Conductive Adhesives and Their Impact on Energy Harvesting Devices

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives Technology Background and Objectives

Conductive adhesives have emerged as a critical enabling technology in modern electronics, particularly in the rapidly evolving field of energy harvesting devices. The development of these specialized adhesives can be traced back to the 1950s when the first electrically conductive adhesives (ECAs) were introduced as alternatives to traditional soldering methods. Over subsequent decades, the technology has undergone significant refinement, transitioning from simple metal-filled polymer systems to sophisticated nanocomposite formulations with precisely engineered electrical, thermal, and mechanical properties.

The evolution of conductive adhesives has been driven by several converging technological trends, including the miniaturization of electronic components, the rise of flexible electronics, and increasing environmental regulations restricting the use of lead-based solders. The development trajectory has been characterized by continuous improvements in conductivity, adhesion strength, processing temperature, and long-term reliability under various environmental conditions.

Recent advancements in nanomaterials science have dramatically accelerated innovation in this field. The incorporation of carbon nanotubes, graphene, silver nanowires, and other nanoscale conductive fillers has enabled unprecedented combinations of electrical performance and mechanical flexibility. These developments have been particularly significant for energy harvesting applications, where the interface between dissimilar materials often presents both mechanical and electrical challenges.

The primary technical objective in this domain is to develop conductive adhesive systems that can simultaneously satisfy multiple competing requirements: excellent electrical conductivity (approaching that of bulk metals), strong adhesion to diverse substrate materials, mechanical compliance to accommodate thermal and mechanical stresses, environmental stability, and compatibility with low-temperature processing methods suitable for temperature-sensitive energy harvesting components.

Specifically for energy harvesting devices, conductive adhesives must address unique challenges related to the integration of disparate materials with mismatched thermal expansion coefficients, while maintaining stable electrical connections under cyclical mechanical stresses typical in vibration harvesters, or thermal cycling in thermoelectric generators. Additionally, these adhesives must maintain performance integrity over extended operational lifetimes, often in harsh environmental conditions.

The technological trajectory points toward increasingly specialized formulations tailored for specific energy harvesting modalities, including piezoelectric, thermoelectric, triboelectric, and photovoltaic systems. Each of these applications presents distinct interface requirements that drive specialized development paths within the broader conductive adhesive technology landscape.

The evolution of conductive adhesives has been driven by several converging technological trends, including the miniaturization of electronic components, the rise of flexible electronics, and increasing environmental regulations restricting the use of lead-based solders. The development trajectory has been characterized by continuous improvements in conductivity, adhesion strength, processing temperature, and long-term reliability under various environmental conditions.

Recent advancements in nanomaterials science have dramatically accelerated innovation in this field. The incorporation of carbon nanotubes, graphene, silver nanowires, and other nanoscale conductive fillers has enabled unprecedented combinations of electrical performance and mechanical flexibility. These developments have been particularly significant for energy harvesting applications, where the interface between dissimilar materials often presents both mechanical and electrical challenges.

The primary technical objective in this domain is to develop conductive adhesive systems that can simultaneously satisfy multiple competing requirements: excellent electrical conductivity (approaching that of bulk metals), strong adhesion to diverse substrate materials, mechanical compliance to accommodate thermal and mechanical stresses, environmental stability, and compatibility with low-temperature processing methods suitable for temperature-sensitive energy harvesting components.

Specifically for energy harvesting devices, conductive adhesives must address unique challenges related to the integration of disparate materials with mismatched thermal expansion coefficients, while maintaining stable electrical connections under cyclical mechanical stresses typical in vibration harvesters, or thermal cycling in thermoelectric generators. Additionally, these adhesives must maintain performance integrity over extended operational lifetimes, often in harsh environmental conditions.

The technological trajectory points toward increasingly specialized formulations tailored for specific energy harvesting modalities, including piezoelectric, thermoelectric, triboelectric, and photovoltaic systems. Each of these applications presents distinct interface requirements that drive specialized development paths within the broader conductive adhesive technology landscape.

Market Analysis for Energy Harvesting Applications

The global energy harvesting market is experiencing robust growth, projected to reach $1.3 billion by 2027, with a compound annual growth rate of approximately 8.4% from 2022. This expansion is primarily driven by increasing demand for sustainable power solutions across multiple sectors including industrial automation, consumer electronics, building automation, and transportation. Conductive adhesives play a crucial role in this market as they provide essential electrical and mechanical connections in energy harvesting devices while offering advantages over traditional soldering methods.

The industrial sector currently represents the largest application segment for energy harvesting technologies incorporating conductive adhesives, accounting for roughly 32% of the market share. This dominance stems from the growing implementation of wireless sensor networks and IoT devices in manufacturing environments where self-powered solutions reduce maintenance costs and enhance operational efficiency. The consumer electronics sector follows closely at 28%, where energy harvesting components are increasingly integrated into wearable devices, smartphones, and portable electronics.

Regional analysis reveals that North America and Europe currently lead the market with approximately 30% and 28% market share respectively, primarily due to advanced technological infrastructure and supportive regulatory frameworks promoting green technologies. However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.2% annually, driven by rapid industrialization, expanding electronics manufacturing, and increasing adoption of IoT technologies across China, Japan, South Korea, and India.

The market for conductive adhesives specifically within energy harvesting applications is valued at approximately $245 million in 2022, with isotropic conductive adhesives (ICAs) holding 65% of this segment due to their versatility and cost-effectiveness. Anisotropic conductive adhesives (ACAs) account for the remaining 35% but are growing at a faster rate due to their advantages in fine-pitch applications and emerging flexible electronics.

Key market drivers include the proliferation of IoT devices requiring maintenance-free power sources, increasing focus on sustainable energy solutions, and the growing demand for flexible and wearable electronics. The miniaturization trend in electronics is particularly significant, as it necessitates advanced bonding solutions that traditional soldering cannot adequately address, creating substantial opportunities for conductive adhesive technologies.

Market challenges include price sensitivity, especially in consumer applications, technical limitations related to conductivity and long-term reliability, and competition from alternative bonding technologies. Additionally, the fragmented nature of the energy harvesting market, with diverse applications requiring specialized solutions, presents both challenges and opportunities for conductive adhesive manufacturers to develop tailored products for specific energy harvesting technologies.

The industrial sector currently represents the largest application segment for energy harvesting technologies incorporating conductive adhesives, accounting for roughly 32% of the market share. This dominance stems from the growing implementation of wireless sensor networks and IoT devices in manufacturing environments where self-powered solutions reduce maintenance costs and enhance operational efficiency. The consumer electronics sector follows closely at 28%, where energy harvesting components are increasingly integrated into wearable devices, smartphones, and portable electronics.

Regional analysis reveals that North America and Europe currently lead the market with approximately 30% and 28% market share respectively, primarily due to advanced technological infrastructure and supportive regulatory frameworks promoting green technologies. However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.2% annually, driven by rapid industrialization, expanding electronics manufacturing, and increasing adoption of IoT technologies across China, Japan, South Korea, and India.

The market for conductive adhesives specifically within energy harvesting applications is valued at approximately $245 million in 2022, with isotropic conductive adhesives (ICAs) holding 65% of this segment due to their versatility and cost-effectiveness. Anisotropic conductive adhesives (ACAs) account for the remaining 35% but are growing at a faster rate due to their advantages in fine-pitch applications and emerging flexible electronics.

Key market drivers include the proliferation of IoT devices requiring maintenance-free power sources, increasing focus on sustainable energy solutions, and the growing demand for flexible and wearable electronics. The miniaturization trend in electronics is particularly significant, as it necessitates advanced bonding solutions that traditional soldering cannot adequately address, creating substantial opportunities for conductive adhesive technologies.

Market challenges include price sensitivity, especially in consumer applications, technical limitations related to conductivity and long-term reliability, and competition from alternative bonding technologies. Additionally, the fragmented nature of the energy harvesting market, with diverse applications requiring specialized solutions, presents both challenges and opportunities for conductive adhesive manufacturers to develop tailored products for specific energy harvesting technologies.

Current Challenges in Conductive Adhesive Technology

Despite significant advancements in conductive adhesive technology, several critical challenges continue to impede their widespread adoption in energy harvesting devices. The primary obstacle remains the trade-off between electrical conductivity and mechanical adhesion strength. As conductive filler content increases to improve electrical performance, mechanical properties often deteriorate, creating reliability concerns for devices subjected to mechanical stress or vibration in real-world applications.

Thermal stability presents another significant challenge, particularly for energy harvesting devices operating in variable temperature environments. Many conductive adhesives exhibit performance degradation when exposed to thermal cycling, with coefficient of thermal expansion mismatches causing stress at interfaces and potentially leading to delamination or increased contact resistance over time.

Environmental durability remains problematic, especially for outdoor energy harvesting applications. Moisture ingress can significantly degrade electrical performance through oxidation of metallic fillers or swelling of polymer matrices. Additionally, UV exposure often accelerates polymer degradation, compromising long-term reliability in solar energy harvesting systems.

Manufacturing scalability continues to limit commercial viability. Current high-performance conductive adhesives often require complex processing conditions, including precise temperature control, specialized curing protocols, or inert atmospheres. These requirements increase production costs and complexity, hindering mass production capabilities for energy harvesting devices.

The cost-performance ratio represents a persistent barrier to market penetration. Premium conductive adhesives with optimal properties for energy harvesting applications typically incorporate expensive materials such as silver, gold, or specialized carbon nanomaterials. This cost structure makes them prohibitive for price-sensitive consumer applications, limiting their use to high-value specialized sectors.

Compatibility issues with emerging energy harvesting substrates pose additional challenges. As flexible, stretchable, and biodegradable substrates gain prominence in next-generation energy harvesting devices, traditional conductive adhesives often fail to maintain performance when interfacing with these novel materials.

Standardization gaps further complicate technology adoption. The lack of universally accepted testing protocols and performance metrics for conductive adhesives in energy harvesting applications makes comparative evaluation difficult. This absence of standardization creates uncertainty for device manufacturers when selecting appropriate materials for specific applications.

Thermal stability presents another significant challenge, particularly for energy harvesting devices operating in variable temperature environments. Many conductive adhesives exhibit performance degradation when exposed to thermal cycling, with coefficient of thermal expansion mismatches causing stress at interfaces and potentially leading to delamination or increased contact resistance over time.

Environmental durability remains problematic, especially for outdoor energy harvesting applications. Moisture ingress can significantly degrade electrical performance through oxidation of metallic fillers or swelling of polymer matrices. Additionally, UV exposure often accelerates polymer degradation, compromising long-term reliability in solar energy harvesting systems.

Manufacturing scalability continues to limit commercial viability. Current high-performance conductive adhesives often require complex processing conditions, including precise temperature control, specialized curing protocols, or inert atmospheres. These requirements increase production costs and complexity, hindering mass production capabilities for energy harvesting devices.

The cost-performance ratio represents a persistent barrier to market penetration. Premium conductive adhesives with optimal properties for energy harvesting applications typically incorporate expensive materials such as silver, gold, or specialized carbon nanomaterials. This cost structure makes them prohibitive for price-sensitive consumer applications, limiting their use to high-value specialized sectors.

Compatibility issues with emerging energy harvesting substrates pose additional challenges. As flexible, stretchable, and biodegradable substrates gain prominence in next-generation energy harvesting devices, traditional conductive adhesives often fail to maintain performance when interfacing with these novel materials.

Standardization gaps further complicate technology adoption. The lack of universally accepted testing protocols and performance metrics for conductive adhesives in energy harvesting applications makes comparative evaluation difficult. This absence of standardization creates uncertainty for device manufacturers when selecting appropriate materials for specific applications.

Existing Conductive Adhesive Solutions for Energy Harvesting

01 Metal-filled conductive adhesives

Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to create electrical conductivity. These adhesives typically consist of a polymer matrix loaded with conductive metal fillers that form conductive pathways when cured. The concentration and distribution of metal particles directly affect the conductivity level, with higher metal loading generally providing better conductivity. These adhesives are widely used in electronics assembly, semiconductor packaging, and circuit board manufacturing where electrical connections need to be established without traditional soldering.- Conductive fillers in adhesive compositions: Conductive adhesives incorporate various conductive fillers to achieve electrical conductivity. These fillers include metal particles (such as silver, gold, copper), carbon-based materials (like carbon nanotubes, graphene), and metal-coated particles. The type, size, shape, and concentration of these fillers significantly impact the conductivity, adhesion strength, and processing characteristics of the adhesive. Optimizing the filler loading is crucial to balance conductivity with mechanical properties.

- Polymer matrices for conductive adhesives: The polymer matrix serves as the binding component in conductive adhesives, providing adhesion while suspending conductive fillers. Common polymer systems include epoxies, silicones, acrylics, and polyurethanes. These matrices can be formulated as thermosetting or thermoplastic systems, each offering different processing and performance characteristics. The selection of polymer matrix affects curing conditions, temperature resistance, flexibility, and compatibility with various substrates in electronic applications.

- Anisotropic conductive adhesives: Anisotropic conductive adhesives (ACAs) provide electrical conductivity in a specific direction while maintaining insulation in other directions. These specialized adhesives typically contain conductive particles dispersed in an insulating adhesive matrix at concentrations below the percolation threshold. When compressed between electrical contacts, the particles form conductive pathways only in the compression direction. ACAs are particularly valuable in fine-pitch electronics assembly, display technologies, and flexible circuit connections.

- Thermal management in conductive adhesives: Conductive adhesives often serve dual purposes of electrical connection and thermal management. Formulations can be designed to enhance thermal conductivity through the incorporation of thermally conductive fillers such as aluminum oxide, boron nitride, or metal particles. These adhesives help dissipate heat in electronic assemblies, preventing overheating of components. The balance between electrical conductivity, thermal conductivity, and mechanical properties is critical in applications like LED mounting, power electronics, and heat sink attachment.

- Environmental and processing considerations: Modern conductive adhesive formulations address environmental concerns by eliminating lead and other hazardous materials, making them compatible with RoHS and REACH regulations. Processing parameters such as curing conditions, pot life, and storage stability are optimized for various manufacturing environments. Recent innovations focus on low-temperature curing systems, reworkability, and compatibility with automated dispensing equipment. Water resistance, humidity stability, and long-term reliability under thermal cycling are also important considerations in formulation development.

02 Carbon-based conductive adhesives

Carbon-based conductive adhesives utilize carbon materials such as graphite, carbon black, carbon nanotubes, or graphene as conductive fillers. These materials provide electrical conductivity while often being more cost-effective than precious metal fillers. Carbon-based adhesives typically offer moderate conductivity suitable for applications requiring electrostatic discharge protection or moderate current flow. The unique properties of carbon nanomaterials, particularly their high aspect ratio and intrinsic conductivity, allow for achieving conductivity at lower filler loadings compared to traditional carbon fillers, resulting in better mechanical properties of the adhesive.Expand Specific Solutions03 Anisotropic conductive adhesives

Anisotropic conductive adhesives (ACAs) provide electrical conductivity in one direction while maintaining insulation in others. These specialized adhesives typically contain conductive particles dispersed in an insulating adhesive matrix. When compressed between electrical contacts, the particles form conductive pathways in the z-direction (thickness) while remaining electrically isolated in the x and y directions. This unique property makes them ideal for high-density interconnections in display technologies, flexible electronics, and chip-on-flex or chip-on-glass applications where fine-pitch connections are required without the risk of short circuits between adjacent contacts.Expand Specific Solutions04 Thermally conductive adhesives

Thermally conductive adhesives are designed to transfer heat while providing bonding functionality. These adhesives incorporate thermally conductive fillers such as aluminum oxide, boron nitride, aluminum nitride, or metal particles into a polymer matrix. They are crucial in electronic applications where heat dissipation is essential for device performance and reliability. The thermal conductivity can be tailored by adjusting the type, size, shape, and concentration of fillers. These adhesives are commonly used in bonding heat sinks, LED assemblies, power electronics, and other thermal management applications where both heat transfer and structural bonding are required.Expand Specific Solutions05 Flexible and stretchable conductive adhesives

Flexible and stretchable conductive adhesives maintain electrical conductivity while accommodating bending, flexing, or stretching. These advanced formulations typically combine elastomeric polymer matrices with specially designed conductive fillers or networks that can withstand mechanical deformation without losing electrical connectivity. Some designs incorporate liquid metal alloys, conductive hydrogels, or specially structured conductive networks that can elongate while maintaining conductive pathways. These adhesives are essential for wearable electronics, flexible displays, soft robotics, and medical devices where the adhesive must conform to moving or non-planar surfaces while maintaining reliable electrical connections.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conductive adhesives market for energy harvesting devices is in a growth phase, with increasing demand driven by renewable energy applications. The market is expected to expand significantly as energy harvesting technologies mature, with projections showing substantial growth over the next decade. Technologically, conductive adhesives are evolving from traditional epoxy-based systems to more advanced formulations with enhanced conductivity and flexibility. Key players dominating this space include Henkel AG & Co. KGaA with their comprehensive adhesive technology portfolio, 3M Innovative Properties offering specialized solutions, RESONAC CORP (formerly Hitachi Chemical) focusing on semiconductor applications, and Dexerials Corp developing cutting-edge electronic materials. Other significant contributors include Nitto Denko, ZEON Corp, and Designer Molecules, who are advancing material science in this field through proprietary formulations and application-specific innovations.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced conductive adhesive technologies specifically designed for energy harvesting applications. Their LOCTITE ABLESTIK electrically conductive adhesives (ECAs) utilize silver-filled epoxy formulations that provide excellent electrical conductivity while maintaining strong mechanical bonds. These adhesives feature fine-pitch capability down to 50 microns, allowing for precise application in miniaturized energy harvesting devices[1]. Henkel's technology incorporates proprietary filler treatments that prevent silver migration and oxidation, extending device lifespan in harsh environments. Their latest generation of conductive adhesives offers curing temperatures as low as 80°C, making them compatible with temperature-sensitive substrates used in flexible energy harvesters[2]. The company has also developed hybrid formulations that combine isotropic and anisotropic conductivity properties, enabling selective electrical connections in multi-layered energy harvesting systems while maintaining thermal management capabilities[3].

Strengths: Superior electrical conductivity combined with mechanical flexibility makes these adhesives ideal for flexible energy harvesting devices. The low-temperature curing capability preserves substrate integrity. Weaknesses: Higher cost compared to traditional soldering methods, and some formulations may have limited shelf life requiring refrigerated storage.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered thermally conductive adhesives specifically engineered for energy harvesting applications. Their proprietary technology combines acrylic-based adhesive matrices with precisely dispersed conductive particles (typically silver, copper, or carbon) to create adhesives with tailored conductivity profiles. 3M's TC-2810 series features thermal conductivity of 1.0 W/m-K while maintaining electrical isolation, critical for thermoelectric energy harvesting devices[1]. The company has developed specialized manufacturing processes that ensure uniform particle distribution, preventing hot spots and ensuring consistent performance across large surface areas. Their adhesives incorporate stress-relaxation chemistry that accommodates the different thermal expansion coefficients of joined materials, maintaining bond integrity through thermal cycling commonly experienced in energy harvesting applications[2]. 3M's latest innovations include optically clear conductive adhesives for photovoltaic applications that achieve over 90% light transmission while providing electrical pathways for harvested energy[3].

Strengths: Excellent thermal management capabilities combined with strong adhesion to diverse substrates enables application across multiple energy harvesting technologies. Weaknesses: Some formulations may experience conductivity degradation under extreme humidity conditions, and certain specialized versions require complex application equipment.

Key Patents and Technical Innovations

Electrically conductive adhesives

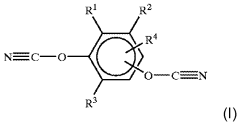

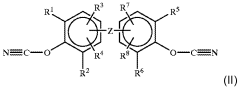

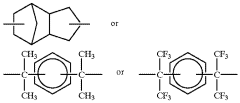

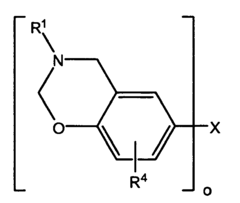

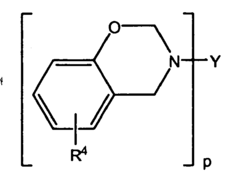

PatentWO2011003948A2

Innovation

- The adhesive composition includes a combination of cyanate ester and epoxy resin components, a nitrogen-containing curative, and low melting point metal fillers, optionally with additional electrically conductive fillers, allowing for rapid curing at low temperatures and forming a stable, conductive bond between substrates.

Electrically conductive adhesives

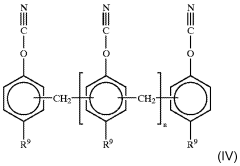

PatentActiveEP2431438B1

Innovation

- A novel adhesive composition comprising a thermosetting or thermoplastic resin with 70-90 wt-% micron-sized electrically conductive particles (2-50 µm) and 0.01-15 wt-% sub-micron-sized particles (300-900 nm), which forms a stable and conductive bond between substrates, offering low processing viscosity and high electrical conductivity with improved resistance to fatigue.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive adhesives in energy harvesting devices represents a critical consideration in the sustainable development of modern electronics. Traditional soldering methods often rely on lead-based materials that pose significant environmental hazards throughout their lifecycle. In contrast, many conductive adhesives offer lead-free alternatives that substantially reduce toxic waste generation and align with global environmental regulations such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives.

The manufacturing processes for conductive adhesives typically require lower curing temperatures compared to conventional soldering methods, resulting in reduced energy consumption during production. This energy efficiency translates to a smaller carbon footprint across the manufacturing supply chain. Additionally, the lower processing temperatures help extend the lifespan of sensitive components in energy harvesting devices, potentially reducing electronic waste generation over time.

Material composition represents another key sustainability factor. Isotropically conductive adhesives (ICAs) and anisotropically conductive adhesives (ACAs) increasingly incorporate bio-based materials and renewable resources as alternatives to petroleum-derived polymers. Research into conductive fillers derived from sustainable sources, such as carbon materials from biomass, demonstrates promising advances toward reducing dependence on rare or environmentally problematic metals.

End-of-life considerations reveal significant advantages for energy harvesting systems utilizing conductive adhesives. These systems generally demonstrate improved recyclability compared to traditionally soldered counterparts. The adhesive bonds can often be disassembled through specific thermal or chemical processes that facilitate component separation and material recovery, enhancing circular economy principles in electronics manufacturing.

Water usage and pollution metrics also favor conductive adhesives over conventional methods. The elimination of flux cleaning processes associated with traditional soldering reduces water consumption and prevents the release of cleaning solvents into wastewater systems. This aspect becomes particularly relevant as water scarcity concerns intensify globally.

Life Cycle Assessment (LCA) studies comparing energy harvesting devices with conductive adhesives versus conventional joining technologies consistently demonstrate reduced environmental impact across multiple categories, including global warming potential, acidification, and resource depletion. However, these assessments also highlight areas for improvement, particularly regarding the long-term stability and durability of some adhesive formulations under extreme environmental conditions.

Future sustainability improvements focus on developing conductive adhesives with enhanced biodegradability without compromising electrical performance. Research into self-healing conductive adhesives shows promise for extending device lifespans, while innovations in disassembly-friendly adhesive systems could revolutionize electronics recycling processes, further reducing the environmental footprint of energy harvesting technologies.

The manufacturing processes for conductive adhesives typically require lower curing temperatures compared to conventional soldering methods, resulting in reduced energy consumption during production. This energy efficiency translates to a smaller carbon footprint across the manufacturing supply chain. Additionally, the lower processing temperatures help extend the lifespan of sensitive components in energy harvesting devices, potentially reducing electronic waste generation over time.

Material composition represents another key sustainability factor. Isotropically conductive adhesives (ICAs) and anisotropically conductive adhesives (ACAs) increasingly incorporate bio-based materials and renewable resources as alternatives to petroleum-derived polymers. Research into conductive fillers derived from sustainable sources, such as carbon materials from biomass, demonstrates promising advances toward reducing dependence on rare or environmentally problematic metals.

End-of-life considerations reveal significant advantages for energy harvesting systems utilizing conductive adhesives. These systems generally demonstrate improved recyclability compared to traditionally soldered counterparts. The adhesive bonds can often be disassembled through specific thermal or chemical processes that facilitate component separation and material recovery, enhancing circular economy principles in electronics manufacturing.

Water usage and pollution metrics also favor conductive adhesives over conventional methods. The elimination of flux cleaning processes associated with traditional soldering reduces water consumption and prevents the release of cleaning solvents into wastewater systems. This aspect becomes particularly relevant as water scarcity concerns intensify globally.

Life Cycle Assessment (LCA) studies comparing energy harvesting devices with conductive adhesives versus conventional joining technologies consistently demonstrate reduced environmental impact across multiple categories, including global warming potential, acidification, and resource depletion. However, these assessments also highlight areas for improvement, particularly regarding the long-term stability and durability of some adhesive formulations under extreme environmental conditions.

Future sustainability improvements focus on developing conductive adhesives with enhanced biodegradability without compromising electrical performance. Research into self-healing conductive adhesives shows promise for extending device lifespans, while innovations in disassembly-friendly adhesive systems could revolutionize electronics recycling processes, further reducing the environmental footprint of energy harvesting technologies.

Performance Metrics and Testing Standards

The evaluation of conductive adhesives for energy harvesting applications requires standardized performance metrics and testing protocols to ensure reliability and comparability across different formulations and manufacturers. Current industry standards primarily focus on electrical conductivity, measured in Siemens per meter (S/m) or ohm-centimeters (Ω·cm), with high-performance conductive adhesives typically achieving 10^4-10^6 S/m. Thermal conductivity, measured in watts per meter-kelvin (W/m·K), represents another critical parameter, particularly for thermoelectric energy harvesting devices where efficient heat transfer directly impacts energy conversion efficiency.

Adhesion strength testing follows standards such as ASTM D1002 for lap shear strength and ASTM D3359 for tape adhesion tests, with minimum requirements typically ranging from 8-15 MPa for structural applications. Environmental durability metrics include temperature cycling resistance (typically -40°C to +125°C for automotive applications), humidity resistance (85% RH/85°C testing), and salt spray exposure according to ASTM B117 protocols.

For energy harvesting specific applications, specialized metrics have emerged including power density impact (measured in μW/cm²), conversion efficiency maintenance, and fatigue resistance under cyclic loading. The IEC 62830 series provides standardized testing methodologies specifically for energy harvesting devices, with part 5 focusing on interface materials including conductive adhesives.

Reliability testing standards incorporate accelerated aging protocols, with the Arrhenius equation commonly applied to predict long-term performance. The industry typically requires 1000+ hours of operation under elevated stress conditions without significant performance degradation. Creep resistance testing under constant load (ASTM D2294) is particularly relevant for vibration-based energy harvesters where mechanical stability directly impacts energy output consistency.

Recent developments in testing standards include the introduction of in-situ monitoring techniques that evaluate conductive adhesive performance during actual device operation. These methods employ impedance spectroscopy and thermal imaging to detect early signs of degradation before catastrophic failure occurs. Additionally, emerging standards are beginning to address nano-enabled conductive adhesives, with specialized protocols for evaluating percolation threshold stability and nanoparticle distribution uniformity.

The harmonization of testing standards remains challenging due to the diverse application requirements across different energy harvesting technologies. Industry consortia including the IEEE Standards Association and IPC (Association Connecting Electronics Industries) are currently developing unified testing frameworks specifically addressing the unique requirements of conductive adhesives in energy harvesting applications, with draft standards expected for industry review by late 2023.

Adhesion strength testing follows standards such as ASTM D1002 for lap shear strength and ASTM D3359 for tape adhesion tests, with minimum requirements typically ranging from 8-15 MPa for structural applications. Environmental durability metrics include temperature cycling resistance (typically -40°C to +125°C for automotive applications), humidity resistance (85% RH/85°C testing), and salt spray exposure according to ASTM B117 protocols.

For energy harvesting specific applications, specialized metrics have emerged including power density impact (measured in μW/cm²), conversion efficiency maintenance, and fatigue resistance under cyclic loading. The IEC 62830 series provides standardized testing methodologies specifically for energy harvesting devices, with part 5 focusing on interface materials including conductive adhesives.

Reliability testing standards incorporate accelerated aging protocols, with the Arrhenius equation commonly applied to predict long-term performance. The industry typically requires 1000+ hours of operation under elevated stress conditions without significant performance degradation. Creep resistance testing under constant load (ASTM D2294) is particularly relevant for vibration-based energy harvesters where mechanical stability directly impacts energy output consistency.

Recent developments in testing standards include the introduction of in-situ monitoring techniques that evaluate conductive adhesive performance during actual device operation. These methods employ impedance spectroscopy and thermal imaging to detect early signs of degradation before catastrophic failure occurs. Additionally, emerging standards are beginning to address nano-enabled conductive adhesives, with specialized protocols for evaluating percolation threshold stability and nanoparticle distribution uniformity.

The harmonization of testing standards remains challenging due to the diverse application requirements across different energy harvesting technologies. Industry consortia including the IEEE Standards Association and IPC (Association Connecting Electronics Industries) are currently developing unified testing frameworks specifically addressing the unique requirements of conductive adhesives in energy harvesting applications, with draft standards expected for industry review by late 2023.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!