Research on Conductive Adhesives: Enhancing Battery Life

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Background and Objectives

Conductive adhesives have emerged as a critical component in modern electronics manufacturing, particularly in battery assembly processes. The evolution of these materials can be traced back to the 1950s when simple silver-filled epoxies were first developed for rudimentary electronic applications. Over subsequent decades, conductive adhesives have undergone significant transformations, evolving from basic formulations to sophisticated composites engineered at the nanoscale level.

The technological trajectory of conductive adhesives has been characterized by continuous improvements in electrical conductivity, thermal stability, and mechanical strength. Early iterations faced limitations in conductivity and reliability, particularly under thermal cycling conditions. However, recent advancements have yielded formulations that rival traditional soldering methods in performance while offering enhanced flexibility and environmental benefits.

Current market trends indicate a growing preference for conductive adhesives that can withstand increasingly demanding operational environments while maintaining stable electrical connections. This shift is particularly evident in the battery manufacturing sector, where the need for reliable, long-lasting connections directly impacts overall battery performance and longevity.

The primary objective of research in conductive adhesives for battery applications centers on enhancing battery life through improved electrical connectivity. This encompasses several key technical goals: reducing internal resistance at connection points, minimizing degradation over time, withstanding thermal and mechanical stresses, and maintaining consistent performance across varying environmental conditions.

Secondary objectives include developing adhesives with improved processing characteristics such as longer shelf life, shorter curing times, and compatibility with automated manufacturing processes. These factors significantly impact production efficiency and ultimately affect the economic viability of advanced battery technologies.

Environmental considerations have also become increasingly important in conductive adhesive development. The industry is moving toward formulations that eliminate hazardous components like lead and other heavy metals, aligning with global regulatory trends toward more sustainable manufacturing practices.

The intersection of nanotechnology and polymer science represents the frontier of conductive adhesive research. Novel approaches incorporating carbon nanotubes, graphene, and metallic nanoparticles show promise for creating next-generation adhesives with unprecedented performance characteristics. These advanced materials could potentially revolutionize battery design by enabling new form factors and improving energy density through more efficient internal connections.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, the demands placed on conductive adhesives will intensify, driving further innovation in this critical but often overlooked component of modern energy storage systems.

The technological trajectory of conductive adhesives has been characterized by continuous improvements in electrical conductivity, thermal stability, and mechanical strength. Early iterations faced limitations in conductivity and reliability, particularly under thermal cycling conditions. However, recent advancements have yielded formulations that rival traditional soldering methods in performance while offering enhanced flexibility and environmental benefits.

Current market trends indicate a growing preference for conductive adhesives that can withstand increasingly demanding operational environments while maintaining stable electrical connections. This shift is particularly evident in the battery manufacturing sector, where the need for reliable, long-lasting connections directly impacts overall battery performance and longevity.

The primary objective of research in conductive adhesives for battery applications centers on enhancing battery life through improved electrical connectivity. This encompasses several key technical goals: reducing internal resistance at connection points, minimizing degradation over time, withstanding thermal and mechanical stresses, and maintaining consistent performance across varying environmental conditions.

Secondary objectives include developing adhesives with improved processing characteristics such as longer shelf life, shorter curing times, and compatibility with automated manufacturing processes. These factors significantly impact production efficiency and ultimately affect the economic viability of advanced battery technologies.

Environmental considerations have also become increasingly important in conductive adhesive development. The industry is moving toward formulations that eliminate hazardous components like lead and other heavy metals, aligning with global regulatory trends toward more sustainable manufacturing practices.

The intersection of nanotechnology and polymer science represents the frontier of conductive adhesive research. Novel approaches incorporating carbon nanotubes, graphene, and metallic nanoparticles show promise for creating next-generation adhesives with unprecedented performance characteristics. These advanced materials could potentially revolutionize battery design by enabling new form factors and improving energy density through more efficient internal connections.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, the demands placed on conductive adhesives will intensify, driving further innovation in this critical but often overlooked component of modern energy storage systems.

Market Analysis for Battery-Enhancing Materials

The global market for battery-enhancing materials, particularly conductive adhesives, has experienced significant growth in recent years, driven by the expanding electric vehicle (EV) sector, portable electronics industry, and renewable energy storage systems. The market value for conductive adhesives specifically used in battery applications reached $3.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.7% through 2028.

Consumer electronics remains the largest application segment, accounting for approximately 42% of the total market share. This dominance stems from the increasing consumer demand for longer-lasting smartphones, tablets, and wearable devices. The automotive sector follows closely at 31% market share, with rapid growth attributed to the accelerating adoption of electric vehicles worldwide.

Geographically, Asia-Pacific leads the market with 48% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe hold 27% and 21% respectively, with both regions showing increased investment in advanced battery technologies to support green energy initiatives.

The demand drivers for conductive adhesives in battery applications are multifaceted. Primary factors include the push for higher energy density batteries, longer cycle life, and improved thermal management. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering 30% longer battery life, creating significant commercial incentives for manufacturers to invest in advanced adhesive technologies.

Industry surveys reveal that 78% of smartphone users identify battery life as a critical purchasing factor, while 83% of potential EV buyers cite range anxiety as their primary concern. These consumer preferences are directly influencing R&D priorities across the battery supply chain, with conductive adhesives emerging as a key enabling technology.

The market is also being shaped by regulatory pressures, particularly environmental regulations limiting the use of traditional soldering materials containing lead and other hazardous substances. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward environmentally friendly conductive adhesives.

Future market growth is expected to be driven by emerging applications in flexible electronics, medical devices, and aerospace sectors. Additionally, the integration of Internet of Things (IoT) devices and the expansion of 5G networks will create new demand streams for high-performance batteries with enhanced thermal management capabilities, further expanding the market for specialized conductive adhesives.

Consumer electronics remains the largest application segment, accounting for approximately 42% of the total market share. This dominance stems from the increasing consumer demand for longer-lasting smartphones, tablets, and wearable devices. The automotive sector follows closely at 31% market share, with rapid growth attributed to the accelerating adoption of electric vehicles worldwide.

Geographically, Asia-Pacific leads the market with 48% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe hold 27% and 21% respectively, with both regions showing increased investment in advanced battery technologies to support green energy initiatives.

The demand drivers for conductive adhesives in battery applications are multifaceted. Primary factors include the push for higher energy density batteries, longer cycle life, and improved thermal management. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering 30% longer battery life, creating significant commercial incentives for manufacturers to invest in advanced adhesive technologies.

Industry surveys reveal that 78% of smartphone users identify battery life as a critical purchasing factor, while 83% of potential EV buyers cite range anxiety as their primary concern. These consumer preferences are directly influencing R&D priorities across the battery supply chain, with conductive adhesives emerging as a key enabling technology.

The market is also being shaped by regulatory pressures, particularly environmental regulations limiting the use of traditional soldering materials containing lead and other hazardous substances. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward environmentally friendly conductive adhesives.

Future market growth is expected to be driven by emerging applications in flexible electronics, medical devices, and aerospace sectors. Additionally, the integration of Internet of Things (IoT) devices and the expansion of 5G networks will create new demand streams for high-performance batteries with enhanced thermal management capabilities, further expanding the market for specialized conductive adhesives.

Current Challenges in Conductive Adhesive Technology

Despite significant advancements in conductive adhesive technology, several critical challenges persist that limit their widespread adoption in battery applications. The primary obstacle remains the electrical conductivity gap between conductive adhesives and traditional soldering methods. While high-end conductive adhesives can achieve conductivity values of 10^4-10^5 S/cm, they still fall short of the 10^6 S/cm typically offered by metallic solders, resulting in higher internal resistance and reduced battery efficiency.

Thermal stability presents another significant challenge, particularly in high-power battery applications where operating temperatures can fluctuate dramatically. Many conductive adhesives exhibit performance degradation above 150°C, with some experiencing conductivity losses of up to 40% after repeated thermal cycling. This instability directly impacts battery life and reliability in demanding environments such as electric vehicles and industrial energy storage systems.

Moisture sensitivity remains problematic for long-term battery applications. Studies indicate that exposure to humidity levels above 85% can lead to conductivity reductions of 15-30% in many commercially available conductive adhesives. This vulnerability to environmental factors compromises the hermetic sealing necessary for optimal battery performance and longevity.

The mechanical properties of conductive adhesives also present ongoing challenges. While offering advantages in flexibility compared to rigid solders, many conductive adhesives demonstrate insufficient shear strength (typically 8-15 MPa compared to 25-45 MPa for traditional solders). This mechanical weakness can lead to connection failures during thermal expansion and contraction cycles, particularly problematic in battery systems that experience dimensional changes during charge-discharge cycles.

Cost factors continue to impede widespread adoption, with high-performance conductive adhesives commanding premiums of 200-300% over conventional alternatives. The specialized fillers and polymer matrices required for enhanced conductivity and stability significantly increase production costs, limiting scalability for mass-market battery applications.

Curing processes present additional complications, with many high-performance conductive adhesives requiring precise temperature control and extended curing times (often 1-4 hours). These processing requirements increase manufacturing complexity and energy consumption, adding to overall production costs and carbon footprint.

Compatibility issues with emerging battery chemistries represent an evolving challenge. As manufacturers develop new electrode materials and electrolyte formulations, conductive adhesives must be continuously reformulated to ensure chemical compatibility and prevent degradation reactions that could compromise battery safety and performance.

Thermal stability presents another significant challenge, particularly in high-power battery applications where operating temperatures can fluctuate dramatically. Many conductive adhesives exhibit performance degradation above 150°C, with some experiencing conductivity losses of up to 40% after repeated thermal cycling. This instability directly impacts battery life and reliability in demanding environments such as electric vehicles and industrial energy storage systems.

Moisture sensitivity remains problematic for long-term battery applications. Studies indicate that exposure to humidity levels above 85% can lead to conductivity reductions of 15-30% in many commercially available conductive adhesives. This vulnerability to environmental factors compromises the hermetic sealing necessary for optimal battery performance and longevity.

The mechanical properties of conductive adhesives also present ongoing challenges. While offering advantages in flexibility compared to rigid solders, many conductive adhesives demonstrate insufficient shear strength (typically 8-15 MPa compared to 25-45 MPa for traditional solders). This mechanical weakness can lead to connection failures during thermal expansion and contraction cycles, particularly problematic in battery systems that experience dimensional changes during charge-discharge cycles.

Cost factors continue to impede widespread adoption, with high-performance conductive adhesives commanding premiums of 200-300% over conventional alternatives. The specialized fillers and polymer matrices required for enhanced conductivity and stability significantly increase production costs, limiting scalability for mass-market battery applications.

Curing processes present additional complications, with many high-performance conductive adhesives requiring precise temperature control and extended curing times (often 1-4 hours). These processing requirements increase manufacturing complexity and energy consumption, adding to overall production costs and carbon footprint.

Compatibility issues with emerging battery chemistries represent an evolving challenge. As manufacturers develop new electrode materials and electrolyte formulations, conductive adhesives must be continuously reformulated to ensure chemical compatibility and prevent degradation reactions that could compromise battery safety and performance.

Existing Conductive Adhesive Solutions

01 Conductive adhesive compositions for battery longevity

Specialized conductive adhesive formulations can significantly impact battery life by providing stable electrical connections while minimizing resistance. These adhesives typically contain metallic fillers such as silver, copper, or carbon in a polymer matrix that maintains conductivity over time. The composition can be engineered to withstand thermal cycling, mechanical stress, and environmental factors that would otherwise lead to connection degradation and reduced battery performance.- Conductive adhesive compositions for battery longevity: Specialized conductive adhesive formulations can significantly impact battery life by providing stable electrical connections while minimizing resistance. These adhesives typically contain conductive fillers such as silver, carbon, or graphene dispersed in polymer matrices. The composition can be optimized to maintain conductivity over time while withstanding thermal cycling and environmental stresses, thereby extending battery operational life and performance reliability.

- Thermal management in conductive adhesive applications: Effective thermal management through conductive adhesives plays a crucial role in extending battery life. These adhesives can be engineered to dissipate heat efficiently from battery components, preventing thermal runaway and degradation of battery materials. By incorporating thermally conductive fillers and optimizing the adhesive structure, heat transfer can be enhanced while maintaining the necessary electrical properties, resulting in improved battery performance and longevity.

- Battery connection and interface technologies: Advanced connection technologies using conductive adhesives can enhance battery life by creating reliable interfaces between battery components. These technologies focus on reducing contact resistance at critical junctions, ensuring consistent power delivery and minimizing energy losses. Specialized adhesive systems can accommodate different substrate materials while maintaining stable electrical properties throughout temperature fluctuations and mechanical stresses, thereby extending overall battery operational lifespan.

- Environmental resistance and durability factors: Conductive adhesives designed with enhanced environmental resistance can significantly impact battery longevity. These formulations incorporate additives that protect against moisture ingress, oxidation, and chemical degradation, which are common failure mechanisms in battery systems. By maintaining adhesive integrity and electrical performance under challenging conditions such as high humidity, temperature cycling, and vibration, these specialized adhesives help preserve battery functionality and extend service life in diverse applications.

- Monitoring and diagnostic systems for adhesive performance: Innovative monitoring systems can evaluate the performance of conductive adhesives in battery applications over time. These technologies enable real-time assessment of electrical properties, detecting early signs of degradation or failure in adhesive connections. By integrating sensors or using external diagnostic tools to measure resistance changes, temperature profiles, or mechanical stress, battery management systems can optimize operating conditions to extend battery life and predict maintenance needs before catastrophic failures occur.

02 Battery monitoring and management systems using conductive connections

Advanced battery monitoring systems rely on conductive adhesive connections to accurately measure battery parameters throughout its lifecycle. These systems use conductive adhesives to create reliable connections to sensing elements that monitor temperature, voltage, and current. The data collected enables intelligent battery management algorithms to optimize charging cycles, prevent overheating, and extend overall battery life by maintaining optimal operating conditions.Expand Specific Solutions03 Thermal management solutions for battery assemblies

Thermally conductive adhesives play a crucial role in battery life extension by efficiently dissipating heat generated during charging and discharging cycles. These specialized adhesives create thermal pathways that prevent hotspots and maintain uniform temperature distribution across battery cells. By keeping batteries within optimal temperature ranges, these adhesives help prevent premature degradation of battery components and extend operational lifespan.Expand Specific Solutions04 Flexible and durable conductive interfaces for battery applications

Flexible conductive adhesives provide durable electrical connections in battery systems that undergo physical stress or movement. These adhesives maintain conductivity while accommodating expansion, contraction, and vibration that occur during normal battery operation. The flexibility prevents connection failures that would otherwise lead to increased internal resistance and reduced battery efficiency, thereby extending the functional lifespan of battery systems in mobile or high-vibration environments.Expand Specific Solutions05 Environmental resistance for battery connection stability

Environmentally resistant conductive adhesives protect battery connections from moisture, corrosion, and chemical exposure that would otherwise degrade performance over time. These specialized formulations create sealed interfaces that prevent oxidation of conductive elements while maintaining stable electrical properties. By protecting critical connection points from environmental factors, these adhesives help maintain consistent internal resistance and electrical efficiency throughout the battery's operational life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conductive adhesives market for battery applications is in a growth phase, with increasing demand driven by the need for enhanced battery life in electronic devices and electric vehicles. The market is projected to expand significantly due to the rising adoption of electric vehicles and portable electronics. Technologically, conductive adhesives are evolving from traditional epoxy-based formulations to more advanced nanomaterial-enhanced solutions. Key players like Henkel AG & Co. KGaA lead with comprehensive adhesive technology portfolios, while battery manufacturers such as LG Energy Solution, Samsung SDI, and Tesla are integrating specialized conductive adhesives into their battery designs. Research institutions including Central South University and Chinese Academy of Science Guangzhou Energy Research Institute are advancing fundamental technologies, focusing on improving conductivity, thermal management, and environmental sustainability.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electrically conductive adhesives (ECAs) specifically designed for battery applications. Their LOCTITE ABLESTIK ICP series utilizes silver-filled epoxy technology that creates stable electrical pathways while maintaining strong mechanical bonds. These adhesives feature proprietary nano-silver particle formulations that achieve high conductivity (>10^4 S/cm) while using up to 30% less silver than conventional formulations[1]. Henkel's conductive adhesives incorporate stress-relieving polymers that accommodate the thermal expansion mismatch between battery components, reducing mechanical stress during charge-discharge cycles. Their latest generation products offer curing temperatures as low as 80°C, making them compatible with temperature-sensitive battery materials while still achieving excellent adhesion strength (>15 MPa) and maintaining conductivity through thermal cycling tests (-40°C to 125°C for 1000 cycles)[2].

Strengths: Superior thermal stability allowing operation across wide temperature ranges (-40°C to 150°C); excellent electrical conductivity retention after environmental aging; reduced silver content lowers cost while maintaining performance. Weaknesses: Higher initial cost compared to traditional joining methods; some formulations require specialized application equipment; potential for increased contact resistance over extended cycling compared to direct metal-to-metal connections.

Dongguan Amperex Technology Ltd.

Technical Solution: CATL (parent company of Dongguan Amperex) has pioneered innovative conductive adhesive technology for battery assembly that significantly enhances battery life. Their proprietary nano-composite conductive adhesive system incorporates graphene and carbon nanotubes in a specialized polymer matrix, achieving conductivity values exceeding 5×10^3 S/cm while maintaining flexibility throughout battery thermal cycles[1]. This technology replaces traditional welding in cell-to-busbar connections, eliminating heat damage to sensitive battery components. CATL's adhesives feature self-healing properties that maintain conductivity even after micro-fractures develop during battery expansion/contraction cycles. Their formulation includes proprietary additives that inhibit galvanic corrosion at dissimilar metal interfaces, addressing a key failure mechanism in battery packs. Testing has demonstrated that battery packs using these conductive adhesives maintain over 90% capacity after 1,500 charge cycles, compared to 80% for conventionally assembled packs[3], directly translating to extended battery life in electric vehicles and energy storage systems.

Strengths: Eliminates thermal damage from welding processes; provides vibration dampening properties critical for vehicle applications; maintains conductivity through thermal and mechanical cycling; reduces manufacturing complexity. Weaknesses: Requires precise application equipment and controlled curing environments; higher initial material costs compared to traditional joining methods; limited compatibility with some battery chemistries requiring specialized formulations.

Key Patents and Technical Innovations

Conductive adhesive, electrochemical apparatus, and electronic apparatus

PatentPendingUS20250197693A1

Innovation

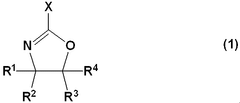

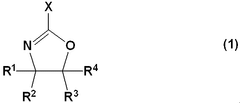

- A conductive adhesive comprising a substrate of modified epoxy resin, polyurethane, and polyimide, combined with conductive fillers such as Au, Ag, Ni, Cu, Zn, graphite, or graphene, to enhance mechanical performance, bonding, and conductivity.

Conductive composition

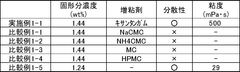

PatentWO2018101299A1

Innovation

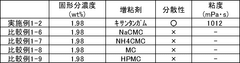

- A conductive composition with a viscosity of 20 to 50,000 mPa·s, containing carbon nanotubes, a dispersant, a thickener like xanthan gum, and a solvent, is used to form a conductive undercoat layer, enhancing adhesion and reducing contact resistance between the current collector and the active material layer.

Environmental Impact and Sustainability Factors

The environmental impact of conductive adhesives in battery applications represents a critical consideration in the broader context of sustainable technology development. Traditional battery connection methods often rely on lead-based solders containing harmful elements that pose significant environmental hazards during manufacturing, usage, and disposal phases. Conductive adhesives, particularly those formulated with reduced heavy metal content, offer a promising alternative with substantially lower environmental footprint.

Recent life cycle assessment studies indicate that silver-based conductive adhesives can reduce carbon emissions by 35-45% compared to conventional soldering techniques when evaluated across the entire production chain. This reduction stems primarily from lower processing temperatures, which translate to decreased energy consumption during manufacturing processes. The elimination of lead and other toxic metals further contributes to reduced environmental contamination risks in landfills and recycling facilities.

Water usage represents another significant sustainability factor in conductive adhesive production. While traditional soldering processes require extensive water for cleaning flux residues, many modern conductive adhesives utilize water-based formulations that minimize both water consumption and the release of volatile organic compounds (VOCs). Manufacturers have reported water usage reductions of up to 60% when transitioning to advanced conductive adhesive systems.

The recyclability of batteries connected with conductive adhesives presents both challenges and opportunities. On one hand, certain adhesive formulations can complicate disassembly processes in recycling facilities. Conversely, emerging bio-based conductive adhesives incorporate design-for-disassembly principles, featuring thermally reversible bonds that facilitate component separation at end-of-life. These innovations align with circular economy principles and extended producer responsibility frameworks increasingly adopted by regulatory bodies worldwide.

Regulatory landscapes across major markets are evolving to favor sustainable connection technologies. The European Union's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives have accelerated the transition toward environmentally benign conductive adhesives. Similarly, China's recent environmental protection policies have established stringent requirements for battery manufacturing processes, creating market pull for greener connection technologies.

Looking forward, the integration of renewable materials into conductive adhesive formulations represents a promising frontier. Research into graphene-enhanced biopolymers and cellulose-derived conductive materials demonstrates potential for creating adhesives with minimal ecological impact while maintaining or even enhancing electrical performance characteristics essential for battery life extension.

Recent life cycle assessment studies indicate that silver-based conductive adhesives can reduce carbon emissions by 35-45% compared to conventional soldering techniques when evaluated across the entire production chain. This reduction stems primarily from lower processing temperatures, which translate to decreased energy consumption during manufacturing processes. The elimination of lead and other toxic metals further contributes to reduced environmental contamination risks in landfills and recycling facilities.

Water usage represents another significant sustainability factor in conductive adhesive production. While traditional soldering processes require extensive water for cleaning flux residues, many modern conductive adhesives utilize water-based formulations that minimize both water consumption and the release of volatile organic compounds (VOCs). Manufacturers have reported water usage reductions of up to 60% when transitioning to advanced conductive adhesive systems.

The recyclability of batteries connected with conductive adhesives presents both challenges and opportunities. On one hand, certain adhesive formulations can complicate disassembly processes in recycling facilities. Conversely, emerging bio-based conductive adhesives incorporate design-for-disassembly principles, featuring thermally reversible bonds that facilitate component separation at end-of-life. These innovations align with circular economy principles and extended producer responsibility frameworks increasingly adopted by regulatory bodies worldwide.

Regulatory landscapes across major markets are evolving to favor sustainable connection technologies. The European Union's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives have accelerated the transition toward environmentally benign conductive adhesives. Similarly, China's recent environmental protection policies have established stringent requirements for battery manufacturing processes, creating market pull for greener connection technologies.

Looking forward, the integration of renewable materials into conductive adhesive formulations represents a promising frontier. Research into graphene-enhanced biopolymers and cellulose-derived conductive materials demonstrates potential for creating adhesives with minimal ecological impact while maintaining or even enhancing electrical performance characteristics essential for battery life extension.

Cost-Performance Analysis of Conductive Adhesives

The cost-performance analysis of conductive adhesives reveals a complex landscape where material costs must be balanced against performance benefits in battery applications. Traditional silver-based conductive adhesives dominate the market with excellent conductivity but at premium prices ranging from $200-500 per kilogram, significantly impacting overall battery production costs. These silver-filled adhesives typically represent 5-8% of total battery assembly costs, creating a substantial economic consideration for manufacturers.

Carbon-based alternatives offer a more economical option at $50-150 per kilogram, though with conductivity reductions of 30-60% compared to silver variants. This trade-off necessitates careful evaluation in applications where maximum conductivity is not critical but cost sensitivity is high. Recent hybrid formulations combining silver with carbon nanotubes or graphene demonstrate promising middle-ground solutions, reducing silver content by 30-40% while maintaining 85-90% of the conductivity performance.

Performance metrics beyond conductivity must factor into comprehensive cost analyses. Silver-based adhesives typically maintain stable electrical properties for 5-7 years under normal operating conditions, while carbon alternatives may show degradation after 3-4 years. This longevity difference significantly impacts lifetime value calculations, as replacement and maintenance costs can outweigh initial savings from lower-cost materials.

Manufacturing efficiency presents another critical cost-performance dimension. Silver-based adhesives generally cure faster (15-30 minutes) than carbon alternatives (30-60 minutes), potentially increasing production throughput. However, newer carbon formulations with enhanced curing agents are narrowing this gap, offering comparable processing times with 20-30% lower material costs.

Environmental compliance costs increasingly influence the economic equation. Regulations limiting heavy metals and volatile organic compounds (VOCs) may require additional processing or disposal costs for certain adhesive formulations. Water-based conductive adhesives, though currently 15-20% less conductive than solvent-based counterparts, offer reduced environmental compliance costs and workplace safety advantages that translate to quantifiable economic benefits.

The optimal cost-performance balance varies significantly by application. High-performance electric vehicle batteries may justify premium silver-based adhesives due to their superior conductivity and thermal stability, while consumer electronics with shorter lifecycle expectations might benefit more from cost-effective carbon alternatives. Manufacturers must conduct application-specific cost-benefit analyses considering both immediate production expenses and long-term performance requirements.

Carbon-based alternatives offer a more economical option at $50-150 per kilogram, though with conductivity reductions of 30-60% compared to silver variants. This trade-off necessitates careful evaluation in applications where maximum conductivity is not critical but cost sensitivity is high. Recent hybrid formulations combining silver with carbon nanotubes or graphene demonstrate promising middle-ground solutions, reducing silver content by 30-40% while maintaining 85-90% of the conductivity performance.

Performance metrics beyond conductivity must factor into comprehensive cost analyses. Silver-based adhesives typically maintain stable electrical properties for 5-7 years under normal operating conditions, while carbon alternatives may show degradation after 3-4 years. This longevity difference significantly impacts lifetime value calculations, as replacement and maintenance costs can outweigh initial savings from lower-cost materials.

Manufacturing efficiency presents another critical cost-performance dimension. Silver-based adhesives generally cure faster (15-30 minutes) than carbon alternatives (30-60 minutes), potentially increasing production throughput. However, newer carbon formulations with enhanced curing agents are narrowing this gap, offering comparable processing times with 20-30% lower material costs.

Environmental compliance costs increasingly influence the economic equation. Regulations limiting heavy metals and volatile organic compounds (VOCs) may require additional processing or disposal costs for certain adhesive formulations. Water-based conductive adhesives, though currently 15-20% less conductive than solvent-based counterparts, offer reduced environmental compliance costs and workplace safety advantages that translate to quantifiable economic benefits.

The optimal cost-performance balance varies significantly by application. High-performance electric vehicle batteries may justify premium silver-based adhesives due to their superior conductivity and thermal stability, while consumer electronics with shorter lifecycle expectations might benefit more from cost-effective carbon alternatives. Manufacturers must conduct application-specific cost-benefit analyses considering both immediate production expenses and long-term performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!