Analysis of Conductive Adhesives in Antenna Design

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Evolution and Objectives

Conductive adhesives have evolved significantly since their inception in the electronics industry in the 1960s. Initially developed as alternatives to traditional soldering methods, these materials have undergone substantial transformation in composition, performance characteristics, and application scope. The evolution trajectory began with simple silver-filled epoxy formulations that offered basic electrical conductivity but suffered from reliability issues and limited thermal performance.

By the 1980s, advancements in polymer chemistry led to the development of second-generation conductive adhesives with improved thermal stability and adhesion properties. The 1990s witnessed the emergence of isotropically conductive adhesives (ICAs) and anisotropically conductive adhesives (ACAs), expanding the application possibilities in microelectronics assembly.

The early 2000s marked a pivotal shift with the introduction of nano-enhanced conductive adhesives, incorporating carbon nanotubes, graphene, and metallic nanoparticles. These innovations significantly improved electrical conductivity while maintaining or enhancing mechanical flexibility – properties particularly valuable for antenna applications.

In the antenna design domain, conductive adhesives have transitioned from being merely alternative bonding solutions to becoming enabling materials for novel antenna architectures. The integration of conductive adhesives in flexible electronics has revolutionized antenna design approaches, allowing for conformal, stretchable, and wearable antenna systems that were previously unattainable with conventional metallic conductors and soldering techniques.

The primary objectives of current conductive adhesive research for antenna applications focus on several critical aspects. First, enhancing electrical performance to achieve conductivity levels comparable to or exceeding traditional metallic conductors while maintaining adhesive properties. Second, improving environmental stability to ensure consistent performance across varying temperature, humidity, and mechanical stress conditions.

Third, developing formulations with optimized curing processes compatible with temperature-sensitive substrates, particularly important for flexible and organic electronics. Fourth, creating adhesives with tunable electromagnetic properties to enable frequency-selective antenna designs and improved signal integrity.

Fifth, advancing sustainability through the development of lead-free, halogen-free formulations with reduced environmental impact. Finally, achieving cost-effectiveness to facilitate broader commercial adoption across consumer electronics, automotive, aerospace, and medical device sectors.

The convergence of these evolutionary trends and research objectives is driving the integration of conductive adhesives in next-generation antenna designs, particularly for 5G/6G communications, Internet of Things (IoT) devices, and advanced radar systems where form factor, weight, and performance flexibility are paramount considerations.

By the 1980s, advancements in polymer chemistry led to the development of second-generation conductive adhesives with improved thermal stability and adhesion properties. The 1990s witnessed the emergence of isotropically conductive adhesives (ICAs) and anisotropically conductive adhesives (ACAs), expanding the application possibilities in microelectronics assembly.

The early 2000s marked a pivotal shift with the introduction of nano-enhanced conductive adhesives, incorporating carbon nanotubes, graphene, and metallic nanoparticles. These innovations significantly improved electrical conductivity while maintaining or enhancing mechanical flexibility – properties particularly valuable for antenna applications.

In the antenna design domain, conductive adhesives have transitioned from being merely alternative bonding solutions to becoming enabling materials for novel antenna architectures. The integration of conductive adhesives in flexible electronics has revolutionized antenna design approaches, allowing for conformal, stretchable, and wearable antenna systems that were previously unattainable with conventional metallic conductors and soldering techniques.

The primary objectives of current conductive adhesive research for antenna applications focus on several critical aspects. First, enhancing electrical performance to achieve conductivity levels comparable to or exceeding traditional metallic conductors while maintaining adhesive properties. Second, improving environmental stability to ensure consistent performance across varying temperature, humidity, and mechanical stress conditions.

Third, developing formulations with optimized curing processes compatible with temperature-sensitive substrates, particularly important for flexible and organic electronics. Fourth, creating adhesives with tunable electromagnetic properties to enable frequency-selective antenna designs and improved signal integrity.

Fifth, advancing sustainability through the development of lead-free, halogen-free formulations with reduced environmental impact. Finally, achieving cost-effectiveness to facilitate broader commercial adoption across consumer electronics, automotive, aerospace, and medical device sectors.

The convergence of these evolutionary trends and research objectives is driving the integration of conductive adhesives in next-generation antenna designs, particularly for 5G/6G communications, Internet of Things (IoT) devices, and advanced radar systems where form factor, weight, and performance flexibility are paramount considerations.

Market Analysis for Antenna Conductive Adhesives

The global market for conductive adhesives in antenna design is experiencing robust growth, driven by the rapid expansion of wireless communication technologies and the increasing demand for miniaturized electronic devices. The market size was valued at approximately 3.2 billion USD in 2022 and is projected to reach 5.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 10.2% during the forecast period.

The demand for conductive adhesives in antenna applications is primarily fueled by the ongoing deployment of 5G infrastructure worldwide. As 5G networks require more complex antenna systems, including massive MIMO (Multiple-Input Multiple-Output) and phased array antennas, the need for specialized conductive adhesives that can maintain signal integrity at higher frequencies has increased significantly.

Consumer electronics represents the largest application segment, accounting for nearly 40% of the market share. The miniaturization trend in smartphones, wearables, and IoT devices has created substantial demand for conductive adhesives that can replace traditional soldering methods while providing reliable electrical connections in compact spaces.

Automotive applications are emerging as the fastest-growing segment, with a CAGR of 12.8%. The increasing integration of advanced driver-assistance systems (ADAS), connected car features, and in-vehicle entertainment systems has boosted the demand for specialized antenna solutions that can withstand harsh environmental conditions.

Geographically, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses such as China, South Korea, and Taiwan. North America follows with a 28% market share, driven by technological innovations and the presence of major aerospace and defense contractors.

Silver-filled epoxy adhesives currently lead the market with a 38% share due to their excellent conductivity and reliability. However, newer formulations based on graphene and carbon nanotubes are gaining traction, especially in high-frequency applications where signal loss minimization is critical.

Key customer segments include telecommunications equipment manufacturers (32%), consumer electronics producers (40%), automotive suppliers (15%), aerospace and defense contractors (8%), and medical device manufacturers (5%). Each segment has distinct requirements regarding conductivity, durability, processing temperature, and environmental resistance.

Price sensitivity varies significantly across applications. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and defense customers focus more on performance reliability and are willing to pay premium prices for adhesives that meet stringent specifications.

The demand for conductive adhesives in antenna applications is primarily fueled by the ongoing deployment of 5G infrastructure worldwide. As 5G networks require more complex antenna systems, including massive MIMO (Multiple-Input Multiple-Output) and phased array antennas, the need for specialized conductive adhesives that can maintain signal integrity at higher frequencies has increased significantly.

Consumer electronics represents the largest application segment, accounting for nearly 40% of the market share. The miniaturization trend in smartphones, wearables, and IoT devices has created substantial demand for conductive adhesives that can replace traditional soldering methods while providing reliable electrical connections in compact spaces.

Automotive applications are emerging as the fastest-growing segment, with a CAGR of 12.8%. The increasing integration of advanced driver-assistance systems (ADAS), connected car features, and in-vehicle entertainment systems has boosted the demand for specialized antenna solutions that can withstand harsh environmental conditions.

Geographically, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses such as China, South Korea, and Taiwan. North America follows with a 28% market share, driven by technological innovations and the presence of major aerospace and defense contractors.

Silver-filled epoxy adhesives currently lead the market with a 38% share due to their excellent conductivity and reliability. However, newer formulations based on graphene and carbon nanotubes are gaining traction, especially in high-frequency applications where signal loss minimization is critical.

Key customer segments include telecommunications equipment manufacturers (32%), consumer electronics producers (40%), automotive suppliers (15%), aerospace and defense contractors (8%), and medical device manufacturers (5%). Each segment has distinct requirements regarding conductivity, durability, processing temperature, and environmental resistance.

Price sensitivity varies significantly across applications. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and defense customers focus more on performance reliability and are willing to pay premium prices for adhesives that meet stringent specifications.

Technical Challenges in Conductive Adhesive Implementation

Despite the promising applications of conductive adhesives in antenna design, several significant technical challenges impede their widespread implementation. The primary concern revolves around electrical conductivity stability over time. Conductive adhesives typically contain metal particles (silver, copper, or nickel) suspended in polymer matrices, which can experience conductivity degradation due to oxidation, thermal cycling, and environmental exposure. This degradation manifests as increased resistance, potentially compromising antenna performance in long-term applications.

Mechanical reliability presents another substantial challenge. The coefficient of thermal expansion (CTE) mismatch between conductive adhesives and substrate materials creates stress at interfaces during temperature fluctuations. This stress can lead to microcracks, delamination, and eventual connection failure. For antennas deployed in harsh environments or those experiencing frequent thermal cycling, this reliability issue becomes particularly critical.

Processing complexity further complicates implementation. Conductive adhesives require precise control of curing parameters including temperature, time, and pressure. Insufficient curing results in poor conductivity, while excessive curing can cause brittleness and reduced adhesion strength. Additionally, the viscosity of these adhesives must be carefully managed to ensure proper dispensing and prevent issues like voiding or inconsistent bond lines.

Environmental sensitivity represents a significant hurdle for outdoor antenna applications. Moisture absorption by the polymer matrix can dramatically alter electrical properties and accelerate degradation mechanisms. Similarly, UV exposure can degrade the polymer component, affecting both mechanical and electrical performance over time. These environmental factors necessitate additional protective measures, increasing complexity and cost.

Cost considerations also pose implementation challenges. High-performance conductive adhesives often contain precious metals like silver, making them significantly more expensive than traditional soldering methods. This cost differential becomes particularly problematic for large-scale antenna manufacturing or applications requiring extensive adhesive coverage.

Compatibility with existing manufacturing processes presents integration difficulties. Many electronics manufacturing facilities are optimized for soldering processes, and transitioning to conductive adhesives requires new equipment, process development, and worker training. The lack of standardized testing and qualification procedures for conductive adhesives in antenna applications further complicates adoption and quality assurance.

Finally, RF performance optimization remains challenging. The dielectric properties of the polymer component in conductive adhesives can affect signal propagation characteristics, potentially introducing losses or altering antenna radiation patterns. Engineers must carefully model and account for these effects when designing antennas using conductive adhesive technology.

Mechanical reliability presents another substantial challenge. The coefficient of thermal expansion (CTE) mismatch between conductive adhesives and substrate materials creates stress at interfaces during temperature fluctuations. This stress can lead to microcracks, delamination, and eventual connection failure. For antennas deployed in harsh environments or those experiencing frequent thermal cycling, this reliability issue becomes particularly critical.

Processing complexity further complicates implementation. Conductive adhesives require precise control of curing parameters including temperature, time, and pressure. Insufficient curing results in poor conductivity, while excessive curing can cause brittleness and reduced adhesion strength. Additionally, the viscosity of these adhesives must be carefully managed to ensure proper dispensing and prevent issues like voiding or inconsistent bond lines.

Environmental sensitivity represents a significant hurdle for outdoor antenna applications. Moisture absorption by the polymer matrix can dramatically alter electrical properties and accelerate degradation mechanisms. Similarly, UV exposure can degrade the polymer component, affecting both mechanical and electrical performance over time. These environmental factors necessitate additional protective measures, increasing complexity and cost.

Cost considerations also pose implementation challenges. High-performance conductive adhesives often contain precious metals like silver, making them significantly more expensive than traditional soldering methods. This cost differential becomes particularly problematic for large-scale antenna manufacturing or applications requiring extensive adhesive coverage.

Compatibility with existing manufacturing processes presents integration difficulties. Many electronics manufacturing facilities are optimized for soldering processes, and transitioning to conductive adhesives requires new equipment, process development, and worker training. The lack of standardized testing and qualification procedures for conductive adhesives in antenna applications further complicates adoption and quality assurance.

Finally, RF performance optimization remains challenging. The dielectric properties of the polymer component in conductive adhesives can affect signal propagation characteristics, potentially introducing losses or altering antenna radiation patterns. Engineers must carefully model and account for these effects when designing antennas using conductive adhesive technology.

Current Conductive Adhesive Solutions for Antennas

01 Conductive fillers in adhesive compositions

Conductive adhesives incorporate various conductive fillers to achieve electrical conductivity. These fillers include metal particles (such as silver, copper, nickel), carbon-based materials (like carbon nanotubes, graphene), and metal-coated particles. The type, size, shape, and concentration of these fillers significantly impact the adhesive's conductivity, mechanical properties, and processing characteristics. Optimizing the filler loading allows for balancing conductivity requirements with adhesion strength and flexibility.- Metal-filled conductive adhesives: Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These particles form conductive pathways when the adhesive cures, allowing for electrical connections between components. The metal fillers provide excellent electrical conductivity while maintaining adhesive properties. These formulations are widely used in electronics assembly, particularly for applications requiring high conductivity and reliability.

- Carbon-based conductive adhesives: Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials provide moderate electrical conductivity at lower cost compared to metal fillers. Carbon-based adhesives offer advantages including lighter weight, corrosion resistance, and in some cases, thermal conductivity. They are particularly useful in applications where moderate conductivity is sufficient and cost considerations are important.

- Anisotropic conductive adhesives: Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These specialized adhesives typically contain conductive particles dispersed in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive paths only in the direction of compression. This technology is particularly valuable for fine-pitch connections in display technologies, flexible electronics, and high-density interconnects.

- Thermally conductive adhesives: Thermally conductive adhesives are designed to transfer heat while maintaining electrical insulation or providing electrical conductivity as needed. These adhesives incorporate fillers such as aluminum oxide, boron nitride, or metal particles to enhance thermal conductivity. They are crucial for heat management in electronic devices, bonding heat sinks, and thermal interface applications. Advanced formulations balance thermal conductivity, adhesion strength, and application-specific requirements like flexibility or reworkability.

- Environmentally friendly conductive adhesives: Environmentally friendly conductive adhesives address concerns about toxicity and environmental impact by eliminating or reducing hazardous materials like lead and certain solvents. These formulations may use bio-based resins, water-based systems, or alternative conductive fillers that comply with regulations such as RoHS and REACH. They maintain performance standards while offering improved sustainability, reduced VOC emissions, and safer handling. Applications include consumer electronics, medical devices, and green technology sectors.

02 Polymer matrices for conductive adhesives

The polymer matrix serves as the binding component in conductive adhesives, providing adhesion while supporting the conductive network. Common polymer systems include epoxies, silicones, acrylics, and polyurethanes. Each polymer type offers different characteristics regarding curing mechanisms, temperature resistance, flexibility, and environmental stability. Advanced formulations may incorporate hybrid polymer systems or specialized additives to enhance specific properties such as thermal conductivity, moisture resistance, or flexibility while maintaining electrical conductivity.Expand Specific Solutions03 Anisotropic conductive adhesives

Anisotropic conductive adhesives (ACAs) provide electrical conductivity in a specific direction while maintaining insulation in other directions. These specialized adhesives typically contain conductive particles dispersed in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive pathways in the z-direction while remaining isolated laterally. This technology is particularly valuable for fine-pitch electronics assembly, display technologies, and flexible electronics where directional conductivity is required without the risk of short circuits.Expand Specific Solutions04 Thermal management in conductive adhesives

Conductive adhesives often serve dual purposes of electrical connection and thermal management. Formulations may incorporate thermally conductive fillers such as aluminum oxide, boron nitride, or metal particles to enhance heat dissipation. The balance between electrical conductivity, thermal conductivity, and mechanical properties is critical for applications in power electronics, LED packaging, and other heat-generating devices. Advanced formulations may use hybrid filler systems to optimize both electrical and thermal pathways within the adhesive matrix.Expand Specific Solutions05 Application-specific conductive adhesive formulations

Conductive adhesives are tailored for specific applications with unique requirements. For flexible electronics, adhesives must maintain conductivity under bending and stretching conditions. For automotive and aerospace applications, formulations focus on vibration resistance and temperature stability. Medical device adhesives require biocompatibility alongside conductivity. Printable conductive adhesives enable new manufacturing methods for electronic circuits. Each application drives specific formulation choices regarding cure conditions, viscosity, pot life, and long-term reliability under environmental stresses.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conductive adhesives market in antenna design is experiencing rapid growth, driven by increasing demand for miniaturized electronic devices and flexible antennas. Currently in its growth phase, the market is expanding at a CAGR of approximately 8-10%, with significant technological advancements from key players. Companies like Apple and Huawei are leading consumer electronics applications, while Motorola Solutions and TE Connectivity dominate specialized communications sectors. Technical maturity varies across applications, with Samsung Electro Mechanics, Avery Dennison, and tesa SE advancing adhesive formulations for improved conductivity and reliability. Research institutions like Shanghai University and Shenzhen Institutes of Advanced Technology are collaborating with industry leaders to develop next-generation conductive adhesives with enhanced thermal and electrical properties.

TE Connectivity Corp.

Technical Solution: TE Connectivity has developed advanced conductive adhesive solutions specifically engineered for antenna applications. Their technology utilizes silver-filled epoxy systems that provide excellent electrical conductivity (typically >104 S/cm) while maintaining strong mechanical bonding properties. Their proprietary formulations incorporate nano-silver particles suspended in thermosetting polymers, creating flexible joints that can withstand thermal cycling and mechanical stress. TE's antenna-specific adhesives feature controlled rheology for precision dispensing and screen printing applications, with curing temperatures as low as 80°C to protect sensitive components. Their solutions enable direct attachment of antenna elements to flexible substrates, eliminating the need for traditional soldering while reducing assembly thickness by up to 40% compared to conventional methods.

Strengths: Superior electrical performance with minimal signal loss; excellent environmental resistance including humidity and temperature cycling; compatible with automated manufacturing processes. Weaknesses: Higher cost compared to traditional soldering; requires specialized application equipment; some formulations have limited shelf life requiring controlled storage conditions.

Fractal Antenna Systems, Inc.

Technical Solution: Fractal Antenna Systems has pioneered innovative conductive adhesive technologies specifically optimized for their proprietary fractal antenna designs. Their approach integrates specialized silver-based anisotropic conductive adhesives (ACAs) that enable precise electrical connections between complex fractal patterns while maintaining the geometric integrity critical to fractal antenna performance. The company's proprietary formulations achieve conductivity exceeding 5×10^5 S/m while providing flexibility to accommodate their unique antenna geometries. Their adhesive systems incorporate carbon nanotubes to enhance both conductivity and mechanical strength, allowing for reliable connections in their miniaturized antenna designs. Fractal's technology enables direct integration of antenna elements onto curved and irregular surfaces, with their adhesives engineered to maintain consistent electrical properties across varying substrate materials including polymers, ceramics, and composite materials.

Strengths: Specialized formulations optimized specifically for fractal antenna geometries; enables complex antenna designs that traditional connection methods cannot support; excellent performance in high-frequency applications up to 40GHz. Weaknesses: Highly specialized for fractal designs with limited application in conventional antenna structures; requires precise application techniques; higher cost compared to standard conductive adhesives.

Key Patents and Technical Innovations

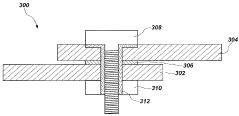

Conductive adhesive and method of forming same

PatentInactiveUS20130142986A1

Innovation

- A method of forming a conductive adhesive by condensation-polymerizing a carrier onto carbon nanotubes, allowing them to extend continuously through the carrier, enabling removability and reusability by maintaining the carrier while removing the substrate, thus creating a dry, two-sided adhesive with excellent mechanical, electrical, and thermal conductivity properties.

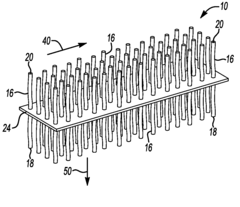

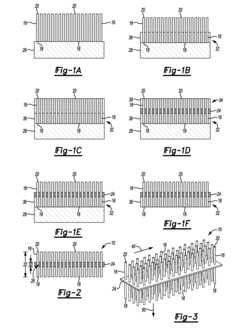

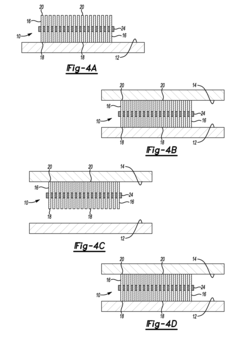

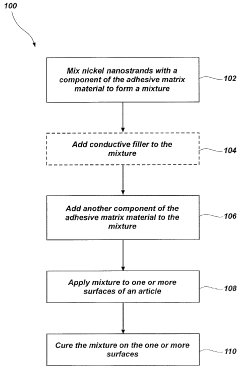

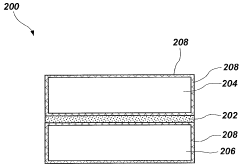

Electrically conductive adhesives, assemblies including the electrically conductive adhesives, and related methods

PatentActiveUS9963619B2

Innovation

- The use of nickel nanostrands dispersed in a matrix of bisphenol-F epoxy resin and resorcinol diglycidyl ether epoxy monomer with an amine-containing curing agent, providing a balance between electrical conductivity and adhesion strength, with tensile adhesion greater than 5,000 psi and volume resistivity less than 0.01 Ω cm.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive adhesives in antenna design represents a critical consideration as electronics manufacturers face increasing pressure to adopt sustainable practices. Traditional antenna manufacturing processes often rely on lead-based solders and harsh chemical treatments that pose significant environmental hazards. Conductive adhesives, particularly those based on silver, copper, and carbon nanomaterials, offer promising alternatives with reduced environmental footprints. These materials typically require lower curing temperatures than conventional soldering methods, resulting in decreased energy consumption during the manufacturing process and associated reduction in carbon emissions.

Recent life cycle assessments comparing conductive adhesives to traditional soldering techniques demonstrate up to 30% reduction in overall environmental impact when properly implemented in antenna production lines. The elimination of lead and other heavy metals from the manufacturing process significantly reduces the potential for soil and water contamination, addressing growing regulatory concerns in major markets including the European Union, North America, and Asia.

Despite these advantages, certain conductive adhesive formulations present their own environmental challenges. Nanosilver particles, while effective for conductivity, may pose ecotoxicological risks if improperly disposed of or released into aquatic environments. Research indicates that silver nanoparticles can adversely affect microbial communities and aquatic organisms at relatively low concentrations. This necessitates careful consideration of end-of-life management for antenna components utilizing these materials.

Recyclability represents another key sustainability factor in conductive adhesive selection. Thermoplastic-based conductive adhesives offer advantages over thermoset varieties, as they can potentially be reprocessed at end-of-life. However, the composite nature of these materials—combining polymeric matrices with metallic fillers—creates separation challenges in conventional recycling streams. Emerging technologies utilizing solvent-based recovery methods show promise for reclaiming valuable metals from adhesive matrices, though commercial-scale implementation remains limited.

Biobased alternatives to petroleum-derived polymer matrices are gaining attention in conductive adhesive research. Formulations incorporating cellulose derivatives, lignin, and other renewable resources demonstrate comparable performance to conventional systems while reducing dependence on fossil resources. These bio-derived systems typically decompose more readily in appropriate end-of-life scenarios, though their electrical performance characteristics may require further optimization for demanding antenna applications.

Water-based conductive adhesive systems represent another environmentally favorable direction, eliminating volatile organic compound (VOC) emissions associated with solvent-based formulations. These systems reduce workplace exposure hazards and atmospheric pollution while maintaining acceptable conductivity profiles for many antenna designs. Recent advancements in water-based silver and graphene dispersions have narrowed the performance gap with solvent-based alternatives, making them increasingly viable for commercial applications.

Recent life cycle assessments comparing conductive adhesives to traditional soldering techniques demonstrate up to 30% reduction in overall environmental impact when properly implemented in antenna production lines. The elimination of lead and other heavy metals from the manufacturing process significantly reduces the potential for soil and water contamination, addressing growing regulatory concerns in major markets including the European Union, North America, and Asia.

Despite these advantages, certain conductive adhesive formulations present their own environmental challenges. Nanosilver particles, while effective for conductivity, may pose ecotoxicological risks if improperly disposed of or released into aquatic environments. Research indicates that silver nanoparticles can adversely affect microbial communities and aquatic organisms at relatively low concentrations. This necessitates careful consideration of end-of-life management for antenna components utilizing these materials.

Recyclability represents another key sustainability factor in conductive adhesive selection. Thermoplastic-based conductive adhesives offer advantages over thermoset varieties, as they can potentially be reprocessed at end-of-life. However, the composite nature of these materials—combining polymeric matrices with metallic fillers—creates separation challenges in conventional recycling streams. Emerging technologies utilizing solvent-based recovery methods show promise for reclaiming valuable metals from adhesive matrices, though commercial-scale implementation remains limited.

Biobased alternatives to petroleum-derived polymer matrices are gaining attention in conductive adhesive research. Formulations incorporating cellulose derivatives, lignin, and other renewable resources demonstrate comparable performance to conventional systems while reducing dependence on fossil resources. These bio-derived systems typically decompose more readily in appropriate end-of-life scenarios, though their electrical performance characteristics may require further optimization for demanding antenna applications.

Water-based conductive adhesive systems represent another environmentally favorable direction, eliminating volatile organic compound (VOC) emissions associated with solvent-based formulations. These systems reduce workplace exposure hazards and atmospheric pollution while maintaining acceptable conductivity profiles for many antenna designs. Recent advancements in water-based silver and graphene dispersions have narrowed the performance gap with solvent-based alternatives, making them increasingly viable for commercial applications.

Reliability Testing and Performance Standards

Reliability testing and performance standards for conductive adhesives in antenna design represent critical aspects that determine the long-term viability of these materials in practical applications. The industry has established several standardized testing protocols to evaluate the performance and durability of conductive adhesives under various environmental conditions. These tests typically include thermal cycling, humidity resistance, salt spray exposure, and mechanical stress evaluations to simulate real-world operating environments.

The IPC-6012 and IPC-6013 standards provide comprehensive guidelines for the qualification and performance requirements of rigid and flexible printed boards, which include specifications for conductive adhesives used in antenna applications. Additionally, the ASTM D5656 standard offers methods for measuring the shear properties of structural adhesives, which is particularly relevant for assessing the mechanical stability of conductive adhesive joints in antenna assemblies.

Temperature cycling tests, conducted according to JEDEC JESD22-A104, evaluate the ability of conductive adhesives to maintain electrical conductivity and mechanical integrity when subjected to repeated temperature variations. This is crucial for antenna applications where devices may experience significant temperature fluctuations during operation. The standard typically requires testing between -40°C and +125°C for automotive and industrial applications, with more stringent requirements for aerospace and military uses.

Humidity resistance testing, following IPC-TM-650 method 2.6.3, assesses the performance of conductive adhesives under high humidity conditions (85% relative humidity at 85°C) for extended periods. This test is particularly important for outdoor antenna installations where moisture ingress can significantly impact conductivity and signal transmission efficiency.

Adhesion strength testing, conducted according to ASTM D1002 or ISO 4587, measures the bond strength between the conductive adhesive and substrate materials. For antenna applications, a minimum adhesion strength of 8-10 MPa is typically required to ensure mechanical stability during operation and handling.

Electrical performance standards for conductive adhesives in antenna applications typically specify maximum volume resistivity values below 10^-4 Ω·cm and surface resistance less than 0.1 Ω/square. These parameters are critical for ensuring efficient signal transmission and minimal power loss in the antenna system. The IEC 61189-2 standard provides methods for measuring these electrical properties under various environmental conditions.

Accelerated aging tests, such as those outlined in ASTM F1980, help predict the long-term reliability of conductive adhesives by subjecting samples to elevated temperatures for specified periods. The Arrhenius equation is commonly used to correlate accelerated aging results with expected real-world performance, allowing manufacturers to estimate the operational lifetime of antenna systems using conductive adhesives.

The IPC-6012 and IPC-6013 standards provide comprehensive guidelines for the qualification and performance requirements of rigid and flexible printed boards, which include specifications for conductive adhesives used in antenna applications. Additionally, the ASTM D5656 standard offers methods for measuring the shear properties of structural adhesives, which is particularly relevant for assessing the mechanical stability of conductive adhesive joints in antenna assemblies.

Temperature cycling tests, conducted according to JEDEC JESD22-A104, evaluate the ability of conductive adhesives to maintain electrical conductivity and mechanical integrity when subjected to repeated temperature variations. This is crucial for antenna applications where devices may experience significant temperature fluctuations during operation. The standard typically requires testing between -40°C and +125°C for automotive and industrial applications, with more stringent requirements for aerospace and military uses.

Humidity resistance testing, following IPC-TM-650 method 2.6.3, assesses the performance of conductive adhesives under high humidity conditions (85% relative humidity at 85°C) for extended periods. This test is particularly important for outdoor antenna installations where moisture ingress can significantly impact conductivity and signal transmission efficiency.

Adhesion strength testing, conducted according to ASTM D1002 or ISO 4587, measures the bond strength between the conductive adhesive and substrate materials. For antenna applications, a minimum adhesion strength of 8-10 MPa is typically required to ensure mechanical stability during operation and handling.

Electrical performance standards for conductive adhesives in antenna applications typically specify maximum volume resistivity values below 10^-4 Ω·cm and surface resistance less than 0.1 Ω/square. These parameters are critical for ensuring efficient signal transmission and minimal power loss in the antenna system. The IEC 61189-2 standard provides methods for measuring these electrical properties under various environmental conditions.

Accelerated aging tests, such as those outlined in ASTM F1980, help predict the long-term reliability of conductive adhesives by subjecting samples to elevated temperatures for specified periods. The Arrhenius equation is commonly used to correlate accelerated aging results with expected real-world performance, allowing manufacturers to estimate the operational lifetime of antenna systems using conductive adhesives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!