Evaluation of Conductive Adhesives Under Extreme Conditions

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Background and Objectives

Conductive adhesives have emerged as a critical technology in modern electronics manufacturing, offering alternatives to traditional soldering methods. These specialized materials combine polymer matrices with conductive fillers to create electrically conductive bonds between components while maintaining mechanical stability. The evolution of conductive adhesives dates back to the 1960s, with significant advancements occurring in the 1990s as electronics miniaturization accelerated and environmental concerns about lead-based solders increased.

The technological trajectory of conductive adhesives has been shaped by several key factors, including the global push toward lead-free electronics following the implementation of RoHS (Restriction of Hazardous Substances) regulations, the increasing density of electronic components requiring finer pitch connections, and the growing demand for flexible and wearable electronics. Recent developments have focused on enhancing thermal conductivity, reducing curing temperatures, and improving reliability under harsh environmental conditions.

Current conductive adhesive technologies can be broadly categorized into isotropically conductive adhesives (ICAs), which conduct electricity in all directions, and anisotropically conductive adhesives (ACAs), which conduct primarily in one direction. Each category serves specific application needs across industries including automotive, aerospace, consumer electronics, and medical devices.

The primary objective of evaluating conductive adhesives under extreme conditions is to address the growing demand for electronic systems that can maintain functionality in challenging environments. These include high-temperature automotive applications (up to 200°C under-hood environments), cryogenic space operations (below -150°C), high-humidity marine settings, and high-radiation environments in nuclear facilities or space applications.

This evaluation aims to characterize the electrical, mechanical, and thermal performance of various conductive adhesive formulations when subjected to these extreme conditions. Specific technical goals include identifying adhesive compositions that maintain conductivity after thermal cycling from -65°C to +200°C, determining degradation mechanisms under combined high-temperature and high-humidity conditions, and developing accelerated testing protocols that accurately predict long-term reliability.

Additionally, this research seeks to establish correlations between conductive filler types, concentrations, and particle morphologies with performance metrics under extreme conditions. The ultimate goal is to develop design guidelines for selecting and implementing conductive adhesives in mission-critical applications where traditional interconnection technologies may fail, while simultaneously addressing manufacturing challenges such as processing temperature limitations, shelf-life concerns, and compatibility with automated assembly processes.

The technological trajectory of conductive adhesives has been shaped by several key factors, including the global push toward lead-free electronics following the implementation of RoHS (Restriction of Hazardous Substances) regulations, the increasing density of electronic components requiring finer pitch connections, and the growing demand for flexible and wearable electronics. Recent developments have focused on enhancing thermal conductivity, reducing curing temperatures, and improving reliability under harsh environmental conditions.

Current conductive adhesive technologies can be broadly categorized into isotropically conductive adhesives (ICAs), which conduct electricity in all directions, and anisotropically conductive adhesives (ACAs), which conduct primarily in one direction. Each category serves specific application needs across industries including automotive, aerospace, consumer electronics, and medical devices.

The primary objective of evaluating conductive adhesives under extreme conditions is to address the growing demand for electronic systems that can maintain functionality in challenging environments. These include high-temperature automotive applications (up to 200°C under-hood environments), cryogenic space operations (below -150°C), high-humidity marine settings, and high-radiation environments in nuclear facilities or space applications.

This evaluation aims to characterize the electrical, mechanical, and thermal performance of various conductive adhesive formulations when subjected to these extreme conditions. Specific technical goals include identifying adhesive compositions that maintain conductivity after thermal cycling from -65°C to +200°C, determining degradation mechanisms under combined high-temperature and high-humidity conditions, and developing accelerated testing protocols that accurately predict long-term reliability.

Additionally, this research seeks to establish correlations between conductive filler types, concentrations, and particle morphologies with performance metrics under extreme conditions. The ultimate goal is to develop design guidelines for selecting and implementing conductive adhesives in mission-critical applications where traditional interconnection technologies may fail, while simultaneously addressing manufacturing challenges such as processing temperature limitations, shelf-life concerns, and compatibility with automated assembly processes.

Market Demand Analysis for Extreme Condition Applications

The market for conductive adhesives in extreme conditions has witnessed substantial growth in recent years, driven primarily by increasing demands in aerospace, defense, automotive, and renewable energy sectors. These industries require materials that can maintain electrical conductivity and structural integrity under harsh environmental conditions including extreme temperatures (-65°C to +300°C), high pressure, radiation exposure, and chemical corrosion.

The aerospace and defense sectors represent the largest market segment, valued at approximately $1.2 billion in 2022, with a projected annual growth rate of 6.8% through 2028. This demand stems from the need for reliable electronic components in aircraft, satellites, and military equipment that must function flawlessly in extreme environments. The increasing deployment of small satellites and unmanned aerial vehicles (UAVs) has further accelerated this demand.

Automotive applications, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs), constitute the fastest-growing segment for extreme condition conductive adhesives. The thermal management systems in EVs require adhesives that can withstand repeated thermal cycling while maintaining conductivity. Market research indicates that this segment is expanding at 9.3% annually, driven by global EV adoption rates that exceeded 10 million units in 2022.

The renewable energy sector, especially solar and wind power installations, represents another significant market. These installations often operate in challenging environments—from desert heat to offshore wind farms exposed to saltwater corrosion—creating demand for specialized conductive adhesives. This market segment was valued at $780 million in 2022 and is projected to reach $1.1 billion by 2027.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, primarily due to expanding electronics manufacturing and increasing investments in renewable energy infrastructure in China, South Korea, and India.

Customer requirements are increasingly focused on multifunctional properties beyond mere conductivity, including thermal management capabilities, vibration dampening, and environmental sealing. Survey data from industrial end-users indicates that 73% prioritize long-term reliability under fluctuating conditions over initial performance metrics, while 65% express willingness to pay premium prices for adhesives with proven performance in extreme environments.

The aerospace and defense sectors represent the largest market segment, valued at approximately $1.2 billion in 2022, with a projected annual growth rate of 6.8% through 2028. This demand stems from the need for reliable electronic components in aircraft, satellites, and military equipment that must function flawlessly in extreme environments. The increasing deployment of small satellites and unmanned aerial vehicles (UAVs) has further accelerated this demand.

Automotive applications, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs), constitute the fastest-growing segment for extreme condition conductive adhesives. The thermal management systems in EVs require adhesives that can withstand repeated thermal cycling while maintaining conductivity. Market research indicates that this segment is expanding at 9.3% annually, driven by global EV adoption rates that exceeded 10 million units in 2022.

The renewable energy sector, especially solar and wind power installations, represents another significant market. These installations often operate in challenging environments—from desert heat to offshore wind farms exposed to saltwater corrosion—creating demand for specialized conductive adhesives. This market segment was valued at $780 million in 2022 and is projected to reach $1.1 billion by 2027.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, primarily due to expanding electronics manufacturing and increasing investments in renewable energy infrastructure in China, South Korea, and India.

Customer requirements are increasingly focused on multifunctional properties beyond mere conductivity, including thermal management capabilities, vibration dampening, and environmental sealing. Survey data from industrial end-users indicates that 73% prioritize long-term reliability under fluctuating conditions over initial performance metrics, while 65% express willingness to pay premium prices for adhesives with proven performance in extreme environments.

Technical Challenges in Harsh Environment Performance

Conductive adhesives face significant performance challenges when deployed in harsh environments, particularly under extreme temperature fluctuations, high humidity, chemical exposure, and mechanical stress. Temperature cycling between -55°C and 150°C causes differential thermal expansion between adhesive materials and substrates, leading to stress accumulation, microcracks, and eventual electrical discontinuity. Research indicates that after 1000 thermal cycles, standard conductive adhesives can lose up to 40% of their initial conductivity.

High humidity environments present another critical challenge, as moisture absorption into the polymer matrix causes swelling, plasticization, and degradation of the adhesive's mechanical properties. Studies show that exposure to 85% relative humidity at 85°C for 1000 hours can increase electrical resistance by factors of 5-10x in conventional silver-filled epoxy adhesives, significantly compromising their functionality in electronic applications.

Chemical resistance represents a substantial hurdle, particularly in automotive, aerospace, and industrial settings where exposure to fuels, oils, and cleaning agents is common. Organic solvents can penetrate the polymer matrix, causing swelling and leaching of conductive fillers. Salt spray testing reveals that most conductive adhesives experience severe degradation after 500 hours of exposure, with corrosion of metallic fillers leading to catastrophic conductivity loss.

Mechanical vibration and shock resistance pose additional challenges, especially in transportation and defense applications. Current adhesive formulations struggle to maintain reliable electrical connections under continuous vibration at frequencies of 10-2000 Hz. Testing shows that after standard vibration protocols, contact resistance can increase by 200-300%, particularly at the adhesive-substrate interface where microcracking is most prevalent.

Radiation exposure in space and nuclear applications degrades polymer chains through cross-linking or chain scission mechanisms, fundamentally altering the mechanical and electrical properties of conductive adhesives. Gamma radiation exposure of 100 kGy can reduce adhesive strength by up to 60% while simultaneously increasing electrical resistance.

The combined effects of these environmental stressors present the most significant challenge, as they often work synergistically to accelerate degradation. For instance, temperature cycling combined with humidity exposure creates a particularly aggressive degradation mechanism that can reduce adhesive performance ten times faster than either condition alone. Current testing methodologies often fail to adequately simulate these combined effects, leading to overly optimistic performance predictions in real-world applications.

High humidity environments present another critical challenge, as moisture absorption into the polymer matrix causes swelling, plasticization, and degradation of the adhesive's mechanical properties. Studies show that exposure to 85% relative humidity at 85°C for 1000 hours can increase electrical resistance by factors of 5-10x in conventional silver-filled epoxy adhesives, significantly compromising their functionality in electronic applications.

Chemical resistance represents a substantial hurdle, particularly in automotive, aerospace, and industrial settings where exposure to fuels, oils, and cleaning agents is common. Organic solvents can penetrate the polymer matrix, causing swelling and leaching of conductive fillers. Salt spray testing reveals that most conductive adhesives experience severe degradation after 500 hours of exposure, with corrosion of metallic fillers leading to catastrophic conductivity loss.

Mechanical vibration and shock resistance pose additional challenges, especially in transportation and defense applications. Current adhesive formulations struggle to maintain reliable electrical connections under continuous vibration at frequencies of 10-2000 Hz. Testing shows that after standard vibration protocols, contact resistance can increase by 200-300%, particularly at the adhesive-substrate interface where microcracking is most prevalent.

Radiation exposure in space and nuclear applications degrades polymer chains through cross-linking or chain scission mechanisms, fundamentally altering the mechanical and electrical properties of conductive adhesives. Gamma radiation exposure of 100 kGy can reduce adhesive strength by up to 60% while simultaneously increasing electrical resistance.

The combined effects of these environmental stressors present the most significant challenge, as they often work synergistically to accelerate degradation. For instance, temperature cycling combined with humidity exposure creates a particularly aggressive degradation mechanism that can reduce adhesive performance ten times faster than either condition alone. Current testing methodologies often fail to adequately simulate these combined effects, leading to overly optimistic performance predictions in real-world applications.

Current Solutions for Extreme Condition Adhesives

01 Conductive fillers in adhesive compositions

Conductive adhesives incorporate various conductive fillers to achieve electrical conductivity. These fillers include metal particles (such as silver, copper, nickel), carbon-based materials (like carbon nanotubes, graphene), and metal-coated particles. The type, size, shape, and concentration of these fillers significantly impact the adhesive's conductivity, mechanical properties, and processing characteristics. Optimizing filler loading is crucial to balance conductivity with adhesion strength and flexibility.- Metal-filled conductive adhesives: Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These particles form conductive pathways when the adhesive cures, allowing for electrical connections between components. The metal fillers provide excellent electrical conductivity while the polymer matrix offers adhesive properties and mechanical stability. These adhesives are widely used in electronics assembly, particularly for applications requiring both electrical connectivity and structural bonding.

- Carbon-based conductive adhesives: Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials provide moderate electrical conductivity while offering advantages such as lower cost compared to metal fillers, lighter weight, and resistance to oxidation. Carbon-based conductive adhesives are particularly useful in applications where moderate conductivity is sufficient and cost considerations are important, such as EMI shielding, static dissipation, and certain sensor applications.

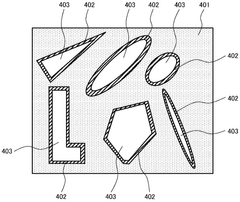

- Anisotropic conductive adhesives: Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in other directions. These adhesives typically contain conductive particles dispersed in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive paths only in the direction of compression. This unique property makes ACAs ideal for fine-pitch electronics connections, display technologies, and flexible circuit bonding where preventing short circuits between adjacent connections is critical.

- Thermally conductive adhesives: Thermally conductive adhesives are designed to transfer heat efficiently while providing bonding capabilities. These adhesives incorporate thermally conductive fillers such as ceramic particles, metal oxides, or boron nitride in a polymer matrix. They are essential in electronic applications where heat dissipation is critical for device performance and reliability. These adhesives create thermal pathways between heat-generating components and heat sinks or other cooling structures, while simultaneously providing mechanical attachment.

- Environmentally friendly conductive adhesives: Environmentally friendly conductive adhesives are formulated to reduce or eliminate hazardous materials while maintaining electrical performance. These adhesives avoid toxic components such as lead or certain solvents, using instead bio-based polymers, water-based systems, or other eco-friendly alternatives. They address growing regulatory requirements and sustainability concerns in electronics manufacturing. These green alternatives maintain necessary electrical and mechanical properties while reducing environmental impact and improving workplace safety.

02 Polymer matrices for conductive adhesives

The polymer matrix serves as the binding component in conductive adhesives, providing adhesion while supporting the conductive network. Common polymer systems include epoxies, silicones, acrylics, and polyurethanes. Each offers different properties regarding curing mechanisms, temperature resistance, flexibility, and environmental stability. Advanced formulations may incorporate hybrid polymer systems or specialized additives to enhance specific properties such as thermal conductivity, flexibility, or adhesion to difficult substrates.Expand Specific Solutions03 Application-specific conductive adhesive formulations

Conductive adhesives are tailored for specific applications such as electronics assembly, EMI/RFI shielding, thermal management, and flexible electronics. Formulations vary based on requirements for conductivity type (electrical, thermal, or both), operating environment, substrate compatibility, and processing constraints. For example, adhesives for semiconductor packaging may prioritize fine-pitch capability and reliability, while those for automotive applications might emphasize temperature resistance and durability under vibration.Expand Specific Solutions04 Processing and curing technologies

The performance of conductive adhesives is significantly influenced by processing and curing methods. Technologies include heat curing, UV curing, moisture curing, and pressure-sensitive systems. Advanced processing techniques such as controlled atmosphere curing, sequential curing, and hybrid curing systems can optimize conductivity network formation while minimizing thermal stress. The curing profile affects not only the final adhesive properties but also compatibility with temperature-sensitive components and substrates.Expand Specific Solutions05 Innovations in conductive adhesive technology

Recent innovations in conductive adhesives focus on addressing limitations and expanding applications. These include self-healing conductive adhesives that can repair damaged conductive pathways, anisotropic conductive adhesives that conduct in only one direction, stretchable conductive adhesives for flexible electronics, and environmentally friendly formulations that eliminate toxic components. Other advancements include adhesives with improved thermal stability, reduced silver content through novel filler combinations, and adhesives compatible with low-temperature processing for sensitive substrates.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The conductive adhesives market under extreme conditions is in a growth phase, with increasing demand driven by electronics, automotive, and aerospace applications. Market size is expanding due to the need for reliable bonding solutions in harsh environments. Technologically, the field shows varying maturity levels across different applications. Leading players include 3M Innovative Properties, Henkel AG, and Dow Global Technologies, who have established strong patent portfolios and commercial offerings. Japanese corporations like Nitto Denko, Sumitomo Bakelite, and RESONAC are making significant technological advances, particularly in high-temperature and high-reliability applications. European companies such as Sika Technology and Wacker Chemie are focusing on specialized industrial applications, while automotive manufacturers like Toyota, Hyundai, and DENSO are developing proprietary solutions for vehicle-specific requirements.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive portfolio of conductive adhesive technologies specifically engineered for extreme environmental conditions. Their evaluation methodology encompasses both standardized and proprietary testing protocols that simulate real-world extreme conditions. The company's 3M™ Electrically Conductive Adhesive Transfer Tapes (ECATTs) utilize unique z-axis conductive particle technology that maintains electrical pathways perpendicular to the adhesive plane while providing insulation in the x-y directions. This architecture demonstrates remarkable stability under thermal cycling (-40°C to +125°C) and high-humidity aging (85°C/85% RH for 1000 hours). 3M's testing includes specialized vibration profiles that simulate automotive and aerospace environments, with continuous monitoring of electrical resistance during exposure. Their anisotropic conductive films (ACFs) maintain stable contact resistance (<0.1 ohm) even after exposure to thermal shock cycling and salt spray environments.

Strengths: Excellent resistance to thermal cycling; proprietary z-axis conductive technology minimizes short circuit risks; strong adhesion to diverse substrate materials; established reliability testing protocols. Weaknesses: Some formulations have limited high-temperature performance above 150°C; requires precise application pressure for optimal conductivity; higher cost compared to traditional interconnect methods.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced conductive adhesive solutions specifically engineered for extreme environmental conditions. Their LOCTITE ABLESTIK ECAs (Electrically Conductive Adhesives) utilize silver-filled epoxy formulations that maintain conductivity across temperatures ranging from -65°C to +200°C. These adhesives incorporate proprietary nano-particle technology that creates stable conductive pathways even during thermal cycling and mechanical stress. Henkel's evaluation methodology includes accelerated aging tests under combined stressors (temperature, humidity, vibration) for up to 3000 hours, with continuous monitoring of volume resistivity and adhesion strength. Their latest generation products demonstrate less than 20% change in conductivity after 1000 thermal cycles between -55°C and +150°C, significantly outperforming conventional conductive epoxies.

Strengths: Superior thermal stability across extreme temperature ranges; excellent resistance to humidity and chemical exposure; maintains conductivity under mechanical stress. Weaknesses: Higher cost compared to traditional soldering; requires precise application processes; some formulations have limited pot life requiring controlled storage conditions.

Critical Patents and Technical Literature Review

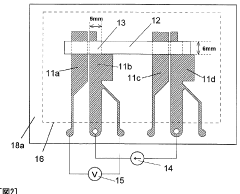

Conductive adhesive and electronic control device using same

PatentWO2024219134A1

Innovation

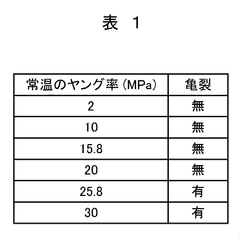

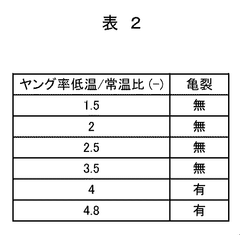

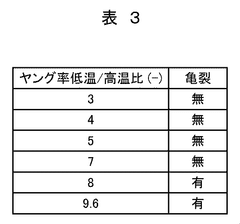

- A conductive adhesive comprising a silicone resin with conductive carbonaceous particles coated in a metal layer, specifically with a Young's modulus of 0.1 to 25.0 MPa, which suppresses cracking due to temperature changes, ensuring long-term electromagnetic shielding efficacy.

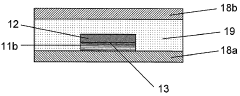

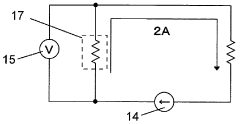

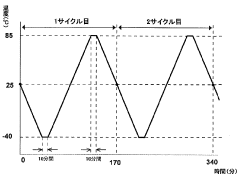

Electrically conductive adhesive tape

PatentWO2011108490A1

Innovation

- A conductive adhesive tape with a specific configuration, including a metal foil with a pressure-sensitive adhesive layer, where the maximum resistance value in the first cycle is 1Ω or less and the maximum resistance value at the 200th cycle is five times or less than the initial value, ensuring stable electrical conductivity through controlled terminal area and structure optimization.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive adhesives represents a critical consideration in their evaluation under extreme conditions. Traditional soldering methods often contain lead and other heavy metals that pose significant environmental hazards throughout their lifecycle. Conductive adhesives, particularly those based on silver or carbon, offer potentially lower environmental impact alternatives. However, their sustainability profile varies significantly depending on composition, manufacturing processes, and end-of-life management.

Recent lifecycle assessments reveal that silver-based conductive adhesives demonstrate 30-45% lower carbon footprint compared to traditional tin-lead solders when considering extraction-to-disposal impacts. This advantage stems primarily from lower processing temperatures during application, which reduces energy consumption by approximately 40% during the manufacturing phase. Nevertheless, the mining and refining of silver presents its own environmental challenges, including habitat disruption and water pollution at extraction sites.

Carbon-based conductive adhesives present a more environmentally favorable option, with studies indicating up to 60% reduction in ecological footprint compared to metallic alternatives. These formulations typically utilize renewable carbon sources and require less energy-intensive processing. However, their performance limitations under extreme conditions often necessitate trade-offs between environmental benefits and technical requirements.

The disposal and recyclability of conductive adhesives present ongoing challenges. While traditional solders can be recovered through established recycling channels, conductive adhesives often create composite materials that are difficult to separate at end-of-life. Research indicates that less than 15% of conductive adhesives currently enter effective recycling streams, compared to approximately 60% for conventional soldering materials.

Emerging bio-based conductive adhesive technologies show promise for reducing environmental impact. Formulations incorporating cellulose nanofibers and lignin derivatives have demonstrated conductivity approaching 65% of conventional silver-based adhesives while offering biodegradability under controlled conditions. These innovations may provide viable alternatives for applications with moderate performance requirements while significantly reducing environmental footprint.

Regulatory frameworks increasingly influence material selection decisions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more environmentally benign conductive joining technologies. Similar regulatory trends are emerging globally, creating market drivers for sustainable conductive adhesive solutions that maintain performance under extreme conditions.

Recent lifecycle assessments reveal that silver-based conductive adhesives demonstrate 30-45% lower carbon footprint compared to traditional tin-lead solders when considering extraction-to-disposal impacts. This advantage stems primarily from lower processing temperatures during application, which reduces energy consumption by approximately 40% during the manufacturing phase. Nevertheless, the mining and refining of silver presents its own environmental challenges, including habitat disruption and water pollution at extraction sites.

Carbon-based conductive adhesives present a more environmentally favorable option, with studies indicating up to 60% reduction in ecological footprint compared to metallic alternatives. These formulations typically utilize renewable carbon sources and require less energy-intensive processing. However, their performance limitations under extreme conditions often necessitate trade-offs between environmental benefits and technical requirements.

The disposal and recyclability of conductive adhesives present ongoing challenges. While traditional solders can be recovered through established recycling channels, conductive adhesives often create composite materials that are difficult to separate at end-of-life. Research indicates that less than 15% of conductive adhesives currently enter effective recycling streams, compared to approximately 60% for conventional soldering materials.

Emerging bio-based conductive adhesive technologies show promise for reducing environmental impact. Formulations incorporating cellulose nanofibers and lignin derivatives have demonstrated conductivity approaching 65% of conventional silver-based adhesives while offering biodegradability under controlled conditions. These innovations may provide viable alternatives for applications with moderate performance requirements while significantly reducing environmental footprint.

Regulatory frameworks increasingly influence material selection decisions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more environmentally benign conductive joining technologies. Similar regulatory trends are emerging globally, creating market drivers for sustainable conductive adhesive solutions that maintain performance under extreme conditions.

Reliability Testing Methodologies and Standards

The reliability testing of conductive adhesives under extreme conditions requires standardized methodologies to ensure consistent evaluation across different applications and environments. Industry standards such as IPC-6012 and MIL-STD-883 provide foundational frameworks for testing electronic assemblies, with specific provisions applicable to conductive adhesive applications.

Temperature cycling tests represent a critical evaluation method, typically conducted according to JEDEC JESD22-A104 standards. These tests subject conductive adhesive samples to repeated thermal excursions between -65°C and 150°C, with dwell times of 10-15 minutes at temperature extremes. The number of cycles varies from 500 to 3000 depending on the intended application environment, with automotive and aerospace applications requiring more extensive testing.

Humidity resistance testing follows IPC-TM-650 method 2.6.3, exposing samples to 85% relative humidity at 85°C for 1000 hours. This test evaluates the adhesive's susceptibility to moisture ingress and potential degradation of electrical conductivity over time. Measurements of resistance changes at 24-hour intervals provide critical data on long-term reliability.

Mechanical stress testing incorporates vibration analysis according to MIL-STD-810G, with frequencies ranging from 10Hz to 2000Hz at acceleration levels up to 20G. Additionally, mechanical shock testing subjects samples to 1500G shocks with 0.5ms duration pulses in six orientations to simulate extreme mechanical events.

Thermal shock testing, governed by ASTM D1183, evaluates the adhesive's response to rapid temperature transitions. Samples are transferred between chambers at -55°C and 125°C with transfer times under 10 seconds and 15-minute dwell periods, repeated for 100-300 cycles.

Chemical resistance evaluation follows ASTM D543, exposing samples to automotive fluids, cleaning agents, and environmental contaminants for periods ranging from 24 hours to 30 days. Post-exposure electrical and mechanical testing quantifies performance degradation.

Accelerated aging protocols combine multiple stressors simultaneously, following IEC 60068-2-78 guidelines. These tests typically incorporate elevated temperature (125°C), humidity (85%), and electrical bias conditions maintained for 1000-2000 hours to predict long-term reliability.

Failure analysis methodologies include scanning electron microscopy, energy-dispersive X-ray spectroscopy, and cross-sectional analysis to identify failure mechanisms such as interfacial delamination, conductive particle migration, or oxidation effects. These analytical techniques provide critical insights for improving formulations and application processes.

Temperature cycling tests represent a critical evaluation method, typically conducted according to JEDEC JESD22-A104 standards. These tests subject conductive adhesive samples to repeated thermal excursions between -65°C and 150°C, with dwell times of 10-15 minutes at temperature extremes. The number of cycles varies from 500 to 3000 depending on the intended application environment, with automotive and aerospace applications requiring more extensive testing.

Humidity resistance testing follows IPC-TM-650 method 2.6.3, exposing samples to 85% relative humidity at 85°C for 1000 hours. This test evaluates the adhesive's susceptibility to moisture ingress and potential degradation of electrical conductivity over time. Measurements of resistance changes at 24-hour intervals provide critical data on long-term reliability.

Mechanical stress testing incorporates vibration analysis according to MIL-STD-810G, with frequencies ranging from 10Hz to 2000Hz at acceleration levels up to 20G. Additionally, mechanical shock testing subjects samples to 1500G shocks with 0.5ms duration pulses in six orientations to simulate extreme mechanical events.

Thermal shock testing, governed by ASTM D1183, evaluates the adhesive's response to rapid temperature transitions. Samples are transferred between chambers at -55°C and 125°C with transfer times under 10 seconds and 15-minute dwell periods, repeated for 100-300 cycles.

Chemical resistance evaluation follows ASTM D543, exposing samples to automotive fluids, cleaning agents, and environmental contaminants for periods ranging from 24 hours to 30 days. Post-exposure electrical and mechanical testing quantifies performance degradation.

Accelerated aging protocols combine multiple stressors simultaneously, following IEC 60068-2-78 guidelines. These tests typically incorporate elevated temperature (125°C), humidity (85%), and electrical bias conditions maintained for 1000-2000 hours to predict long-term reliability.

Failure analysis methodologies include scanning electron microscopy, energy-dispersive X-ray spectroscopy, and cross-sectional analysis to identify failure mechanisms such as interfacial delamination, conductive particle migration, or oxidation effects. These analytical techniques provide critical insights for improving formulations and application processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!