Conductive Adhesives and Nanomaterial Integration: A Research Outlook

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Evolution and Research Objectives

Conductive adhesives have evolved significantly over the past decades, transitioning from simple metal-filled polymers to sophisticated composite materials incorporating advanced nanomaterials. The journey began in the 1950s with silver-filled epoxies primarily used in niche applications, but gained momentum in the 1970s as electronics miniaturization demanded alternatives to traditional soldering. By the 1990s, environmental concerns regarding lead-based solders accelerated research into electrically conductive adhesives (ECAs) as viable replacements.

The evolution of conductive adhesives has been characterized by continuous improvements in conductivity, adhesion strength, and processing parameters. Early formulations suffered from reliability issues, including conductivity degradation under thermal cycling and humidity exposure. These challenges drove innovations in polymer chemistry and filler technologies, leading to the development of hybrid systems combining different conductive particles to optimize performance characteristics.

The integration of nanomaterials represents the most recent and transformative phase in conductive adhesive development. Carbon nanotubes, first incorporated in the early 2000s, demonstrated the potential for achieving high conductivity at lower filler loadings. Graphene followed in the 2010s, offering exceptional electrical properties along with mechanical reinforcement. Most recently, metallic nanowires and nanoparticles have enabled unprecedented combinations of flexibility and conductivity, opening new application spaces in flexible electronics and wearable technology.

Current research objectives focus on several key areas that address remaining limitations in nanomaterial-enhanced conductive adhesives. Primary among these is the development of scalable manufacturing processes that maintain nanomaterial dispersion quality while enabling high-volume production. Researchers are also targeting improved interfacial interactions between nanomaterials and polymer matrices to enhance both electrical and mechanical properties simultaneously.

Another critical research objective involves reducing the environmental impact of conductive adhesives through the development of bio-based polymer matrices and less toxic conductive fillers. This sustainability focus aligns with global trends toward greener electronics manufacturing while maintaining performance requirements. Additionally, researchers are exploring self-healing capabilities through the incorporation of dynamic chemical bonds and responsive nanomaterials that can restore conductivity after mechanical damage.

The ultimate technical goal remains the creation of conductive adhesive systems that match or exceed the performance of traditional soldering in terms of electrical conductivity, thermal conductivity, and long-term reliability, while offering advantages in processing temperature, flexibility, and environmental impact. This requires interdisciplinary approaches combining polymer science, nanomaterial engineering, and surface chemistry to overcome current limitations and unlock new application possibilities in advanced electronics, renewable energy systems, and biomedical devices.

The evolution of conductive adhesives has been characterized by continuous improvements in conductivity, adhesion strength, and processing parameters. Early formulations suffered from reliability issues, including conductivity degradation under thermal cycling and humidity exposure. These challenges drove innovations in polymer chemistry and filler technologies, leading to the development of hybrid systems combining different conductive particles to optimize performance characteristics.

The integration of nanomaterials represents the most recent and transformative phase in conductive adhesive development. Carbon nanotubes, first incorporated in the early 2000s, demonstrated the potential for achieving high conductivity at lower filler loadings. Graphene followed in the 2010s, offering exceptional electrical properties along with mechanical reinforcement. Most recently, metallic nanowires and nanoparticles have enabled unprecedented combinations of flexibility and conductivity, opening new application spaces in flexible electronics and wearable technology.

Current research objectives focus on several key areas that address remaining limitations in nanomaterial-enhanced conductive adhesives. Primary among these is the development of scalable manufacturing processes that maintain nanomaterial dispersion quality while enabling high-volume production. Researchers are also targeting improved interfacial interactions between nanomaterials and polymer matrices to enhance both electrical and mechanical properties simultaneously.

Another critical research objective involves reducing the environmental impact of conductive adhesives through the development of bio-based polymer matrices and less toxic conductive fillers. This sustainability focus aligns with global trends toward greener electronics manufacturing while maintaining performance requirements. Additionally, researchers are exploring self-healing capabilities through the incorporation of dynamic chemical bonds and responsive nanomaterials that can restore conductivity after mechanical damage.

The ultimate technical goal remains the creation of conductive adhesive systems that match or exceed the performance of traditional soldering in terms of electrical conductivity, thermal conductivity, and long-term reliability, while offering advantages in processing temperature, flexibility, and environmental impact. This requires interdisciplinary approaches combining polymer science, nanomaterial engineering, and surface chemistry to overcome current limitations and unlock new application possibilities in advanced electronics, renewable energy systems, and biomedical devices.

Market Analysis for Nanomaterial-Enhanced Conductive Adhesives

The global market for nanomaterial-enhanced conductive adhesives has experienced significant growth in recent years, driven by increasing demand for miniaturized electronic components and the need for high-performance interconnection materials. According to industry reports, the market was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate (CAGR) of 10.1%.

The electronics industry remains the primary consumer of these advanced adhesives, accounting for nearly 65% of the total market share. Within this sector, consumer electronics manufacturers are the largest end-users, followed by automotive electronics and aerospace applications. The rapid expansion of electric vehicles has created a substantial new demand segment, with requirements for thermal management solutions and high-reliability electrical connections.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, South Korea, and Taiwan. North America follows with 28% market share, driven by advanced electronics and aerospace applications. Europe accounts for 22% of the market, with particular strength in automotive electronics and industrial applications.

Silver-based nanomaterial conductive adhesives currently hold the largest market segment at 58%, owing to their superior conductivity and established manufacturing processes. However, copper and carbon-based alternatives are gaining traction due to cost advantages and sustainability considerations, growing at rates of 12.3% and 14.7% respectively.

Key market drivers include the ongoing miniaturization trend in electronics, increasing demand for flexible and stretchable electronics, and the growing adoption of 5G technology requiring high-frequency compatible materials. Additionally, sustainability concerns are pushing manufacturers toward environmentally friendly formulations with reduced silver content.

Market challenges include high material costs, particularly for noble metal nanoparticles, technical barriers in achieving consistent electrical performance across operating conditions, and regulatory concerns regarding nanomaterial safety and disposal. The price sensitivity in consumer electronics also presents a significant constraint on market expansion in certain segments.

Emerging opportunities exist in medical electronics, where biocompatible conductive adhesives are gaining importance for wearable health monitoring devices. The Internet of Things (IoT) ecosystem represents another high-growth application area, with billions of connected devices requiring reliable and cost-effective interconnection solutions.

The electronics industry remains the primary consumer of these advanced adhesives, accounting for nearly 65% of the total market share. Within this sector, consumer electronics manufacturers are the largest end-users, followed by automotive electronics and aerospace applications. The rapid expansion of electric vehicles has created a substantial new demand segment, with requirements for thermal management solutions and high-reliability electrical connections.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, South Korea, and Taiwan. North America follows with 28% market share, driven by advanced electronics and aerospace applications. Europe accounts for 22% of the market, with particular strength in automotive electronics and industrial applications.

Silver-based nanomaterial conductive adhesives currently hold the largest market segment at 58%, owing to their superior conductivity and established manufacturing processes. However, copper and carbon-based alternatives are gaining traction due to cost advantages and sustainability considerations, growing at rates of 12.3% and 14.7% respectively.

Key market drivers include the ongoing miniaturization trend in electronics, increasing demand for flexible and stretchable electronics, and the growing adoption of 5G technology requiring high-frequency compatible materials. Additionally, sustainability concerns are pushing manufacturers toward environmentally friendly formulations with reduced silver content.

Market challenges include high material costs, particularly for noble metal nanoparticles, technical barriers in achieving consistent electrical performance across operating conditions, and regulatory concerns regarding nanomaterial safety and disposal. The price sensitivity in consumer electronics also presents a significant constraint on market expansion in certain segments.

Emerging opportunities exist in medical electronics, where biocompatible conductive adhesives are gaining importance for wearable health monitoring devices. The Internet of Things (IoT) ecosystem represents another high-growth application area, with billions of connected devices requiring reliable and cost-effective interconnection solutions.

Current Challenges in Nanomaterial Integration Technologies

Despite significant advancements in nanomaterial integration technologies, several critical challenges continue to impede the widespread adoption of conductive adhesives incorporating nanomaterials. The primary technical obstacle remains achieving consistent dispersion of nanomaterials within polymer matrices. Nanomaterials, particularly carbon nanotubes and metallic nanoparticles, exhibit strong van der Waals forces that cause agglomeration, resulting in non-uniform electrical conductivity and mechanical property degradation across the adhesive system.

Interface compatibility presents another substantial challenge, as the surface chemistry of nanomaterials often conflicts with the polymer matrices used in conductive adhesives. This incompatibility creates weak interfacial bonding, leading to performance deterioration under thermal and mechanical stress conditions. Current surface modification techniques frequently compromise the intrinsic electrical properties of nanomaterials, creating an undesirable trade-off between dispersion quality and conductivity performance.

Scalable manufacturing processes represent a significant bottleneck in commercialization efforts. Laboratory-scale successes in nanomaterial integration have proven difficult to translate to industrial production environments. The precise control of nanomaterial orientation, concentration gradients, and three-dimensional distribution patterns—critical for optimized performance—becomes increasingly challenging at larger scales. Additionally, quality control methodologies for nanomaterial-enhanced adhesives remain underdeveloped, with limited in-line monitoring capabilities.

Environmental stability poses ongoing concerns, as many nanomaterial-polymer systems demonstrate performance degradation when exposed to humidity, temperature fluctuations, and oxidative environments. This vulnerability significantly limits application potential in harsh operating conditions. The degradation mechanisms at the nano-bio interface remain insufficiently understood, hampering the development of effective mitigation strategies.

Regulatory and safety considerations further complicate development efforts. The potential environmental and health impacts of nanomaterials, particularly during manufacturing processes and at end-of-life disposal, remain subjects of ongoing research and regulatory scrutiny. This uncertainty creates hesitation among industrial adopters and complicates commercialization pathways.

Cost-effectiveness continues to challenge widespread implementation, with high-quality nanomaterials commanding premium prices that make final products economically unviable for many applications. Current synthesis methods for specialized nanomaterials with tailored properties often involve complex, multi-step processes with low yields, further exacerbating cost concerns. The absence of standardized characterization protocols also hinders quality assurance and consistent performance benchmarking across the industry.

Interface compatibility presents another substantial challenge, as the surface chemistry of nanomaterials often conflicts with the polymer matrices used in conductive adhesives. This incompatibility creates weak interfacial bonding, leading to performance deterioration under thermal and mechanical stress conditions. Current surface modification techniques frequently compromise the intrinsic electrical properties of nanomaterials, creating an undesirable trade-off between dispersion quality and conductivity performance.

Scalable manufacturing processes represent a significant bottleneck in commercialization efforts. Laboratory-scale successes in nanomaterial integration have proven difficult to translate to industrial production environments. The precise control of nanomaterial orientation, concentration gradients, and three-dimensional distribution patterns—critical for optimized performance—becomes increasingly challenging at larger scales. Additionally, quality control methodologies for nanomaterial-enhanced adhesives remain underdeveloped, with limited in-line monitoring capabilities.

Environmental stability poses ongoing concerns, as many nanomaterial-polymer systems demonstrate performance degradation when exposed to humidity, temperature fluctuations, and oxidative environments. This vulnerability significantly limits application potential in harsh operating conditions. The degradation mechanisms at the nano-bio interface remain insufficiently understood, hampering the development of effective mitigation strategies.

Regulatory and safety considerations further complicate development efforts. The potential environmental and health impacts of nanomaterials, particularly during manufacturing processes and at end-of-life disposal, remain subjects of ongoing research and regulatory scrutiny. This uncertainty creates hesitation among industrial adopters and complicates commercialization pathways.

Cost-effectiveness continues to challenge widespread implementation, with high-quality nanomaterials commanding premium prices that make final products economically unviable for many applications. Current synthesis methods for specialized nanomaterials with tailored properties often involve complex, multi-step processes with low yields, further exacerbating cost concerns. The absence of standardized characterization protocols also hinders quality assurance and consistent performance benchmarking across the industry.

Existing Nanomaterial Integration Methods

01 Carbon-based nanomaterials in conductive adhesives

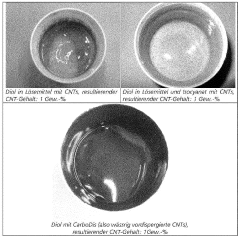

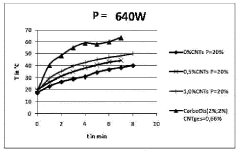

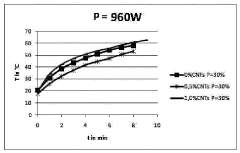

Carbon-based nanomaterials such as carbon nanotubes, graphene, and carbon black can be integrated into adhesive formulations to enhance electrical conductivity. These materials create conductive pathways within the adhesive matrix, allowing for efficient electron transfer. The unique structure of carbon nanomaterials provides high aspect ratios and excellent intrinsic conductivity, making them ideal fillers for conductive adhesive applications. These adhesives can maintain flexibility while achieving high conductivity levels.- Carbon-based nanomaterials for conductive adhesives: Carbon-based nanomaterials such as carbon nanotubes, graphene, and carbon black can be incorporated into adhesive formulations to enhance electrical conductivity. These materials create conductive pathways within the adhesive matrix, allowing for efficient electron transfer. The high aspect ratio of carbon nanotubes and the excellent conductivity of graphene make them particularly effective for developing adhesives with superior electrical performance while maintaining mechanical strength and flexibility.

- Metal nanoparticle integration for enhanced conductivity: Metal nanoparticles, including silver, gold, and copper, can be dispersed within adhesive matrices to create highly conductive pathways. These nanoparticles offer excellent electrical conductivity while requiring lower loading levels compared to traditional metal fillers. The size, shape, and surface treatment of the metal nanoparticles can be optimized to improve dispersion and prevent agglomeration, resulting in adhesives with uniform conductivity and improved processing characteristics.

- Hybrid nanomaterial systems for synergistic effects: Combining different types of nanomaterials, such as metal nanoparticles with carbon nanotubes or graphene, creates hybrid systems with synergistic effects on conductivity. These hybrid systems can achieve higher conductivity at lower filler loadings, maintaining better mechanical properties and processing characteristics. The different nanomaterials can form interconnected networks that provide multiple conductive pathways, resulting in adhesives with enhanced electrical performance and reliability under various environmental conditions.

- Surface functionalization of nanomaterials for improved dispersion: Surface functionalization of nanomaterials improves their compatibility with adhesive matrices, leading to better dispersion and enhanced conductivity. Chemical modifications can prevent agglomeration of nanomaterials and strengthen the interface between the nanomaterials and the adhesive matrix. This results in more uniform distribution of conductive fillers and more efficient formation of conductive networks, ultimately improving the electrical performance and reliability of the adhesive.

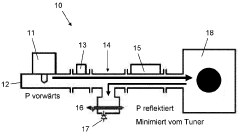

- Processing techniques for nanomaterial-enhanced conductive adhesives: Advanced processing techniques, such as ultrasonication, high-shear mixing, and in-situ synthesis, can significantly improve the dispersion of nanomaterials in adhesive formulations. These techniques help to break up agglomerates and ensure uniform distribution of nanomaterials throughout the adhesive matrix. Additionally, controlled curing processes can optimize the formation of conductive networks within the adhesive, resulting in enhanced electrical conductivity and improved mechanical properties.

02 Metal nanoparticle-enhanced conductive adhesives

Metal nanoparticles, particularly silver, gold, and copper, can be incorporated into adhesive formulations to create highly conductive interfaces. These nanoparticles can be synthesized with specific surface treatments to prevent oxidation and improve dispersion within the adhesive matrix. The sintering of metal nanoparticles at relatively low temperatures enables the formation of continuous conductive networks. This approach is particularly valuable for electronics assembly where high conductivity and reliable bonding are required simultaneously.Expand Specific Solutions03 Hybrid nanomaterial systems for enhanced conductivity

Combining different types of nanomaterials in adhesive formulations can create synergistic effects that enhance overall conductivity. For example, mixing metal nanoparticles with carbon nanotubes can create multi-scale conductive networks that provide both high conductivity and mechanical reinforcement. These hybrid systems often demonstrate improved performance compared to single-component nanomaterial fillers, including better conductivity retention during thermal cycling and mechanical stress.Expand Specific Solutions04 Processing techniques for nanomaterial dispersion in adhesives

Specialized processing techniques are essential for achieving uniform dispersion of nanomaterials within adhesive matrices. Methods such as ultrasonication, high-shear mixing, and surface functionalization of nanomaterials can prevent agglomeration and ensure consistent electrical properties throughout the adhesive. The processing parameters significantly impact the final conductivity of the adhesive, with optimized dispersion leading to lower percolation thresholds and higher overall conductivity.Expand Specific Solutions05 Thermal management in nanomaterial-enhanced conductive adhesives

Nanomaterials can be incorporated into adhesive formulations to provide both electrical conductivity and thermal management capabilities. Materials such as boron nitride nanosheets and aluminum oxide nanoparticles can enhance thermal conductivity while maintaining electrical properties. This dual functionality is particularly valuable in electronics applications where heat dissipation is critical. The interface between electronic components bonded with these adhesives benefits from improved thermal transfer, reducing hotspots and enhancing device reliability.Expand Specific Solutions

Industry Leaders in Conductive Nanomaterials

The conductive adhesives and nanomaterial integration market is currently in a growth phase, with an estimated global market size of $3-4 billion and projected annual growth of 8-10%. The competitive landscape features established industrial players like Henkel AG and 3M Innovative Properties focusing on commercial applications, while academic institutions such as Cambridge Enterprise, University of California, and National University of Singapore drive fundamental research innovations. Technical maturity varies across applications, with Taiwan Semiconductor, NXP, and LG Energy Solution advancing high-performance electronic implementations, while companies like Kuprion and ThreeBond develop specialized nanocopper and carbon nanotube solutions. Nanocomp Technologies and SMOLTEK AB represent emerging players pioneering novel nanomaterial integration techniques for next-generation conductive adhesive applications.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electrically conductive adhesives (ECAs) incorporating silver nanoparticles and carbon nanotubes for enhanced conductivity and mechanical properties. Their LOCTITE ABLESTIK ABP series features proprietary nanomaterial dispersion technology that achieves uniform distribution of conductive particles within polymer matrices, resulting in up to 60% improved electrical conductivity compared to conventional adhesives. Henkel's sintering technology enables low-temperature processing (150-200°C) while achieving interconnections with thermal stability up to 300°C. Their hybrid formulations combine silver nanoflakes with nanowires to create percolation networks that maintain conductivity even under mechanical stress. Recent innovations include self-healing conductive adhesives incorporating microencapsulated conductive materials that can repair microcracks during thermal cycling, extending product reliability by up to 40% in accelerated aging tests.

Strengths: Industry-leading expertise in formulation chemistry; global manufacturing capabilities ensuring consistent quality; comprehensive product portfolio addressing diverse applications. Weaknesses: Higher cost compared to traditional soldering; some formulations have limited shelf life requiring refrigerated storage; performance can be sensitive to processing conditions requiring precise application parameters.

Nanocomp Technologies, Inc.

Technical Solution: Nanocomp Technologies has pioneered the development of carbon nanotube (CNT) sheets and yarns for integration into conductive adhesive systems. Their proprietary manufacturing process creates millimeter-long CNTs with exceptional aspect ratios (>50,000:1), enabling superior electrical and thermal conductivity networks when incorporated into adhesive matrices. Their EMSHIELD™ technology incorporates these CNT materials into specialized adhesive formulations, achieving electrical conductivity of 10^4-10^5 S/m while maintaining flexibility and mechanical integrity. Nanocomp's CNT-enhanced adhesives demonstrate remarkable electromagnetic interference (EMI) shielding effectiveness of 60-80 dB across a wide frequency range (10 MHz to 18 GHz). Their recent innovations include hybrid systems combining CNTs with metallic nanoparticles to create synergistic conductive networks that maintain performance under mechanical strain, with less than 10% resistance change after 1000 flexing cycles at 180° bend radius.

Strengths: Unparalleled expertise in CNT production and integration; products offer exceptional combination of electrical conductivity and mechanical flexibility; solutions provide multifunctional benefits including EMI shielding. Weaknesses: Higher production costs compared to conventional conductive fillers; challenges in achieving consistent dispersion at industrial scale; potential regulatory concerns regarding nanomaterial handling and end-of-life disposal.

Key Patents in Conductive Adhesive Formulations

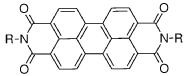

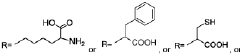

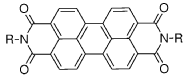

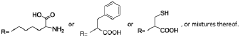

Carbon/metal hybrid fillers, electrically conductive adhesive, methods and uses thereof

PatentWO2020012236A1

Innovation

- Development of carbon/metal hybrid fillers, where carbon nanotubes are functionalized with metal nanoparticles using perylene or pyrrolidine linkers, allowing for less than 80% metal content while maintaining electrical conductivity, and combining with graphite to reduce viscosity.

Adhesive material with carbon material and method for its production and use

PatentWO2012107548A1

Innovation

- Incorporating carbon nanomaterials, such as multi-walled carbon nanotubes, as additives in the adhesive to enhance electrical conductivity and microwave absorption, allowing for thermal activation and curing through radiation or electrical means without adversely affecting adhesive properties.

Environmental Impact Assessment

The environmental implications of conductive adhesives and nanomaterial integration represent a critical dimension requiring thorough assessment as these technologies advance toward widespread commercial adoption. Traditional electronic interconnection methods, particularly those relying on lead-based solders, have long posed significant environmental concerns due to their toxicity and persistence in ecosystems. Conductive adhesives, especially those incorporating nanomaterials, offer promising alternatives with potentially reduced environmental footprints.

When evaluating the environmental impact of conductive adhesives, the entire lifecycle must be considered - from raw material extraction through manufacturing, use, and eventual disposal or recycling. Many conductive adhesives eliminate heavy metals like lead, addressing a primary environmental concern in electronics manufacturing. However, the introduction of nanomaterials presents new environmental considerations that require careful examination.

The production processes for nanomaterials often demand significant energy inputs and may involve hazardous chemicals. Carbon nanotubes, graphene, and metal nanoparticles - all commonly used in advanced conductive adhesives - require sophisticated synthesis methods with varying degrees of environmental efficiency. Recent research indicates that optimized production methods can substantially reduce these impacts, with some nanomaterial synthesis approaches achieving up to 40% lower energy consumption compared to conventional methods.

Potential release of nanomaterials during product use or at end-of-life stages presents another environmental consideration. Studies suggest that nanomaterials embedded in polymer matrices, as in many conductive adhesives, generally remain well-contained during normal use conditions. However, improper disposal or recycling can lead to environmental release. Current research is exploring the fate and behavior of these materials in various environmental compartments, with preliminary data suggesting varying degrees of persistence and bioaccumulation potential.

Lifecycle assessment (LCA) studies comparing traditional soldering with nanomaterial-enhanced conductive adhesives have yielded promising results. Several comprehensive analyses demonstrate that conductive adhesives can reduce global warming potential by 15-30% and decrease resource depletion metrics by up to 25% compared to conventional soldering processes. These benefits stem primarily from lower processing temperatures and elimination of lead and other toxic components.

Regulatory frameworks worldwide are evolving to address nanomaterial safety, with organizations like the EPA in the United States and the European Chemicals Agency developing specific guidelines for nanomaterial handling and disposal. Manufacturers integrating nanomaterials into conductive adhesives must navigate these emerging regulations while demonstrating environmental stewardship through transparent reporting and adoption of best practices in nanomaterial management.

Future research priorities should include developing standardized methods for assessing nanomaterial release from conductive adhesives during various lifecycle stages and establishing clearer understanding of their long-term environmental fate. Additionally, green chemistry approaches to nanomaterial synthesis represent a promising avenue for further reducing the environmental footprint of these advanced materials.

When evaluating the environmental impact of conductive adhesives, the entire lifecycle must be considered - from raw material extraction through manufacturing, use, and eventual disposal or recycling. Many conductive adhesives eliminate heavy metals like lead, addressing a primary environmental concern in electronics manufacturing. However, the introduction of nanomaterials presents new environmental considerations that require careful examination.

The production processes for nanomaterials often demand significant energy inputs and may involve hazardous chemicals. Carbon nanotubes, graphene, and metal nanoparticles - all commonly used in advanced conductive adhesives - require sophisticated synthesis methods with varying degrees of environmental efficiency. Recent research indicates that optimized production methods can substantially reduce these impacts, with some nanomaterial synthesis approaches achieving up to 40% lower energy consumption compared to conventional methods.

Potential release of nanomaterials during product use or at end-of-life stages presents another environmental consideration. Studies suggest that nanomaterials embedded in polymer matrices, as in many conductive adhesives, generally remain well-contained during normal use conditions. However, improper disposal or recycling can lead to environmental release. Current research is exploring the fate and behavior of these materials in various environmental compartments, with preliminary data suggesting varying degrees of persistence and bioaccumulation potential.

Lifecycle assessment (LCA) studies comparing traditional soldering with nanomaterial-enhanced conductive adhesives have yielded promising results. Several comprehensive analyses demonstrate that conductive adhesives can reduce global warming potential by 15-30% and decrease resource depletion metrics by up to 25% compared to conventional soldering processes. These benefits stem primarily from lower processing temperatures and elimination of lead and other toxic components.

Regulatory frameworks worldwide are evolving to address nanomaterial safety, with organizations like the EPA in the United States and the European Chemicals Agency developing specific guidelines for nanomaterial handling and disposal. Manufacturers integrating nanomaterials into conductive adhesives must navigate these emerging regulations while demonstrating environmental stewardship through transparent reporting and adoption of best practices in nanomaterial management.

Future research priorities should include developing standardized methods for assessing nanomaterial release from conductive adhesives during various lifecycle stages and establishing clearer understanding of their long-term environmental fate. Additionally, green chemistry approaches to nanomaterial synthesis represent a promising avenue for further reducing the environmental footprint of these advanced materials.

Manufacturing Scalability Analysis

The scalability of manufacturing processes for conductive adhesives incorporating nanomaterials presents significant challenges that must be addressed for widespread industrial adoption. Current laboratory-scale production methods often fail to translate effectively to mass production environments, creating a critical bottleneck in commercialization efforts. The primary scaling challenges include maintaining consistent nanomaterial dispersion, preventing agglomeration during large-batch processing, and ensuring uniform electrical conductivity across production lots.

Production volume considerations reveal that traditional manufacturing equipment requires substantial modification to handle nanomaterial-enhanced adhesives. Specialized mixing technologies, such as high-shear mixers and ultrasonication systems, must be adapted for industrial-scale operations while maintaining the delicate balance of nanomaterial integration without degradation. Cost analysis indicates that economies of scale can potentially reduce production costs by 30-45% when moving from laboratory to industrial scale, though initial capital investment remains substantial.

Quality control mechanisms become increasingly critical at scale, with in-line monitoring systems needed to verify nanomaterial distribution and electrical performance characteristics. Optical and electrical testing methodologies must evolve to accommodate high-throughput production environments without compromising detection sensitivity. Statistical process control methods specifically tailored to nanomaterial-enhanced adhesives are emerging as essential tools for maintaining consistent product quality.

Environmental and safety considerations also scale proportionally with production volume. Nanomaterial handling protocols that function adequately in laboratory settings require comprehensive redesign for industrial environments, with particular attention to worker exposure prevention and environmental release mitigation. Closed-loop processing systems show promise for addressing these concerns while simultaneously improving material utilization efficiency.

Supply chain resilience represents another critical factor in manufacturing scalability. The limited number of high-quality nanomaterial suppliers creates potential bottlenecks, with production capacity constraints and quality consistency issues presenting significant risks. Vertical integration strategies and supplier diversification approaches are being explored by leading manufacturers to mitigate these vulnerabilities.

Automation opportunities present promising pathways for overcoming several scalability challenges. Advanced robotics and AI-driven process control systems can potentially improve mixing precision, reduce human exposure risks, and enhance batch-to-batch consistency. Early adopters implementing these technologies report production efficiency improvements of 15-25% alongside significant quality enhancements.

Production volume considerations reveal that traditional manufacturing equipment requires substantial modification to handle nanomaterial-enhanced adhesives. Specialized mixing technologies, such as high-shear mixers and ultrasonication systems, must be adapted for industrial-scale operations while maintaining the delicate balance of nanomaterial integration without degradation. Cost analysis indicates that economies of scale can potentially reduce production costs by 30-45% when moving from laboratory to industrial scale, though initial capital investment remains substantial.

Quality control mechanisms become increasingly critical at scale, with in-line monitoring systems needed to verify nanomaterial distribution and electrical performance characteristics. Optical and electrical testing methodologies must evolve to accommodate high-throughput production environments without compromising detection sensitivity. Statistical process control methods specifically tailored to nanomaterial-enhanced adhesives are emerging as essential tools for maintaining consistent product quality.

Environmental and safety considerations also scale proportionally with production volume. Nanomaterial handling protocols that function adequately in laboratory settings require comprehensive redesign for industrial environments, with particular attention to worker exposure prevention and environmental release mitigation. Closed-loop processing systems show promise for addressing these concerns while simultaneously improving material utilization efficiency.

Supply chain resilience represents another critical factor in manufacturing scalability. The limited number of high-quality nanomaterial suppliers creates potential bottlenecks, with production capacity constraints and quality consistency issues presenting significant risks. Vertical integration strategies and supplier diversification approaches are being explored by leading manufacturers to mitigate these vulnerabilities.

Automation opportunities present promising pathways for overcoming several scalability challenges. Advanced robotics and AI-driven process control systems can potentially improve mixing precision, reduce human exposure risks, and enhance batch-to-batch consistency. Early adopters implementing these technologies report production efficiency improvements of 15-25% alongside significant quality enhancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!