What Are the Design Parameters for Effective Cold Plasma Treatment?

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold Plasma Technology Background and Objectives

Cold plasma technology, also known as non-thermal plasma or low-temperature plasma, has emerged as a versatile tool across multiple industries over the past several decades. Unlike conventional thermal plasmas that operate at equilibrium temperatures, cold plasma maintains a significant temperature difference between electrons and heavy particles, allowing for material treatment without thermal damage. The evolution of this technology began in the mid-20th century with basic research into plasma physics, but has accelerated dramatically since the 1990s with the development of more efficient and controllable plasma generation methods.

The technological trajectory has moved from simple dielectric barrier discharge systems to sophisticated atmospheric pressure plasma jets, surface dielectric barrier discharges, and microplasma arrays. Each advancement has expanded the potential applications while improving energy efficiency, treatment uniformity, and process control. Recent innovations have focused on developing modular and scalable systems that can be integrated into existing industrial processes.

The primary objective of cold plasma technology research is to establish precise design parameters that optimize treatment efficacy across diverse applications. These applications span medical sterilization, surface modification of polymers, food safety enhancement, agricultural seed treatment, and environmental remediation. Each application domain presents unique requirements regarding plasma characteristics such as electron density, reactive species composition, and exposure protocols.

Current research aims to develop standardized methodologies for characterizing plasma properties and correlating them with treatment outcomes. This includes establishing quantitative relationships between input parameters (power, frequency, gas composition) and resulting plasma characteristics (electron temperature, reactive species concentration, UV emission). Understanding these relationships is crucial for designing plasma systems that deliver consistent and predictable results.

Another key objective is to enhance energy efficiency and reduce operational costs, making cold plasma treatments economically viable for widespread industrial adoption. This involves optimizing power supply designs, improving electrode configurations, and developing intelligent control systems that can adapt treatment parameters in real-time based on feedback mechanisms.

The field is also moving toward more sustainable approaches, with research focused on reducing gas consumption, minimizing harmful byproducts, and developing plasma systems powered by renewable energy sources. These sustainability considerations are becoming increasingly important as the technology transitions from laboratory research to commercial applications.

The technological trajectory has moved from simple dielectric barrier discharge systems to sophisticated atmospheric pressure plasma jets, surface dielectric barrier discharges, and microplasma arrays. Each advancement has expanded the potential applications while improving energy efficiency, treatment uniformity, and process control. Recent innovations have focused on developing modular and scalable systems that can be integrated into existing industrial processes.

The primary objective of cold plasma technology research is to establish precise design parameters that optimize treatment efficacy across diverse applications. These applications span medical sterilization, surface modification of polymers, food safety enhancement, agricultural seed treatment, and environmental remediation. Each application domain presents unique requirements regarding plasma characteristics such as electron density, reactive species composition, and exposure protocols.

Current research aims to develop standardized methodologies for characterizing plasma properties and correlating them with treatment outcomes. This includes establishing quantitative relationships between input parameters (power, frequency, gas composition) and resulting plasma characteristics (electron temperature, reactive species concentration, UV emission). Understanding these relationships is crucial for designing plasma systems that deliver consistent and predictable results.

Another key objective is to enhance energy efficiency and reduce operational costs, making cold plasma treatments economically viable for widespread industrial adoption. This involves optimizing power supply designs, improving electrode configurations, and developing intelligent control systems that can adapt treatment parameters in real-time based on feedback mechanisms.

The field is also moving toward more sustainable approaches, with research focused on reducing gas consumption, minimizing harmful byproducts, and developing plasma systems powered by renewable energy sources. These sustainability considerations are becoming increasingly important as the technology transitions from laboratory research to commercial applications.

Market Applications and Demand Analysis

Cold plasma treatment technology has witnessed significant market growth across multiple industries due to its versatility, eco-friendliness, and effectiveness. The global cold plasma market was valued at approximately 1.5 billion USD in 2020 and is projected to reach 3.2 billion USD by 2026, growing at a CAGR of around 15.6% during the forecast period. This substantial growth reflects the expanding applications and increasing demand for cold plasma technologies across various sectors.

The healthcare and medical industry represents the largest market segment for cold plasma applications, accounting for nearly 40% of the total market share. Within this sector, wound healing, sterilization of medical equipment, dental treatments, and cancer therapies are driving significant demand. The ability of cold plasma to effectively eliminate pathogens without damaging sensitive materials makes it particularly valuable in hospital settings where antimicrobial resistance is a growing concern.

The electronics and semiconductor industry has emerged as another major market for cold plasma technology, particularly for surface modification and cleaning processes. As electronic devices become smaller and more complex, the demand for precise, non-destructive treatment methods has increased substantially. Cold plasma offers advantages in terms of uniform treatment, minimal substrate damage, and compatibility with sensitive components.

In the food processing industry, cold plasma is gaining traction as a non-thermal food preservation technique. Consumer demand for minimally processed foods with extended shelf life has pushed manufacturers to explore alternatives to traditional preservation methods. Cold plasma can effectively decontaminate food surfaces without affecting nutritional content or sensory qualities, addressing key consumer concerns about food safety and quality.

The textile industry has also recognized the potential of cold plasma for fabric treatment, with applications in water repellency, dyeability enhancement, and antimicrobial finishing. The growing emphasis on sustainable manufacturing processes has further accelerated adoption, as cold plasma treatments typically require less water and chemicals compared to conventional methods.

Regional analysis indicates that North America and Europe currently dominate the cold plasma market, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about plasma technology applications in countries like China, Japan, and South Korea.

Market challenges include high initial equipment costs, technical complexity requiring specialized knowledge, and the need for standardization across applications. Despite these barriers, the expanding range of applications and ongoing technological advancements continue to drive market growth for cold plasma treatment technologies.

The healthcare and medical industry represents the largest market segment for cold plasma applications, accounting for nearly 40% of the total market share. Within this sector, wound healing, sterilization of medical equipment, dental treatments, and cancer therapies are driving significant demand. The ability of cold plasma to effectively eliminate pathogens without damaging sensitive materials makes it particularly valuable in hospital settings where antimicrobial resistance is a growing concern.

The electronics and semiconductor industry has emerged as another major market for cold plasma technology, particularly for surface modification and cleaning processes. As electronic devices become smaller and more complex, the demand for precise, non-destructive treatment methods has increased substantially. Cold plasma offers advantages in terms of uniform treatment, minimal substrate damage, and compatibility with sensitive components.

In the food processing industry, cold plasma is gaining traction as a non-thermal food preservation technique. Consumer demand for minimally processed foods with extended shelf life has pushed manufacturers to explore alternatives to traditional preservation methods. Cold plasma can effectively decontaminate food surfaces without affecting nutritional content or sensory qualities, addressing key consumer concerns about food safety and quality.

The textile industry has also recognized the potential of cold plasma for fabric treatment, with applications in water repellency, dyeability enhancement, and antimicrobial finishing. The growing emphasis on sustainable manufacturing processes has further accelerated adoption, as cold plasma treatments typically require less water and chemicals compared to conventional methods.

Regional analysis indicates that North America and Europe currently dominate the cold plasma market, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about plasma technology applications in countries like China, Japan, and South Korea.

Market challenges include high initial equipment costs, technical complexity requiring specialized knowledge, and the need for standardization across applications. Despite these barriers, the expanding range of applications and ongoing technological advancements continue to drive market growth for cold plasma treatment technologies.

Current Technical Challenges in Cold Plasma Systems

Despite significant advancements in cold plasma technology, several technical challenges continue to impede its widespread implementation and optimization. One of the primary obstacles is achieving precise control over plasma parameters, particularly electron temperature, ion density, and reactive species concentration. These parameters directly influence treatment efficacy but are notoriously difficult to maintain consistently across different operational conditions and substrate materials.

The scalability of cold plasma systems presents another significant challenge. While laboratory-scale devices demonstrate promising results, scaling up to industrial applications often leads to non-uniform plasma distribution and inconsistent treatment outcomes. This is particularly problematic for treating three-dimensional objects or large surface areas where maintaining homogeneous plasma exposure becomes increasingly complex.

Power efficiency remains a critical concern in cold plasma system design. Current systems typically convert only 10-30% of input energy into useful plasma generation, with the remainder dissipated as heat. This inefficiency not only increases operational costs but also limits the deployment of portable or battery-operated plasma devices for field applications or point-of-care medical treatments.

Material compatibility issues continue to challenge engineers developing cold plasma systems. Electrode degradation occurs through sputtering and chemical etching during operation, leading to contamination of the plasma and treated surfaces. Additionally, many electrode materials cannot withstand prolonged exposure to reactive plasma species, resulting in shortened operational lifespans and increased maintenance requirements.

Temperature management represents another significant technical hurdle. Although termed "cold," these plasmas still generate heat that can accumulate during extended operation. This thermal buildup can damage temperature-sensitive substrates and alter plasma characteristics, potentially compromising treatment outcomes. Current cooling mechanisms add complexity, weight, and cost to system designs.

Real-time monitoring and feedback control systems remain underdeveloped for cold plasma applications. The lack of robust, integrated sensors capable of withstanding plasma environments limits the ability to implement closed-loop control systems that could automatically adjust operational parameters to maintain optimal treatment conditions.

Gas management and environmental control present additional challenges, particularly for atmospheric pressure systems. Ambient humidity, gas impurities, and environmental contaminants can significantly alter plasma chemistry and treatment outcomes. Creating controlled atmospheres for consistent plasma generation often requires complex gas delivery systems and environmental isolation chambers.

Finally, standardization across the field remains inadequate. The diversity of plasma generation methods, operational parameters, and application-specific requirements has resulted in fragmented approaches to system design and evaluation metrics, hampering comparative studies and technology transfer between research institutions and industry.

The scalability of cold plasma systems presents another significant challenge. While laboratory-scale devices demonstrate promising results, scaling up to industrial applications often leads to non-uniform plasma distribution and inconsistent treatment outcomes. This is particularly problematic for treating three-dimensional objects or large surface areas where maintaining homogeneous plasma exposure becomes increasingly complex.

Power efficiency remains a critical concern in cold plasma system design. Current systems typically convert only 10-30% of input energy into useful plasma generation, with the remainder dissipated as heat. This inefficiency not only increases operational costs but also limits the deployment of portable or battery-operated plasma devices for field applications or point-of-care medical treatments.

Material compatibility issues continue to challenge engineers developing cold plasma systems. Electrode degradation occurs through sputtering and chemical etching during operation, leading to contamination of the plasma and treated surfaces. Additionally, many electrode materials cannot withstand prolonged exposure to reactive plasma species, resulting in shortened operational lifespans and increased maintenance requirements.

Temperature management represents another significant technical hurdle. Although termed "cold," these plasmas still generate heat that can accumulate during extended operation. This thermal buildup can damage temperature-sensitive substrates and alter plasma characteristics, potentially compromising treatment outcomes. Current cooling mechanisms add complexity, weight, and cost to system designs.

Real-time monitoring and feedback control systems remain underdeveloped for cold plasma applications. The lack of robust, integrated sensors capable of withstanding plasma environments limits the ability to implement closed-loop control systems that could automatically adjust operational parameters to maintain optimal treatment conditions.

Gas management and environmental control present additional challenges, particularly for atmospheric pressure systems. Ambient humidity, gas impurities, and environmental contaminants can significantly alter plasma chemistry and treatment outcomes. Creating controlled atmospheres for consistent plasma generation often requires complex gas delivery systems and environmental isolation chambers.

Finally, standardization across the field remains inadequate. The diversity of plasma generation methods, operational parameters, and application-specific requirements has resulted in fragmented approaches to system design and evaluation metrics, hampering comparative studies and technology transfer between research institutions and industry.

Current Design Parameters and Control Methods

01 Medical applications of cold plasma treatment

Cold plasma treatment has shown effectiveness in various medical applications. It can be used for wound healing, sterilization of medical equipment, and treatment of skin conditions. The non-thermal nature of cold plasma allows for targeted treatment without causing thermal damage to surrounding tissues. This technology has demonstrated antimicrobial properties that can help in treating infections and promoting faster healing in medical settings.- Medical applications of cold plasma treatment: Cold plasma treatment has shown effectiveness in various medical applications. It can be used for wound healing, tissue regeneration, and treatment of infections. The non-thermal nature of cold plasma allows for targeted treatment of affected areas without causing damage to surrounding healthy tissues. The reactive species generated by cold plasma can effectively kill bacteria, including antibiotic-resistant strains, making it a promising approach for treating infections.

- Sterilization and decontamination effectiveness: Cold plasma treatment is highly effective for sterilization and decontamination purposes. It can inactivate a wide range of microorganisms including bacteria, viruses, fungi, and spores on various surfaces and materials. The reactive species generated by cold plasma can penetrate biofilms and reach microorganisms in hard-to-access areas. This makes cold plasma treatment particularly useful in healthcare settings, food processing facilities, and other environments where maintaining sterility is crucial.

- Surface modification and material treatment: Cold plasma treatment effectively modifies surface properties of various materials. It can enhance adhesion, wettability, and biocompatibility of surfaces without altering their bulk properties. The treatment can create functional groups on material surfaces, improving their interaction with other substances. This makes cold plasma particularly valuable in manufacturing processes, textile industry, and biomedical applications where surface characteristics play a crucial role in product performance.

- Agricultural and food preservation applications: Cold plasma treatment has demonstrated effectiveness in agricultural applications and food preservation. It can decontaminate seeds, fruits, vegetables, and other food products without affecting their nutritional value or sensory qualities. The treatment can inactivate foodborne pathogens, extending shelf life while maintaining food safety. Additionally, cold plasma can stimulate seed germination and plant growth, making it a promising technology for sustainable agriculture practices.

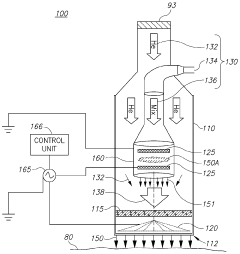

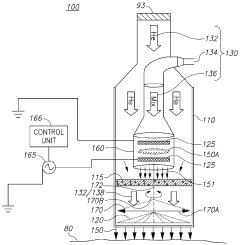

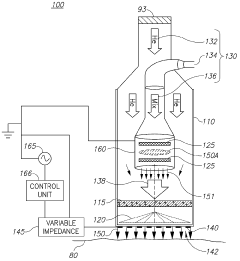

- Device design for optimizing cold plasma effectiveness: The effectiveness of cold plasma treatment is significantly influenced by device design and operational parameters. Various configurations of electrodes, power sources, and gas compositions have been developed to optimize treatment outcomes for specific applications. Portable and flexible cold plasma devices allow for targeted treatment in hard-to-reach areas. Advanced control systems enable precise adjustment of plasma characteristics, ensuring consistent and reliable treatment results across different settings and applications.

02 Cold plasma for surface modification and sterilization

Cold plasma treatment is effective for modifying surface properties of materials and sterilizing various surfaces. The treatment can alter surface energy, wettability, and adhesion properties of materials. It is particularly useful in industrial applications where surface modification is required without affecting the bulk properties of the material. The sterilization capability of cold plasma makes it valuable for decontaminating surfaces in healthcare settings and food processing industries.Expand Specific Solutions03 Biological effects and therapeutic applications

Cold plasma treatment has demonstrated significant biological effects that make it effective for therapeutic applications. It can stimulate cell proliferation, modulate immune responses, and induce selective apoptosis in certain cell types. These properties make cold plasma treatment promising for cancer therapy, dermatological treatments, and tissue regeneration. The controlled application of cold plasma can target specific biological processes without causing systemic side effects.Expand Specific Solutions04 Cold plasma devices and delivery systems

The effectiveness of cold plasma treatment is significantly influenced by the design of plasma generation devices and delivery systems. Various configurations of electrodes, power sources, and gas delivery systems have been developed to optimize plasma properties for specific applications. Portable and targeted delivery systems have enhanced the practical application of cold plasma in clinical settings. The development of precise control mechanisms for plasma parameters has improved treatment outcomes across different applications.Expand Specific Solutions05 Industrial and agricultural applications

Cold plasma treatment has proven effective in various industrial and agricultural applications. It can be used for seed treatment to enhance germination rates and crop yields. In industrial settings, cold plasma is effective for surface cleaning, coating adhesion improvement, and polymer modification. The environmentally friendly nature of cold plasma treatment makes it an attractive alternative to chemical treatments in food processing and agricultural applications. It can also be used for water treatment and air purification.Expand Specific Solutions

Leading Companies and Research Institutions

Cold plasma treatment technology is evolving rapidly, with the market currently in a growth phase characterized by increasing applications across medical, semiconductor, and consumer industries. The global market size is projected to reach several billion dollars by 2025, driven by expanding applications in wound healing, surface modification, and sterilization. From a technological maturity perspective, companies demonstrate varying levels of advancement: established semiconductor equipment manufacturers like Tokyo Electron, Lam Research, and SMIC have integrated cold plasma into mature production processes, while specialized medical technology firms such as Plasmology4, US Medical Innovations, and CINOGY GmbH are advancing clinical applications. Consumer product companies like L'Oréal are exploring cosmetic applications, indicating market diversification. Research institutions including Dalian University of Technology and Université Libre de Bruxelles continue to expand fundamental understanding, suggesting the technology still has significant untapped potential despite commercial deployment.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed sophisticated cold plasma treatment systems primarily for semiconductor manufacturing with precise design parameters. Their approach centers on radio frequency (RF) and microwave plasma sources operating at 13.56 MHz and 2.45 GHz respectively, with power densities ranging from 0.1-5 W/cm². TEL's systems feature advanced gas delivery with mass flow controllers providing accuracy of ±0.5% for precise gas mixture ratios, critical for controlled surface modification. Their plasma chambers incorporate temperature-controlled substrates (15-350°C) with ±1°C precision to optimize treatment conditions while preventing thermal damage. TEL's technology utilizes impedance matching networks with auto-tuning capabilities that maintain optimal power transfer efficiency >95% despite plasma load variations. For semiconductor applications, they've developed specialized electrode configurations that ensure plasma uniformity within ±3% across 300mm wafers. Their systems also feature in-situ plasma diagnostics including optical emission spectroscopy and ion energy analyzers that provide real-time feedback for process control and repeatability. TEL's cold plasma treatment parameters are optimized through computational fluid dynamics and plasma physics modeling to predict reactive species distribution and surface interactions.

Strengths: Exceptional plasma uniformity across large surface areas; highly precise control of process parameters; sophisticated in-situ monitoring capabilities enabling real-time adjustments; proven reliability in high-volume manufacturing environments. Weaknesses: Systems primarily optimized for semiconductor applications with less flexibility for other industries; high capital investment requirements; complex operation requiring specialized technical expertise; limited portability due to sophisticated infrastructure requirements.

Lam Research Corp.

Technical Solution: Lam Research has developed advanced cold plasma treatment systems with precisely defined design parameters focused on semiconductor manufacturing applications. Their technology utilizes capacitively coupled plasma (CCP) and inductively coupled plasma (ICP) sources operating at frequencies between 2-60 MHz with power densities ranging from 0.1-2.5 W/cm². Lam's systems feature proprietary gas distribution technology that ensures uniform delivery across treatment surfaces with flow rates precisely controlled between 10-1000 sccm. Their plasma chambers incorporate multi-zone temperature control systems maintaining substrate temperatures between 20-150°C with ±1°C precision, critical for preventing thermal damage while optimizing surface modification. Lam's cold plasma technology employs pulsed RF power delivery with duty cycles from 10-90% and frequencies of 10 Hz to 10 kHz, allowing for enhanced control of ion energy distribution and reactive species generation. For advanced semiconductor processes, they've developed specialized electrode designs that create tailored electric field distributions, enabling selective treatment of complex topographies. Their systems also incorporate real-time plasma monitoring using optical emission spectroscopy and RF impedance analysis to maintain process stability and repeatability. Lam's cold plasma treatment parameters are optimized through extensive computational modeling and empirical testing to achieve specific surface modification objectives while minimizing damage to sensitive materials.

Strengths: Industry-leading plasma uniformity across large wafers; sophisticated pulsed plasma capabilities enabling precise control of ion energies; advanced real-time monitoring systems ensuring process stability; proven track record in high-volume semiconductor manufacturing. Weaknesses: Systems primarily designed for semiconductor applications with limited flexibility for other industries; high capital and operational costs; complex operation requiring specialized technical expertise; substantial facility requirements including clean room environments and specialized utilities.

Key Patents and Scientific Breakthroughs

Cold plasma treatment

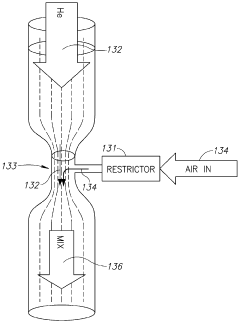

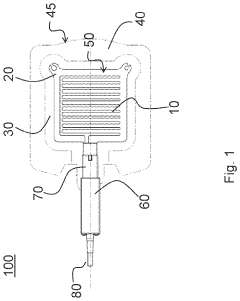

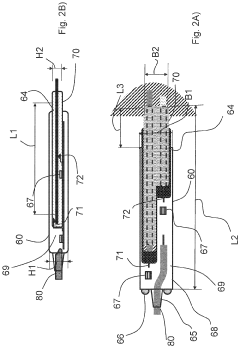

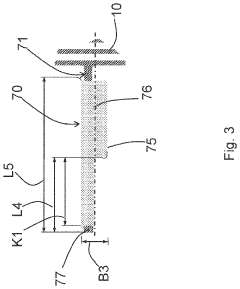

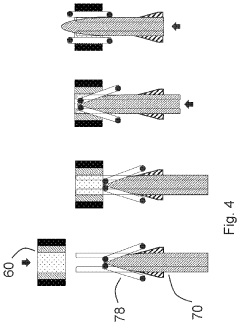

PatentWO2015059702A1

Innovation

- A plasma treatment device with a nozzle configured to receive a first gas and an auxiliary gas, and at least one electrode applying a radiofrequency electromagnetic field to ionize the gases, emitting plasma uniformly over a large treatment area, using a rotating or vibrating electrode configuration to prevent hot spots and ensure even plasma distribution.

Plasma applicator

PatentPendingUS20230165624A1

Innovation

- The development of an electrotechnical core with a simplified design that is safe to touch, eliminating the need for complex enclosures, and incorporating a third electrode structure for grounding and EMC shielding, along with features such as a taper for single-use assurance and a flexible shape for adaptable surface treatment.

Safety Standards and Regulatory Framework

The regulatory landscape for cold plasma technology is complex and evolving, with standards varying significantly across different regions and applications. In medical applications, cold plasma devices must comply with IEC 60601 standards for medical electrical equipment safety, with specific attention to parts 1-2 covering electromagnetic compatibility requirements. The FDA in the United States classifies plasma devices based on intended use, with most falling under Class II (moderate risk) requiring 510(k) clearance, while novel applications may be classified as Class III requiring premarket approval.

For industrial applications, workplace safety standards such as OSHA regulations in the US and the EU's Machinery Directive 2006/42/EC govern the implementation of cold plasma systems. These frameworks mandate risk assessment procedures, proper engineering controls, and operator training protocols. The International Electrotechnical Commission (IEC) provides additional standards for electrical safety through IEC 61010 for laboratory equipment.

Emission standards represent another critical regulatory consideration, with cold plasma systems potentially generating ozone, nitrogen oxides, and electromagnetic radiation. The EPA in the US and similar environmental agencies worldwide establish permissible exposure limits for these byproducts. The IEEE C95.1 standard specifically addresses human exposure to electromagnetic fields, which is particularly relevant for radio-frequency generated plasma systems.

Material compatibility regulations must also be considered when plasma-treated products contact food or human tissue. The EU's REACH regulation and FDA's biocompatibility guidelines under ISO 10993 series provide frameworks for evaluating potential chemical interactions and residual treatment effects. For food processing applications, cold plasma systems must comply with food safety regulations including FDA's Food Safety Modernization Act in the US and the EU's Regulation (EC) No 852/2004.

Documentation requirements across these regulatory frameworks necessitate comprehensive technical files including risk management documentation (ISO 14971), validation protocols, and performance data. Manufacturers must implement quality management systems compliant with ISO 13485 for medical applications or ISO 9001 for industrial uses. Regular audits and post-market surveillance are mandatory in most jurisdictions to ensure ongoing compliance and safety.

As cold plasma technology continues to evolve, regulatory frameworks are adapting to address emerging applications. International harmonization efforts are underway to standardize safety requirements, though significant regional variations persist, creating compliance challenges for global deployment of cold plasma treatment systems.

For industrial applications, workplace safety standards such as OSHA regulations in the US and the EU's Machinery Directive 2006/42/EC govern the implementation of cold plasma systems. These frameworks mandate risk assessment procedures, proper engineering controls, and operator training protocols. The International Electrotechnical Commission (IEC) provides additional standards for electrical safety through IEC 61010 for laboratory equipment.

Emission standards represent another critical regulatory consideration, with cold plasma systems potentially generating ozone, nitrogen oxides, and electromagnetic radiation. The EPA in the US and similar environmental agencies worldwide establish permissible exposure limits for these byproducts. The IEEE C95.1 standard specifically addresses human exposure to electromagnetic fields, which is particularly relevant for radio-frequency generated plasma systems.

Material compatibility regulations must also be considered when plasma-treated products contact food or human tissue. The EU's REACH regulation and FDA's biocompatibility guidelines under ISO 10993 series provide frameworks for evaluating potential chemical interactions and residual treatment effects. For food processing applications, cold plasma systems must comply with food safety regulations including FDA's Food Safety Modernization Act in the US and the EU's Regulation (EC) No 852/2004.

Documentation requirements across these regulatory frameworks necessitate comprehensive technical files including risk management documentation (ISO 14971), validation protocols, and performance data. Manufacturers must implement quality management systems compliant with ISO 13485 for medical applications or ISO 9001 for industrial uses. Regular audits and post-market surveillance are mandatory in most jurisdictions to ensure ongoing compliance and safety.

As cold plasma technology continues to evolve, regulatory frameworks are adapting to address emerging applications. International harmonization efforts are underway to standardize safety requirements, though significant regional variations persist, creating compliance challenges for global deployment of cold plasma treatment systems.

Environmental Impact Assessment

Cold plasma treatment technologies, while offering significant advantages over conventional methods, must be carefully evaluated for their environmental impacts. The assessment of these impacts is crucial for ensuring sustainable implementation and regulatory compliance.

The energy consumption of cold plasma systems represents a primary environmental consideration. Compared to traditional thermal treatments, cold plasma typically requires 30-50% less energy, operating at ambient temperatures rather than the 300-400°C needed for many thermal processes. This reduced energy footprint translates to lower greenhouse gas emissions, with studies indicating potential reductions of 2-3 tons of CO2 equivalent per industrial unit annually.

Water usage presents another critical environmental parameter. Cold plasma treatments generally operate in dry conditions, potentially reducing water consumption by 70-90% compared to wet chemical processes. This aspect is particularly significant in water-stressed regions and industries with high water demands such as textile processing and semiconductor manufacturing.

Regarding chemical inputs, cold plasma significantly reduces or eliminates the need for hazardous chemicals in many applications. For instance, in surface sterilization, cold plasma can replace chlorine-based disinfectants, reducing toxic effluent by up to 85%. The technology generates reactive species in situ without requiring chemical storage or transportation, further minimizing environmental risks associated with chemical handling.

Waste generation and management constitute important considerations in environmental impact assessment. Cold plasma treatments typically produce minimal solid waste compared to conventional methods. In textile treatments, for example, cold plasma finishing can reduce chemical waste by approximately 60-75%. However, the potential generation of NOx and ozone during operation requires proper ventilation and monitoring systems to prevent air quality issues.

Life cycle assessment (LCA) studies indicate that cold plasma systems generally demonstrate favorable environmental profiles when properly designed. A comprehensive LCA of plasma-based surface treatment showed 40-60% lower environmental impact scores across categories including global warming potential, acidification, and resource depletion compared to conventional chemical treatments.

Regulatory frameworks increasingly recognize cold plasma as an environmentally preferable technology. The European Union's Best Available Techniques Reference Documents (BREFs) have begun incorporating cold plasma treatments as environmentally advantageous options in several industrial sectors, while the US EPA has classified certain plasma applications as pollution prevention technologies eligible for regulatory incentives.

The energy consumption of cold plasma systems represents a primary environmental consideration. Compared to traditional thermal treatments, cold plasma typically requires 30-50% less energy, operating at ambient temperatures rather than the 300-400°C needed for many thermal processes. This reduced energy footprint translates to lower greenhouse gas emissions, with studies indicating potential reductions of 2-3 tons of CO2 equivalent per industrial unit annually.

Water usage presents another critical environmental parameter. Cold plasma treatments generally operate in dry conditions, potentially reducing water consumption by 70-90% compared to wet chemical processes. This aspect is particularly significant in water-stressed regions and industries with high water demands such as textile processing and semiconductor manufacturing.

Regarding chemical inputs, cold plasma significantly reduces or eliminates the need for hazardous chemicals in many applications. For instance, in surface sterilization, cold plasma can replace chlorine-based disinfectants, reducing toxic effluent by up to 85%. The technology generates reactive species in situ without requiring chemical storage or transportation, further minimizing environmental risks associated with chemical handling.

Waste generation and management constitute important considerations in environmental impact assessment. Cold plasma treatments typically produce minimal solid waste compared to conventional methods. In textile treatments, for example, cold plasma finishing can reduce chemical waste by approximately 60-75%. However, the potential generation of NOx and ozone during operation requires proper ventilation and monitoring systems to prevent air quality issues.

Life cycle assessment (LCA) studies indicate that cold plasma systems generally demonstrate favorable environmental profiles when properly designed. A comprehensive LCA of plasma-based surface treatment showed 40-60% lower environmental impact scores across categories including global warming potential, acidification, and resource depletion compared to conventional chemical treatments.

Regulatory frameworks increasingly recognize cold plasma as an environmentally preferable technology. The European Union's Best Available Techniques Reference Documents (BREFs) have begun incorporating cold plasma treatments as environmentally advantageous options in several industrial sectors, while the US EPA has classified certain plasma applications as pollution prevention technologies eligible for regulatory incentives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!