Comparison of Conductive Adhesives for Aerospace Applications

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Conductive Adhesives Background and Objectives

Conductive adhesives have emerged as a critical technology in aerospace applications, evolving significantly since their introduction in the 1960s. Initially developed as alternatives to traditional soldering methods, these specialized materials have undergone continuous refinement to meet the increasingly demanding requirements of modern aerospace systems. The evolution trajectory shows a clear shift from simple metal-filled polymers to sophisticated nano-enhanced composites with multifunctional capabilities.

The aerospace industry presents unique environmental challenges that conventional joining technologies struggle to address. Extreme temperature fluctuations (-65°C to +150°C), vacuum conditions, radiation exposure, and zero-gravity environments all demand exceptional material performance. Conductive adhesives must maintain electrical conductivity, mechanical integrity, and thermal stability under these severe conditions while also meeting strict weight requirements critical to aerospace applications.

Current technological objectives focus on developing conductive adhesives that offer superior electrical conductivity (approaching that of metallic solders, >104 S/cm) while maintaining excellent mechanical properties (shear strength >30 MPa) across the aerospace operational temperature range. Additional goals include reducing curing temperatures below 150°C to accommodate temperature-sensitive components, extending operational lifespans beyond 20 years, and ensuring compatibility with increasingly miniaturized aerospace electronics.

Recent advancements have introduced nanomaterial-enhanced conductive adhesives incorporating carbon nanotubes, graphene, and metallic nanoparticles. These innovations aim to address the conductivity-flexibility trade-off that has historically limited adhesive performance. Parallel developments in space-grade epoxy systems have improved radiation resistance and outgassing characteristics, critical factors for components operating in the vacuum of space.

The industry is witnessing a convergence of multiple technologies, with conductive adhesives increasingly integrating structural, thermal, and electrical functions. This multifunctionality trend aligns with the aerospace sector's push toward system integration and weight reduction. Simultaneously, environmental considerations are driving research into lead-free and low-toxicity formulations that maintain performance while meeting increasingly stringent regulatory requirements.

As spacecraft design evolves toward more compact, efficient systems, conductive adhesives are positioned to play an expanding role in mission-critical applications. The technology roadmap indicates continued development toward higher temperature resistance, improved reliability under mechanical stress, and enhanced long-term stability in space environments. These improvements will be essential to support next-generation aerospace systems including small satellites, space habitats, and advanced propulsion technologies.

The aerospace industry presents unique environmental challenges that conventional joining technologies struggle to address. Extreme temperature fluctuations (-65°C to +150°C), vacuum conditions, radiation exposure, and zero-gravity environments all demand exceptional material performance. Conductive adhesives must maintain electrical conductivity, mechanical integrity, and thermal stability under these severe conditions while also meeting strict weight requirements critical to aerospace applications.

Current technological objectives focus on developing conductive adhesives that offer superior electrical conductivity (approaching that of metallic solders, >104 S/cm) while maintaining excellent mechanical properties (shear strength >30 MPa) across the aerospace operational temperature range. Additional goals include reducing curing temperatures below 150°C to accommodate temperature-sensitive components, extending operational lifespans beyond 20 years, and ensuring compatibility with increasingly miniaturized aerospace electronics.

Recent advancements have introduced nanomaterial-enhanced conductive adhesives incorporating carbon nanotubes, graphene, and metallic nanoparticles. These innovations aim to address the conductivity-flexibility trade-off that has historically limited adhesive performance. Parallel developments in space-grade epoxy systems have improved radiation resistance and outgassing characteristics, critical factors for components operating in the vacuum of space.

The industry is witnessing a convergence of multiple technologies, with conductive adhesives increasingly integrating structural, thermal, and electrical functions. This multifunctionality trend aligns with the aerospace sector's push toward system integration and weight reduction. Simultaneously, environmental considerations are driving research into lead-free and low-toxicity formulations that maintain performance while meeting increasingly stringent regulatory requirements.

As spacecraft design evolves toward more compact, efficient systems, conductive adhesives are positioned to play an expanding role in mission-critical applications. The technology roadmap indicates continued development toward higher temperature resistance, improved reliability under mechanical stress, and enhanced long-term stability in space environments. These improvements will be essential to support next-generation aerospace systems including small satellites, space habitats, and advanced propulsion technologies.

Market Demand Analysis for Aerospace-Grade Conductive Adhesives

The aerospace industry has witnessed a significant surge in demand for specialized conductive adhesives, driven primarily by the increasing adoption of lightweight composite materials in aircraft and spacecraft construction. Market research indicates that the global aerospace conductive adhesives market is projected to grow at a compound annual growth rate of 6.2% from 2023 to 2028, reaching a market value of 2.7 billion USD by the end of the forecast period.

This growth is largely attributed to the aerospace industry's continuous pursuit of weight reduction strategies to improve fuel efficiency and reduce emissions. Conductive adhesives offer a viable alternative to traditional mechanical fastening methods, providing weight savings of up to 15% in certain applications while maintaining electrical conductivity essential for lightning strike protection and electromagnetic interference shielding.

The commercial aviation segment currently dominates the market demand, accounting for approximately 45% of the total consumption of aerospace-grade conductive adhesives. This is followed by military aircraft (30%), space applications (15%), and other segments including unmanned aerial vehicles and general aviation (10%). The demand distribution reflects the varying requirements across different aerospace sectors, with commercial aviation prioritizing cost-effectiveness alongside performance, while military and space applications emphasize reliability under extreme conditions.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe (32%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to the expanding aerospace manufacturing capabilities in China, Japan, and India.

Customer requirements for aerospace-grade conductive adhesives have evolved significantly, with increasing emphasis on thermal stability across extreme temperature ranges (-65°C to +200°C), resistance to cosmic radiation, and compatibility with composite substrates. Additionally, there is growing demand for adhesives with improved electrical conductivity without compromising mechanical properties, particularly shear strength and peel resistance.

Environmental regulations, particularly those restricting the use of certain heavy metals and volatile organic compounds, are reshaping market demands. The industry is increasingly seeking environmentally friendly formulations that comply with REACH and other global regulations while maintaining performance standards required for aerospace applications.

The aftermarket segment also represents a significant opportunity, with maintenance, repair, and overhaul (MRO) activities requiring specialized conductive adhesives for aircraft refurbishment and upgrades. This segment is expected to grow at 7.5% annually, outpacing the overall market growth rate.

This growth is largely attributed to the aerospace industry's continuous pursuit of weight reduction strategies to improve fuel efficiency and reduce emissions. Conductive adhesives offer a viable alternative to traditional mechanical fastening methods, providing weight savings of up to 15% in certain applications while maintaining electrical conductivity essential for lightning strike protection and electromagnetic interference shielding.

The commercial aviation segment currently dominates the market demand, accounting for approximately 45% of the total consumption of aerospace-grade conductive adhesives. This is followed by military aircraft (30%), space applications (15%), and other segments including unmanned aerial vehicles and general aviation (10%). The demand distribution reflects the varying requirements across different aerospace sectors, with commercial aviation prioritizing cost-effectiveness alongside performance, while military and space applications emphasize reliability under extreme conditions.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe (32%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to the expanding aerospace manufacturing capabilities in China, Japan, and India.

Customer requirements for aerospace-grade conductive adhesives have evolved significantly, with increasing emphasis on thermal stability across extreme temperature ranges (-65°C to +200°C), resistance to cosmic radiation, and compatibility with composite substrates. Additionally, there is growing demand for adhesives with improved electrical conductivity without compromising mechanical properties, particularly shear strength and peel resistance.

Environmental regulations, particularly those restricting the use of certain heavy metals and volatile organic compounds, are reshaping market demands. The industry is increasingly seeking environmentally friendly formulations that comply with REACH and other global regulations while maintaining performance standards required for aerospace applications.

The aftermarket segment also represents a significant opportunity, with maintenance, repair, and overhaul (MRO) activities requiring specialized conductive adhesives for aircraft refurbishment and upgrades. This segment is expected to grow at 7.5% annually, outpacing the overall market growth rate.

Current State and Challenges in Aerospace Adhesive Technology

The aerospace industry currently faces significant challenges in adhesive technology, particularly in the domain of conductive adhesives. Traditional joining methods like welding and mechanical fastening are increasingly being replaced by adhesive bonding due to its advantages in weight reduction, stress distribution, and design flexibility. However, the extreme operating conditions of aerospace applications—including temperature fluctuations from -65°C to over 200°C, vacuum exposure, radiation, and high mechanical stresses—create unique demands for adhesive performance.

Conductive adhesives in aerospace must simultaneously provide structural integrity and electrical conductivity, a combination that presents formidable technical challenges. Current silver-filled epoxy systems, while offering good conductivity, often struggle with thermal cycling resistance and long-term reliability in space environments. The degradation of electrical properties over time remains a critical concern, particularly for satellite and spacecraft applications where maintenance is impossible.

Another significant challenge is the balance between conductivity and mechanical properties. Higher filler content improves electrical performance but typically compromises flexibility and adhesion strength. This trade-off becomes especially problematic in applications involving dissimilar materials with different coefficients of thermal expansion, where stress management is crucial.

Manufacturing consistency presents additional difficulties. The dispersion of conductive particles within the adhesive matrix must be uniform to ensure reliable electrical performance across production batches. Current processing techniques often result in variability that is unacceptable for high-reliability aerospace systems, where performance predictability is paramount.

Environmental regulations have further complicated the landscape. Traditional conductive adhesives often contain components that are being restricted under global environmental regulations, including certain solvents, hardeners, and heavy metals. The aerospace industry must navigate these regulatory challenges while maintaining the high performance standards required for flight certification.

Recent advancements in nanomaterials, particularly carbon nanotubes and graphene, offer promising alternatives to traditional metal fillers, potentially addressing some conductivity-flexibility trade-offs. However, these materials introduce new challenges in processing, dispersion, and long-term stability that have yet to be fully resolved.

The qualification and certification process for new adhesive technologies in aerospace applications represents perhaps the most significant barrier to innovation. The extensive testing required—including thermal cycling, outgassing, radiation resistance, and mechanical performance—can take years to complete and costs millions of dollars, creating a substantial hurdle for the introduction of novel conductive adhesive systems.

Conductive adhesives in aerospace must simultaneously provide structural integrity and electrical conductivity, a combination that presents formidable technical challenges. Current silver-filled epoxy systems, while offering good conductivity, often struggle with thermal cycling resistance and long-term reliability in space environments. The degradation of electrical properties over time remains a critical concern, particularly for satellite and spacecraft applications where maintenance is impossible.

Another significant challenge is the balance between conductivity and mechanical properties. Higher filler content improves electrical performance but typically compromises flexibility and adhesion strength. This trade-off becomes especially problematic in applications involving dissimilar materials with different coefficients of thermal expansion, where stress management is crucial.

Manufacturing consistency presents additional difficulties. The dispersion of conductive particles within the adhesive matrix must be uniform to ensure reliable electrical performance across production batches. Current processing techniques often result in variability that is unacceptable for high-reliability aerospace systems, where performance predictability is paramount.

Environmental regulations have further complicated the landscape. Traditional conductive adhesives often contain components that are being restricted under global environmental regulations, including certain solvents, hardeners, and heavy metals. The aerospace industry must navigate these regulatory challenges while maintaining the high performance standards required for flight certification.

Recent advancements in nanomaterials, particularly carbon nanotubes and graphene, offer promising alternatives to traditional metal fillers, potentially addressing some conductivity-flexibility trade-offs. However, these materials introduce new challenges in processing, dispersion, and long-term stability that have yet to be fully resolved.

The qualification and certification process for new adhesive technologies in aerospace applications represents perhaps the most significant barrier to innovation. The extensive testing required—including thermal cycling, outgassing, radiation resistance, and mechanical performance—can take years to complete and costs millions of dollars, creating a substantial hurdle for the introduction of novel conductive adhesive systems.

Current Technical Solutions and Implementation Methods

01 Metal-filled conductive adhesives

Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These particles form conductive pathways when the adhesive is cured. The concentration, size, and shape of the metal particles significantly affect the conductivity of the adhesive. These adhesives are widely used in electronics assembly, providing both mechanical bonding and electrical connectivity between components.- Conductive fillers in adhesive compositions: Conductive adhesives incorporate various conductive fillers to achieve electrical conductivity. These fillers include metallic particles (such as silver, copper, nickel), carbon-based materials (like carbon nanotubes, graphene), and metal-coated particles. The type, size, shape, and concentration of these fillers significantly impact the adhesive's conductivity, mechanical strength, and processing characteristics. Optimizing the filler loading allows for balancing conductivity requirements with adhesive properties.

- Polymer matrices for conductive adhesives: The polymer matrix serves as the binding component in conductive adhesives, providing adhesion and mechanical stability. Common polymer systems include epoxies, silicones, acrylics, and polyurethanes. These matrices can be formulated as thermosetting or thermoplastic systems, each offering different processing and performance characteristics. The polymer selection affects curing conditions, temperature resistance, flexibility, and compatibility with various substrates, which is crucial for electronic applications.

- Electronic packaging and interconnection applications: Conductive adhesives are widely used in electronic packaging and interconnection applications as alternatives to traditional soldering. They provide electrical connections between components while also offering mechanical bonding. Applications include die attachment, surface mount technology, flip chip bonding, and flexible electronics. These adhesives enable lower processing temperatures compared to solders, making them suitable for temperature-sensitive components and substrates. They also facilitate miniaturization in electronic devices and can accommodate thermal expansion mismatches.

- Thermal management in conductive adhesives: Conductive adhesives often incorporate thermal management capabilities alongside electrical conductivity. These formulations include thermally conductive fillers such as aluminum oxide, boron nitride, or metal particles to enhance heat dissipation. This dual functionality is particularly important in high-power electronic applications where heat management is critical. The adhesives can be designed with specific thermal conductivity values to meet application requirements while maintaining electrical performance and bonding strength.

- Environmentally friendly conductive adhesive formulations: Recent developments in conductive adhesives focus on environmentally friendly formulations to replace lead-based solders and reduce environmental impact. These include lead-free, halogen-free, and low-VOC (volatile organic compound) formulations. Bio-based polymers and sustainable conductive fillers are being explored to create more eco-friendly options. These adhesives comply with regulations such as RoHS and REACH while maintaining performance requirements for electrical conductivity, adhesion strength, and reliability in various environmental conditions.

02 Carbon-based conductive adhesives

Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials provide electrical conductivity while often being more cost-effective than metal-filled alternatives. Carbon-based conductive adhesives typically offer moderate conductivity suitable for applications like EMI shielding, static dissipation, and thermal management. The unique properties of carbon nanomaterials can enhance both the mechanical and electrical performance of these adhesives.Expand Specific Solutions03 Anisotropic conductive adhesives

Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These adhesives typically contain conductive particles dispersed in an insulating polymer matrix. When compressed between electrical contacts, the particles form conductive pathways only in the direction of compression. ACAs are particularly valuable in fine-pitch electronics assembly, display technologies, and flexible circuit connections where directional conductivity is required.Expand Specific Solutions04 Thermally conductive adhesives

Thermally conductive adhesives are designed to transfer heat efficiently while providing adhesive properties. These formulations typically incorporate thermally conductive fillers such as ceramic particles, metal oxides, or boron nitride in a polymer matrix. They are essential in electronics cooling applications, LED assembly, power electronics, and other scenarios where heat dissipation is critical. Advanced formulations balance thermal conductivity with other properties like flexibility, strength, and electrical insulation.Expand Specific Solutions05 Environmentally friendly conductive adhesives

Environmentally friendly conductive adhesives address concerns about toxicity and environmental impact by eliminating or reducing hazardous materials like lead and certain solvents. These formulations often use bio-based polymers, water-based systems, or renewable materials as their base. They maintain electrical conductivity through carefully selected conductive fillers while meeting increasingly stringent environmental regulations. These adhesives are gaining importance in consumer electronics, medical devices, and other applications where sustainability is prioritized.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The conductive adhesives market for aerospace applications is in a growth phase, driven by increasing demand for lightweight materials and electronic integration in aircraft. The market size is expanding steadily, estimated to reach significant value as aerospace manufacturers seek reliable bonding solutions that meet stringent performance requirements. Technologically, the field is moderately mature but continuously evolving, with key players demonstrating varying levels of specialization. Henkel AG leads with comprehensive adhesive technology solutions, while 3M Innovative Properties offers diversified materials expertise. Boeing and Mitsubishi Heavy Industries provide aerospace-specific implementation knowledge. DuPont and Hexcel Composites contribute advanced materials science, with PRC-DeSoto International focusing on specialized aerospace coatings and sealants. The competitive landscape shows a balance between chemical conglomerates and aerospace manufacturers developing proprietary solutions.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed LOCTITE ABLESTIK aerospace-grade conductive adhesives specifically engineered for high-reliability applications in extreme environments. Their silver-filled epoxy systems provide excellent electrical conductivity (resistivity as low as 0.0001 ohm-cm) while maintaining mechanical strength at temperatures ranging from -65°C to +175°C. These adhesives feature specialized formulations that address thermal cycling resistance, with some variants incorporating nano-fillers to enhance thermal conductivity (up to 3 W/m-K) while maintaining flexibility to accommodate the different coefficients of thermal expansion between joined materials. Henkel's aerospace conductive adhesives are also designed with controlled outgassing properties (<1% TML) to meet NASA and ESA specifications for space applications, and offer radiation resistance for satellite components.

Strengths: Superior electrical conductivity combined with mechanical reliability in extreme temperature conditions; excellent resistance to thermal cycling; formulations specifically qualified to aerospace standards. Weaknesses: Higher cost compared to conventional adhesives; some formulations require specialized curing equipment; shelf-life limitations requiring controlled storage conditions.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered anisotropic conductive adhesives (ACAs) for aerospace applications that provide electrical conductivity in the z-axis while maintaining insulation in the x-y plane. Their technology incorporates precisely dispersed conductive particles (typically gold-coated nickel spheres or silver particles at 5-10μm diameter) in a proprietary epoxy matrix that can withstand the vibration and thermal cycling demands of aerospace environments. 3M's aerospace-grade conductive films demonstrate shear strengths exceeding 25 MPa and can maintain reliable electrical connections across temperature ranges from -55°C to +150°C. Their latest generation incorporates self-healing properties that allow the adhesive to maintain electrical pathways even after mechanical stress events, with demonstrated reliability through 1000+ thermal cycles without significant resistance changes.

Strengths: Excellent directional conductivity allowing high-density interconnections without risk of shorts; proven long-term reliability in aerospace vibration environments; compatible with various substrate materials including composites. Weaknesses: More complex application process requiring precise pressure during curing; higher initial investment in application equipment; limited reworkability once cured.

Critical Patents and Technical Literature Analysis

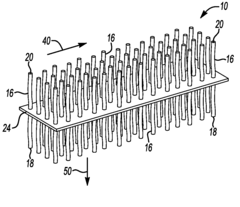

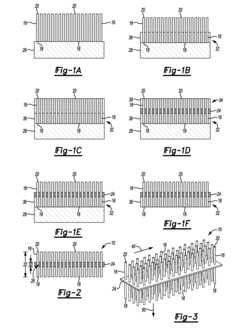

Conductive adhesive and method of forming same

PatentInactiveUS20130142986A1

Innovation

- A method of forming a conductive adhesive by condensation-polymerizing a carrier onto carbon nanotubes, allowing them to extend continuously through the carrier, enabling removability and reusability by maintaining the carrier while removing the substrate, thus creating a dry, two-sided adhesive with excellent mechanical, electrical, and thermal conductivity properties.

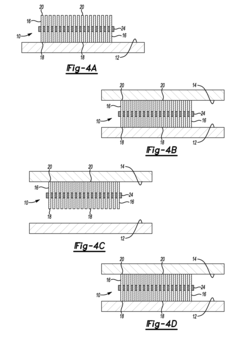

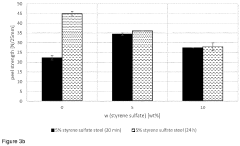

Conductive pressure sensitive adhesive

PatentPendingEP4328247A1

Innovation

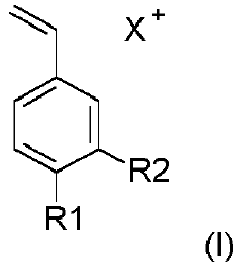

- A conductive pressure sensitive adhesive composition comprising a copolymer from a reaction mixture of acrylic monomers and a compound of Formula (I), which includes a sulfate or sulfonate group, incorporated into an acrylate polymeric backbone, optionally with an ionic liquid, providing improved ion conductivity and peel strength without water addition, suitable for dry film applications.

Environmental and Thermal Performance Considerations

Environmental conditions in aerospace applications present extreme challenges for conductive adhesives, requiring exceptional performance across temperature ranges from -65°C to over 200°C. These materials must maintain electrical conductivity, mechanical strength, and adhesion properties under thermal cycling, vacuum conditions, and radiation exposure. Traditional epoxy-based conductive adhesives often experience significant performance degradation when subjected to these harsh environments, particularly at temperature extremes.

Thermal conductivity represents a critical parameter for aerospace conductive adhesives, with silver-filled systems typically offering 2-5 W/m·K compared to conventional solder's 30-50 W/m·K. Recent advancements in nano-enhanced formulations have achieved improvements of 30-40% in thermal conductivity, addressing heat dissipation requirements in densely packed aerospace electronics. These enhanced thermal properties help prevent localized hotspots that could otherwise lead to premature component failure.

Outgassing behavior under vacuum conditions presents another significant consideration, as volatile compounds released from adhesives can contaminate sensitive optical equipment and electronics. NASA outgassing standards require total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%. Silver-filled silicone adhesives typically demonstrate superior outgassing performance compared to epoxy systems, though at the cost of reduced mechanical strength.

Radiation resistance varies significantly among conductive adhesive formulations. Silicone-based systems generally exhibit superior performance under radiation exposure compared to epoxy alternatives, maintaining electrical conductivity after exposure to 10⁶ Gy of gamma radiation. However, the addition of conductive fillers can sometimes reduce radiation resistance, creating a complex optimization challenge for aerospace applications.

Humidity and moisture resistance represent additional environmental concerns, particularly for ground-based operations and during launch conditions. Moisture ingress can significantly impact electrical performance through increased resistance and potential galvanic corrosion at filler-matrix interfaces. Hydrophobic additives and specialized surface treatments have demonstrated effectiveness in reducing moisture sensitivity by up to 75% in laboratory testing.

Thermal cycling resistance remains perhaps the most demanding requirement, with aerospace components often experiencing thousands of thermal cycles during service life. Coefficient of thermal expansion (CTE) mismatch between adhesives and substrates creates mechanical stress that can lead to delamination and conductivity loss. Hybrid adhesive systems incorporating both rigid and flexible components have shown promising results, maintaining over 90% of initial conductivity after 1,000 thermal cycles between -55°C and 125°C.

Thermal conductivity represents a critical parameter for aerospace conductive adhesives, with silver-filled systems typically offering 2-5 W/m·K compared to conventional solder's 30-50 W/m·K. Recent advancements in nano-enhanced formulations have achieved improvements of 30-40% in thermal conductivity, addressing heat dissipation requirements in densely packed aerospace electronics. These enhanced thermal properties help prevent localized hotspots that could otherwise lead to premature component failure.

Outgassing behavior under vacuum conditions presents another significant consideration, as volatile compounds released from adhesives can contaminate sensitive optical equipment and electronics. NASA outgassing standards require total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%. Silver-filled silicone adhesives typically demonstrate superior outgassing performance compared to epoxy systems, though at the cost of reduced mechanical strength.

Radiation resistance varies significantly among conductive adhesive formulations. Silicone-based systems generally exhibit superior performance under radiation exposure compared to epoxy alternatives, maintaining electrical conductivity after exposure to 10⁶ Gy of gamma radiation. However, the addition of conductive fillers can sometimes reduce radiation resistance, creating a complex optimization challenge for aerospace applications.

Humidity and moisture resistance represent additional environmental concerns, particularly for ground-based operations and during launch conditions. Moisture ingress can significantly impact electrical performance through increased resistance and potential galvanic corrosion at filler-matrix interfaces. Hydrophobic additives and specialized surface treatments have demonstrated effectiveness in reducing moisture sensitivity by up to 75% in laboratory testing.

Thermal cycling resistance remains perhaps the most demanding requirement, with aerospace components often experiencing thousands of thermal cycles during service life. Coefficient of thermal expansion (CTE) mismatch between adhesives and substrates creates mechanical stress that can lead to delamination and conductivity loss. Hybrid adhesive systems incorporating both rigid and flexible components have shown promising results, maintaining over 90% of initial conductivity after 1,000 thermal cycles between -55°C and 125°C.

Certification and Reliability Testing Standards

The aerospace industry demands exceptionally high standards for all components, with conductive adhesives being no exception. Certification and reliability testing standards for these materials are rigorous and comprehensive, designed to ensure performance under extreme conditions encountered in aerospace applications.

The primary certification framework governing conductive adhesives in aerospace is the AS5003 standard, developed by SAE International specifically for electrically conductive adhesives. This standard establishes baseline requirements for electrical conductivity, mechanical strength, and environmental resistance. Additionally, the NASA-STD-8739.1 provides detailed specifications for workmanship standards when using conductive adhesives in space flight hardware.

Military specifications MIL-STD-883 and MIL-STD-810G outline testing protocols for electronic components, including those bonded with conductive adhesives. These standards cover thermal cycling, mechanical shock, vibration, and humidity resistance—all critical factors in aerospace environments where temperature fluctuations can range from -65°C to +150°C.

Reliability testing for conductive adhesives typically follows a multi-tiered approach. Initial qualification testing includes adhesion strength measurements according to ASTM D1002 or D3163 standards, which evaluate shear strength under various conditions. Electrical performance testing follows IPC-TM-650 methods, measuring volume resistivity and contact resistance before and after environmental exposure.

Accelerated aging tests are particularly important for aerospace applications, where components must maintain performance over decades. These tests include thermal aging (1000+ hours at elevated temperatures), thermal cycling (typically 1000 cycles between temperature extremes), and combined environments testing that simultaneously applies thermal, mechanical, and electrical stresses.

Outgassing characteristics are evaluated using ASTM E595 standards, which are critical for space applications where volatile compounds can condense on optical surfaces or sensitive equipment. Conductive adhesives must typically demonstrate total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%.

Radiation resistance testing follows ASTM D5208 or equivalent standards, evaluating performance degradation after exposure to various radiation types encountered in space environments. This includes gamma radiation, electron radiation, and proton radiation at doses representative of mission profiles.

The European Space Agency (ESA) has developed its own set of standards, including ECSS-Q-ST-70-38C, which provides additional requirements for conductive adhesives used in European space missions. These standards often complement rather than replace the SAE and NASA requirements, creating a comprehensive certification framework.

The primary certification framework governing conductive adhesives in aerospace is the AS5003 standard, developed by SAE International specifically for electrically conductive adhesives. This standard establishes baseline requirements for electrical conductivity, mechanical strength, and environmental resistance. Additionally, the NASA-STD-8739.1 provides detailed specifications for workmanship standards when using conductive adhesives in space flight hardware.

Military specifications MIL-STD-883 and MIL-STD-810G outline testing protocols for electronic components, including those bonded with conductive adhesives. These standards cover thermal cycling, mechanical shock, vibration, and humidity resistance—all critical factors in aerospace environments where temperature fluctuations can range from -65°C to +150°C.

Reliability testing for conductive adhesives typically follows a multi-tiered approach. Initial qualification testing includes adhesion strength measurements according to ASTM D1002 or D3163 standards, which evaluate shear strength under various conditions. Electrical performance testing follows IPC-TM-650 methods, measuring volume resistivity and contact resistance before and after environmental exposure.

Accelerated aging tests are particularly important for aerospace applications, where components must maintain performance over decades. These tests include thermal aging (1000+ hours at elevated temperatures), thermal cycling (typically 1000 cycles between temperature extremes), and combined environments testing that simultaneously applies thermal, mechanical, and electrical stresses.

Outgassing characteristics are evaluated using ASTM E595 standards, which are critical for space applications where volatile compounds can condense on optical surfaces or sensitive equipment. Conductive adhesives must typically demonstrate total mass loss (TML) below 1.0% and collected volatile condensable materials (CVCM) below 0.1%.

Radiation resistance testing follows ASTM D5208 or equivalent standards, evaluating performance degradation after exposure to various radiation types encountered in space environments. This includes gamma radiation, electron radiation, and proton radiation at doses representative of mission profiles.

The European Space Agency (ESA) has developed its own set of standards, including ECSS-Q-ST-70-38C, which provides additional requirements for conductive adhesives used in European space missions. These standards often complement rather than replace the SAE and NASA requirements, creating a comprehensive certification framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!