The Role of Conductive Adhesives in Hydrogel Development

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives in Hydrogel Technology: Background and Objectives

Conductive adhesives have emerged as a critical component in the development of hydrogels, marking a significant technological advancement in materials science over the past two decades. The integration of conductive properties into hydrogels represents a convergence of multiple disciplines including polymer chemistry, materials engineering, and biomedical science. This technological evolution began with simple hydrogel formulations in the 1960s, progressing through various stages of sophistication to today's smart, responsive materials with electrical conductivity.

The trajectory of conductive adhesive technology in hydrogels has been characterized by several key milestones. Initially, hydrogels were primarily valued for their biocompatibility and water retention properties. The introduction of conductive elements in the early 2000s opened new possibilities for applications in biosensing, tissue engineering, and wearable electronics. Recent advancements have focused on enhancing the mechanical stability and electrical performance of these materials while maintaining their inherent biocompatibility.

Current research trends indicate a growing interest in developing conductive hydrogels with improved adhesion properties, particularly for applications requiring intimate contact with biological tissues or electronic components. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles has significantly enhanced the conductivity of hydrogels, while novel polymer chemistries have improved their adhesive characteristics.

The primary technical objective in this field is to develop conductive adhesive hydrogels that combine optimal electrical conductivity with strong adhesion properties, flexibility, and biocompatibility. This represents a complex materials design challenge, as these properties often present contradictory requirements at the molecular level. For instance, increasing conductivity through higher loading of conductive fillers can compromise mechanical properties and biocompatibility.

Another critical goal is to achieve stable performance under various environmental conditions, including temperature fluctuations, mechanical stress, and exposure to biological fluids. This stability is essential for applications in wearable health monitoring devices, implantable electronics, and soft robotics, where consistent performance over extended periods is required.

Looking forward, the field is moving toward multifunctional conductive adhesive hydrogels that can simultaneously sense multiple parameters, self-heal when damaged, and respond to specific stimuli. These advanced materials are expected to enable new generations of bioelectronic devices, tissue engineering scaffolds, and drug delivery systems, potentially revolutionizing healthcare and consumer electronics sectors.

The development of conductive adhesives for hydrogels thus represents a frontier in materials science with significant implications for multiple industries, driving continued research and innovation in this dynamic field.

The trajectory of conductive adhesive technology in hydrogels has been characterized by several key milestones. Initially, hydrogels were primarily valued for their biocompatibility and water retention properties. The introduction of conductive elements in the early 2000s opened new possibilities for applications in biosensing, tissue engineering, and wearable electronics. Recent advancements have focused on enhancing the mechanical stability and electrical performance of these materials while maintaining their inherent biocompatibility.

Current research trends indicate a growing interest in developing conductive hydrogels with improved adhesion properties, particularly for applications requiring intimate contact with biological tissues or electronic components. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles has significantly enhanced the conductivity of hydrogels, while novel polymer chemistries have improved their adhesive characteristics.

The primary technical objective in this field is to develop conductive adhesive hydrogels that combine optimal electrical conductivity with strong adhesion properties, flexibility, and biocompatibility. This represents a complex materials design challenge, as these properties often present contradictory requirements at the molecular level. For instance, increasing conductivity through higher loading of conductive fillers can compromise mechanical properties and biocompatibility.

Another critical goal is to achieve stable performance under various environmental conditions, including temperature fluctuations, mechanical stress, and exposure to biological fluids. This stability is essential for applications in wearable health monitoring devices, implantable electronics, and soft robotics, where consistent performance over extended periods is required.

Looking forward, the field is moving toward multifunctional conductive adhesive hydrogels that can simultaneously sense multiple parameters, self-heal when damaged, and respond to specific stimuli. These advanced materials are expected to enable new generations of bioelectronic devices, tissue engineering scaffolds, and drug delivery systems, potentially revolutionizing healthcare and consumer electronics sectors.

The development of conductive adhesives for hydrogels thus represents a frontier in materials science with significant implications for multiple industries, driving continued research and innovation in this dynamic field.

Market Analysis for Conductive Hydrogel Applications

The conductive hydrogel market is experiencing significant growth, driven by increasing applications in healthcare, electronics, and energy sectors. The global market for conductive hydrogels was valued at approximately 3.2 billion USD in 2022 and is projected to reach 5.7 billion USD by 2028, representing a compound annual growth rate of 10.2%. This growth trajectory is primarily fueled by the expanding applications in wound healing, drug delivery systems, biosensors, and tissue engineering.

Healthcare applications currently dominate the market, accounting for nearly 45% of the total market share. Within this segment, wound dressings and tissue engineering applications are witnessing the highest demand due to their ability to provide electrical stimulation that promotes tissue regeneration and accelerates healing processes. The aging population and increasing prevalence of chronic wounds and diabetic ulcers further amplify this demand.

The wearable electronics sector represents the fastest-growing application segment, with an estimated growth rate of 14.5% annually. This surge is attributed to the rising consumer interest in health monitoring devices and the integration of conductive hydrogels in flexible electronics. The unique combination of electrical conductivity and mechanical flexibility makes these materials ideal for creating comfortable, skin-adherent biosensors and monitoring devices.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing healthcare expenditure, growing electronics manufacturing, and substantial investments in research and development activities, particularly in China, Japan, and South Korea.

Key market challenges include high production costs, scalability issues, and concerns regarding long-term stability of conductive properties. The average cost of specialized conductive hydrogels remains 3-5 times higher than conventional hydrogels, limiting widespread adoption in cost-sensitive applications. Additionally, regulatory hurdles for medical applications present significant market entry barriers, with approval processes typically taking 18-24 months.

Emerging opportunities exist in the development of self-healing conductive hydrogels, biodegradable formulations, and hydrogels with tunable conductivity. The integration of conductive hydrogels with 3D printing technologies is also opening new avenues for customized medical implants and devices, potentially creating a specialized market segment estimated to reach 850 million USD by 2027.

Healthcare applications currently dominate the market, accounting for nearly 45% of the total market share. Within this segment, wound dressings and tissue engineering applications are witnessing the highest demand due to their ability to provide electrical stimulation that promotes tissue regeneration and accelerates healing processes. The aging population and increasing prevalence of chronic wounds and diabetic ulcers further amplify this demand.

The wearable electronics sector represents the fastest-growing application segment, with an estimated growth rate of 14.5% annually. This surge is attributed to the rising consumer interest in health monitoring devices and the integration of conductive hydrogels in flexible electronics. The unique combination of electrical conductivity and mechanical flexibility makes these materials ideal for creating comfortable, skin-adherent biosensors and monitoring devices.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing healthcare expenditure, growing electronics manufacturing, and substantial investments in research and development activities, particularly in China, Japan, and South Korea.

Key market challenges include high production costs, scalability issues, and concerns regarding long-term stability of conductive properties. The average cost of specialized conductive hydrogels remains 3-5 times higher than conventional hydrogels, limiting widespread adoption in cost-sensitive applications. Additionally, regulatory hurdles for medical applications present significant market entry barriers, with approval processes typically taking 18-24 months.

Emerging opportunities exist in the development of self-healing conductive hydrogels, biodegradable formulations, and hydrogels with tunable conductivity. The integration of conductive hydrogels with 3D printing technologies is also opening new avenues for customized medical implants and devices, potentially creating a specialized market segment estimated to reach 850 million USD by 2027.

Current Challenges in Conductive Adhesive-Hydrogel Integration

The integration of conductive adhesives with hydrogels presents significant technical challenges that currently limit their widespread application in bioelectronics, wearable devices, and medical implants. One primary obstacle is the inherent mechanical mismatch between rigid conductive materials and soft, water-rich hydrogels. This incompatibility often leads to delamination at the interface during deformation, compromising the electrical connectivity and overall device performance.

Adhesion stability in physiological environments poses another critical challenge. When exposed to aqueous environments, many conductive adhesives experience hydrolytic degradation, resulting in weakened bonding strength and electrical conductivity deterioration over time. This issue becomes particularly problematic for applications requiring long-term stability in biological systems, such as implantable sensors or drug delivery devices.

The biocompatibility of conductive adhesives represents a significant hurdle, especially for medical applications. Many conventional conductive adhesives contain potentially toxic components like silver particles, certain solvents, or curing agents that may leach into surrounding tissues. Developing adhesives that maintain conductivity while ensuring biocompatibility remains a delicate balancing act for researchers.

Manufacturing scalability presents technical difficulties as well. Current methods for integrating conductive adhesives with hydrogels often involve complex, multi-step processes that are difficult to standardize and scale up for mass production. The precise control of adhesive thickness, curing conditions, and interface properties requires sophisticated equipment and expertise, limiting commercial viability.

Electrical performance consistency across different environmental conditions remains challenging. Hydrogels experience significant volumetric changes with varying humidity, temperature, and pH levels. These dimensional fluctuations strain the conductive adhesive interface, potentially causing microcracks that increase electrical resistance and create signal noise in sensing applications.

The trade-off between conductivity and adhesion strength represents another technical dilemma. Increasing the conductive filler content typically enhances electrical performance but often compromises adhesive properties. Conversely, formulations optimized for strong adhesion may exhibit insufficient conductivity for demanding applications like high-frequency signal transmission or power delivery.

Recent research has identified additional challenges related to long-term reliability. Repeated mechanical deformation, thermal cycling, and exposure to UV radiation can accelerate degradation at the hydrogel-adhesive interface. This aging process manifests as increasing contact resistance, diminishing signal quality, and eventual mechanical failure, limiting the practical lifespan of integrated devices.

Adhesion stability in physiological environments poses another critical challenge. When exposed to aqueous environments, many conductive adhesives experience hydrolytic degradation, resulting in weakened bonding strength and electrical conductivity deterioration over time. This issue becomes particularly problematic for applications requiring long-term stability in biological systems, such as implantable sensors or drug delivery devices.

The biocompatibility of conductive adhesives represents a significant hurdle, especially for medical applications. Many conventional conductive adhesives contain potentially toxic components like silver particles, certain solvents, or curing agents that may leach into surrounding tissues. Developing adhesives that maintain conductivity while ensuring biocompatibility remains a delicate balancing act for researchers.

Manufacturing scalability presents technical difficulties as well. Current methods for integrating conductive adhesives with hydrogels often involve complex, multi-step processes that are difficult to standardize and scale up for mass production. The precise control of adhesive thickness, curing conditions, and interface properties requires sophisticated equipment and expertise, limiting commercial viability.

Electrical performance consistency across different environmental conditions remains challenging. Hydrogels experience significant volumetric changes with varying humidity, temperature, and pH levels. These dimensional fluctuations strain the conductive adhesive interface, potentially causing microcracks that increase electrical resistance and create signal noise in sensing applications.

The trade-off between conductivity and adhesion strength represents another technical dilemma. Increasing the conductive filler content typically enhances electrical performance but often compromises adhesive properties. Conversely, formulations optimized for strong adhesion may exhibit insufficient conductivity for demanding applications like high-frequency signal transmission or power delivery.

Recent research has identified additional challenges related to long-term reliability. Repeated mechanical deformation, thermal cycling, and exposure to UV radiation can accelerate degradation at the hydrogel-adhesive interface. This aging process manifests as increasing contact resistance, diminishing signal quality, and eventual mechanical failure, limiting the practical lifespan of integrated devices.

Current Technical Solutions for Conductive Adhesive-Hydrogel Systems

01 Metal-filled conductive adhesives

Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These adhesives typically consist of a polymer matrix loaded with conductive metal fillers that form conductive pathways when cured. The concentration and distribution of metal particles directly affect the conductivity level. These adhesives are widely used in electronics assembly, providing both mechanical bonding and electrical connectivity between components.- Metal-filled conductive adhesives: Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These adhesives typically consist of a polymer matrix with dispersed metal fillers that form conductive pathways when cured. The concentration and distribution of metal particles directly affect the conductivity level. These adhesives are widely used in electronics assembly, providing both mechanical bonding and electrical connectivity between components.

- Carbon-based conductive adhesives: Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials offer advantages including lower cost compared to precious metals, lighter weight, and resistance to oxidation. Carbon-based adhesives can achieve moderate to high conductivity depending on the type and concentration of carbon materials used. They are particularly useful in applications requiring electromagnetic interference (EMI) shielding or static dissipation.

- Anisotropic conductive adhesives: Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in others. These specialized adhesives contain conductive particles suspended in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive pathways in the z-direction while remaining electrically isolated in the x and y directions. This technology is particularly valuable for high-density interconnections in display technologies, flexible electronics, and fine-pitch applications.

- Thermally conductive adhesives: Thermally conductive adhesives are designed to transfer heat while providing adhesive properties. These formulations incorporate thermally conductive fillers such as aluminum oxide, boron nitride, or metal particles within an adhesive matrix. They serve dual functions by creating mechanical bonds between components while efficiently dissipating heat. These adhesives are crucial in electronic assemblies where thermal management is essential for device reliability and performance, particularly in power electronics and LED applications.

- Novel formulations and manufacturing methods: Advanced formulation techniques and manufacturing methods are being developed to enhance the performance of conductive adhesives. These innovations include hybrid filler systems combining different conductive materials, nano-engineered particles for improved conductivity at lower loading levels, and environmentally friendly formulations that eliminate toxic components. Novel curing mechanisms and processing techniques aim to reduce processing temperatures while maintaining or improving conductivity, adhesion strength, and long-term reliability under various environmental conditions.

02 Carbon-based conductive adhesives

Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials offer advantages including lower cost compared to precious metals, lighter weight, and resistance to oxidation. Carbon-based adhesives can provide moderate to high conductivity depending on the type and concentration of carbon materials used, while maintaining good adhesion properties and flexibility.Expand Specific Solutions03 Anisotropic conductive adhesives

Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These specialized adhesives contain conductive particles dispersed in an insulating adhesive matrix. When compressed between components, the particles form conductive paths in the z-axis direction only. This technology is particularly valuable for fine-pitch connections in display technologies, flexible electronics, and high-density interconnects where preventing short circuits between adjacent connections is critical.Expand Specific Solutions04 Thermally conductive adhesives

Thermally conductive adhesives are designed to transfer heat efficiently while providing bonding strength. These adhesives incorporate thermally conductive fillers such as ceramic particles, metal oxides, or boron nitride in a polymer matrix. They serve dual functions by creating mechanical bonds between components while facilitating heat dissipation from heat-generating elements. These materials are crucial in electronic assemblies where thermal management is essential for device reliability and performance.Expand Specific Solutions05 Environmentally friendly conductive adhesives

Environmentally friendly conductive adhesives address sustainability concerns by eliminating toxic components like lead while maintaining electrical performance. These formulations often use bio-based polymers, water-based systems, or renewable materials as alternatives to traditional petroleum-based adhesives. They may incorporate novel conductive fillers that reduce environmental impact while providing necessary conductivity. These adhesives support compliance with environmental regulations while meeting technical requirements for electronic applications.Expand Specific Solutions

Leading Companies and Research Institutions in Conductive Hydrogels

The conductive adhesives market in hydrogel development is in a growth phase, with increasing applications in biomedical engineering and wearable health technologies. The market is expanding rapidly due to rising demand for flexible electronics and medical devices, estimated to reach several billion dollars by 2028. Technologically, the field shows varying maturity levels across applications. Academic institutions like Korea Advanced Institute of Science & Technology, Tsinghua University, and Japan Science & Technology Agency lead fundamental research, while companies including DuPont, CONMED, and Surmodics are commercializing applications. Biogelx and Actamax Surgical Materials represent specialized players focusing on innovative hydrogel formulations. The integration of conductive properties into hydrogels remains an active research area with significant potential for healthcare and electronic applications.

Surmodics, Inc.

Technical Solution: Surmodics has developed advanced conductive hydrogel adhesive technologies based on their proprietary PhotoLink® surface modification platform. Their approach integrates conductive polymers (primarily PEDOT:PSS) with hydrophilic polymers to create adhesive interfaces that maintain both electrical conductivity and strong tissue adhesion in wet biological environments. The company's technology achieves conductivity through interpenetrating networks of conductive polymers within hydrogel matrices, rather than relying solely on particulate fillers, resulting in more uniform electrical properties and enhanced durability. Surmodics' conductive adhesives demonstrate impedance stability over extended periods (>30 days) in physiological conditions, making them suitable for long-term implantable devices[3]. Their formulations incorporate specialized surface chemistry that promotes strong bonding to both biological tissues and electronic components, with adhesion strengths exceeding 50 kPa in wet conditions. The technology has been successfully implemented in glucose sensors and neural interfaces requiring stable electrical connections to hydrated tissues.

Strengths: Exceptional stability in biological environments; proprietary surface chemistry enables strong adhesion to diverse substrates; established regulatory pathway for medical applications. Weaknesses: Limited stretchability compared to newer elastomeric systems; higher electrical resistance than metal-filled alternatives; complex manufacturing process increases production costs.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed proprietary conductive adhesive technologies specifically for hydrogel applications, focusing on biocompatible silver-based formulations that maintain electrical conductivity while preserving hydrogel flexibility. Their approach incorporates silver nanoparticles and flakes suspended in biocompatible polymeric matrices that form strong interfacial bonds with hydrogels while maintaining ionic conductivity. DuPont's technology enables the creation of stretchable electronic systems with minimal impedance changes during deformation, achieving up to 200% strain without significant conductivity loss[1]. Their formulations include specialized coupling agents that enhance adhesion between metallic fillers and hydrogel matrices, creating stable interfaces even in high-moisture environments. This technology has been implemented in medical monitoring devices and advanced wound care products requiring reliable electrical connections to hydrogel substrates.

Strengths: Superior adhesion strength in wet environments; excellent biocompatibility profile; maintains conductivity under mechanical strain; established manufacturing infrastructure. Weaknesses: Higher cost compared to conventional adhesives; requires specialized application techniques; limited shelf life in certain formulations.

Key Patents and Innovations in Conductive Hydrogel Adhesives

Electrically conductive adhesive hydrogels with two initiators

PatentInactiveUS20050136077A1

Innovation

- A composition for electrically conductive hydrogels is developed, incorporating a monomer, a cross-linking agent, and multiple initiators at specific concentrations, along with a solubilizer to enhance polymerization, reducing residual monomeric compounds and improving adhesion, hydration, and stability, while minimizing skin irritation and odor.

Conductive hydrogel comprising mussel adhesive protein and preparation method thereof

PatentPendingUS20240124656A1

Innovation

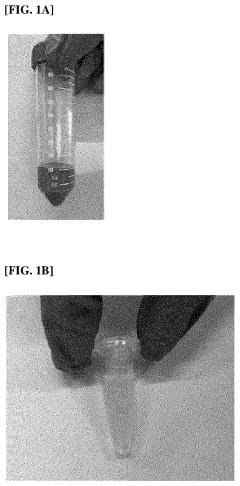

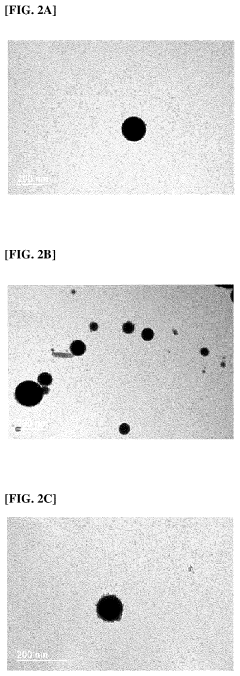

- A conductive hydrogel is developed by incorporating a mussel adhesive protein, liquid metal nanoparticles coated with hyaluronic acid, and applying electrical stimulation to form a coacervate-based hydrogel, which maintains adhesive strength and conductivity without additional adhesives.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical concern in the development of conductive adhesives for hydrogel applications, particularly in biomedical contexts. When integrating conductive materials into hydrogels that interface with biological tissues, the potential for adverse reactions must be thoroughly evaluated. Traditional conductive materials such as metal particles and carbon-based fillers may trigger inflammatory responses or exhibit cytotoxicity when in direct contact with cells and tissues.

Recent advancements have focused on developing biocompatible conductive adhesives specifically designed for hydrogel applications. Materials such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) and polyaniline derivatives have demonstrated improved biocompatibility profiles while maintaining necessary electrical conductivity. These materials undergo rigorous testing protocols including cytotoxicity assays, hemolysis tests, and inflammatory response evaluations to ensure their safety for biological applications.

The leaching of conductive particles or monomers from adhesives represents a significant safety concern, particularly in long-term implantable devices. Research indicates that proper crosslinking and encapsulation techniques can substantially reduce leaching potential, enhancing the overall safety profile of conductive hydrogel systems. Additionally, degradation byproducts must be non-toxic and readily cleared by the body to prevent accumulation and subsequent adverse effects.

Regulatory considerations play a pivotal role in the development pathway for conductive adhesives in hydrogels. Materials intended for medical applications must comply with ISO 10993 standards for biocompatibility testing and FDA guidelines for medical devices. These regulatory frameworks necessitate comprehensive documentation of material composition, manufacturing processes, and biocompatibility test results before clinical implementation.

The interface between conductive adhesives and biological tissues presents unique challenges regarding mechanical compatibility. Mismatches in mechanical properties between rigid conductive components and soft tissues can lead to inflammation and fibrotic encapsulation. Recent innovations have focused on developing conductive adhesives with tunable mechanical properties that better mimic native tissue characteristics, thereby reducing foreign body responses and improving long-term biocompatibility.

Sterilization compatibility represents another critical consideration, as many conductive materials may degrade or lose functionality during standard sterilization processes. Research indicates that gamma irradiation and ethylene oxide sterilization methods can be optimized for certain conductive adhesive formulations, though careful validation is required to ensure both sterility and preserved functionality post-sterilization.

Recent advancements have focused on developing biocompatible conductive adhesives specifically designed for hydrogel applications. Materials such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) and polyaniline derivatives have demonstrated improved biocompatibility profiles while maintaining necessary electrical conductivity. These materials undergo rigorous testing protocols including cytotoxicity assays, hemolysis tests, and inflammatory response evaluations to ensure their safety for biological applications.

The leaching of conductive particles or monomers from adhesives represents a significant safety concern, particularly in long-term implantable devices. Research indicates that proper crosslinking and encapsulation techniques can substantially reduce leaching potential, enhancing the overall safety profile of conductive hydrogel systems. Additionally, degradation byproducts must be non-toxic and readily cleared by the body to prevent accumulation and subsequent adverse effects.

Regulatory considerations play a pivotal role in the development pathway for conductive adhesives in hydrogels. Materials intended for medical applications must comply with ISO 10993 standards for biocompatibility testing and FDA guidelines for medical devices. These regulatory frameworks necessitate comprehensive documentation of material composition, manufacturing processes, and biocompatibility test results before clinical implementation.

The interface between conductive adhesives and biological tissues presents unique challenges regarding mechanical compatibility. Mismatches in mechanical properties between rigid conductive components and soft tissues can lead to inflammation and fibrotic encapsulation. Recent innovations have focused on developing conductive adhesives with tunable mechanical properties that better mimic native tissue characteristics, thereby reducing foreign body responses and improving long-term biocompatibility.

Sterilization compatibility represents another critical consideration, as many conductive materials may degrade or lose functionality during standard sterilization processes. Research indicates that gamma irradiation and ethylene oxide sterilization methods can be optimized for certain conductive adhesive formulations, though careful validation is required to ensure both sterility and preserved functionality post-sterilization.

Sustainability and Environmental Impact Assessment

The environmental impact of conductive adhesives in hydrogel development represents a critical consideration as these materials gain prominence in biomedical applications, wearable electronics, and sensing technologies. Traditional conductive materials often contain heavy metals and toxic components that pose significant environmental hazards throughout their lifecycle. In contrast, many conductive adhesives used in hydrogel systems offer improved sustainability profiles through biodegradable components and reduced toxic element content.

Life cycle assessment (LCA) studies indicate that conductive hydrogels incorporating natural polymers and water-based conductive adhesives demonstrate substantially lower environmental footprints compared to conventional electronic materials. The water-soluble nature of many hydrogel-compatible adhesives facilitates end-of-life processing and reduces persistent environmental contamination. However, challenges remain in quantifying the long-term ecological impacts of novel nanomaterials frequently incorporated into these systems.

Manufacturing processes for conductive adhesives in hydrogel applications typically consume less energy than traditional electronic component production, with reduced greenhouse gas emissions. The ability to process these materials at lower temperatures and often using aqueous systems rather than organic solvents contributes significantly to their environmental advantages. Recent innovations in green chemistry approaches have yielded conductive adhesive formulations derived from renewable resources, including cellulose derivatives and alginate-based compounds.

Regulatory frameworks increasingly emphasize the importance of environmental considerations in medical and electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the development of environmentally benign conductive adhesives suitable for hydrogel applications. These regulatory pressures have stimulated research into alternatives to silver and other potentially problematic conductive fillers.

Biodegradability represents a particularly promising aspect of sustainability for conductive adhesives in hydrogel systems. Recent research has demonstrated functional conductive adhesives with controlled degradation profiles, allowing for transient electronics and implantable devices that naturally decompose after fulfilling their intended purpose. This approach minimizes waste and eliminates the need for surgical removal of implanted devices, reducing both environmental impact and patient burden.

Circular economy principles are increasingly being applied to conductive adhesive development, with emerging technologies enabling the recovery and reuse of valuable conductive components. Innovations in design for disassembly and material separation techniques show promise for improving the recyclability of hydrogel-based electronic systems, though significant technical challenges remain in efficiently separating the integrated components at end-of-life.

Life cycle assessment (LCA) studies indicate that conductive hydrogels incorporating natural polymers and water-based conductive adhesives demonstrate substantially lower environmental footprints compared to conventional electronic materials. The water-soluble nature of many hydrogel-compatible adhesives facilitates end-of-life processing and reduces persistent environmental contamination. However, challenges remain in quantifying the long-term ecological impacts of novel nanomaterials frequently incorporated into these systems.

Manufacturing processes for conductive adhesives in hydrogel applications typically consume less energy than traditional electronic component production, with reduced greenhouse gas emissions. The ability to process these materials at lower temperatures and often using aqueous systems rather than organic solvents contributes significantly to their environmental advantages. Recent innovations in green chemistry approaches have yielded conductive adhesive formulations derived from renewable resources, including cellulose derivatives and alginate-based compounds.

Regulatory frameworks increasingly emphasize the importance of environmental considerations in medical and electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the development of environmentally benign conductive adhesives suitable for hydrogel applications. These regulatory pressures have stimulated research into alternatives to silver and other potentially problematic conductive fillers.

Biodegradability represents a particularly promising aspect of sustainability for conductive adhesives in hydrogel systems. Recent research has demonstrated functional conductive adhesives with controlled degradation profiles, allowing for transient electronics and implantable devices that naturally decompose after fulfilling their intended purpose. This approach minimizes waste and eliminates the need for surgical removal of implanted devices, reducing both environmental impact and patient burden.

Circular economy principles are increasingly being applied to conductive adhesive development, with emerging technologies enabling the recovery and reuse of valuable conductive components. Innovations in design for disassembly and material separation techniques show promise for improving the recyclability of hydrogel-based electronic systems, though significant technical challenges remain in efficiently separating the integrated components at end-of-life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!