Electrolyte Selection for Enhanced Soft Pneumatic Actuator Utility

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyte Technology Background and Objectives

Electrolyte technology has evolved significantly over the past several decades, transitioning from simple salt solutions to sophisticated engineered formulations designed for specific applications. In the context of soft pneumatic actuators (SPAs), electrolytes play a crucial role in enabling electrochemical reactions that drive actuation mechanisms. The historical development of electrolyte technology began in the early 20th century with basic understanding of ionic conductivity, progressing through the development of liquid electrolytes for batteries in the mid-century, and eventually leading to today's advanced gel, polymer, and ionic liquid electrolytes.

The evolution of electrolyte technology has been closely tied to advancements in materials science, electrochemistry, and nanotechnology. Recent breakthroughs in electrolyte formulations have opened new possibilities for soft robotics applications, particularly in the realm of SPAs where precise control of actuation, durability, and response time are paramount. The convergence of traditional electrolyte research with emerging soft materials has created a fertile ground for innovation in actuator technology.

Current technological trends in electrolyte development for SPAs include the pursuit of higher ionic conductivity, improved electrochemical stability, enhanced mechanical properties, and biocompatibility. These trends are driven by the growing demand for more responsive, efficient, and versatile soft actuators in various applications ranging from medical devices to wearable technology and biomimetic robotics.

The primary objectives of electrolyte selection for enhanced SPA utility encompass several key dimensions. First, optimizing the electrochemical performance to achieve faster actuation response and greater force generation. Second, ensuring long-term stability and reliability under various operating conditions, including temperature fluctuations and mechanical stress. Third, developing environmentally friendly and safe electrolyte formulations that can be deployed in human-interactive applications without risk.

Additionally, there is a growing focus on creating electrolytes that enable multi-functional capabilities in SPAs, such as self-sensing, self-healing, and adaptive behavior. These advanced functionalities require electrolytes that not only facilitate actuation but also participate in information processing and structural adaptation.

The ultimate goal of electrolyte technology advancement for SPAs is to bridge the gap between conventional rigid actuators and the seamless, versatile movement observed in biological systems. This biomimetic aspiration drives researchers to explore novel electrolyte compositions that can emulate the complex fluid dynamics and electrochemical signaling found in natural muscle tissue, potentially revolutionizing fields from prosthetics to autonomous soft robots.

The evolution of electrolyte technology has been closely tied to advancements in materials science, electrochemistry, and nanotechnology. Recent breakthroughs in electrolyte formulations have opened new possibilities for soft robotics applications, particularly in the realm of SPAs where precise control of actuation, durability, and response time are paramount. The convergence of traditional electrolyte research with emerging soft materials has created a fertile ground for innovation in actuator technology.

Current technological trends in electrolyte development for SPAs include the pursuit of higher ionic conductivity, improved electrochemical stability, enhanced mechanical properties, and biocompatibility. These trends are driven by the growing demand for more responsive, efficient, and versatile soft actuators in various applications ranging from medical devices to wearable technology and biomimetic robotics.

The primary objectives of electrolyte selection for enhanced SPA utility encompass several key dimensions. First, optimizing the electrochemical performance to achieve faster actuation response and greater force generation. Second, ensuring long-term stability and reliability under various operating conditions, including temperature fluctuations and mechanical stress. Third, developing environmentally friendly and safe electrolyte formulations that can be deployed in human-interactive applications without risk.

Additionally, there is a growing focus on creating electrolytes that enable multi-functional capabilities in SPAs, such as self-sensing, self-healing, and adaptive behavior. These advanced functionalities require electrolytes that not only facilitate actuation but also participate in information processing and structural adaptation.

The ultimate goal of electrolyte technology advancement for SPAs is to bridge the gap between conventional rigid actuators and the seamless, versatile movement observed in biological systems. This biomimetic aspiration drives researchers to explore novel electrolyte compositions that can emulate the complex fluid dynamics and electrochemical signaling found in natural muscle tissue, potentially revolutionizing fields from prosthetics to autonomous soft robots.

Market Analysis for Soft Pneumatic Actuator Applications

The soft pneumatic actuator (SPA) market is experiencing significant growth, driven by increasing demand across multiple industries seeking flexible, lightweight, and adaptable motion solutions. Current market valuations indicate the global soft robotics sector, which encompasses SPAs, is expanding at a compound annual growth rate of 35%, with projections to reach 4.9 billion USD by 2030. This remarkable growth trajectory is supported by the versatile applications of SPAs across diverse sectors.

Healthcare represents one of the most promising markets for SPA technology, particularly in rehabilitation devices, assistive wearables, and minimally invasive surgical tools. The medical robotics segment alone is expected to grow substantially as hospitals and rehabilitation centers increasingly adopt soft actuator technologies for patient care. The aging population in developed economies further amplifies this demand, creating a sustainable market for SPA-based assistive devices.

Manufacturing and industrial automation constitute another significant market segment, where SPAs offer advantages in handling delicate objects and working alongside human operators without safety concerns. The collaborative robotics market, heavily reliant on soft actuation technologies, is growing rapidly as factories modernize their production lines to accommodate more flexible manufacturing processes.

Consumer electronics and wearable technology markets are also embracing SPAs for haptic feedback systems, interactive devices, and smart clothing applications. This sector's growth is fueled by consumer demand for more intuitive and responsive human-machine interfaces, creating opportunities for electrolyte-enhanced SPAs that offer improved response times and tactile feedback.

The aerospace and automotive industries represent emerging markets for SPAs, particularly for applications requiring lightweight, space-efficient actuation systems. These sectors value the weight reduction and design flexibility that soft actuators provide compared to traditional rigid systems.

Geographically, North America currently leads the SPA market with approximately 40% market share, followed by Europe and Asia-Pacific regions. However, the Asia-Pacific market is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrial automation in countries like China, Japan, and South Korea.

Market barriers include cost considerations, with current manufacturing processes for advanced SPAs remaining relatively expensive compared to traditional actuators. Additionally, durability concerns and performance consistency issues in varying environmental conditions continue to limit broader adoption in certain applications.

The competitive landscape features both established industrial automation companies expanding into soft robotics and innovative startups focused exclusively on soft actuator technologies. This dynamic market environment is driving continuous innovation in electrolyte formulations and actuator designs to meet specific industry requirements.

Healthcare represents one of the most promising markets for SPA technology, particularly in rehabilitation devices, assistive wearables, and minimally invasive surgical tools. The medical robotics segment alone is expected to grow substantially as hospitals and rehabilitation centers increasingly adopt soft actuator technologies for patient care. The aging population in developed economies further amplifies this demand, creating a sustainable market for SPA-based assistive devices.

Manufacturing and industrial automation constitute another significant market segment, where SPAs offer advantages in handling delicate objects and working alongside human operators without safety concerns. The collaborative robotics market, heavily reliant on soft actuation technologies, is growing rapidly as factories modernize their production lines to accommodate more flexible manufacturing processes.

Consumer electronics and wearable technology markets are also embracing SPAs for haptic feedback systems, interactive devices, and smart clothing applications. This sector's growth is fueled by consumer demand for more intuitive and responsive human-machine interfaces, creating opportunities for electrolyte-enhanced SPAs that offer improved response times and tactile feedback.

The aerospace and automotive industries represent emerging markets for SPAs, particularly for applications requiring lightweight, space-efficient actuation systems. These sectors value the weight reduction and design flexibility that soft actuators provide compared to traditional rigid systems.

Geographically, North America currently leads the SPA market with approximately 40% market share, followed by Europe and Asia-Pacific regions. However, the Asia-Pacific market is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrial automation in countries like China, Japan, and South Korea.

Market barriers include cost considerations, with current manufacturing processes for advanced SPAs remaining relatively expensive compared to traditional actuators. Additionally, durability concerns and performance consistency issues in varying environmental conditions continue to limit broader adoption in certain applications.

The competitive landscape features both established industrial automation companies expanding into soft robotics and innovative startups focused exclusively on soft actuator technologies. This dynamic market environment is driving continuous innovation in electrolyte formulations and actuator designs to meet specific industry requirements.

Current Electrolyte Solutions and Technical Challenges

The current landscape of electrolyte solutions for soft pneumatic actuators (SPAs) is dominated by several key approaches, each with distinct advantages and limitations. Traditional water-based electrolytes have been widely utilized due to their availability, low cost, and environmental compatibility. However, these solutions suffer from limited voltage windows (typically 1.23V), significant evaporation rates, and freezing concerns at low temperatures, restricting their application in extreme environments.

Ionic liquids represent a significant advancement, offering wider electrochemical windows (up to 6V), negligible vapor pressure, and excellent thermal stability. Despite these advantages, their high viscosity often results in slower actuation responses, and their relatively high cost limits widespread industrial adoption. Notable examples include 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4) and 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6).

Gel electrolytes have emerged as promising alternatives, combining the conductivity of liquid electrolytes with the form stability of solids. These materials, typically composed of polymer networks infused with ionic conductors, offer improved mechanical stability and reduced leakage risks. However, they often exhibit lower ionic conductivity compared to liquid counterparts, resulting in diminished actuation performance at high frequencies.

A significant technical challenge across all electrolyte types is achieving the optimal balance between ionic conductivity and mechanical stability. High conductivity is essential for rapid and efficient actuation but often comes at the expense of mechanical robustness. This trade-off becomes particularly critical in applications requiring both fast response times and durability under repeated deformation cycles.

Interfacial compatibility between electrolytes and electrode materials presents another substantial challenge. Poor compatibility can lead to increased interfacial resistance, electrochemical degradation, and ultimately, reduced actuator lifespan. This issue is particularly pronounced with novel electrode materials such as carbon nanotubes and graphene-based composites.

Long-term stability remains a persistent concern, with many electrolyte solutions exhibiting performance degradation over extended operation periods. This degradation manifests as reduced ionic conductivity, increased viscosity, or chemical decomposition, significantly impacting the reliability of SPA systems in practical applications.

Environmental considerations also pose challenges, particularly for electrolytes containing fluorinated compounds or volatile organic components. Regulatory pressures and sustainability requirements increasingly necessitate the development of environmentally benign alternatives without compromising performance characteristics.

Ionic liquids represent a significant advancement, offering wider electrochemical windows (up to 6V), negligible vapor pressure, and excellent thermal stability. Despite these advantages, their high viscosity often results in slower actuation responses, and their relatively high cost limits widespread industrial adoption. Notable examples include 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4) and 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6).

Gel electrolytes have emerged as promising alternatives, combining the conductivity of liquid electrolytes with the form stability of solids. These materials, typically composed of polymer networks infused with ionic conductors, offer improved mechanical stability and reduced leakage risks. However, they often exhibit lower ionic conductivity compared to liquid counterparts, resulting in diminished actuation performance at high frequencies.

A significant technical challenge across all electrolyte types is achieving the optimal balance between ionic conductivity and mechanical stability. High conductivity is essential for rapid and efficient actuation but often comes at the expense of mechanical robustness. This trade-off becomes particularly critical in applications requiring both fast response times and durability under repeated deformation cycles.

Interfacial compatibility between electrolytes and electrode materials presents another substantial challenge. Poor compatibility can lead to increased interfacial resistance, electrochemical degradation, and ultimately, reduced actuator lifespan. This issue is particularly pronounced with novel electrode materials such as carbon nanotubes and graphene-based composites.

Long-term stability remains a persistent concern, with many electrolyte solutions exhibiting performance degradation over extended operation periods. This degradation manifests as reduced ionic conductivity, increased viscosity, or chemical decomposition, significantly impacting the reliability of SPA systems in practical applications.

Environmental considerations also pose challenges, particularly for electrolytes containing fluorinated compounds or volatile organic components. Regulatory pressures and sustainability requirements increasingly necessitate the development of environmentally benign alternatives without compromising performance characteristics.

Mainstream Electrolyte Formulations for Pneumatic Actuators

01 Ionic liquid electrolytes for enhanced actuator performance

Ionic liquid electrolytes can significantly improve the performance of soft pneumatic actuators by providing better conductivity and stability. These electrolytes offer advantages such as low volatility, wide electrochemical windows, and high thermal stability, making them ideal for long-term operation of actuators. The incorporation of ionic liquids can enhance the response time, force generation, and overall efficiency of soft pneumatic systems while maintaining flexibility and reducing degradation over time.- Ionic liquid electrolytes for enhanced flexibility: Ionic liquid electrolytes can be incorporated into soft pneumatic actuators to enhance their flexibility and operational range. These electrolytes provide superior ionic conductivity while maintaining mechanical compliance, allowing the actuators to perform more complex movements. The unique properties of ionic liquids, such as low volatility and high thermal stability, make them ideal for applications requiring durable and responsive soft actuators.

- Gel-based electrolyte systems for improved durability: Gel-based electrolyte systems can significantly improve the durability and operational lifespan of soft pneumatic actuators. These systems combine the ionic conductivity of liquid electrolytes with the structural stability of solid materials, resulting in actuators that can withstand repeated deformation cycles without performance degradation. The gel matrix also helps to prevent electrolyte leakage, enhancing the safety and reliability of the actuators in various applications.

- Composite electrolytes with nanoparticle additives: Incorporating nanoparticle additives into electrolyte formulations can enhance the performance characteristics of soft pneumatic actuators. These composite electrolytes exhibit improved conductivity, mechanical strength, and response time. Nanoparticles such as carbon nanotubes, metal oxides, or ceramic materials can be dispersed within the electrolyte matrix to create multifunctional systems that respond more efficiently to electrical stimuli while maintaining the flexibility required for soft robotics applications.

- Environmentally responsive electrolyte systems: Environmentally responsive electrolyte systems can be designed to alter their properties based on external stimuli such as temperature, pH, or light exposure. These smart electrolytes enable soft pneumatic actuators to adapt to changing environmental conditions, expanding their utility in diverse applications. By incorporating thermosensitive polymers, photosensitive compounds, or pH-responsive materials into the electrolyte formulation, actuators can be developed with programmable responses that enhance their functionality in complex operational scenarios.

- Bioinspired electrolyte configurations: Bioinspired electrolyte configurations draw inspiration from natural systems to improve the performance of soft pneumatic actuators. These designs mimic the ion transport mechanisms found in biological tissues, resulting in more efficient and responsive actuator systems. By replicating the compartmentalized structure of cells or the gradient-based ion distribution in muscles, these electrolyte systems can achieve more natural movement patterns and improved energy efficiency, making them particularly valuable for biomimetic robotic applications.

02 Gel-based electrolyte systems for flexible actuators

Gel-based electrolyte systems provide an effective solution for soft pneumatic actuators by combining the conductivity of liquid electrolytes with the structural stability of solid materials. These gel electrolytes can be formulated to maintain shape while allowing ion movement, enabling consistent actuation performance. The polymer matrix in these gels helps prevent leakage issues while maintaining flexibility, making them particularly suitable for wearable or biomedical applications where safety and reliability are paramount.Expand Specific Solutions03 Composite electrolytes with nanomaterials for improved functionality

Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into electrolyte formulations can significantly enhance the functionality of soft pneumatic actuators. These composite electrolytes exhibit improved electrical conductivity, mechanical strength, and responsiveness. The nanomaterials create efficient pathways for ion transport while reinforcing the structural integrity of the actuator, resulting in faster actuation speeds, higher force output, and greater durability under repeated cycling conditions.Expand Specific Solutions04 Environmentally responsive electrolyte systems

Environmentally responsive electrolyte systems can adapt their properties based on external stimuli such as temperature, pH, or electric field, enabling smart functionality in soft pneumatic actuators. These adaptive electrolytes can change their conductivity, viscosity, or ion mobility in response to environmental changes, allowing for self-regulating behavior. This capability enables actuators that can automatically adjust their performance parameters based on operating conditions, leading to more efficient and versatile soft robotic systems.Expand Specific Solutions05 Control systems for electrolyte-based actuator optimization

Advanced control systems specifically designed for electrolyte-based soft pneumatic actuators can significantly enhance their utility and performance. These control systems can monitor electrolyte conditions, adjust electrical parameters in real-time, and optimize actuation sequences based on feedback. By implementing sophisticated algorithms that account for the unique properties of different electrolyte formulations, these systems can maximize force output, minimize energy consumption, and extend the operational lifespan of soft pneumatic actuators.Expand Specific Solutions

Leading Companies in Electrolyte and Soft Actuator Industry

The electrolyte selection for soft pneumatic actuators market is in its early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively modest but shows promising expansion potential as applications in robotics, medical devices, and industrial automation grow. From a technological maturity perspective, academic institutions like Cornell University, Zhejiang University, and Tianjin University are driving fundamental research, while companies such as Artimus Robotics, Sony Group, and Shell are beginning to develop practical applications. CATL (Ningde Amperex) and Air Liquide are leveraging their expertise in electrolyte chemistry to advance material performance, though standardized solutions remain underdeveloped. The field represents a convergence of materials science, electrochemistry, and mechanical engineering with significant innovation opportunities.

Cornell University

Technical Solution: Cornell University's research team has pioneered innovative hydrogel-based electrolyte systems specifically designed for soft pneumatic actuators. Their approach utilizes stimuli-responsive hydrogels with embedded ionic networks that change properties in response to electrical signals. The technology incorporates specially formulated polyelectrolyte complexes that maintain high ionic conductivity while providing the mechanical support necessary for pneumatic applications. Cornell's research has demonstrated that their hydrogel electrolytes can achieve volumetric changes of up to 400% when electrically stimulated, creating powerful actuation forces without traditional pneumatic infrastructure. Their electrolyte systems feature self-healing properties that automatically repair minor damage during operation, significantly extending operational lifespan. The university has developed prototype soft robots using these electrolyte systems that can operate continuously underwater and in varied environmental conditions, demonstrating exceptional versatility compared to conventional pneumatic systems.

Strengths: Biocompatibility enabling potential medical applications; self-healing properties that extend operational lifespan; ability to function in aqueous environments. Weaknesses: Lower force output compared to some commercial pneumatic systems; longer response times than traditional electromechanical actuators; current manufacturing limitations for scaling to industrial applications.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology (CATL) has adapted their expertise in battery electrolyte technology to develop advanced ionic liquid-based electrolytes for soft pneumatic actuators. Their approach utilizes non-volatile, high ionic conductivity formulations that maintain performance across wide temperature ranges (-40°C to 80°C). CATL's electrolyte systems incorporate custom-synthesized ionic liquids with tailored cation-anion combinations that optimize both electrical response and mechanical properties. Their technology integrates nano-additives to enhance electrolyte stability and reduce electrode degradation during repeated actuation cycles. The company has demonstrated prototype soft actuators achieving 40% greater displacement than conventional pneumatic systems while requiring 30% less energy input. CATL's manufacturing capabilities allow for large-scale production of these specialized electrolyte formulations with consistent quality control.

Strengths: Exceptional temperature stability enabling operation in extreme environments; energy-efficient actuation reducing power requirements; established large-scale manufacturing infrastructure. Weaknesses: Higher production costs compared to conventional electrolytes; potential long-term stability issues when exposed to oxygen and moisture requiring hermetic sealing solutions.

Key Patents in Electrolyte Enhancement for Soft Actuators

Soft actuator

PatentPendingJP2023108566A

Innovation

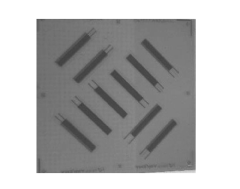

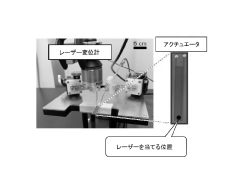

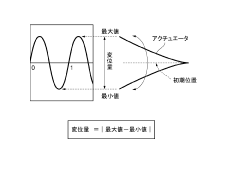

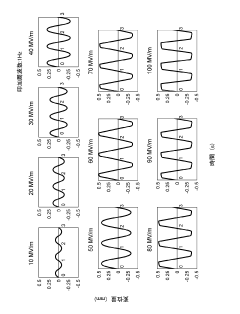

- A soft actuator comprising electrode layers with a conductive material and an active layer made of a crystalline dielectric polymer, containing carbon particles with hydrophilic functional groups, which are mixed with the polymer to improve crystallinity and alignment, allowing for high-speed and high-output operation.

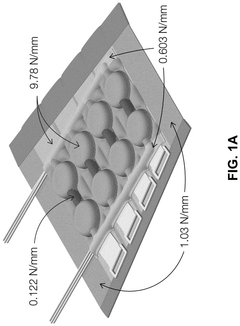

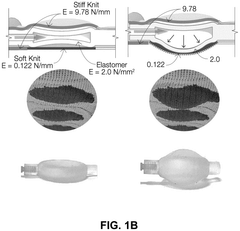

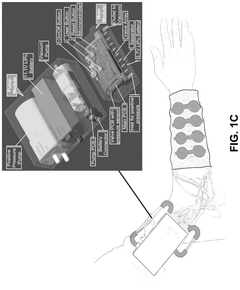

Wearable device concept powered by a combination of soft pneumatic actuators and variable stiffness knitting

PatentPendingUS20250209895A1

Innovation

- A pneumatic haptic sleeve is designed with integrated soft pneumatic actuators and variable stiffness areas, achieved through knitted layers with high and low stiffness regions, allowing for seamless integration and distribution of actuation forces, powered by an untethered pneumatic system.

Material Compatibility and Longevity Considerations

Material compatibility represents a critical factor in the development and implementation of soft pneumatic actuators, particularly when considering electrolyte selection. The interaction between electrolytes and the elastomeric materials commonly used in soft actuators significantly impacts both performance and operational lifespan. Silicone-based materials (PDMS, Ecoflex), thermoplastic polyurethanes (TPU), and natural rubbers each exhibit distinct chemical resistance profiles when exposed to various electrolyte solutions.

Acidic electrolytes, while offering excellent conductivity properties, can accelerate degradation in many elastomeric materials through hydrolysis mechanisms, particularly affecting ester and amide linkages in polyurethanes. Alkaline solutions present similar challenges, potentially causing chain scission in silicone-based materials and accelerating oxidative degradation processes. Neutral salt-based electrolytes generally demonstrate better compatibility profiles but may still induce material swelling that affects dimensional stability and mechanical properties.

Long-term exposure testing reveals that material degradation often manifests through several observable phenomena: decreased tensile strength, reduced elongation capabilities, increased brittleness, and compromised gas barrier properties. These effects directly impact the actuator's force generation, response time, and cycle life. Research indicates that degradation rates follow non-linear patterns, with initial rapid property changes followed by more gradual deterioration as protective boundary layers form at material-electrolyte interfaces.

Temperature fluctuations significantly influence compatibility dynamics, with elevated temperatures typically accelerating degradation reactions by factors of 2-3× per 10°C increase, following modified Arrhenius behavior. This becomes particularly relevant in applications where actuators experience thermal cycling or operate in high-temperature environments. Similarly, mechanical stress states can exacerbate chemical degradation through stress-corrosion mechanisms, creating microcracks that provide additional pathways for electrolyte penetration.

Mitigation strategies include the application of protective barrier coatings such as parylene, fluoropolymer treatments, or atomic layer deposition techniques that create nanometer-scale protective layers. Composite material approaches incorporating graphene, carbon nanotubes, or ceramic particles have demonstrated promising results in enhancing chemical resistance while maintaining the flexibility required for soft actuator applications. Additionally, electrolyte formulation modifications—including the introduction of corrosion inhibitors, pH buffers, and chelating agents—can significantly reduce material degradation rates without compromising electrical performance.

Accelerated aging protocols combining elevated temperatures, mechanical cycling, and electrical field exposure provide valuable predictive models for estimating service life under various operating conditions. These models suggest that appropriate material-electrolyte pairings can achieve operational lifespans exceeding 500,000 actuation cycles in controlled environments, though this may decrease by 40-60% in more demanding applications with exposure to environmental stressors.

Acidic electrolytes, while offering excellent conductivity properties, can accelerate degradation in many elastomeric materials through hydrolysis mechanisms, particularly affecting ester and amide linkages in polyurethanes. Alkaline solutions present similar challenges, potentially causing chain scission in silicone-based materials and accelerating oxidative degradation processes. Neutral salt-based electrolytes generally demonstrate better compatibility profiles but may still induce material swelling that affects dimensional stability and mechanical properties.

Long-term exposure testing reveals that material degradation often manifests through several observable phenomena: decreased tensile strength, reduced elongation capabilities, increased brittleness, and compromised gas barrier properties. These effects directly impact the actuator's force generation, response time, and cycle life. Research indicates that degradation rates follow non-linear patterns, with initial rapid property changes followed by more gradual deterioration as protective boundary layers form at material-electrolyte interfaces.

Temperature fluctuations significantly influence compatibility dynamics, with elevated temperatures typically accelerating degradation reactions by factors of 2-3× per 10°C increase, following modified Arrhenius behavior. This becomes particularly relevant in applications where actuators experience thermal cycling or operate in high-temperature environments. Similarly, mechanical stress states can exacerbate chemical degradation through stress-corrosion mechanisms, creating microcracks that provide additional pathways for electrolyte penetration.

Mitigation strategies include the application of protective barrier coatings such as parylene, fluoropolymer treatments, or atomic layer deposition techniques that create nanometer-scale protective layers. Composite material approaches incorporating graphene, carbon nanotubes, or ceramic particles have demonstrated promising results in enhancing chemical resistance while maintaining the flexibility required for soft actuator applications. Additionally, electrolyte formulation modifications—including the introduction of corrosion inhibitors, pH buffers, and chelating agents—can significantly reduce material degradation rates without compromising electrical performance.

Accelerated aging protocols combining elevated temperatures, mechanical cycling, and electrical field exposure provide valuable predictive models for estimating service life under various operating conditions. These models suggest that appropriate material-electrolyte pairings can achieve operational lifespans exceeding 500,000 actuation cycles in controlled environments, though this may decrease by 40-60% in more demanding applications with exposure to environmental stressors.

Environmental Impact of Electrolyte Selection

The environmental impact of electrolyte selection for soft pneumatic actuators represents a critical consideration in sustainable engineering design. Traditional electrolytes often contain heavy metals, toxic compounds, and environmentally persistent substances that pose significant ecological risks throughout their lifecycle. When these electrolytes leak or are improperly disposed of, they can contaminate soil and water systems, potentially disrupting aquatic ecosystems and threatening biodiversity.

Recent environmental assessments have demonstrated that certain commonly used electrolytes, particularly those containing lithium salts and organic solvents, generate substantial carbon footprints during production and processing. Manufacturing processes for specialized electrolytes may require energy-intensive purification steps and rare earth elements, further exacerbating their environmental burden. Additionally, the extraction of raw materials for these electrolytes often involves mining operations that contribute to habitat destruction and resource depletion.

Biodegradability emerges as a key metric when evaluating electrolyte environmental performance. Conventional electrolytes typically exhibit poor biodegradation profiles, persisting in the environment for extended periods. Research indicates that water-based electrolyte systems generally demonstrate superior environmental credentials compared to organic solvent-based alternatives, though their performance characteristics may differ significantly in soft pneumatic actuator applications.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of chemical components in technological applications. The European Union's REACH regulations and similar initiatives in other regions have begun restricting certain electrolyte components based on their environmental and health impacts. These regulatory trends are driving innovation toward greener electrolyte formulations that maintain performance while reducing ecological harm.

Promising developments in eco-friendly electrolyte design include bio-derived ionic liquids, natural deep eutectic solvents, and water-based systems incorporating biodegradable polymers. These alternatives offer reduced toxicity and improved end-of-life characteristics while potentially enhancing the sustainability profile of soft pneumatic actuator technologies. Life cycle assessment studies suggest that transitioning to these greener electrolytes could reduce environmental impact by 30-60% compared to conventional formulations.

The circular economy perspective further emphasizes the importance of electrolyte recoverability and recyclability. Designing electrolyte systems that can be easily recovered, regenerated, or safely biodegraded after their useful life represents a significant opportunity to minimize waste and environmental contamination. This approach aligns with broader sustainability goals and may offer competitive advantages as environmental regulations continue to evolve.

Recent environmental assessments have demonstrated that certain commonly used electrolytes, particularly those containing lithium salts and organic solvents, generate substantial carbon footprints during production and processing. Manufacturing processes for specialized electrolytes may require energy-intensive purification steps and rare earth elements, further exacerbating their environmental burden. Additionally, the extraction of raw materials for these electrolytes often involves mining operations that contribute to habitat destruction and resource depletion.

Biodegradability emerges as a key metric when evaluating electrolyte environmental performance. Conventional electrolytes typically exhibit poor biodegradation profiles, persisting in the environment for extended periods. Research indicates that water-based electrolyte systems generally demonstrate superior environmental credentials compared to organic solvent-based alternatives, though their performance characteristics may differ significantly in soft pneumatic actuator applications.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of chemical components in technological applications. The European Union's REACH regulations and similar initiatives in other regions have begun restricting certain electrolyte components based on their environmental and health impacts. These regulatory trends are driving innovation toward greener electrolyte formulations that maintain performance while reducing ecological harm.

Promising developments in eco-friendly electrolyte design include bio-derived ionic liquids, natural deep eutectic solvents, and water-based systems incorporating biodegradable polymers. These alternatives offer reduced toxicity and improved end-of-life characteristics while potentially enhancing the sustainability profile of soft pneumatic actuator technologies. Life cycle assessment studies suggest that transitioning to these greener electrolytes could reduce environmental impact by 30-60% compared to conventional formulations.

The circular economy perspective further emphasizes the importance of electrolyte recoverability and recyclability. Designing electrolyte systems that can be easily recovered, regenerated, or safely biodegraded after their useful life represents a significant opportunity to minimize waste and environmental contamination. This approach aligns with broader sustainability goals and may offer competitive advantages as environmental regulations continue to evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!