Conductive Adhesives for High-performance Computing: Technical Insights

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Background and Objectives

Conductive adhesives have emerged as a critical component in the evolution of high-performance computing (HPC) systems, representing a significant advancement in electronic packaging and interconnection technologies. These specialized materials combine electrical conductivity with adhesive properties, offering unique solutions to the mounting challenges of thermal management, miniaturization, and reliability in advanced computing architectures. The development trajectory of conductive adhesives spans several decades, evolving from simple metal-filled polymers to sophisticated nanocomposite formulations engineered at the molecular level.

The technological progression in this field has been driven by the exponential growth in computing power and the corresponding increase in heat generation within increasingly compact devices. Early conductive adhesives primarily focused on basic electrical connectivity, while contemporary formulations must address complex multifunctional requirements including thermal conductivity, mechanical stability under thermal cycling, and compatibility with diverse substrate materials.

Recent advancements have introduced novel conductive fillers such as silver nanoparticles, carbon nanotubes, and graphene derivatives, significantly enhancing performance characteristics. The integration of these nanomaterials has enabled unprecedented improvements in electrical conductivity while maintaining essential mechanical properties. Simultaneously, polymer matrix innovations have yielded adhesives with enhanced temperature stability and reduced curing temperatures, critical for protecting sensitive electronic components.

The primary technical objectives in conductive adhesive development for HPC applications center on achieving optimal balance between electrical performance, thermal management, and long-term reliability. Specifically, research aims to develop formulations that deliver conductivity approaching that of solder connections (>104 S/cm) while maintaining flexibility and adhesion across operating temperature ranges from -55°C to 150°C. Additionally, these materials must demonstrate resistance to environmental factors including humidity, oxidation, and electromagnetic interference.

Another crucial objective involves reducing the environmental impact of electronic assembly processes. As global regulations increasingly restrict the use of lead-based solders and other hazardous materials, conductive adhesives represent a promising eco-friendly alternative. This regulatory landscape has accelerated research into sustainable formulations that maintain high performance while eliminating toxic components.

The convergence of nanotechnology, materials science, and electronic engineering continues to push the boundaries of what's possible in conductive adhesive technology. Future development trajectories point toward "smart" adhesives with self-healing capabilities, integrated sensing functions, and adaptive properties that respond to environmental conditions. These innovations will be essential to meeting the demands of next-generation computing systems, including quantum computing, neuromorphic architectures, and ultra-compact edge computing devices.

The technological progression in this field has been driven by the exponential growth in computing power and the corresponding increase in heat generation within increasingly compact devices. Early conductive adhesives primarily focused on basic electrical connectivity, while contemporary formulations must address complex multifunctional requirements including thermal conductivity, mechanical stability under thermal cycling, and compatibility with diverse substrate materials.

Recent advancements have introduced novel conductive fillers such as silver nanoparticles, carbon nanotubes, and graphene derivatives, significantly enhancing performance characteristics. The integration of these nanomaterials has enabled unprecedented improvements in electrical conductivity while maintaining essential mechanical properties. Simultaneously, polymer matrix innovations have yielded adhesives with enhanced temperature stability and reduced curing temperatures, critical for protecting sensitive electronic components.

The primary technical objectives in conductive adhesive development for HPC applications center on achieving optimal balance between electrical performance, thermal management, and long-term reliability. Specifically, research aims to develop formulations that deliver conductivity approaching that of solder connections (>104 S/cm) while maintaining flexibility and adhesion across operating temperature ranges from -55°C to 150°C. Additionally, these materials must demonstrate resistance to environmental factors including humidity, oxidation, and electromagnetic interference.

Another crucial objective involves reducing the environmental impact of electronic assembly processes. As global regulations increasingly restrict the use of lead-based solders and other hazardous materials, conductive adhesives represent a promising eco-friendly alternative. This regulatory landscape has accelerated research into sustainable formulations that maintain high performance while eliminating toxic components.

The convergence of nanotechnology, materials science, and electronic engineering continues to push the boundaries of what's possible in conductive adhesive technology. Future development trajectories point toward "smart" adhesives with self-healing capabilities, integrated sensing functions, and adaptive properties that respond to environmental conditions. These innovations will be essential to meeting the demands of next-generation computing systems, including quantum computing, neuromorphic architectures, and ultra-compact edge computing devices.

Market Demand Analysis for HPC Thermal Solutions

The high-performance computing (HPC) market is experiencing unprecedented growth, driving significant demand for advanced thermal management solutions. As computational power continues to increase exponentially, traditional cooling methods are reaching their physical limitations, creating a critical need for innovative thermal interface materials (TIMs) such as conductive adhesives. Market research indicates that the global HPC thermal solutions market is projected to grow at a compound annual growth rate of 8.7% through 2028, with the thermal interface materials segment showing particularly strong momentum.

This growth is primarily driven by the rapid expansion of data centers worldwide, with major cloud service providers investing heavily in infrastructure to support AI workloads, big data analytics, and edge computing applications. These applications generate substantial heat that must be efficiently dissipated to maintain system reliability and performance. Industry surveys reveal that thermal management has become a top priority for 78% of data center operators, with 65% actively seeking more efficient solutions than traditional thermal greases and pads.

The demand for conductive adhesives in HPC applications is further fueled by the miniaturization trend in electronics. As component density increases and form factors shrink, the thermal challenges become more complex, requiring materials that can provide both mechanical stability and superior thermal conductivity. This is particularly evident in the growing market for high-density computing modules where traditional cooling solutions are inadequate.

Energy efficiency requirements are also reshaping market demands. With data centers accounting for approximately 1% of global electricity consumption, there is increasing pressure to improve cooling efficiency. Advanced thermal interface materials that reduce thermal resistance can significantly contribute to overall system efficiency, with potential energy savings of 15-20% compared to conventional solutions.

Geographically, North America currently dominates the market for HPC thermal solutions, accounting for 42% of global demand, followed by Asia-Pacific at 31%. However, the Asia-Pacific region is expected to show the fastest growth rate due to rapid expansion of data center infrastructure in China, India, and Singapore. This regional shift is creating new market opportunities for thermal solution providers who can adapt to local requirements and supply chains.

Customer requirements are evolving toward materials that offer longer operational lifespans, consistent performance under thermal cycling, and compatibility with automated assembly processes. There is also growing interest in environmentally sustainable solutions, with 53% of enterprise customers expressing preference for thermal management products with reduced environmental impact. This trend is driving research into bio-based conductive fillers and recyclable polymer matrices for next-generation conductive adhesives.

This growth is primarily driven by the rapid expansion of data centers worldwide, with major cloud service providers investing heavily in infrastructure to support AI workloads, big data analytics, and edge computing applications. These applications generate substantial heat that must be efficiently dissipated to maintain system reliability and performance. Industry surveys reveal that thermal management has become a top priority for 78% of data center operators, with 65% actively seeking more efficient solutions than traditional thermal greases and pads.

The demand for conductive adhesives in HPC applications is further fueled by the miniaturization trend in electronics. As component density increases and form factors shrink, the thermal challenges become more complex, requiring materials that can provide both mechanical stability and superior thermal conductivity. This is particularly evident in the growing market for high-density computing modules where traditional cooling solutions are inadequate.

Energy efficiency requirements are also reshaping market demands. With data centers accounting for approximately 1% of global electricity consumption, there is increasing pressure to improve cooling efficiency. Advanced thermal interface materials that reduce thermal resistance can significantly contribute to overall system efficiency, with potential energy savings of 15-20% compared to conventional solutions.

Geographically, North America currently dominates the market for HPC thermal solutions, accounting for 42% of global demand, followed by Asia-Pacific at 31%. However, the Asia-Pacific region is expected to show the fastest growth rate due to rapid expansion of data center infrastructure in China, India, and Singapore. This regional shift is creating new market opportunities for thermal solution providers who can adapt to local requirements and supply chains.

Customer requirements are evolving toward materials that offer longer operational lifespans, consistent performance under thermal cycling, and compatibility with automated assembly processes. There is also growing interest in environmentally sustainable solutions, with 53% of enterprise customers expressing preference for thermal management products with reduced environmental impact. This trend is driving research into bio-based conductive fillers and recyclable polymer matrices for next-generation conductive adhesives.

Technical Challenges in Conductive Adhesive Development

Despite significant advancements in conductive adhesive technology, several critical challenges persist in developing solutions suitable for high-performance computing applications. The primary obstacle remains achieving electrical conductivity comparable to traditional soldering methods while maintaining long-term reliability. Current conductive adhesives typically demonstrate resistivity values between 10^-4 and 10^-5 ohm-cm, whereas conventional solders achieve 10^-6 ohm-cm or lower, creating a performance gap that becomes increasingly problematic as computing demands escalate.

Thermal management presents another significant challenge. High-performance computing environments generate substantial heat, requiring adhesives that can withstand temperatures exceeding 150°C while maintaining structural integrity and conductivity. The coefficient of thermal expansion (CTE) mismatch between adhesives and bonded components leads to mechanical stress during thermal cycling, potentially causing connection failures over time.

Environmental stability poses additional complications, as conductive adhesives must resist oxidation and moisture ingress that can degrade electrical performance. Current formulations often show conductivity deterioration after exposure to high humidity (85% RH) and elevated temperatures (85°C) for extended periods, limiting their application in demanding computing environments.

Manufacturing integration challenges also exist. Conductive adhesives typically require specific curing processes that may be incompatible with existing high-volume production lines. The curing temperatures and times needed for optimal performance can conflict with the thermal budgets of sensitive electronic components, creating process engineering dilemmas.

Particle distribution uniformity within the adhesive matrix remains problematic. Achieving consistent electrical pathways throughout the material requires precise control of conductive filler distribution. Current manufacturing methods struggle to prevent agglomeration of conductive particles, leading to inconsistent performance across production batches.

Cost considerations further complicate development efforts. While traditional solders use relatively inexpensive metals, high-performance conductive adhesives often incorporate precious metals or specialized nanomaterials that significantly increase production costs. This cost differential creates market adoption barriers despite potential technical advantages.

Lastly, the industry faces significant challenges in developing standardized testing protocols for conductive adhesives. Unlike traditional interconnect technologies with well-established reliability standards, conductive adhesives lack comprehensive testing frameworks that accurately predict long-term performance in high-performance computing applications. This absence of standardization complicates qualification processes and slows industry adoption despite promising laboratory results.

Thermal management presents another significant challenge. High-performance computing environments generate substantial heat, requiring adhesives that can withstand temperatures exceeding 150°C while maintaining structural integrity and conductivity. The coefficient of thermal expansion (CTE) mismatch between adhesives and bonded components leads to mechanical stress during thermal cycling, potentially causing connection failures over time.

Environmental stability poses additional complications, as conductive adhesives must resist oxidation and moisture ingress that can degrade electrical performance. Current formulations often show conductivity deterioration after exposure to high humidity (85% RH) and elevated temperatures (85°C) for extended periods, limiting their application in demanding computing environments.

Manufacturing integration challenges also exist. Conductive adhesives typically require specific curing processes that may be incompatible with existing high-volume production lines. The curing temperatures and times needed for optimal performance can conflict with the thermal budgets of sensitive electronic components, creating process engineering dilemmas.

Particle distribution uniformity within the adhesive matrix remains problematic. Achieving consistent electrical pathways throughout the material requires precise control of conductive filler distribution. Current manufacturing methods struggle to prevent agglomeration of conductive particles, leading to inconsistent performance across production batches.

Cost considerations further complicate development efforts. While traditional solders use relatively inexpensive metals, high-performance conductive adhesives often incorporate precious metals or specialized nanomaterials that significantly increase production costs. This cost differential creates market adoption barriers despite potential technical advantages.

Lastly, the industry faces significant challenges in developing standardized testing protocols for conductive adhesives. Unlike traditional interconnect technologies with well-established reliability standards, conductive adhesives lack comprehensive testing frameworks that accurately predict long-term performance in high-performance computing applications. This absence of standardization complicates qualification processes and slows industry adoption despite promising laboratory results.

Current Conductive Adhesive Solutions for HPC

01 Metal-filled conductive adhesives

Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These particles form conductive pathways when the adhesive cures, allowing for electrical connections between components. The concentration and type of metal filler significantly impact the conductivity level, with silver typically providing the highest conductivity. These adhesives are widely used in electronics assembly, particularly for applications requiring both mechanical bonding and electrical connectivity.- Metal-filled conductive adhesives: Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel into adhesive matrices to create electrical conductivity. These formulations typically use metal particles in various forms including flakes, powders, or nanoparticles to establish conductive pathways. The metal content and particle distribution significantly affect the conductivity, with higher metal loading generally providing better electrical performance. These adhesives are widely used in electronics assembly, particularly in applications where traditional soldering is not suitable.

- Carbon-based conductive adhesives: Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials offer advantages including lower cost compared to precious metals, lighter weight, and corrosion resistance. Carbon nanotubes and graphene in particular can provide excellent conductivity at lower filler loadings due to their high aspect ratio and intrinsic electrical properties. These adhesives find applications in electromagnetic shielding, static dissipation, and flexible electronics where moderate conductivity is sufficient.

- Anisotropic conductive adhesives: Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These specialized adhesives typically contain conductive particles dispersed in an insulating adhesive matrix at concentrations below the percolation threshold. When compressed between electrical contacts, the particles form conductive pathways only in the direction of compression. This unique property makes them ideal for fine-pitch electronics connections, display technologies, and flexible circuit bonding where preventing short circuits between adjacent connections is critical.

- Thermally conductive adhesives: Thermally conductive adhesives are designed to transfer heat while providing bonding functionality. These formulations incorporate thermally conductive fillers such as aluminum oxide, boron nitride, aluminum nitride, or metal particles into adhesive systems. The thermal conductivity can be enhanced by optimizing filler loading, particle size distribution, and surface treatments. These adhesives are crucial in electronics packaging, LED assembly, power electronics, and other applications where heat dissipation is essential for device performance and reliability.

- Environmentally friendly conductive adhesives: Environmentally friendly conductive adhesives are formulated to reduce or eliminate hazardous materials while maintaining electrical performance. These adhesives often replace lead-based solders or adhesives containing volatile organic compounds with more sustainable alternatives. Innovations include bio-based polymer matrices, non-toxic conductive fillers, and formulations that cure at lower temperatures to reduce energy consumption. These green alternatives are increasingly important as electronics manufacturers face stricter environmental regulations and sustainability requirements.

02 Carbon-based conductive adhesives

Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials provide moderate conductivity at lower cost compared to metal fillers. Carbon nanotubes and graphene offer excellent electrical properties while requiring lower loading levels, which helps maintain better mechanical properties. These adhesives are particularly useful in applications where moderate conductivity is sufficient and cost considerations are important, such as EMI shielding, static dissipation, and certain sensor applications.Expand Specific Solutions03 Anisotropic conductive adhesives

Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These specialized adhesives contain conductive particles suspended in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive paths only in the direction of compression. This unique property makes ACAs ideal for fine-pitch electronics connections, display technologies, and flexible circuit applications where preventing short circuits between adjacent connections is critical.Expand Specific Solutions04 Thermally conductive adhesives

Thermally conductive adhesives are designed to transfer heat while providing bonding strength. These formulations incorporate thermally conductive fillers such as aluminum oxide, boron nitride, or aluminum nitride within the adhesive matrix. They serve dual functions by creating mechanical bonds between components while efficiently dissipating heat from electronic devices. These adhesives are crucial in high-power electronics, LED applications, and thermal management systems where heat dissipation is essential for preventing component failure and extending device lifespan.Expand Specific Solutions05 Environmentally friendly conductive adhesives

Environmentally friendly conductive adhesives address sustainability concerns by eliminating toxic components like lead while maintaining electrical performance. These formulations use bio-based resins, water-based systems, or recyclable components to reduce environmental impact. Some incorporate novel conductive fillers derived from sustainable sources or use reduced amounts of precious metals. These green alternatives are gaining importance as electronics manufacturers face stricter environmental regulations and increasing consumer demand for sustainable products.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conductive adhesives market for high-performance computing is currently in a growth phase, with increasing demand driven by miniaturization trends and thermal management requirements. The market is projected to expand significantly as electronic devices become more compact and powerful. Technologically, companies like Henkel, RESONAC (formerly Hitachi Chemical), and Namics lead with advanced formulations offering superior thermal and electrical conductivity. Shin-Etsu Chemical and Dexerials are advancing polymer-based solutions, while 3M and Dow focus on reliability improvements. LINTEC and Sekisui Chemical are developing specialized adhesives for semiconductor packaging. Research institutions like Karlsruher Institut für Technologie and Georgia Tech are exploring next-generation materials including graphene-enhanced adhesives, positioning this technology at the intersection of mature commercial applications and emerging innovations.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electrically conductive adhesives (ECAs) specifically designed for high-performance computing applications. Their LOCTITE ABLESTIK ECAs utilize silver-filled epoxy technology with precisely controlled particle size distribution to achieve optimal electrical conductivity while maintaining mechanical strength. These adhesives feature thermal conductivity values up to 20 W/m·K and electrical resistivity as low as 1×10^-4 Ω·cm, making them suitable for die-attach applications in high-performance computing environments. Henkel's formulations incorporate proprietary additives that enhance reliability during thermal cycling (-55°C to 150°C) with minimal degradation in conductivity over 1000+ cycles. Their latest generation products offer curing temperatures as low as 125°C, enabling compatibility with temperature-sensitive components while achieving excellent adhesion to various substrate materials including copper, aluminum, and ceramic.

Strengths: Superior thermal stability with minimal outgassing during curing process; excellent electrical performance retention after environmental stress testing; compatible with automated dispensing systems for high-volume manufacturing. Weaknesses: Higher cost compared to traditional soldering methods; some formulations require specialized storage conditions; potential for silver migration under high humidity conditions.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered anisotropic conductive adhesives (ACAs) for high-performance computing applications that provide electrical conductivity in the z-axis while maintaining insulation in the x-y plane. Their proprietary technology incorporates conductive particles (typically gold-coated polymer spheres or nickel particles) suspended in a polymer matrix at precisely controlled concentrations. These adhesives achieve connection pitches down to 40 μm with contact resistance below 20 mΩ per connection. 3M's thermal conductive adhesives for high-performance computing utilize ceramic fillers to achieve thermal conductivity up to 3 W/m·K while maintaining electrical insulation properties. Their latest innovations include reworkable conductive adhesives that allow component removal and replacement without damaging the substrate, addressing a critical need in high-value computing applications. 3M's formulations are engineered to withstand operating temperatures up to 150°C continuously while maintaining stable electrical performance.

Strengths: Excellent fine-pitch capability for increasingly dense computing architectures; consistent performance across wide temperature ranges; established manufacturing processes with high reliability. Weaknesses: Lower bulk conductivity compared to solder or silver-filled systems; requires precise application equipment and process control; higher initial implementation costs.

Key Patents and Technical Innovations

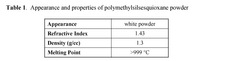

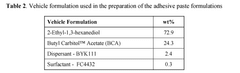

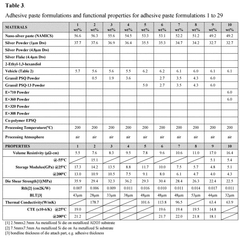

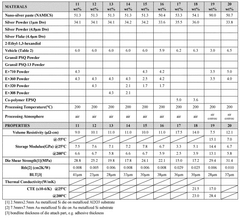

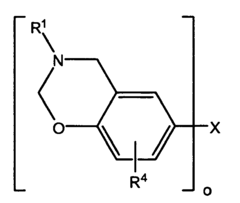

High performance, thermally conductive surface mount (die attach) adhesives

PatentWO2017022191A1

Innovation

- A high-performance adhesive composition incorporating thermally conductive silver components and polyorganosilsesquioxane powders, which can be processed over a wide temperature range, providing low stress, high thermal conductivity, and excellent adhesion, stability, and resistance to moisture, suitable for high-temperature applications.

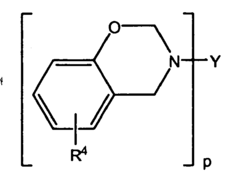

Electrically conductive adhesives

PatentActiveEP2431438B1

Innovation

- A novel adhesive composition comprising a thermosetting or thermoplastic resin with 70-90 wt-% micron-sized electrically conductive particles (2-50 µm) and 0.01-15 wt-% sub-micron-sized particles (300-900 nm), which forms a stable and conductive bond between substrates, offering low processing viscosity and high electrical conductivity with improved resistance to fatigue.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive adhesives in high-performance computing represents a critical consideration as the industry moves toward more sustainable practices. Traditional interconnection technologies, particularly those using lead-based solders, have faced increasing scrutiny due to their environmental toxicity and disposal challenges. Conductive adhesives offer promising alternatives with potentially lower environmental footprints, though their sustainability profile requires comprehensive assessment across the entire lifecycle.

Many conventional conductive adhesives contain silver particles, which raise concerns regarding resource depletion and mining impacts. Silver extraction involves significant energy consumption, habitat disruption, and often generates toxic byproducts. However, recent innovations have focused on reducing precious metal content through the incorporation of carbon-based materials like graphene and carbon nanotubes, which can decrease the overall environmental burden while maintaining performance characteristics.

Manufacturing processes for conductive adhesives typically consume less energy compared to traditional soldering techniques, which require high-temperature reflow processes. The lower curing temperatures of many conductive adhesive formulations (often below 150°C compared to 220-250°C for lead-free solders) translate to reduced energy consumption during electronics assembly, contributing to lower carbon emissions in production environments.

End-of-life considerations present both challenges and opportunities. While conductive adhesives can eliminate lead and other heavy metals found in traditional solders, some formulations contain potentially harmful components such as volatile organic compounds (VOCs) or halogenated flame retardants. The recyclability of electronic components joined with conductive adhesives remains an area requiring further development, as separation of bonded components can be more difficult than with traditional soldering methods.

Regulatory frameworks worldwide are increasingly influencing material selection in electronics manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations globally have accelerated the transition away from lead-based interconnection technologies. Conductive adhesives that comply with these regulations while offering reduced carbon footprints may gain competitive advantages as environmental compliance becomes more stringent.

Water usage and contamination represent additional environmental considerations. Some conductive adhesive manufacturing processes require significant water inputs and may generate wastewater containing metal particles or organic solvents. Advanced manufacturers are implementing closed-loop water systems and improved filtration technologies to mitigate these impacts, though industry-wide adoption remains inconsistent.

Many conventional conductive adhesives contain silver particles, which raise concerns regarding resource depletion and mining impacts. Silver extraction involves significant energy consumption, habitat disruption, and often generates toxic byproducts. However, recent innovations have focused on reducing precious metal content through the incorporation of carbon-based materials like graphene and carbon nanotubes, which can decrease the overall environmental burden while maintaining performance characteristics.

Manufacturing processes for conductive adhesives typically consume less energy compared to traditional soldering techniques, which require high-temperature reflow processes. The lower curing temperatures of many conductive adhesive formulations (often below 150°C compared to 220-250°C for lead-free solders) translate to reduced energy consumption during electronics assembly, contributing to lower carbon emissions in production environments.

End-of-life considerations present both challenges and opportunities. While conductive adhesives can eliminate lead and other heavy metals found in traditional solders, some formulations contain potentially harmful components such as volatile organic compounds (VOCs) or halogenated flame retardants. The recyclability of electronic components joined with conductive adhesives remains an area requiring further development, as separation of bonded components can be more difficult than with traditional soldering methods.

Regulatory frameworks worldwide are increasingly influencing material selection in electronics manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations globally have accelerated the transition away from lead-based interconnection technologies. Conductive adhesives that comply with these regulations while offering reduced carbon footprints may gain competitive advantages as environmental compliance becomes more stringent.

Water usage and contamination represent additional environmental considerations. Some conductive adhesive manufacturing processes require significant water inputs and may generate wastewater containing metal particles or organic solvents. Advanced manufacturers are implementing closed-loop water systems and improved filtration technologies to mitigate these impacts, though industry-wide adoption remains inconsistent.

Reliability Testing and Performance Metrics

Reliability testing for conductive adhesives in high-performance computing environments requires rigorous methodologies to ensure consistent performance under extreme conditions. Standard testing protocols include thermal cycling (-55°C to 150°C), humidity resistance (85°C/85% RH), and mechanical stress evaluations. These tests simulate accelerated aging to predict long-term reliability in data center environments where thermal management is critical.

Key performance metrics for conductive adhesives include electrical conductivity stability, which should maintain less than 5% variation over the product lifecycle. Thermal conductivity, typically ranging from 2-10 W/m·K for high-performance applications, must remain consistent to prevent hotspot formation. Adhesion strength, measured through shear and pull tests, should exceed 25 MPa for die-attach applications to withstand thermomechanical stresses.

Time-to-failure testing has become increasingly important as computing demands intensify. Mean Time Between Failures (MTBF) expectations now exceed 50,000 hours for premium conductive adhesives used in server environments. Manufacturers employ Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) to identify potential failure modes before field deployment.

Environmental compliance metrics have gained prominence, with RoHS and REACH requirements mandating the reduction of toxic substances. Lead-free formulations must demonstrate equivalent or superior reliability to traditional lead-based alternatives. Outgassing characteristics are particularly critical for sealed computing environments, with maximum allowable volatile organic compound (VOC) emissions typically below 0.1% by weight.

Reworkability and repairability metrics are increasingly valued in high-performance computing applications. The ideal conductive adhesive allows component removal and replacement without damaging the substrate or adjacent components. Industry standards now include assessments of rework cycles (typically 3-5) before performance degradation occurs.

Correlation between accelerated testing and real-world performance remains challenging. Advanced analytics combining machine learning with reliability data help bridge this gap, enabling more accurate lifetime predictions. Companies like Intel and IBM have developed proprietary reliability models specifically for conductive adhesives in their high-performance computing architectures, establishing de facto industry benchmarks that suppliers must meet.

Key performance metrics for conductive adhesives include electrical conductivity stability, which should maintain less than 5% variation over the product lifecycle. Thermal conductivity, typically ranging from 2-10 W/m·K for high-performance applications, must remain consistent to prevent hotspot formation. Adhesion strength, measured through shear and pull tests, should exceed 25 MPa for die-attach applications to withstand thermomechanical stresses.

Time-to-failure testing has become increasingly important as computing demands intensify. Mean Time Between Failures (MTBF) expectations now exceed 50,000 hours for premium conductive adhesives used in server environments. Manufacturers employ Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) to identify potential failure modes before field deployment.

Environmental compliance metrics have gained prominence, with RoHS and REACH requirements mandating the reduction of toxic substances. Lead-free formulations must demonstrate equivalent or superior reliability to traditional lead-based alternatives. Outgassing characteristics are particularly critical for sealed computing environments, with maximum allowable volatile organic compound (VOC) emissions typically below 0.1% by weight.

Reworkability and repairability metrics are increasingly valued in high-performance computing applications. The ideal conductive adhesive allows component removal and replacement without damaging the substrate or adjacent components. Industry standards now include assessments of rework cycles (typically 3-5) before performance degradation occurs.

Correlation between accelerated testing and real-world performance remains challenging. Advanced analytics combining machine learning with reliability data help bridge this gap, enabling more accurate lifetime predictions. Companies like Intel and IBM have developed proprietary reliability models specifically for conductive adhesives in their high-performance computing architectures, establishing de facto industry benchmarks that suppliers must meet.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!