Analysis of Electrode Kinetics in Soft Pneumatic Actuators

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Electrode Kinetics Background and Objectives

Soft pneumatic actuators (SPAs) have emerged as a revolutionary technology in the field of robotics and biomedical engineering over the past two decades. These flexible, compliant mechanisms utilize pneumatic pressure to generate motion, offering advantages in safety, adaptability, and biomimetic functionality compared to traditional rigid actuators. The evolution of this technology can be traced back to the early 2000s, with significant acceleration in research and development occurring after 2010 when materials science advancements enabled more sophisticated designs and applications.

The electrode kinetics within soft pneumatic actuators represents a critical yet underexplored aspect of their functionality. Electrodes integrated into SPAs serve multiple purposes: sensing deformation, providing feedback control, enabling self-sensing capabilities, and in some advanced applications, actively modifying material properties through electrical stimulation. Understanding the fundamental interactions between these electrodes and the surrounding elastomeric matrices during pneumatic actuation cycles is essential for advancing the field.

Current technological trends point toward increasingly sophisticated electrode systems that maintain functionality under extreme deformation conditions. The field is moving from simple conductive pathways toward complex, multi-functional electrode networks that can simultaneously sense, actuate, and communicate. This evolution necessitates a deeper understanding of electrode behavior under dynamic conditions, particularly regarding conductivity maintenance, fatigue resistance, and signal fidelity during repeated actuation cycles.

The primary technical objectives of this investigation include characterizing the electrochemical interface dynamics between electrodes and elastomeric substrates during pneumatic actuation, quantifying performance degradation mechanisms over extended cycling, and developing predictive models for electrode behavior under various deformation conditions. Additionally, we aim to establish design guidelines for optimizing electrode geometries, materials, and placement to maximize functionality while minimizing interference with actuator performance.

Recent advancements in nanomaterials, particularly liquid metal alloys, carbon nanotubes, and graphene derivatives, have opened new possibilities for electrode integration in SPAs. These materials offer unprecedented combinations of conductivity, stretchability, and durability that could potentially overcome many current limitations. However, their long-term stability and interaction with elastomeric matrices under cyclic pneumatic loading remain inadequately characterized.

The convergence of soft robotics, flexible electronics, and advanced materials science creates a unique opportunity to fundamentally reimagine electrode systems for soft pneumatic actuators. By comprehensively understanding electrode kinetics, we can enable the next generation of self-sensing, adaptive, and intelligent soft robotic systems capable of more sophisticated interactions with humans and environments.

The electrode kinetics within soft pneumatic actuators represents a critical yet underexplored aspect of their functionality. Electrodes integrated into SPAs serve multiple purposes: sensing deformation, providing feedback control, enabling self-sensing capabilities, and in some advanced applications, actively modifying material properties through electrical stimulation. Understanding the fundamental interactions between these electrodes and the surrounding elastomeric matrices during pneumatic actuation cycles is essential for advancing the field.

Current technological trends point toward increasingly sophisticated electrode systems that maintain functionality under extreme deformation conditions. The field is moving from simple conductive pathways toward complex, multi-functional electrode networks that can simultaneously sense, actuate, and communicate. This evolution necessitates a deeper understanding of electrode behavior under dynamic conditions, particularly regarding conductivity maintenance, fatigue resistance, and signal fidelity during repeated actuation cycles.

The primary technical objectives of this investigation include characterizing the electrochemical interface dynamics between electrodes and elastomeric substrates during pneumatic actuation, quantifying performance degradation mechanisms over extended cycling, and developing predictive models for electrode behavior under various deformation conditions. Additionally, we aim to establish design guidelines for optimizing electrode geometries, materials, and placement to maximize functionality while minimizing interference with actuator performance.

Recent advancements in nanomaterials, particularly liquid metal alloys, carbon nanotubes, and graphene derivatives, have opened new possibilities for electrode integration in SPAs. These materials offer unprecedented combinations of conductivity, stretchability, and durability that could potentially overcome many current limitations. However, their long-term stability and interaction with elastomeric matrices under cyclic pneumatic loading remain inadequately characterized.

The convergence of soft robotics, flexible electronics, and advanced materials science creates a unique opportunity to fundamentally reimagine electrode systems for soft pneumatic actuators. By comprehensively understanding electrode kinetics, we can enable the next generation of self-sensing, adaptive, and intelligent soft robotic systems capable of more sophisticated interactions with humans and environments.

Market Applications and Demand Analysis for Soft Pneumatic Actuators

The soft pneumatic actuator (SPA) market is experiencing significant growth driven by increasing demand across multiple industries. The global market for soft robotics, which includes SPAs, is projected to reach $3.27 billion by 2026, with a compound annual growth rate of 35.1% from 2021. This remarkable growth trajectory is fueled by the unique advantages of soft pneumatic actuators, particularly their flexibility, adaptability, and safety in human-machine interactions.

Healthcare represents one of the most promising application areas for SPAs. The medical robotics sector is actively adopting these actuators for rehabilitation devices, surgical tools, and prosthetics. The ability of SPAs to provide gentle, compliant motion makes them ideal for direct patient contact applications. Market research indicates that medical applications currently account for approximately 28% of the total SPA market, with rehabilitation devices showing the strongest growth at 41% annually.

Manufacturing and industrial automation constitute another significant market segment. The demand for collaborative robots (cobots) that can safely work alongside human operators has created substantial opportunities for SPAs. Industries are increasingly seeking flexible automation solutions that can adapt to varying production requirements without extensive retooling. This sector represents about 32% of the current SPA market, with particular strength in precision assembly and material handling applications.

Consumer electronics and wearable technology represent emerging markets with substantial growth potential. The integration of SPAs into haptic feedback systems, virtual reality interfaces, and wearable assistive devices is gaining traction. Market analysts predict this segment will grow at 47% annually over the next five years, albeit from a smaller base of approximately 15% of the current market.

The aerospace and automotive industries are also exploring SPA applications for adaptive structures, morphing surfaces, and human-machine interfaces. These high-value sectors currently represent smaller market shares (11% and 8% respectively) but offer premium pricing opportunities due to their stringent performance requirements.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to show the fastest growth rate at 42% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea.

Market challenges include concerns about durability, response time, and precise control of SPAs in demanding applications. Industry surveys indicate that 67% of potential adopters cite electrode kinetics and control precision as critical factors influencing purchasing decisions. This underscores the importance of advancing electrode kinetics research to address market demands for faster, more precise, and more reliable soft pneumatic actuators.

Healthcare represents one of the most promising application areas for SPAs. The medical robotics sector is actively adopting these actuators for rehabilitation devices, surgical tools, and prosthetics. The ability of SPAs to provide gentle, compliant motion makes them ideal for direct patient contact applications. Market research indicates that medical applications currently account for approximately 28% of the total SPA market, with rehabilitation devices showing the strongest growth at 41% annually.

Manufacturing and industrial automation constitute another significant market segment. The demand for collaborative robots (cobots) that can safely work alongside human operators has created substantial opportunities for SPAs. Industries are increasingly seeking flexible automation solutions that can adapt to varying production requirements without extensive retooling. This sector represents about 32% of the current SPA market, with particular strength in precision assembly and material handling applications.

Consumer electronics and wearable technology represent emerging markets with substantial growth potential. The integration of SPAs into haptic feedback systems, virtual reality interfaces, and wearable assistive devices is gaining traction. Market analysts predict this segment will grow at 47% annually over the next five years, albeit from a smaller base of approximately 15% of the current market.

The aerospace and automotive industries are also exploring SPA applications for adaptive structures, morphing surfaces, and human-machine interfaces. These high-value sectors currently represent smaller market shares (11% and 8% respectively) but offer premium pricing opportunities due to their stringent performance requirements.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to show the fastest growth rate at 42% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea.

Market challenges include concerns about durability, response time, and precise control of SPAs in demanding applications. Industry surveys indicate that 67% of potential adopters cite electrode kinetics and control precision as critical factors influencing purchasing decisions. This underscores the importance of advancing electrode kinetics research to address market demands for faster, more precise, and more reliable soft pneumatic actuators.

Current Electrode Kinetics Challenges in Soft Robotics

The field of soft pneumatic actuators has witnessed significant advancements in recent years, yet electrode kinetics remains a critical challenge that impedes optimal performance. Current electrodes in soft robotics face substantial limitations in maintaining consistent electrical properties during deformation cycles. The primary challenge stems from the inherent contradiction between the mechanical compliance required for soft actuators and the electrical stability needed for reliable operation.

Material interface issues represent a major obstacle, as the junction between rigid electrodes and soft elastomeric substrates creates stress concentrations during actuation. These stress points lead to delamination, cracking, and eventual electrode failure after repeated cycling. Studies have shown that conventional metal electrodes typically fail after 1,000-5,000 actuation cycles when applied to highly deformable substrates, significantly limiting device longevity.

Conductivity degradation under strain presents another significant challenge. Most conductive materials experience dramatic increases in electrical resistance when stretched, with some showing up to 200-300% resistance increase at just 30% strain. This non-linear relationship between strain and conductivity creates unpredictable control dynamics and reduces energy efficiency during operation.

Response time limitations further complicate electrode performance in dynamic applications. Current electrode systems exhibit capacitive effects at material interfaces, creating signal delays ranging from milliseconds to seconds depending on the actuation frequency. These delays become particularly problematic in applications requiring precise temporal control, such as biomimetic locomotion or human-robot interaction.

Manufacturing scalability remains an unresolved challenge for advanced electrode systems. While laboratory demonstrations have shown promising results with nanomaterial-based electrodes, transitioning these technologies to mass production has proven difficult. Current fabrication methods like screen printing and direct writing lack the throughput and consistency needed for commercial-scale production of complex electrode geometries.

Environmental sensitivity also poses significant concerns for real-world deployment. Many high-performance electrode materials exhibit performance degradation when exposed to humidity, oxygen, or UV radiation. This environmental vulnerability necessitates protective encapsulation, which often compromises the mechanical compliance that makes soft actuators advantageous in the first place.

Power efficiency represents perhaps the most pressing challenge for electrode systems in portable soft robotic applications. Current electrode configurations create significant resistive losses, with some systems converting up to 40% of input energy into waste heat rather than mechanical work. This inefficiency severely limits operational duration in battery-powered applications and increases thermal management requirements.

Material interface issues represent a major obstacle, as the junction between rigid electrodes and soft elastomeric substrates creates stress concentrations during actuation. These stress points lead to delamination, cracking, and eventual electrode failure after repeated cycling. Studies have shown that conventional metal electrodes typically fail after 1,000-5,000 actuation cycles when applied to highly deformable substrates, significantly limiting device longevity.

Conductivity degradation under strain presents another significant challenge. Most conductive materials experience dramatic increases in electrical resistance when stretched, with some showing up to 200-300% resistance increase at just 30% strain. This non-linear relationship between strain and conductivity creates unpredictable control dynamics and reduces energy efficiency during operation.

Response time limitations further complicate electrode performance in dynamic applications. Current electrode systems exhibit capacitive effects at material interfaces, creating signal delays ranging from milliseconds to seconds depending on the actuation frequency. These delays become particularly problematic in applications requiring precise temporal control, such as biomimetic locomotion or human-robot interaction.

Manufacturing scalability remains an unresolved challenge for advanced electrode systems. While laboratory demonstrations have shown promising results with nanomaterial-based electrodes, transitioning these technologies to mass production has proven difficult. Current fabrication methods like screen printing and direct writing lack the throughput and consistency needed for commercial-scale production of complex electrode geometries.

Environmental sensitivity also poses significant concerns for real-world deployment. Many high-performance electrode materials exhibit performance degradation when exposed to humidity, oxygen, or UV radiation. This environmental vulnerability necessitates protective encapsulation, which often compromises the mechanical compliance that makes soft actuators advantageous in the first place.

Power efficiency represents perhaps the most pressing challenge for electrode systems in portable soft robotic applications. Current electrode configurations create significant resistive losses, with some systems converting up to 40% of input energy into waste heat rather than mechanical work. This inefficiency severely limits operational duration in battery-powered applications and increases thermal management requirements.

Current Electrode Design Solutions for Pneumatic Actuation

01 Electrode integration in soft pneumatic actuators

Electrodes can be integrated into soft pneumatic actuators to enable sensing and control capabilities. These electrodes can be embedded within the flexible structure of the actuator to monitor deformation, pressure, or contact with objects. The integration of electrodes allows for closed-loop control systems that can precisely regulate the actuator's movement based on real-time feedback. This approach enhances the functionality and versatility of soft pneumatic systems in various applications.- Electrode integration in soft pneumatic actuators: Electrodes can be integrated into soft pneumatic actuators to enable sensing and control capabilities. These electrodes can be embedded within the flexible structure of the actuator to monitor deformation, pressure, or contact. The integration of electrodes allows for closed-loop control systems that can precisely regulate the actuator's movement based on real-time feedback. This approach enhances the functionality and precision of soft pneumatic systems in various applications.

- Kinetic energy harvesting in pneumatic systems: Pneumatic actuators can be designed to harvest kinetic energy during operation. This involves converting mechanical motion or pressure fluctuations into electrical energy through specialized electrode configurations. The harvested energy can be used to power sensors or control systems, reducing the need for external power sources. This approach improves the energy efficiency and autonomy of pneumatic actuator systems, particularly in mobile or remote applications.

- Electrode materials for enhanced pneumatic actuator performance: The selection of electrode materials significantly impacts the performance of soft pneumatic actuators. Conductive polymers, carbon-based materials, and metallic nanostructures can be used to create flexible electrodes that maintain conductivity during deformation. These materials enable better sensing capabilities and more efficient electrical-pneumatic coupling. Advanced electrode materials can improve response time, sensitivity, and durability of the actuator systems while maintaining the required flexibility.

- Control algorithms for electrode-integrated pneumatic actuators: Specialized control algorithms are essential for managing the complex interactions between electrical and pneumatic components in soft actuators. These algorithms process electrode sensor data to optimize pressure distribution, timing, and force application. Machine learning approaches can be implemented to adapt to changing conditions and improve performance over time. The development of these control systems enables more precise and responsive operation of soft pneumatic actuators in various applications.

- Multi-functional electrode arrays for complex pneumatic movements: Arrays of electrodes can be strategically positioned within soft pneumatic actuators to enable complex, multi-directional movements. These electrode arrays provide distributed sensing and actuation capabilities, allowing for more sophisticated motion control. By selectively activating different electrode segments, the actuator can perform intricate movements that mimic biological systems. This approach is particularly valuable in robotics, medical devices, and human-machine interfaces where natural, compliant motion is required.

02 Kinetic energy harvesting in pneumatic systems

Pneumatic actuators can be designed to harvest kinetic energy during operation, improving overall system efficiency. By incorporating specialized electrodes and materials, the mechanical energy from actuator movement can be converted into electrical energy. This harvested energy can be stored or used to power sensors and control systems, reducing the need for external power sources. The kinetic energy harvesting capability is particularly valuable in portable or remote applications where power availability is limited.Expand Specific Solutions03 Electrode materials for enhanced pneumatic actuation

The selection of electrode materials significantly impacts the performance of soft pneumatic actuators. Conductive polymers, carbon-based materials, and metallic nanostructures can be used to create flexible electrodes that maintain conductivity during deformation. These materials enable better electrode kinetics, improving response time and control precision. Advanced electrode materials can also enhance durability and reliability under repeated actuation cycles, making them suitable for demanding applications in robotics and biomedical devices.Expand Specific Solutions04 Control systems for soft pneumatic actuators

Sophisticated control systems can be implemented to optimize the performance of soft pneumatic actuators with integrated electrodes. These systems utilize feedback from embedded sensors to adjust pressure, flow rate, and timing parameters in real-time. Machine learning algorithms can be employed to improve actuation precision and adapt to changing environmental conditions. The control systems can also compensate for nonlinear behaviors inherent in soft materials, ensuring consistent and predictable actuation responses across various operating conditions.Expand Specific Solutions05 Applications of electrode-equipped soft pneumatic actuators

Soft pneumatic actuators with integrated electrodes find applications across multiple fields. In robotics, they enable the development of compliant grippers and manipulators that can safely interact with delicate objects or humans. Medical applications include assistive devices, surgical tools, and rehabilitation equipment that benefit from the combination of precise control and inherent safety. These actuators are also being explored for use in wearable technology, prosthetics, and industrial automation where traditional rigid actuators are unsuitable due to safety concerns or environmental constraints.Expand Specific Solutions

Leading Research Groups and Companies in Soft Robotics

The electrode kinetics in soft pneumatic actuators market is currently in an early growth phase, characterized by intensive academic research and emerging commercial applications. The market size is expanding as these actuators find applications in robotics, biomedical devices, and wearable technology, with projections suggesting significant growth over the next decade. Regarding technical maturity, academic institutions lead development, with Harvard College, MIT, and Zhejiang University pioneering fundamental research. Commercial players like Artimus Robotics and Canon are advancing practical applications, while research organizations such as Naval Research Laboratory and CSIR contribute to specialized developments. The technology shows promising maturity in laboratory settings but requires further refinement for widespread industrial adoption, with collaborative efforts between academia and industry accelerating progress toward commercialization.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered advanced electrode kinetics research for soft pneumatic actuators through their innovative microfluidic systems. Their technology utilizes ionic liquid-based electrodes embedded within elastomeric matrices to achieve precise control over actuation dynamics. The Harvard team has developed a multi-layer fabrication approach that integrates stretchable electrodes with pneumatic chambers, allowing for simultaneous electrical and pneumatic control. Their proprietary electrode formulations incorporate carbon nanotubes and silver nanowires in elastomeric substrates, achieving conductivity maintenance at strains exceeding 300%. This enables real-time modulation of pneumatic actuation through variable electrode polarization, creating hybrid electro-pneumatic control systems with response times under 100ms. Harvard's research has demonstrated that strategic electrode placement can create localized stiffness gradients within actuators, enabling complex motion patterns from simple pneumatic inputs.

Strengths: Superior integration of electrical and pneumatic control systems; exceptional electrode conductivity maintenance under extreme deformation; advanced fabrication techniques for multi-material systems. Weaknesses: Higher manufacturing complexity compared to conventional systems; potential biocompatibility challenges with some electrode materials; requires specialized equipment for fabrication.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking approach to electrode kinetics in soft pneumatic actuators through their Computer Science and Artificial Intelligence Laboratory (CSAIL). Their technology focuses on distributed electrode networks that enable localized control of pneumatic chambers through electrostatic adhesion principles. MIT researchers have created a proprietary electrode composition using liquid metal alloys (primarily gallium-indium) encapsulated in micro-channels adjacent to pneumatic chambers. This configuration allows for variable stiffness control through applied voltage, effectively creating programmable constraint patterns within the actuator. Their system achieves response times of approximately 50ms and can maintain electrode functionality at strains up to 250%. MIT's electrode design incorporates self-healing capabilities through micro-encapsulated conductive fluids that maintain electrical continuity even after mechanical damage. This technology enables precise control over pressure distribution within pneumatic networks, allowing for complex motion sequences from simple input commands.

Strengths: Rapid response time for real-time control applications; self-healing electrode technology increases durability; excellent integration with existing control systems. Weaknesses: Higher power requirements compared to purely pneumatic systems; temperature sensitivity of liquid metal electrodes; more complex manufacturing process requiring specialized equipment.

Key Innovations in Electrode-Pneumatic Interface Technology

Pneumatic soft actuators with tunable force-displacement relation and methods and machines therefor

PatentPendingUS20230373082A1

Innovation

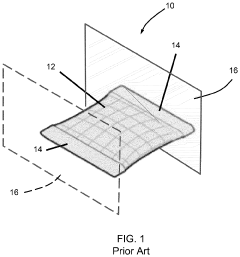

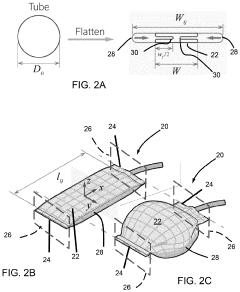

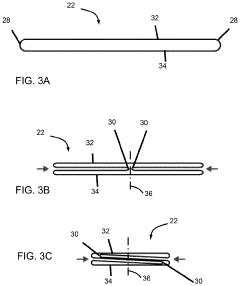

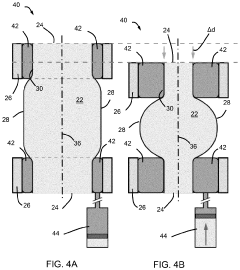

- A pneumatic soft actuator with an inflatable pouch featuring symmetrical folds at its ends, allowing for active modification of the end geometry through a branched tendon and spool mechanism, enabling adjustment of the force-strain relationship and range of motion without altering the pouch's composition or structure.

Wearable device concept powered by a combination of soft pneumatic actuators and variable stiffness knitting

PatentPendingUS20250209895A1

Innovation

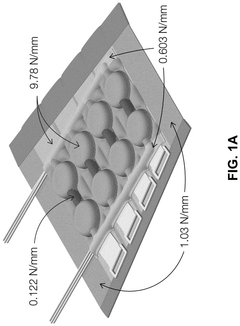

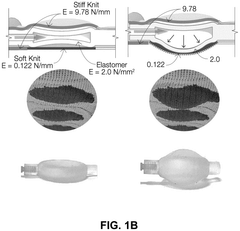

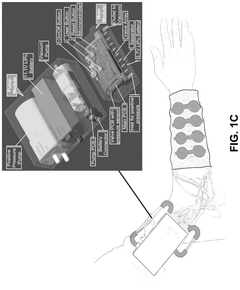

- A pneumatic haptic sleeve is designed with integrated soft pneumatic actuators and variable stiffness areas, achieved through knitted layers with high and low stiffness regions, allowing for seamless integration and distribution of actuation forces, powered by an untethered pneumatic system.

Materials Science Advancements for Flexible Electrodes

Recent advancements in materials science have significantly propelled the development of flexible electrodes, which are crucial components in soft pneumatic actuators. Traditional rigid electrodes have limited the potential applications of soft robotics due to their inherent mechanical constraints. However, the emergence of novel materials and fabrication techniques has opened new avenues for creating electrodes that can maintain electrical performance while undergoing substantial mechanical deformation.

Conductive polymers, particularly PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), have emerged as promising materials for flexible electrodes. These polymers offer a unique combination of electrical conductivity and mechanical flexibility, making them ideal for integration into soft actuators. Recent research has focused on enhancing their conductivity through secondary doping with polar solvents and improving their adhesion to elastomeric substrates.

Carbon-based nanomaterials represent another significant advancement in this field. Carbon nanotubes (CNTs) and graphene have demonstrated exceptional electrical properties while maintaining flexibility. Researchers have developed methods to create composite materials by embedding these carbon nanostructures within elastomeric matrices, resulting in electrodes that can withstand strains exceeding 100% while maintaining functionality. These composites often exhibit self-healing properties and resistance to fatigue, addressing key durability concerns in soft robotics applications.

Liquid metal alloys, particularly gallium-based eutectic alloys like Galinstan, have revolutionized flexible electronics. These materials remain liquid at room temperature while maintaining high electrical conductivity. When encapsulated within microchannels in elastomers, they create stretchable conductors that can deform without compromising electrical performance. Recent innovations include methods to pattern these liquid metals with precision and prevent oxidation, which has been a persistent challenge.

Hybrid materials combining inorganic conductors with organic substrates have also shown promise. Gold nanowires embedded in silicone elastomers, for instance, create percolation networks that maintain conductivity during deformation. Similarly, silver nanowires have been used to create transparent, flexible electrodes suitable for applications requiring optical transparency alongside electrical conductivity.

Fabrication techniques have evolved in parallel with material innovations. Direct ink writing, screen printing, and laser patterning now enable precise deposition of conductive materials onto flexible substrates. These additive manufacturing approaches allow for complex electrode geometries that can be tailored to specific actuation requirements, optimizing the electrode kinetics in soft pneumatic systems.

Conductive polymers, particularly PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), have emerged as promising materials for flexible electrodes. These polymers offer a unique combination of electrical conductivity and mechanical flexibility, making them ideal for integration into soft actuators. Recent research has focused on enhancing their conductivity through secondary doping with polar solvents and improving their adhesion to elastomeric substrates.

Carbon-based nanomaterials represent another significant advancement in this field. Carbon nanotubes (CNTs) and graphene have demonstrated exceptional electrical properties while maintaining flexibility. Researchers have developed methods to create composite materials by embedding these carbon nanostructures within elastomeric matrices, resulting in electrodes that can withstand strains exceeding 100% while maintaining functionality. These composites often exhibit self-healing properties and resistance to fatigue, addressing key durability concerns in soft robotics applications.

Liquid metal alloys, particularly gallium-based eutectic alloys like Galinstan, have revolutionized flexible electronics. These materials remain liquid at room temperature while maintaining high electrical conductivity. When encapsulated within microchannels in elastomers, they create stretchable conductors that can deform without compromising electrical performance. Recent innovations include methods to pattern these liquid metals with precision and prevent oxidation, which has been a persistent challenge.

Hybrid materials combining inorganic conductors with organic substrates have also shown promise. Gold nanowires embedded in silicone elastomers, for instance, create percolation networks that maintain conductivity during deformation. Similarly, silver nanowires have been used to create transparent, flexible electrodes suitable for applications requiring optical transparency alongside electrical conductivity.

Fabrication techniques have evolved in parallel with material innovations. Direct ink writing, screen printing, and laser patterning now enable precise deposition of conductive materials onto flexible substrates. These additive manufacturing approaches allow for complex electrode geometries that can be tailored to specific actuation requirements, optimizing the electrode kinetics in soft pneumatic systems.

Biocompatibility and Safety Standards for Soft Actuators

The integration of soft pneumatic actuators into biomedical applications necessitates rigorous adherence to biocompatibility and safety standards. These standards ensure that devices in contact with human tissues do not cause adverse reactions or compromise patient safety. For soft actuators with electrodes, compliance with ISO 10993 series is fundamental, particularly ISO 10993-1 which outlines the biological evaluation framework for medical devices.

Material selection represents a critical consideration in meeting biocompatibility requirements. Silicone elastomers like polydimethylsiloxane (PDMS) have emerged as preferred materials due to their low toxicity and minimal inflammatory response. However, electrode materials present additional challenges, as conductive components must maintain functionality without leaching harmful substances. Biocompatible conductive materials such as gold, platinum, and certain carbon-based composites have demonstrated promising results in recent studies.

Cytotoxicity testing according to ISO 10993-5 is essential for soft actuators with electrode components. These tests evaluate whether materials release substances that could damage cellular structures. Additionally, sensitization and irritation assessments (ISO 10993-10) help determine potential allergic reactions when devices contact skin or mucous membranes. For implantable soft actuators, more comprehensive testing including genotoxicity and implantation studies becomes necessary.

Electrical safety standards present another critical dimension for electrode-integrated soft actuators. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment. Specific considerations include leakage current limitations, electrical isolation, and protection against electric shock. The unique nature of soft actuators, with their flexible structures and potential for fluid infiltration, requires special attention to maintaining electrical safety under deformation conditions.

Long-term stability testing protocols must address the dynamic nature of soft pneumatic actuators. Standards should evaluate electrode performance under repeated actuation cycles, assessing potential degradation of conductive pathways, delamination risks, and changes in electrical properties over time. Current standards often require adaptation to account for the unique mechanical properties of soft systems.

Regulatory pathways vary by region, with the FDA in the United States requiring premarket approval or 510(k) clearance depending on device classification. In Europe, compliance with Medical Device Regulation (MDR) is mandatory, with soft actuators typically classified based on their intended use and invasiveness level. Documentation of biocompatibility and safety testing forms a crucial component of regulatory submissions across all major markets.

Material selection represents a critical consideration in meeting biocompatibility requirements. Silicone elastomers like polydimethylsiloxane (PDMS) have emerged as preferred materials due to their low toxicity and minimal inflammatory response. However, electrode materials present additional challenges, as conductive components must maintain functionality without leaching harmful substances. Biocompatible conductive materials such as gold, platinum, and certain carbon-based composites have demonstrated promising results in recent studies.

Cytotoxicity testing according to ISO 10993-5 is essential for soft actuators with electrode components. These tests evaluate whether materials release substances that could damage cellular structures. Additionally, sensitization and irritation assessments (ISO 10993-10) help determine potential allergic reactions when devices contact skin or mucous membranes. For implantable soft actuators, more comprehensive testing including genotoxicity and implantation studies becomes necessary.

Electrical safety standards present another critical dimension for electrode-integrated soft actuators. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment. Specific considerations include leakage current limitations, electrical isolation, and protection against electric shock. The unique nature of soft actuators, with their flexible structures and potential for fluid infiltration, requires special attention to maintaining electrical safety under deformation conditions.

Long-term stability testing protocols must address the dynamic nature of soft pneumatic actuators. Standards should evaluate electrode performance under repeated actuation cycles, assessing potential degradation of conductive pathways, delamination risks, and changes in electrical properties over time. Current standards often require adaptation to account for the unique mechanical properties of soft systems.

Regulatory pathways vary by region, with the FDA in the United States requiring premarket approval or 510(k) clearance depending on device classification. In Europe, compliance with Medical Device Regulation (MDR) is mandatory, with soft actuators typically classified based on their intended use and invasiveness level. Documentation of biocompatibility and safety testing forms a crucial component of regulatory submissions across all major markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!