Exploratory Study on Soft Pneumatic Actuator Sustainability

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Background and Objectives

Soft pneumatic actuators (SPAs) have emerged as a revolutionary technology in the field of robotics and automation over the past two decades. These flexible, compliant mechanisms utilize pneumatic pressure to generate motion and force, offering significant advantages over traditional rigid actuators in applications requiring safe human-machine interaction, adaptability to irregular surfaces, and biomimetic movement patterns. The evolution of SPAs can be traced back to the early 2000s, with significant acceleration in research and development occurring after 2010 when advanced manufacturing techniques like 3D printing became more accessible.

The technological trajectory of SPAs has been characterized by progressive improvements in materials, design methodologies, and control systems. Initially developed using simple elastomeric materials like silicone rubber, contemporary SPAs now incorporate advanced composite structures, fiber reinforcements, and multi-material designs that significantly enhance performance characteristics including force output, response time, and operational lifespan.

Current research trends indicate a growing focus on sustainability aspects of SPA technology, addressing critical challenges related to material selection, energy efficiency, end-of-life considerations, and manufacturing processes. This shift reflects broader industry movements toward environmentally responsible engineering practices and circular economy principles in technological development.

The primary objectives of this exploratory study on SPA sustainability are multifaceted. First, to comprehensively assess the environmental impact of current SPA designs across their complete lifecycle, from raw material extraction to disposal or recycling. Second, to identify critical sustainability bottlenecks in existing SPA technologies, particularly concerning material degradation, energy consumption during operation, and recyclability challenges.

Third, to evaluate potential alternative materials and design approaches that could enhance the sustainability profile of SPAs without compromising their functional performance. Fourth, to develop quantitative metrics and assessment frameworks specifically tailored for evaluating SPA sustainability, enabling meaningful comparisons between different design approaches and technologies.

Finally, this study aims to establish a roadmap for future research and development efforts focused on creating next-generation sustainable soft pneumatic actuators. This roadmap will outline promising research directions, potential technological breakthroughs, and implementation strategies for industry adoption of more sustainable SPA technologies.

The significance of this research extends beyond academic interest, as SPAs are increasingly being integrated into commercial applications across healthcare, manufacturing, and consumer products. Establishing sustainability as a core design consideration at this relatively early stage of technology maturation could significantly influence the long-term environmental impact of this emerging field.

The technological trajectory of SPAs has been characterized by progressive improvements in materials, design methodologies, and control systems. Initially developed using simple elastomeric materials like silicone rubber, contemporary SPAs now incorporate advanced composite structures, fiber reinforcements, and multi-material designs that significantly enhance performance characteristics including force output, response time, and operational lifespan.

Current research trends indicate a growing focus on sustainability aspects of SPA technology, addressing critical challenges related to material selection, energy efficiency, end-of-life considerations, and manufacturing processes. This shift reflects broader industry movements toward environmentally responsible engineering practices and circular economy principles in technological development.

The primary objectives of this exploratory study on SPA sustainability are multifaceted. First, to comprehensively assess the environmental impact of current SPA designs across their complete lifecycle, from raw material extraction to disposal or recycling. Second, to identify critical sustainability bottlenecks in existing SPA technologies, particularly concerning material degradation, energy consumption during operation, and recyclability challenges.

Third, to evaluate potential alternative materials and design approaches that could enhance the sustainability profile of SPAs without compromising their functional performance. Fourth, to develop quantitative metrics and assessment frameworks specifically tailored for evaluating SPA sustainability, enabling meaningful comparisons between different design approaches and technologies.

Finally, this study aims to establish a roadmap for future research and development efforts focused on creating next-generation sustainable soft pneumatic actuators. This roadmap will outline promising research directions, potential technological breakthroughs, and implementation strategies for industry adoption of more sustainable SPA technologies.

The significance of this research extends beyond academic interest, as SPAs are increasingly being integrated into commercial applications across healthcare, manufacturing, and consumer products. Establishing sustainability as a core design consideration at this relatively early stage of technology maturation could significantly influence the long-term environmental impact of this emerging field.

Market Analysis for Sustainable Soft Robotics

The sustainable soft robotics market is experiencing significant growth driven by increasing environmental concerns and the need for eco-friendly automation solutions. Current market size estimates place the global soft robotics sector at approximately $1.5 billion, with sustainable variants representing a growing segment projected to reach $500 million by 2025. The compound annual growth rate for sustainable soft pneumatic actuators specifically is outpacing traditional pneumatic systems, demonstrating market recognition of their environmental benefits.

Key market drivers include stringent environmental regulations across industrial sectors, particularly in Europe and North America, which are pushing manufacturers to adopt more sustainable automation technologies. Additionally, consumer-facing industries are increasingly prioritizing green credentials in their production processes, creating demand for environmentally responsible robotic solutions.

Healthcare represents the largest application sector for sustainable soft pneumatic actuators, valued at roughly $180 million, with applications in rehabilitation devices, surgical assistants, and prosthetics. The biomedical sector particularly values biodegradable and biocompatible materials used in sustainable actuators. Manufacturing follows closely as the second-largest market, where soft pneumatic systems are replacing conventional rigid automation in assembly and handling operations.

Regional analysis reveals Europe leading the sustainable soft robotics market with approximately 38% market share, driven by strict environmental policies and substantial research funding. North America follows at 32%, with Asia-Pacific representing the fastest-growing region at a projected 24% annual growth rate, particularly in Japan, South Korea, and Singapore where government initiatives actively support green technology development.

Customer segmentation shows three primary buyer groups: research institutions (25% of market), industrial manufacturers (45%), and healthcare providers (30%). Each segment demonstrates distinct purchasing behaviors and adoption timelines, with research institutions typically serving as early adopters while industrial implementation follows a more conservative adoption curve.

Market challenges include price sensitivity, as sustainable variants currently command a 15-30% premium over conventional pneumatic actuators, creating adoption barriers particularly among small and medium enterprises. Additionally, performance perception issues persist, with some potential customers expressing concerns about durability and reliability of bio-based materials in industrial applications.

Future market projections indicate accelerating adoption as manufacturing scale increases and material costs decrease. The convergence of sustainability demands with performance improvements is expected to expand market penetration across additional sectors including agriculture, food processing, and consumer robotics within the next five years.

Key market drivers include stringent environmental regulations across industrial sectors, particularly in Europe and North America, which are pushing manufacturers to adopt more sustainable automation technologies. Additionally, consumer-facing industries are increasingly prioritizing green credentials in their production processes, creating demand for environmentally responsible robotic solutions.

Healthcare represents the largest application sector for sustainable soft pneumatic actuators, valued at roughly $180 million, with applications in rehabilitation devices, surgical assistants, and prosthetics. The biomedical sector particularly values biodegradable and biocompatible materials used in sustainable actuators. Manufacturing follows closely as the second-largest market, where soft pneumatic systems are replacing conventional rigid automation in assembly and handling operations.

Regional analysis reveals Europe leading the sustainable soft robotics market with approximately 38% market share, driven by strict environmental policies and substantial research funding. North America follows at 32%, with Asia-Pacific representing the fastest-growing region at a projected 24% annual growth rate, particularly in Japan, South Korea, and Singapore where government initiatives actively support green technology development.

Customer segmentation shows three primary buyer groups: research institutions (25% of market), industrial manufacturers (45%), and healthcare providers (30%). Each segment demonstrates distinct purchasing behaviors and adoption timelines, with research institutions typically serving as early adopters while industrial implementation follows a more conservative adoption curve.

Market challenges include price sensitivity, as sustainable variants currently command a 15-30% premium over conventional pneumatic actuators, creating adoption barriers particularly among small and medium enterprises. Additionally, performance perception issues persist, with some potential customers expressing concerns about durability and reliability of bio-based materials in industrial applications.

Future market projections indicate accelerating adoption as manufacturing scale increases and material costs decrease. The convergence of sustainability demands with performance improvements is expected to expand market penetration across additional sectors including agriculture, food processing, and consumer robotics within the next five years.

Current Challenges in Eco-friendly Pneumatic Actuators

The development of eco-friendly pneumatic actuators faces significant challenges despite growing interest in sustainable soft robotics. Traditional pneumatic actuators typically rely on materials like silicone elastomers, which are petroleum-based and non-biodegradable, contributing to environmental pollution throughout their lifecycle. These conventional materials can persist in the environment for hundreds of years, creating substantial waste management issues.

Material selection represents one of the most critical challenges in developing sustainable soft pneumatic actuators. Current biodegradable alternatives often exhibit inferior mechanical properties compared to conventional elastomers, including lower durability, reduced flexibility, and compromised air retention capabilities. These limitations significantly restrict their practical applications in real-world scenarios where consistent performance is essential.

Manufacturing processes for eco-friendly actuators present another substantial hurdle. Traditional fabrication methods like molding and 3D printing often require high energy consumption and generate considerable waste. Additionally, the adhesives and bonding agents used in assembly frequently contain volatile organic compounds (VOCs) and other environmentally harmful substances, contradicting sustainability goals.

Energy efficiency during operation remains problematic for pneumatic systems generally. Conventional pneumatic actuators suffer from air leakage and inefficient pressure distribution, requiring continuous energy input to maintain performance. This inefficiency is often exacerbated when using biodegradable materials, which typically have higher porosity and lower air retention capabilities than synthetic alternatives.

End-of-life considerations pose particular difficulties for pneumatic actuator sustainability. Current recycling infrastructure is inadequately equipped to process composite materials commonly found in these devices. Even biodegradable options may require specific environmental conditions to decompose properly, conditions that standard waste management facilities rarely provide.

Cost factors significantly impede widespread adoption of sustainable pneumatic actuators. Eco-friendly materials and manufacturing processes generally command premium prices compared to conventional alternatives. This price differential creates substantial market barriers, particularly in cost-sensitive industries where immediate economic considerations often outweigh long-term environmental benefits.

Regulatory frameworks and standardization present additional challenges. The lack of unified sustainability metrics and certification standards for soft robotics materials creates uncertainty for manufacturers and consumers alike. This regulatory gap complicates efforts to validate environmental claims and establish meaningful benchmarks for truly sustainable pneumatic actuator solutions.

Material selection represents one of the most critical challenges in developing sustainable soft pneumatic actuators. Current biodegradable alternatives often exhibit inferior mechanical properties compared to conventional elastomers, including lower durability, reduced flexibility, and compromised air retention capabilities. These limitations significantly restrict their practical applications in real-world scenarios where consistent performance is essential.

Manufacturing processes for eco-friendly actuators present another substantial hurdle. Traditional fabrication methods like molding and 3D printing often require high energy consumption and generate considerable waste. Additionally, the adhesives and bonding agents used in assembly frequently contain volatile organic compounds (VOCs) and other environmentally harmful substances, contradicting sustainability goals.

Energy efficiency during operation remains problematic for pneumatic systems generally. Conventional pneumatic actuators suffer from air leakage and inefficient pressure distribution, requiring continuous energy input to maintain performance. This inefficiency is often exacerbated when using biodegradable materials, which typically have higher porosity and lower air retention capabilities than synthetic alternatives.

End-of-life considerations pose particular difficulties for pneumatic actuator sustainability. Current recycling infrastructure is inadequately equipped to process composite materials commonly found in these devices. Even biodegradable options may require specific environmental conditions to decompose properly, conditions that standard waste management facilities rarely provide.

Cost factors significantly impede widespread adoption of sustainable pneumatic actuators. Eco-friendly materials and manufacturing processes generally command premium prices compared to conventional alternatives. This price differential creates substantial market barriers, particularly in cost-sensitive industries where immediate economic considerations often outweigh long-term environmental benefits.

Regulatory frameworks and standardization present additional challenges. The lack of unified sustainability metrics and certification standards for soft robotics materials creates uncertainty for manufacturers and consumers alike. This regulatory gap complicates efforts to validate environmental claims and establish meaningful benchmarks for truly sustainable pneumatic actuator solutions.

Existing Sustainable Material Solutions for SPAs

01 Eco-friendly materials for soft pneumatic actuators

Sustainable materials are being incorporated into soft pneumatic actuator designs to reduce environmental impact. These include biodegradable polymers, recycled materials, and naturally derived elastomers that maintain the flexibility and functionality required for pneumatic operation while improving end-of-life disposal. These materials can be processed using conventional manufacturing techniques while offering reduced carbon footprint compared to traditional petroleum-based elastomers.- Eco-friendly materials for soft pneumatic actuators: Sustainable materials are being incorporated into soft pneumatic actuator designs to reduce environmental impact. These include biodegradable polymers, recycled materials, and naturally derived substances that maintain performance while improving end-of-life disposal. The use of these materials helps minimize the carbon footprint of pneumatic systems while maintaining the flexibility and functionality required for various applications.

- Energy-efficient pneumatic control systems: Advanced control systems are being developed to optimize the energy consumption of soft pneumatic actuators. These systems incorporate smart algorithms, precise pressure regulation, and energy recovery mechanisms to minimize air consumption and power requirements. By improving operational efficiency, these innovations extend the battery life of portable applications and reduce the overall energy footprint of pneumatic actuation systems.

- Lifecycle management and recyclability: Design approaches that consider the entire lifecycle of soft pneumatic actuators are emerging to improve sustainability. These include modular designs that facilitate repair and component replacement, disassembly-friendly construction methods, and material selection strategies that enable effective recycling. Such approaches extend the useful life of pneumatic systems and reduce waste generation through improved end-of-life management.

- Integration with renewable energy sources: Soft pneumatic actuator systems are being designed to operate with renewable energy sources to improve sustainability. These innovations include solar-powered compressors, energy harvesting mechanisms that capture ambient or waste energy, and low-pressure operation modes compatible with renewable energy constraints. By reducing dependence on grid electricity or fossil fuels, these systems offer more environmentally friendly operation.

- Sustainable manufacturing processes: Innovative manufacturing techniques are being developed to produce soft pneumatic actuators with reduced environmental impact. These include additive manufacturing methods that minimize material waste, water-based processing that reduces solvent use, and energy-efficient curing and molding techniques. These sustainable production approaches complement material and design innovations to create comprehensively eco-friendly pneumatic actuation solutions.

02 Energy-efficient pneumatic control systems

Advanced control systems are being developed to optimize the energy consumption of soft pneumatic actuators. These systems incorporate smart valves, pressure sensors, and feedback mechanisms that minimize air consumption and pressure losses. By implementing precise control algorithms and energy recovery techniques, these innovations significantly reduce the power requirements for pneumatic operation, extending battery life in portable applications and decreasing overall energy demands.Expand Specific Solutions03 Lifecycle assessment and circular design approaches

Research is focusing on comprehensive lifecycle assessments for soft pneumatic actuators, analyzing environmental impacts from raw material extraction through manufacturing, use, and disposal. Circular design principles are being applied to create actuators that can be easily disassembled, repaired, and recycled. This approach includes modular components, standardized connections, and design for disassembly techniques that extend product lifespan and facilitate material recovery at end-of-life.Expand Specific Solutions04 Self-healing and adaptive pneumatic systems

Innovative self-healing materials and adaptive designs are extending the operational lifespan of soft pneumatic actuators. These technologies incorporate materials that can automatically repair minor damage and wear, reducing the need for replacement. Adaptive systems can reconfigure their operation to compensate for performance degradation over time, maintaining efficiency despite aging. These approaches significantly reduce waste by delaying replacement and minimizing maintenance requirements.Expand Specific Solutions05 Integration with renewable energy sources

Soft pneumatic actuator systems are being designed to operate with renewable energy sources, reducing their carbon footprint. These designs include solar-powered compressors, energy harvesting mechanisms that capture ambient vibrations or thermal gradients, and integration with sustainable power storage solutions. By eliminating or reducing dependence on grid electricity or fossil fuels, these systems can operate in remote locations with minimal environmental impact while maintaining reliable performance.Expand Specific Solutions

Leading Organizations in Sustainable Soft Robotics

The soft pneumatic actuator sustainability landscape is currently in an early growth phase, characterized by increasing academic-industrial collaboration. The market, while still modest, shows promising expansion potential as sustainable materials and designs gain traction. From a technological maturity perspective, research institutions lead development efforts, with Harvard College, Zhejiang University, and Cornell University pioneering fundamental research. Companies like Moog, Inc., Beijing Soft Robot Technology, and Bioliberty Ltd. are beginning to commercialize applications, though significant gaps remain between laboratory innovations and market-ready sustainable solutions. The competitive landscape features strong academic research clusters in North America, Europe, and Asia, with emerging industrial players focusing on specialized applications in healthcare, manufacturing, and defense sectors.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered sustainable soft pneumatic actuators through their "Bioinspired Soft Robotics" program. Their technical approach focuses on biodegradable elastomers and environmentally friendly fabrication methods for soft actuators. They've developed a comprehensive sustainability framework that addresses material selection, manufacturing processes, and end-of-life considerations. Their proprietary "GreenSPA" technology utilizes plant-derived polymers and water-based manufacturing techniques to create soft pneumatic actuators with minimal environmental impact. The system incorporates closed-loop pneumatic systems that significantly reduce energy consumption during operation. Harvard researchers have also implemented life cycle assessment methodologies specifically tailored for soft robotic systems to quantify environmental impacts across the entire product lifecycle.

Strengths: World-leading expertise in bioinspired design principles; access to advanced fabrication facilities; interdisciplinary collaboration between materials scientists, roboticists, and environmental engineers. Weaknesses: Higher production costs compared to conventional actuators; current biodegradable materials have limited durability and performance characteristics compared to synthetic alternatives.

Zhejiang University

Technical Solution: Zhejiang University's Soft Robotics Research Center has developed the "GreenPneu" platform for sustainable soft pneumatic actuators. Their technical approach focuses on material innovation, energy-efficient design, and circular economy principles. The research team has created a series of biodegradable polyurethane elastomers specifically engineered for soft pneumatic applications, with controlled degradation rates ranging from 6 months to 5 years depending on application requirements. Their fabrication process employs solvent recovery systems that capture and reuse over 90% of chemical solvents, significantly reducing environmental impact and production costs. The university has pioneered multi-material 3D printing techniques that enable the creation of complex actuator geometries with optimized material distribution, reducing overall material consumption by up to 35%. Their pneumatic control architecture incorporates passive valving mechanisms that maintain desired actuation states with minimal continuous air supply, reducing operational energy requirements. Additionally, they've developed self-healing elastomer formulations that extend actuator lifespan by automatically repairing minor damage from repeated deformation cycles.

Strengths: Extensive materials research capabilities; strong integration of computational design with sustainable manufacturing; established partnerships with regional industries for technology transfer. Weaknesses: Biodegradable formulations currently exhibit lower maximum strain capabilities compared to conventional elastomers; self-healing mechanisms add complexity to recycling processes; higher initial production costs.

Key Innovations in Biodegradable Pneumatic Technologies

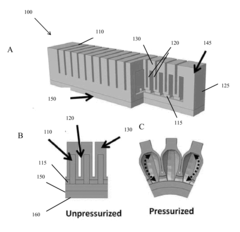

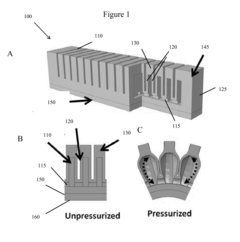

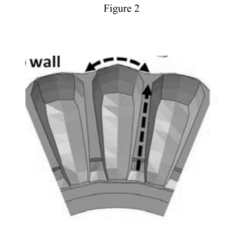

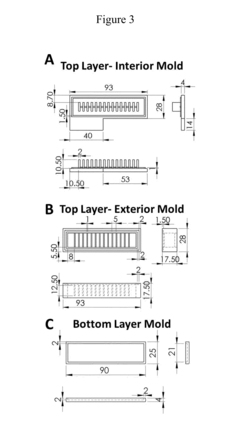

Low strain pneumatic networks for soft robots

PatentActiveUS20150266186A1

Innovation

- Design of pneumatic network actuators with freestanding chambers and a strain limiting base, where interior walls are more compliant than exterior walls, reducing strain and energy loss, and allowing for rapid actuation with minimal volume change, enabling high-speed operation and extended cycle life.

A silicone matrix based soft actuator

PatentActiveZA202213817B

Innovation

- A silicone matrix-based soft actuator with a nichrome coil and methanol or ethanol-methanol liquid phase molecules, which reacts to temperature changes, is developed using acetic-cured silicone, reducing costs and activation temperature, and allowing for efficient actuation in compact spaces.

Life Cycle Assessment of Soft Pneumatic Systems

Life Cycle Assessment (LCA) of soft pneumatic systems provides a comprehensive framework for evaluating the environmental impacts associated with these innovative actuators throughout their entire lifecycle. This assessment begins with raw material extraction, where elastomers like silicone rubber, thermoplastic polyurethanes (TPUs), and natural rubber are sourced through energy-intensive processes with varying environmental footprints. The manufacturing phase involves multiple energy-consuming steps including mixing, molding, curing, and assembly, with significant variations in energy efficiency and waste generation depending on production scale and technology employed.

During the operational phase, soft pneumatic actuators demonstrate notable sustainability advantages compared to conventional rigid actuators. Their inherent compliance reduces energy consumption by eliminating the need for complex control systems, while their lightweight nature decreases overall system mass and associated energy requirements. Furthermore, these systems typically operate at lower pressures (0.1-0.5 MPa) compared to traditional pneumatics, resulting in reduced compressed air consumption and associated energy savings.

The maintenance requirements for soft pneumatic systems present a mixed sustainability profile. While these actuators generally require less lubrication and fewer replacement parts than mechanical alternatives, their elastomeric materials may degrade over time due to environmental factors, potentially necessitating more frequent replacement of certain components. This degradation pattern varies significantly based on operating conditions and material selection.

End-of-life considerations reveal both challenges and opportunities. Current recycling infrastructure is poorly equipped to handle multi-material soft actuators, with elastomers particularly difficult to recycle effectively. However, emerging research demonstrates promising approaches for material recovery, including chemical recycling of silicones and mechanical recycling of thermoplastic elastomers. Biodegradable alternatives using natural rubber compounds or bio-based polymers are also under development.

Comparative LCA studies indicate that soft pneumatic systems generally outperform traditional rigid actuators in global warming potential and cumulative energy demand metrics, primarily due to reduced material intensity and operational efficiency. However, they may score less favorably in categories related to water usage and certain types of emissions associated with elastomer production. These trade-offs necessitate application-specific assessment to determine the most sustainable solution for particular use cases.

During the operational phase, soft pneumatic actuators demonstrate notable sustainability advantages compared to conventional rigid actuators. Their inherent compliance reduces energy consumption by eliminating the need for complex control systems, while their lightweight nature decreases overall system mass and associated energy requirements. Furthermore, these systems typically operate at lower pressures (0.1-0.5 MPa) compared to traditional pneumatics, resulting in reduced compressed air consumption and associated energy savings.

The maintenance requirements for soft pneumatic systems present a mixed sustainability profile. While these actuators generally require less lubrication and fewer replacement parts than mechanical alternatives, their elastomeric materials may degrade over time due to environmental factors, potentially necessitating more frequent replacement of certain components. This degradation pattern varies significantly based on operating conditions and material selection.

End-of-life considerations reveal both challenges and opportunities. Current recycling infrastructure is poorly equipped to handle multi-material soft actuators, with elastomers particularly difficult to recycle effectively. However, emerging research demonstrates promising approaches for material recovery, including chemical recycling of silicones and mechanical recycling of thermoplastic elastomers. Biodegradable alternatives using natural rubber compounds or bio-based polymers are also under development.

Comparative LCA studies indicate that soft pneumatic systems generally outperform traditional rigid actuators in global warming potential and cumulative energy demand metrics, primarily due to reduced material intensity and operational efficiency. However, they may score less favorably in categories related to water usage and certain types of emissions associated with elastomer production. These trade-offs necessitate application-specific assessment to determine the most sustainable solution for particular use cases.

Circular Economy Strategies for Soft Robotics

The circular economy concept offers transformative potential for soft robotics, particularly for pneumatic actuators which currently face end-of-life challenges. By reimagining the entire lifecycle of soft robotic systems, we can shift from the traditional linear "take-make-dispose" model toward a regenerative approach that minimizes waste and environmental impact.

Material selection represents the foundation of circular economy implementation in soft robotics. Biodegradable elastomers such as PCL (polycaprolactone) and PLA (polylactic acid) blends show promise as alternatives to conventional silicones. Recent research demonstrates that these materials can achieve comparable mechanical properties while offering enhanced environmental degradability. Additionally, bio-based elastomers derived from renewable resources present opportunities to reduce petroleum dependence in manufacturing processes.

Design for disassembly constitutes another critical strategy, enabling component separation for maintenance, repair, and eventual recycling. Modular architectures that allow pneumatic chambers, control valves, and structural elements to be easily separated facilitate extended product lifespans through repair rather than replacement. Several research groups have demonstrated prototype soft actuators with snap-fit connections and standardized interfaces that maintain performance while enabling circularity.

Remanufacturing pathways for soft pneumatic actuators are emerging as viable approaches to extend functional lifetimes. This involves collecting used actuators, disassembling them, reconditioning or replacing worn components, and reassembling them to meet original specifications. Laboratory studies indicate that remanufactured soft actuators can retain up to 85% of their original performance characteristics while reducing material consumption by approximately 70%.

Recycling technologies specifically adapted for multi-material soft robotic systems represent an evolving frontier. Chemical recycling methods that can separate silicone elastomers from embedded sensors and pneumatic fittings show particular promise. Solvent-based techniques have demonstrated the ability to recover up to 80% of silicone materials from end-of-life actuators while preserving their molecular structure for reprocessing.

Implementation of these circular strategies requires collaboration across the value chain, from material scientists and design engineers to manufacturers and end-users. Economic incentives, such as product-as-service models where manufacturers retain ownership of actuators while providing pneumatic actuation as a service, could accelerate adoption of circular principles while ensuring proper end-of-life management.

Material selection represents the foundation of circular economy implementation in soft robotics. Biodegradable elastomers such as PCL (polycaprolactone) and PLA (polylactic acid) blends show promise as alternatives to conventional silicones. Recent research demonstrates that these materials can achieve comparable mechanical properties while offering enhanced environmental degradability. Additionally, bio-based elastomers derived from renewable resources present opportunities to reduce petroleum dependence in manufacturing processes.

Design for disassembly constitutes another critical strategy, enabling component separation for maintenance, repair, and eventual recycling. Modular architectures that allow pneumatic chambers, control valves, and structural elements to be easily separated facilitate extended product lifespans through repair rather than replacement. Several research groups have demonstrated prototype soft actuators with snap-fit connections and standardized interfaces that maintain performance while enabling circularity.

Remanufacturing pathways for soft pneumatic actuators are emerging as viable approaches to extend functional lifetimes. This involves collecting used actuators, disassembling them, reconditioning or replacing worn components, and reassembling them to meet original specifications. Laboratory studies indicate that remanufactured soft actuators can retain up to 85% of their original performance characteristics while reducing material consumption by approximately 70%.

Recycling technologies specifically adapted for multi-material soft robotic systems represent an evolving frontier. Chemical recycling methods that can separate silicone elastomers from embedded sensors and pneumatic fittings show particular promise. Solvent-based techniques have demonstrated the ability to recover up to 80% of silicone materials from end-of-life actuators while preserving their molecular structure for reprocessing.

Implementation of these circular strategies requires collaboration across the value chain, from material scientists and design engineers to manufacturers and end-users. Economic incentives, such as product-as-service models where manufacturers retain ownership of actuators while providing pneumatic actuation as a service, could accelerate adoption of circular principles while ensuring proper end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!