How Conductive Adhesives Enhance In-Mold Electronics

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives in IME: Background and Objectives

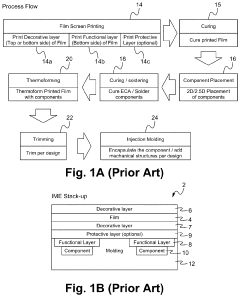

In-Mold Electronics (IME) represents a transformative approach in the manufacturing of electronic devices, combining traditional plastic molding techniques with printed electronics to create three-dimensional electronic structures. Conductive adhesives have emerged as a critical enabling technology in this domain, facilitating the integration of electronic components onto molded substrates. The evolution of conductive adhesives for IME applications can be traced back to the early 2000s, when researchers began exploring alternatives to traditional soldering methods for flexible and conformable electronics.

The technological trajectory of conductive adhesives has been characterized by continuous improvements in electrical conductivity, mechanical flexibility, and thermal stability. Early formulations suffered from limited conductivity and poor adhesion under mechanical stress, but recent advancements have yielded materials capable of maintaining reliable electrical connections even when subjected to the extreme pressures and temperatures of the injection molding process.

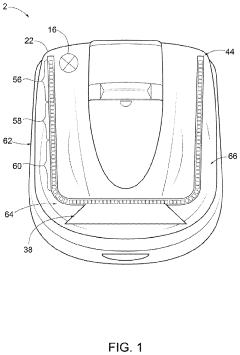

Current market trends indicate a growing demand for miniaturized, lightweight electronic devices with complex geometries, driving the need for more sophisticated IME solutions. The automotive industry, in particular, has embraced IME technology for the production of integrated control panels and touch-sensitive interfaces, creating a substantial market opportunity for conductive adhesive manufacturers.

The primary technical objective in this field is to develop conductive adhesive formulations that can withstand the harsh conditions of the injection molding process while maintaining optimal electrical performance. This includes resistance to high temperatures (typically 180-300°C), pressure resistance (up to 100 MPa), and the ability to accommodate the differential thermal expansion of various substrate materials.

Another critical objective is to enhance the long-term reliability of conductive adhesive joints in IME applications, addressing challenges such as moisture resistance, thermal cycling stability, and resistance to environmental contaminants. The industry is also focused on reducing curing times and temperatures to improve manufacturing efficiency and reduce energy consumption.

From a materials science perspective, researchers are exploring novel conductive fillers, including silver nanoparticles, carbon nanotubes, and graphene derivatives, to enhance the electrical and mechanical properties of adhesive formulations. Hybrid systems combining different types of conductive fillers are showing particular promise in achieving an optimal balance of conductivity, flexibility, and cost-effectiveness.

The convergence of these technological developments is expected to enable the next generation of IME applications, including wearable medical devices, automotive interior components, and consumer electronics with unprecedented form factors and functionality. As the technology continues to mature, the focus is shifting toward scalable manufacturing processes and cost reduction strategies to facilitate broader commercial adoption.

The technological trajectory of conductive adhesives has been characterized by continuous improvements in electrical conductivity, mechanical flexibility, and thermal stability. Early formulations suffered from limited conductivity and poor adhesion under mechanical stress, but recent advancements have yielded materials capable of maintaining reliable electrical connections even when subjected to the extreme pressures and temperatures of the injection molding process.

Current market trends indicate a growing demand for miniaturized, lightweight electronic devices with complex geometries, driving the need for more sophisticated IME solutions. The automotive industry, in particular, has embraced IME technology for the production of integrated control panels and touch-sensitive interfaces, creating a substantial market opportunity for conductive adhesive manufacturers.

The primary technical objective in this field is to develop conductive adhesive formulations that can withstand the harsh conditions of the injection molding process while maintaining optimal electrical performance. This includes resistance to high temperatures (typically 180-300°C), pressure resistance (up to 100 MPa), and the ability to accommodate the differential thermal expansion of various substrate materials.

Another critical objective is to enhance the long-term reliability of conductive adhesive joints in IME applications, addressing challenges such as moisture resistance, thermal cycling stability, and resistance to environmental contaminants. The industry is also focused on reducing curing times and temperatures to improve manufacturing efficiency and reduce energy consumption.

From a materials science perspective, researchers are exploring novel conductive fillers, including silver nanoparticles, carbon nanotubes, and graphene derivatives, to enhance the electrical and mechanical properties of adhesive formulations. Hybrid systems combining different types of conductive fillers are showing particular promise in achieving an optimal balance of conductivity, flexibility, and cost-effectiveness.

The convergence of these technological developments is expected to enable the next generation of IME applications, including wearable medical devices, automotive interior components, and consumer electronics with unprecedented form factors and functionality. As the technology continues to mature, the focus is shifting toward scalable manufacturing processes and cost reduction strategies to facilitate broader commercial adoption.

Market Analysis for In-Mold Electronics Applications

The In-Mold Electronics (IME) market is experiencing significant growth, driven by increasing demand for lightweight, space-saving electronic components across multiple industries. Current market valuations place the global IME sector at approximately $1.5 billion in 2023, with projections indicating a compound annual growth rate of 13.6% through 2028, potentially reaching $2.8 billion by that time.

The automotive industry represents the largest application segment for IME technology, accounting for roughly 40% of the total market share. This dominance stems from the automotive sector's rapid transition toward smart surfaces, touch controls, and integrated lighting systems that replace traditional mechanical buttons and switches. The consumer electronics sector follows closely behind at 32% market share, with applications in smartphones, wearables, and home appliances.

Market research indicates that conductive adhesives play a crucial role in expanding IME applications. The enhanced reliability provided by advanced conductive adhesives has opened new market opportunities in harsh-environment applications, including outdoor equipment, industrial controls, and medical devices. These segments collectively represent the fastest-growing market category, with a 17.8% annual growth rate.

Regional analysis shows Asia-Pacific leading the IME market with 45% share, primarily due to the concentration of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe follow with 28% and 22% respectively, with both regions showing increased adoption in premium automotive and healthcare applications.

Consumer demand for thinner, lighter, and more integrated electronic interfaces is a primary market driver. The ability of conductive adhesives to enable reliable connections in increasingly complex IME designs directly addresses this market need. Industry surveys indicate that 78% of electronics manufacturers are exploring IME solutions specifically because advanced conductive adhesives have resolved previous reliability concerns.

Market barriers include initial manufacturing setup costs, which average 30% higher than traditional electronics assembly methods. However, cost analysis demonstrates that IME solutions using conductive adhesives typically achieve 25-40% reduction in total component count and 15-20% reduction in assembly time, providing compelling long-term economic benefits despite higher initial investments.

The market for conductive adhesives within IME applications is highly fragmented, with specialized formulations being developed for specific industry needs. Silver-based conductive adhesives currently dominate with 65% market share, though copper and carbon-based alternatives are gaining traction due to cost advantages and sustainability considerations.

The automotive industry represents the largest application segment for IME technology, accounting for roughly 40% of the total market share. This dominance stems from the automotive sector's rapid transition toward smart surfaces, touch controls, and integrated lighting systems that replace traditional mechanical buttons and switches. The consumer electronics sector follows closely behind at 32% market share, with applications in smartphones, wearables, and home appliances.

Market research indicates that conductive adhesives play a crucial role in expanding IME applications. The enhanced reliability provided by advanced conductive adhesives has opened new market opportunities in harsh-environment applications, including outdoor equipment, industrial controls, and medical devices. These segments collectively represent the fastest-growing market category, with a 17.8% annual growth rate.

Regional analysis shows Asia-Pacific leading the IME market with 45% share, primarily due to the concentration of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe follow with 28% and 22% respectively, with both regions showing increased adoption in premium automotive and healthcare applications.

Consumer demand for thinner, lighter, and more integrated electronic interfaces is a primary market driver. The ability of conductive adhesives to enable reliable connections in increasingly complex IME designs directly addresses this market need. Industry surveys indicate that 78% of electronics manufacturers are exploring IME solutions specifically because advanced conductive adhesives have resolved previous reliability concerns.

Market barriers include initial manufacturing setup costs, which average 30% higher than traditional electronics assembly methods. However, cost analysis demonstrates that IME solutions using conductive adhesives typically achieve 25-40% reduction in total component count and 15-20% reduction in assembly time, providing compelling long-term economic benefits despite higher initial investments.

The market for conductive adhesives within IME applications is highly fragmented, with specialized formulations being developed for specific industry needs. Silver-based conductive adhesives currently dominate with 65% market share, though copper and carbon-based alternatives are gaining traction due to cost advantages and sustainability considerations.

Technical Challenges in Conductive Adhesive Implementation

Despite the promising advantages of conductive adhesives in In-Mold Electronics (IME), their implementation presents several significant technical challenges. The primary obstacle lies in achieving consistent electrical conductivity across different operating conditions. Conductive adhesives must maintain stable electrical performance under varying temperatures, humidity levels, and mechanical stresses that IME devices typically encounter during their lifecycle. Current formulations often exhibit conductivity degradation when subjected to thermal cycling or prolonged environmental exposure, limiting their reliability in long-term applications.

Adhesion strength represents another critical challenge, particularly at the interface between different substrate materials commonly used in IME. The adhesive must create strong bonds with both rigid and flexible substrates while accommodating their different coefficients of thermal expansion. Failure to address this challenge results in delamination or connection failures that compromise the entire device's functionality. This becomes especially problematic during the molding process where significant temperature and pressure variations occur.

The processing window for conductive adhesives in IME applications remains notably narrow. The curing conditions must be precisely controlled to achieve optimal electrical and mechanical properties without damaging temperature-sensitive components or substrates. Many existing formulations require curing temperatures that exceed the thermal tolerance of certain IME materials, creating compatibility issues during manufacturing. Additionally, the viscosity and rheological properties must be carefully balanced to ensure proper dispensing and prevent bleeding or migration during the molding process.

Miniaturization trends in electronics pose unique challenges for conductive adhesives in IME. As feature sizes decrease, the adhesives must maintain conductivity at ever-smaller scales while preventing issues like bridging between adjacent circuits. Current formulations struggle to deliver consistent performance at fine-pitch applications below certain thresholds, limiting the design flexibility and integration density of IME devices.

Environmental and regulatory considerations further complicate implementation. Many traditional conductive adhesives contain heavy metals or other hazardous substances facing increasing regulatory restrictions. Developing environmentally friendly alternatives that maintain equivalent performance characteristics presents significant formulation challenges. Additionally, these eco-friendly formulations must still meet stringent reliability requirements for automotive, consumer electronics, and medical applications where IME is gaining traction.

Cost-effectiveness remains a persistent challenge, as high-performance conductive adhesives typically incorporate expensive materials like silver or specialized polymers. Finding the optimal balance between performance and cost is crucial for widespread commercial adoption of IME technology across different market segments.

Adhesion strength represents another critical challenge, particularly at the interface between different substrate materials commonly used in IME. The adhesive must create strong bonds with both rigid and flexible substrates while accommodating their different coefficients of thermal expansion. Failure to address this challenge results in delamination or connection failures that compromise the entire device's functionality. This becomes especially problematic during the molding process where significant temperature and pressure variations occur.

The processing window for conductive adhesives in IME applications remains notably narrow. The curing conditions must be precisely controlled to achieve optimal electrical and mechanical properties without damaging temperature-sensitive components or substrates. Many existing formulations require curing temperatures that exceed the thermal tolerance of certain IME materials, creating compatibility issues during manufacturing. Additionally, the viscosity and rheological properties must be carefully balanced to ensure proper dispensing and prevent bleeding or migration during the molding process.

Miniaturization trends in electronics pose unique challenges for conductive adhesives in IME. As feature sizes decrease, the adhesives must maintain conductivity at ever-smaller scales while preventing issues like bridging between adjacent circuits. Current formulations struggle to deliver consistent performance at fine-pitch applications below certain thresholds, limiting the design flexibility and integration density of IME devices.

Environmental and regulatory considerations further complicate implementation. Many traditional conductive adhesives contain heavy metals or other hazardous substances facing increasing regulatory restrictions. Developing environmentally friendly alternatives that maintain equivalent performance characteristics presents significant formulation challenges. Additionally, these eco-friendly formulations must still meet stringent reliability requirements for automotive, consumer electronics, and medical applications where IME is gaining traction.

Cost-effectiveness remains a persistent challenge, as high-performance conductive adhesives typically incorporate expensive materials like silver or specialized polymers. Finding the optimal balance between performance and cost is crucial for widespread commercial adoption of IME technology across different market segments.

Current Conductive Adhesive Solutions for IME

01 Nanomaterial incorporation for conductivity enhancement

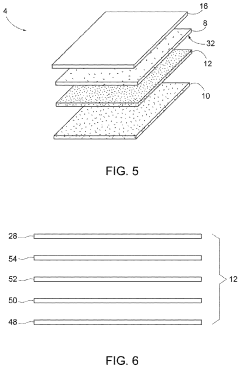

Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into adhesive formulations significantly improves electrical conductivity. These nanomaterials create efficient electron pathways throughout the adhesive matrix, resulting in lower resistance and enhanced current flow. The uniform dispersion of these nanomaterials is critical for achieving optimal conductivity while maintaining adhesive properties.- Incorporation of conductive fillers: Conductive adhesives can be enhanced by incorporating various conductive fillers such as metal particles, carbon nanotubes, or graphene. These fillers create conductive pathways within the adhesive matrix, significantly improving electrical conductivity. The type, size, shape, and concentration of these fillers can be optimized to achieve desired conductivity levels while maintaining adhesive properties. This approach is widely used in electronics manufacturing for creating reliable electrical connections.

- Polymer matrix modifications: Enhancing conductive adhesives through modifications to the polymer matrix involves selecting specific resins or adding modifiers that improve both adhesion and conductivity. Techniques include using epoxy resins with optimized cross-linking properties, incorporating flexible segments to improve mechanical performance, and adding coupling agents to enhance the interface between conductive fillers and the polymer matrix. These modifications can result in adhesives with better thermal stability, flexibility, and overall electrical performance.

- Surface treatment of conductive particles: Surface treatment of conductive particles is an effective method for enhancing conductive adhesives. By modifying the surface of metal particles or carbon-based fillers with functional groups or coatings, the dispersion stability and interfacial bonding within the adhesive matrix can be significantly improved. These treatments prevent agglomeration of particles and enhance the electrical contact between adjacent particles, resulting in higher conductivity and more reliable performance under thermal and mechanical stress.

- Sintering and curing process optimization: Optimizing the sintering and curing processes can significantly enhance the performance of conductive adhesives. Advanced curing methods such as staged curing, microwave curing, or UV-assisted curing can improve the formation of conductive networks within the adhesive. Controlled sintering of metal particles at lower temperatures helps achieve better electrical connections while minimizing thermal stress on sensitive components. These process optimizations result in adhesives with higher conductivity, better mechanical strength, and improved reliability in various environmental conditions.

- Hybrid and nanocomposite formulations: Hybrid and nanocomposite formulations represent an advanced approach to enhancing conductive adhesives. These formulations combine different types of conductive fillers (such as silver particles with carbon nanotubes) or incorporate nanomaterials to create synergistic effects. The multi-scale conductive network formed by these combinations offers improved electrical conductivity at lower filler loadings, better mechanical properties, and enhanced thermal management. These advanced formulations are particularly valuable for high-performance electronics and flexible circuit applications.

02 Metal filler optimization techniques

Optimizing metal fillers in conductive adhesives involves selecting appropriate particle sizes, shapes, and distributions. Silver, copper, and nickel particles are commonly used, with silver offering superior conductivity. Bimodal or multimodal particle size distributions improve packing density and contact points between particles, enhancing conductivity while reducing the overall filler content needed. Surface treatment of metal particles can improve their compatibility with the polymer matrix.Expand Specific Solutions03 Polymer matrix modifications

Modifying the polymer matrix of conductive adhesives through cross-linking agents, curing catalysts, or specialized resins improves both mechanical and electrical properties. These modifications can reduce curing temperatures, enhance adhesion strength, and improve environmental stability. Epoxy, silicone, and polyurethane-based matrices can be tailored with additives to optimize the balance between flexibility and conductivity retention under thermal or mechanical stress.Expand Specific Solutions04 Interface engineering for reduced contact resistance

Engineering the interface between conductive adhesives and substrates reduces contact resistance and improves overall connection reliability. Surface preparation techniques, such as plasma treatment or chemical etching, enhance wetting and bonding. Specialized coupling agents can be incorporated to form strong chemical bonds between the adhesive and various substrate materials, maintaining electrical performance during thermal cycling and environmental exposure.Expand Specific Solutions05 Synergistic filler combinations

Combining different types of conductive fillers creates synergistic effects that enhance overall conductivity beyond what individual fillers can achieve alone. Hybrid systems using both micron-sized and nano-sized particles, or mixing metallic fillers with carbon-based materials, create multiple conduction pathways. These combinations allow for reduced total filler loading while maintaining or improving conductivity, resulting in better processing characteristics and mechanical properties.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

The conductive adhesives market for In-Mold Electronics (IME) is currently in a growth phase, with increasing adoption across automotive and consumer electronics sectors. The global market is projected to expand significantly as IME technology matures, offering lightweight, durable, and cost-effective alternatives to traditional electronics manufacturing. From a technological maturity perspective, industry leaders like Henkel AG, DuPont, and Nitto Denko have developed specialized conductive adhesive formulations that address key IME challenges including thermal stability and flexibility. Emerging players such as Beijing Dream Ink Technology and PrintCB are advancing copper-based alternatives to traditional silver-filled adhesives, while established electronics manufacturers including Samsung, Murata, and DENSO are integrating these materials into commercial applications, signaling the technology's transition from development to commercial implementation.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed specialized conductive adhesives specifically engineered for In-Mold Electronics (IME) applications. Their LOCTITE ECCOBOND series features silver-filled epoxy adhesives that maintain conductivity during the high-pressure molding process. These formulations incorporate proprietary technology that allows the adhesive to withstand temperatures up to 180°C during molding while maintaining flexibility to prevent cracking. Henkel's solution includes isotropically conductive adhesives (ICAs) with particle sizes optimized to 5-10μm to ensure reliable connections without causing short circuits in fine-pitch applications. Their latest generation products feature cure temperatures as low as 80°C, making them compatible with heat-sensitive substrates commonly used in IME. The company has also developed hybrid formulations that combine conductive and structural properties, allowing for simultaneous electrical connection and mechanical reinforcement in a single application step.

Strengths: Industry-leading thermal stability during molding processes; excellent adhesion to multiple substrate types including polycarbonate and PET; low-temperature curing options for heat-sensitive components. Weaknesses: Higher cost compared to traditional soldering methods; requires precise application equipment for optimal performance; some formulations have limited shelf life requiring cold storage.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric Industries has developed advanced conductive adhesive technologies specifically engineered for In-Mold Electronics applications through their SUMILITE™ product family. Their approach utilizes a proprietary blend of silver-coated copper particles suspended in a thermosetting polymer matrix that maintains conductivity through the high-pressure injection molding process. The company's formulations feature dual-cure mechanisms (both thermal and UV-initiated) that allow for precise control of the curing process, enabling both rapid initial tacking and complete polymerization during molding. Sumitomo's technology achieves volume resistivity of approximately 5×10^-4 Ω·cm while withstanding elongation up to 40% without electrical failure. Their latest generation products incorporate nano-sized conductive fillers (100-500nm) alongside micron-sized particles, creating a hierarchical structure that maintains conductivity pathways even under extreme deformation. The company has also developed specialized surface treatments for their conductive particles that prevent oxidation during processing and long-term use, ensuring stable electrical performance throughout the product lifecycle.

Strengths: Excellent balance of conductivity and flexibility; dual-cure capability offers processing advantages in manufacturing; superior oxidation resistance improves long-term reliability in harsh environments. Weaknesses: Higher cost compared to single-metal particle systems; requires specialized mixing equipment to ensure proper particle distribution; more complex processing parameters compared to standard conductive adhesives.

Key Patents and Research in Conductive Adhesive Technology

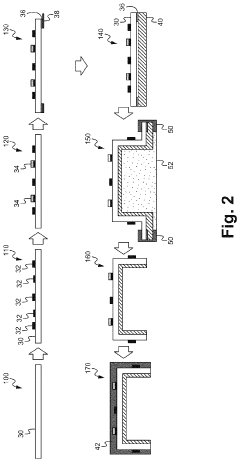

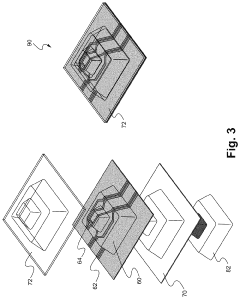

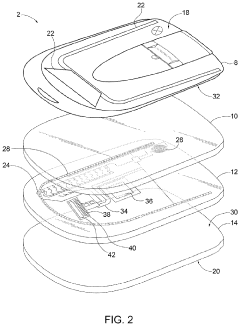

System and method for in-molded electronic unit using stretchable substrates to create deep drawn cavities and features

PatentInactiveUS11039531B1

Innovation

- The integration of a stretchable substrate laminated to a thermoplastic layer, allowing for the formation of conductive interconnects that can be thermoformed into complex shapes without additional mold features, using electrically stretchable conductor ink and thermoforming techniques.

In-mold electronics within a robotic device

PatentActiveUS11490535B2

Innovation

- Incorporating in-mold functional components using thermoformed films and injection molding techniques to embed functional components within the molded part, eliminating the need for additional structural components and providing protection from environmental factors.

Material Compatibility and Durability Considerations

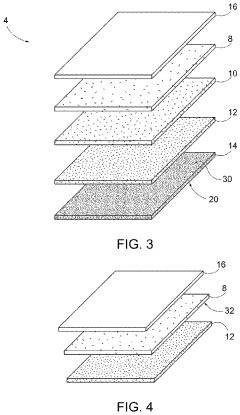

Material compatibility represents a critical factor in the successful implementation of conductive adhesives within in-mold electronics (IME) applications. The interface between conductive adhesives and substrate materials must maintain both electrical conductivity and mechanical integrity throughout the manufacturing process and product lifecycle. Polymer substrates commonly used in IME, such as polycarbonate (PC), polyethylene terephthalate (PET), and thermoplastic polyurethane (TPU), each present unique chemical compatibility challenges with various conductive adhesive formulations.

Temperature resistance emerges as a paramount consideration, as conductive adhesives must withstand the thermal stresses encountered during the injection molding process, which typically ranges from 180°C to 300°C depending on the polymer used. Silver-based conductive adhesives generally demonstrate superior thermal stability compared to carbon-based alternatives, maintaining conductivity at higher processing temperatures. However, coefficient of thermal expansion (CTE) mismatches between adhesives and substrates can lead to delamination or cracking during thermal cycling.

Chemical resistance represents another crucial durability factor, particularly in applications exposed to environmental contaminants, cleaning agents, or operational fluids. Epoxy-based conductive adhesives typically offer superior chemical resistance compared to acrylic-based formulations, though this advantage often comes with reduced flexibility. Recent advancements in hybrid formulations aim to balance chemical resistance with the mechanical flexibility required for IME applications.

Mechanical durability under repeated flexing, bending, or vibration conditions significantly impacts the longevity of IME devices. Traditional rigid conductive adhesives often develop microcracks under mechanical stress, leading to progressive conductivity degradation. Newer elastomeric conductive adhesives incorporate flexible polymeric matrices that can accommodate mechanical deformation while maintaining conductive pathways, though these typically exhibit higher electrical resistance than their rigid counterparts.

Humidity and moisture resistance present ongoing challenges, as water ingress can compromise both adhesion strength and electrical performance. Hydrophobic additives and encapsulation techniques have been developed to enhance moisture resistance, with silicone-modified conductive adhesives showing particular promise in high-humidity environments. Accelerated aging tests indicate that properly formulated conductive adhesives can maintain over 90% of their initial conductivity after 1000 hours of exposure to 85°C/85% relative humidity conditions.

Adhesion strength across the service life of IME products requires careful consideration of surface preparation techniques. Plasma treatment and specialized primers have demonstrated significant improvements in long-term adhesion, particularly for challenging substrates like polyolefins. The development of adhesion promoters specifically designed for conductive adhesive systems represents an active area of research aimed at enhancing durability without compromising electrical performance.

Temperature resistance emerges as a paramount consideration, as conductive adhesives must withstand the thermal stresses encountered during the injection molding process, which typically ranges from 180°C to 300°C depending on the polymer used. Silver-based conductive adhesives generally demonstrate superior thermal stability compared to carbon-based alternatives, maintaining conductivity at higher processing temperatures. However, coefficient of thermal expansion (CTE) mismatches between adhesives and substrates can lead to delamination or cracking during thermal cycling.

Chemical resistance represents another crucial durability factor, particularly in applications exposed to environmental contaminants, cleaning agents, or operational fluids. Epoxy-based conductive adhesives typically offer superior chemical resistance compared to acrylic-based formulations, though this advantage often comes with reduced flexibility. Recent advancements in hybrid formulations aim to balance chemical resistance with the mechanical flexibility required for IME applications.

Mechanical durability under repeated flexing, bending, or vibration conditions significantly impacts the longevity of IME devices. Traditional rigid conductive adhesives often develop microcracks under mechanical stress, leading to progressive conductivity degradation. Newer elastomeric conductive adhesives incorporate flexible polymeric matrices that can accommodate mechanical deformation while maintaining conductive pathways, though these typically exhibit higher electrical resistance than their rigid counterparts.

Humidity and moisture resistance present ongoing challenges, as water ingress can compromise both adhesion strength and electrical performance. Hydrophobic additives and encapsulation techniques have been developed to enhance moisture resistance, with silicone-modified conductive adhesives showing particular promise in high-humidity environments. Accelerated aging tests indicate that properly formulated conductive adhesives can maintain over 90% of their initial conductivity after 1000 hours of exposure to 85°C/85% relative humidity conditions.

Adhesion strength across the service life of IME products requires careful consideration of surface preparation techniques. Plasma treatment and specialized primers have demonstrated significant improvements in long-term adhesion, particularly for challenging substrates like polyolefins. The development of adhesion promoters specifically designed for conductive adhesive systems represents an active area of research aimed at enhancing durability without compromising electrical performance.

Environmental Impact and Sustainability Factors

The integration of conductive adhesives in In-Mold Electronics (IME) presents significant environmental and sustainability advantages compared to traditional electronics manufacturing processes. Conductive adhesives typically contain fewer hazardous substances than conventional soldering materials, which often rely on lead-based or other heavy metal components. This reduction in toxic materials translates to decreased environmental contamination during manufacturing, product use, and end-of-life disposal.

Manufacturing processes utilizing conductive adhesives generally require lower curing temperatures compared to traditional soldering methods, resulting in substantial energy savings. This energy efficiency contributes to reduced carbon emissions throughout the production cycle. Additionally, the lower processing temperatures minimize thermal stress on components and substrates, extending product lifespan and reducing electronic waste generation.

The formulation of modern conductive adhesives increasingly incorporates bio-based materials and environmentally friendly components. Research trends show growing adoption of renewable resources in adhesive development, including plant-based resins and natural fillers that can partially replace petroleum-derived ingredients. These innovations align with circular economy principles and help reduce dependence on finite resources.

IME products enhanced with conductive adhesives typically achieve significant material reduction compared to conventional electronics. The integration of circuitry directly into molded parts eliminates numerous components and assembly steps, resulting in lighter products with smaller material footprints. This streamlined design approach reduces resource consumption and transportation-related emissions throughout the supply chain.

End-of-life considerations also favor conductive adhesive-based IME solutions. The simplified construction facilitates more efficient recycling processes, as fewer material types need separation. Some advanced conductive adhesive formulations are being developed with reversible bonding properties, enabling easier disassembly and component recovery. This characteristic supports extended producer responsibility initiatives and closed-loop material systems.

Water consumption represents another environmental advantage, as conductive adhesive application typically requires less water than traditional PCB manufacturing processes. This reduced water footprint is particularly significant in regions facing water scarcity challenges. Furthermore, the elimination of washing steps associated with flux removal in conventional soldering processes reduces wastewater generation and treatment requirements.

Regulatory compliance is increasingly driving adoption of more sustainable electronics manufacturing approaches. Conductive adhesives help manufacturers meet stringent environmental regulations such as RoHS, REACH, and emerging extended producer responsibility laws. As global sustainability standards continue to evolve, conductive adhesive technologies position IME products advantageously in markets where environmental performance is becoming a competitive differentiator.

Manufacturing processes utilizing conductive adhesives generally require lower curing temperatures compared to traditional soldering methods, resulting in substantial energy savings. This energy efficiency contributes to reduced carbon emissions throughout the production cycle. Additionally, the lower processing temperatures minimize thermal stress on components and substrates, extending product lifespan and reducing electronic waste generation.

The formulation of modern conductive adhesives increasingly incorporates bio-based materials and environmentally friendly components. Research trends show growing adoption of renewable resources in adhesive development, including plant-based resins and natural fillers that can partially replace petroleum-derived ingredients. These innovations align with circular economy principles and help reduce dependence on finite resources.

IME products enhanced with conductive adhesives typically achieve significant material reduction compared to conventional electronics. The integration of circuitry directly into molded parts eliminates numerous components and assembly steps, resulting in lighter products with smaller material footprints. This streamlined design approach reduces resource consumption and transportation-related emissions throughout the supply chain.

End-of-life considerations also favor conductive adhesive-based IME solutions. The simplified construction facilitates more efficient recycling processes, as fewer material types need separation. Some advanced conductive adhesive formulations are being developed with reversible bonding properties, enabling easier disassembly and component recovery. This characteristic supports extended producer responsibility initiatives and closed-loop material systems.

Water consumption represents another environmental advantage, as conductive adhesive application typically requires less water than traditional PCB manufacturing processes. This reduced water footprint is particularly significant in regions facing water scarcity challenges. Furthermore, the elimination of washing steps associated with flux removal in conventional soldering processes reduces wastewater generation and treatment requirements.

Regulatory compliance is increasingly driving adoption of more sustainable electronics manufacturing approaches. Conductive adhesives help manufacturers meet stringent environmental regulations such as RoHS, REACH, and emerging extended producer responsibility laws. As global sustainability standards continue to evolve, conductive adhesive technologies position IME products advantageously in markets where environmental performance is becoming a competitive differentiator.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!