulatory and resource constraints.

Operational expenses must be considered, including electricity consumption (typically 5-15 kW per treatment unit), process gases (argon, nitrogen, oxygen), maintenance (estimated at 5-8% of equipment cost annually), and specialized personnel training. These recurring costs generally range from $10,000 to $50,000 annually depending on production volume and treatment parameters.

The financial benefits of plasma treatment manifest in several ways. Enhanced surface properties lead to extended component lifespans, with treated parts demonstrating 30-200% longer service life depending on application. This translates to reduced replacement frequency and associated maintenance costs. Improved wear resistance can decrease downtime in manufacturing operations by 15-25%, while enhanced corrosion resistance reduces protective coating requirements by up to 40%.

Manufacturing efficiency improvements include reduced chemical consumption (60-80% less than traditional chemical treatments), decreased water usage, and lower waste disposal costs. The environmentally friendly nature of plasma treatment also mitigates regulatory compliance expenses and potential environmental liabilities.

Return on investment typically occurs within 1-3 years for high-volume applications. Industries with high-value components such as aerospace, medical devices, and precision engineering tend to realize faster payback periods due to the significant impact on component performance and reliability. Small-batch manufacturers may experience longer ROI periods unless focusing on high-margin specialty products.

Sensitivity analysis indicates that treatment throughput is the most critical factor affecting economic viability. Operations processing at least 1,000 parts monthly typically achieve favorable economics. The technology becomes increasingly cost-effective as energy prices rise and environmental regulations tighten, positioning plasma treatment as a forward-looking investment that hedges against future regulatory and resource constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!