How Do Soft Pneumatic Actuators Improve Prosthetic Devices

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Technology Background and Objectives

Soft pneumatic actuators (SPAs) represent a significant advancement in the field of prosthetic technology, emerging from the broader domain of soft robotics that began gaining momentum in the early 2000s. These actuators utilize compressed air or fluid to generate motion and force, offering a fundamental departure from traditional rigid actuators that have dominated prosthetic design for decades. The evolution of SPAs can be traced back to pioneering work at institutions like Harvard University and MIT, where researchers first demonstrated the potential of soft, compliant materials in robotic applications.

The technological trajectory of SPAs has been characterized by progressive improvements in materials science, manufacturing techniques, and control systems. Early iterations faced challenges with durability, response time, and force generation capabilities. However, recent advancements in silicone elastomers, fiber reinforcement techniques, and 3D printing have significantly enhanced their performance characteristics, making them increasingly viable for prosthetic applications.

Current research objectives in SPA technology for prosthetics focus on several key areas. First, enhancing the power-to-weight ratio to match or exceed that of biological muscles while maintaining the inherent compliance that makes these actuators valuable. Second, improving response times and precision control to enable more natural movement patterns. Third, developing more energy-efficient designs to extend battery life in portable prosthetic systems.

Another critical objective involves the integration of sensory feedback mechanisms with SPA technology, creating bidirectional interfaces that allow users to not only control their prosthetic devices but also receive tactile information from them. This sensorimotor integration represents a frontier in prosthetic development that could dramatically improve user experience and functional outcomes.

The biomimetic potential of SPAs aligns perfectly with the needs of advanced prosthetics. Unlike conventional rigid actuators, SPAs can replicate the variable stiffness properties of natural muscle tissue, potentially offering more natural movement patterns and improved comfort at the prosthetic-body interface. This characteristic makes them particularly promising for applications requiring delicate force control, such as hand prostheses.

Looking forward, the technological roadmap for SPAs in prosthetics includes miniaturization of pneumatic systems, development of self-healing materials to improve longevity, and creation of more sophisticated control algorithms that can interpret user intent with greater accuracy. The ultimate goal is to create prosthetic devices that not only restore lost function but do so in a way that feels natural and intuitive to the user, minimizing the cognitive load associated with prosthetic use.

The technological trajectory of SPAs has been characterized by progressive improvements in materials science, manufacturing techniques, and control systems. Early iterations faced challenges with durability, response time, and force generation capabilities. However, recent advancements in silicone elastomers, fiber reinforcement techniques, and 3D printing have significantly enhanced their performance characteristics, making them increasingly viable for prosthetic applications.

Current research objectives in SPA technology for prosthetics focus on several key areas. First, enhancing the power-to-weight ratio to match or exceed that of biological muscles while maintaining the inherent compliance that makes these actuators valuable. Second, improving response times and precision control to enable more natural movement patterns. Third, developing more energy-efficient designs to extend battery life in portable prosthetic systems.

Another critical objective involves the integration of sensory feedback mechanisms with SPA technology, creating bidirectional interfaces that allow users to not only control their prosthetic devices but also receive tactile information from them. This sensorimotor integration represents a frontier in prosthetic development that could dramatically improve user experience and functional outcomes.

The biomimetic potential of SPAs aligns perfectly with the needs of advanced prosthetics. Unlike conventional rigid actuators, SPAs can replicate the variable stiffness properties of natural muscle tissue, potentially offering more natural movement patterns and improved comfort at the prosthetic-body interface. This characteristic makes them particularly promising for applications requiring delicate force control, such as hand prostheses.

Looking forward, the technological roadmap for SPAs in prosthetics includes miniaturization of pneumatic systems, development of self-healing materials to improve longevity, and creation of more sophisticated control algorithms that can interpret user intent with greater accuracy. The ultimate goal is to create prosthetic devices that not only restore lost function but do so in a way that feels natural and intuitive to the user, minimizing the cognitive load associated with prosthetic use.

Market Analysis for Advanced Prosthetic Solutions

The global market for advanced prosthetic solutions is experiencing significant growth, driven by technological innovations and increasing demand for more functional and comfortable prosthetic devices. The market was valued at approximately $1.9 billion in 2022 and is projected to reach $3.2 billion by 2028, growing at a CAGR of 9.1% during the forecast period. This growth trajectory is particularly notable in regions with advanced healthcare infrastructure such as North America, Europe, and parts of Asia-Pacific.

Soft pneumatic actuators represent a disruptive technology within this market, addressing critical limitations of conventional prosthetics. Traditional prosthetic devices often suffer from issues related to weight, rigidity, and limited dexterity, resulting in user discomfort and reduced functionality. The introduction of soft pneumatic actuators has created a new market segment focused on biomimetic prosthetics that more closely replicate natural human movement.

Market research indicates that approximately 65% of prosthetic users report dissatisfaction with the comfort and functionality of traditional devices. This dissatisfaction creates a substantial market opportunity for soft pneumatic actuator technology, which offers improved comfort, natural movement patterns, and enhanced user experience. Healthcare providers and insurance companies are increasingly recognizing the long-term benefits of these advanced solutions, despite higher initial costs.

The market landscape is segmented by application type, with upper limb prosthetics currently representing the largest application area for soft pneumatic actuators. This segment accounts for approximately 58% of the market share, followed by lower limb applications at 32% and specialized applications at 10%. The upper limb dominance is attributed to the complex movement requirements of hands and fingers, where soft pneumatic technology offers significant advantages.

Demographic trends further support market growth, with an aging global population and increasing incidence of diabetes leading to higher amputation rates. Military veterans represent another significant user group, with defense departments in several countries investing in advanced prosthetic research. Additionally, the market is benefiting from increased healthcare spending in emerging economies, expanding the potential user base beyond traditional markets.

Consumer preferences are evolving toward more personalized and aesthetically pleasing prosthetic solutions. This trend aligns well with soft pneumatic technology, which offers greater customization potential compared to conventional systems. Market surveys indicate that 78% of prosthetic users consider both functionality and appearance important factors in their purchasing decisions, highlighting the dual-value proposition of soft pneumatic actuator technology.

Soft pneumatic actuators represent a disruptive technology within this market, addressing critical limitations of conventional prosthetics. Traditional prosthetic devices often suffer from issues related to weight, rigidity, and limited dexterity, resulting in user discomfort and reduced functionality. The introduction of soft pneumatic actuators has created a new market segment focused on biomimetic prosthetics that more closely replicate natural human movement.

Market research indicates that approximately 65% of prosthetic users report dissatisfaction with the comfort and functionality of traditional devices. This dissatisfaction creates a substantial market opportunity for soft pneumatic actuator technology, which offers improved comfort, natural movement patterns, and enhanced user experience. Healthcare providers and insurance companies are increasingly recognizing the long-term benefits of these advanced solutions, despite higher initial costs.

The market landscape is segmented by application type, with upper limb prosthetics currently representing the largest application area for soft pneumatic actuators. This segment accounts for approximately 58% of the market share, followed by lower limb applications at 32% and specialized applications at 10%. The upper limb dominance is attributed to the complex movement requirements of hands and fingers, where soft pneumatic technology offers significant advantages.

Demographic trends further support market growth, with an aging global population and increasing incidence of diabetes leading to higher amputation rates. Military veterans represent another significant user group, with defense departments in several countries investing in advanced prosthetic research. Additionally, the market is benefiting from increased healthcare spending in emerging economies, expanding the potential user base beyond traditional markets.

Consumer preferences are evolving toward more personalized and aesthetically pleasing prosthetic solutions. This trend aligns well with soft pneumatic technology, which offers greater customization potential compared to conventional systems. Market surveys indicate that 78% of prosthetic users consider both functionality and appearance important factors in their purchasing decisions, highlighting the dual-value proposition of soft pneumatic actuator technology.

Current Challenges in Pneumatic Actuator Prosthetics

Despite significant advancements in soft pneumatic actuator technology for prosthetic applications, several critical challenges continue to impede widespread adoption and optimal functionality. One primary obstacle remains the power-to-weight ratio limitation. Current pneumatic systems require compressed air sources that add considerable bulk and weight to prosthetic devices, compromising wearability and user comfort during extended use periods. This challenge is particularly pronounced in lower limb prosthetics where weight constraints are more stringent.

Energy efficiency presents another significant hurdle. Pneumatic systems inherently suffer from energy losses due to air compression and transmission processes. These inefficiencies translate to shorter battery life in portable applications, necessitating frequent recharging that disrupts user experience and limits practical daily use scenarios. The development of more efficient miniaturized compressors remains an active research area with limited commercial success.

Control precision and response time constitute persistent technical barriers. Traditional pneumatic systems exhibit inherent compliance and non-linear behavior that complicate precise position and force control. This results in less predictable movements compared to electric motor-driven alternatives, particularly problematic for fine motor tasks in upper limb prosthetics. The latency between command input and actuator response further compounds these control challenges.

Durability and reliability concerns also plague current pneumatic actuator implementations. Soft materials used in these actuators are susceptible to wear, material fatigue, and potential leakage points that compromise long-term performance. The mean time between failures remains significantly lower than conventional rigid prosthetic components, increasing maintenance requirements and user frustration.

Integration complexity with existing prosthetic frameworks represents another substantial challenge. Current prosthetic ecosystems are predominantly designed around electromechanical systems, creating compatibility issues when implementing pneumatic alternatives. This includes both hardware interfaces and control software architectures that require substantial modification to accommodate pneumatic actuation principles.

Standardization and manufacturing scalability issues further hinder widespread adoption. The production of soft pneumatic actuators often involves complex multi-material fabrication processes that are difficult to standardize and scale. This results in higher production costs and limited customization options compared to conventional prosthetic components.

Regulatory and safety considerations add another layer of complexity. Pneumatic systems operating under pressure present unique safety challenges that must be addressed through robust design and extensive testing. Current regulatory frameworks for prosthetic devices are not fully adapted to evaluate and certify pneumatic actuation technologies, creating market entry barriers for innovative solutions.

Energy efficiency presents another significant hurdle. Pneumatic systems inherently suffer from energy losses due to air compression and transmission processes. These inefficiencies translate to shorter battery life in portable applications, necessitating frequent recharging that disrupts user experience and limits practical daily use scenarios. The development of more efficient miniaturized compressors remains an active research area with limited commercial success.

Control precision and response time constitute persistent technical barriers. Traditional pneumatic systems exhibit inherent compliance and non-linear behavior that complicate precise position and force control. This results in less predictable movements compared to electric motor-driven alternatives, particularly problematic for fine motor tasks in upper limb prosthetics. The latency between command input and actuator response further compounds these control challenges.

Durability and reliability concerns also plague current pneumatic actuator implementations. Soft materials used in these actuators are susceptible to wear, material fatigue, and potential leakage points that compromise long-term performance. The mean time between failures remains significantly lower than conventional rigid prosthetic components, increasing maintenance requirements and user frustration.

Integration complexity with existing prosthetic frameworks represents another substantial challenge. Current prosthetic ecosystems are predominantly designed around electromechanical systems, creating compatibility issues when implementing pneumatic alternatives. This includes both hardware interfaces and control software architectures that require substantial modification to accommodate pneumatic actuation principles.

Standardization and manufacturing scalability issues further hinder widespread adoption. The production of soft pneumatic actuators often involves complex multi-material fabrication processes that are difficult to standardize and scale. This results in higher production costs and limited customization options compared to conventional prosthetic components.

Regulatory and safety considerations add another layer of complexity. Pneumatic systems operating under pressure present unique safety challenges that must be addressed through robust design and extensive testing. Current regulatory frameworks for prosthetic devices are not fully adapted to evaluate and certify pneumatic actuation technologies, creating market entry barriers for innovative solutions.

Current Soft Pneumatic Actuator Implementation Methods

01 Material innovations for soft pneumatic actuators

Advanced materials are being developed to enhance the performance of soft pneumatic actuators. These materials include flexible polymers, composite structures, and smart materials that can improve durability, flexibility, and response time. The integration of these materials allows for better deformation characteristics, increased force output, and improved overall functionality of the actuators while maintaining their soft and compliant nature.- Material innovations for soft pneumatic actuators: Advanced materials are being developed to improve the performance of soft pneumatic actuators. These materials include flexible polymers, composite structures, and smart materials that can enhance the durability, flexibility, and responsiveness of the actuators. By using these innovative materials, soft pneumatic actuators can achieve better deformation characteristics, increased force output, and improved longevity under repeated actuation cycles.

- Control systems and algorithms for pneumatic actuation: Sophisticated control systems and algorithms are being developed to enhance the precision and responsiveness of soft pneumatic actuators. These systems incorporate feedback mechanisms, predictive modeling, and adaptive control strategies to optimize actuator performance. Advanced control algorithms enable more accurate positioning, smoother motion profiles, and better coordination of multiple actuators working together in complex systems.

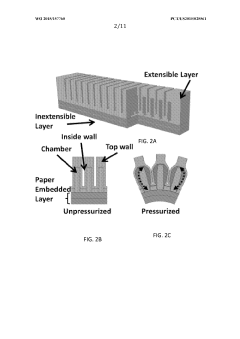

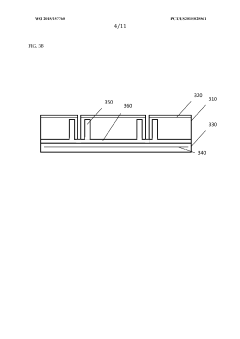

- Novel structural designs for improved functionality: Innovative structural designs are being implemented to enhance the functionality of soft pneumatic actuators. These designs include multi-chamber configurations, biomimetic structures, and modular components that can be combined in various ways. By optimizing the geometry and arrangement of pneumatic chambers, these designs enable more complex movements, increased force output, and better adaptability to different applications.

- Integration of sensors and feedback mechanisms: The incorporation of sensors and feedback mechanisms into soft pneumatic actuators is improving their performance and versatility. These integrated sensing capabilities allow for real-time monitoring of actuator state, including pressure, deformation, and position. By providing continuous feedback, these systems enable more precise control, adaptive behavior, and self-correction capabilities, making the actuators more reliable and effective in various applications.

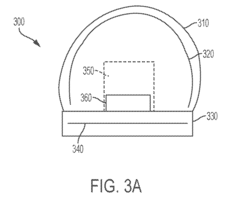

- Energy efficiency and portable power solutions: Advancements in energy efficiency and portable power solutions are enhancing the practicality of soft pneumatic actuators. These improvements include optimized valve designs, reduced air leakage, and more efficient pressure generation systems. Additionally, compact and lightweight power sources are being developed to enable mobile applications. These innovations are making soft pneumatic actuators more suitable for portable devices, wearable technologies, and remote operations.

02 Control systems and mechanisms for pneumatic actuation

Sophisticated control systems are being developed to enhance the precision and responsiveness of soft pneumatic actuators. These systems incorporate sensors, feedback mechanisms, and advanced algorithms to regulate air pressure, flow rate, and actuation timing. By improving control mechanisms, these innovations enable more precise movements, better coordination in multi-actuator systems, and adaptive responses to changing environmental conditions.Expand Specific Solutions03 Structural design improvements for enhanced performance

Novel structural designs are being implemented to improve the performance of soft pneumatic actuators. These designs include optimized chamber geometries, reinforcement patterns, and multi-chamber configurations that enhance force output, range of motion, and operational efficiency. By rethinking the fundamental architecture of these actuators, engineers can achieve more complex movements and better mimic natural biological systems.Expand Specific Solutions04 Integration of soft pneumatic actuators in robotic systems

Soft pneumatic actuators are being integrated into various robotic systems to enable safer human-robot interaction and more adaptable functionality. These applications include wearable assistive devices, medical robots, and industrial automation systems. The integration focuses on combining the compliant nature of soft actuators with traditional robotic components to create hybrid systems that can operate effectively in complex and dynamic environments.Expand Specific Solutions05 Manufacturing techniques and fabrication methods

Advanced manufacturing techniques are being developed to improve the production of soft pneumatic actuators. These methods include 3D printing, multi-material molding, and automated assembly processes that enable more complex geometries, integrated functionalities, and scalable production. Improved fabrication methods also focus on reducing material waste, enhancing consistency between units, and allowing for customization based on specific application requirements.Expand Specific Solutions

Leading Companies and Research Institutions in Soft Actuators

Soft pneumatic actuators are revolutionizing prosthetic devices by offering lightweight, flexible, and biomimetic solutions in a rapidly evolving market. The global prosthetics industry is transitioning from early-stage development to commercial growth, with market size expanding as these technologies demonstrate superior comfort and natural movement capabilities. Leading institutions like Harvard College and Shanghai Jiao Tong University are advancing fundamental research, while companies such as Össur Iceland ehf and Stryker Corp. are commercializing innovative products. Bioliberty Ltd. and Oxipital AI represent emerging players integrating AI with soft robotics. The technology is approaching maturity in specific applications but remains in development for complex use cases, with collaboration between academic institutions and industry partners accelerating progress toward more accessible and functional prosthetic solutions.

President & Fellows of Harvard College

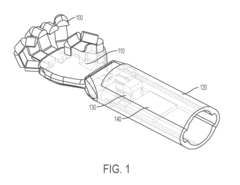

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators for prosthetics through their groundbreaking work in soft robotics. Their technology utilizes elastomeric materials with embedded pneumatic networks that deform predictably when pressurized with air. The Harvard team has developed a multi-layered fabrication approach where silicone-based materials are cast in molds with complex internal air channels, allowing for biomimetic movement patterns. Their prosthetic applications focus on creating lightweight, compliant grippers and artificial muscles that can generate significant force while maintaining adaptability to various object shapes. The Harvard soft pneumatic actuator design incorporates strain-limiting layers that create directional bending when inflated, enabling precise control of prosthetic digits. Recent innovations include integrating embedded sensing capabilities and developing portable, lightweight pneumatic control systems specifically designed for wearable prosthetic applications.

Strengths: Superior compliance and adaptability to irregular objects; inherently safer human interaction due to material softness; simplified control systems compared to traditional electromechanical prosthetics. Weaknesses: Challenges in miniaturization of pneumatic supply systems; potential durability concerns with repeated stress cycles; slower actuation response compared to rigid actuators.

Össur Iceland ehf

Technical Solution: Össur has developed innovative soft pneumatic actuator technology for their prosthetic line, particularly focusing on lower limb applications. Their PROPRIO FOOT® system incorporates pneumatic elements that adapt to terrain changes and user movement patterns. The company's soft pneumatic technology utilizes variable-stiffness air chambers that can dynamically adjust the compliance of prosthetic joints during different phases of the gait cycle. Össur's pneumatic systems employ microprocessor-controlled valves that precisely regulate air pressure in response to sensor data, creating more natural movement transitions. Their proprietary materials include reinforced elastomers specifically engineered to withstand millions of compression cycles while maintaining consistent performance characteristics. The pneumatic components are designed to work in conjunction with their carbon fiber energy-storing structures, creating a hybrid system that combines the energy efficiency of rigid materials with the adaptive properties of pneumatic elements. Recent innovations include self-adjusting pneumatic volume compensation systems that automatically adapt to residual limb volume fluctuations throughout the day.

Strengths: Excellent integration of pneumatic elements with traditional prosthetic materials; strong focus on energy efficiency and return; sophisticated sensor and control systems for adaptive response. Weaknesses: Complex systems require specialized maintenance; higher weight compared to purely mechanical solutions; premium pricing limits accessibility.

Key Patents and Innovations in Soft Actuator Technology

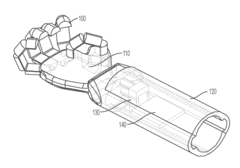

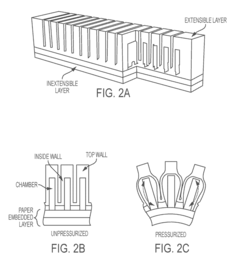

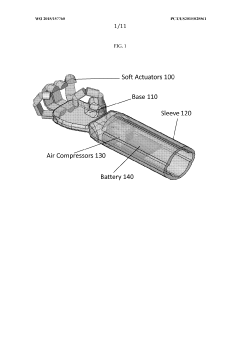

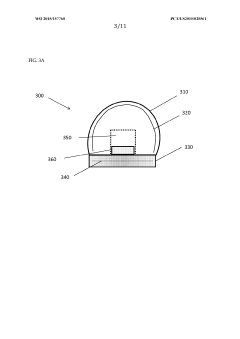

Portable Prosthetic Hand With Soft Pneumatic Fingers

PatentActiveUS20170290681A1

Innovation

- A lightweight prosthetic hand with soft pneumatic fingers actuated by compressors and a control system that uses muscle sensors to control finger movement, incorporating extensible silicone rubber segments with embedded inextensible layers for efficient actuation.

Portable prosthetic hand with soft pneumatic fingers

PatentWO2015157760A1

Innovation

- A portable prosthetic hand with soft pneumatic fingers using fluidically interconnected extensible segments and a control system that employs compressors and pumps to pressurize the fingers, allowing for bending and gripping motions, integrated with a microprocessor for muscle voltage sensing and actuation control.

User Experience and Adaptive Control Systems

The integration of soft pneumatic actuators into prosthetic devices has significantly transformed user experience through more intuitive and responsive control systems. Traditional prosthetics often presented a steep learning curve, requiring users to master complex control mechanisms that felt unnatural and disconnected from their intentions. Soft pneumatic systems have revolutionized this interaction by enabling more natural movement patterns that closely mimic biological limb function.

Adaptive control systems paired with soft pneumatic actuators create a dynamic feedback loop between the user and the prosthetic device. These systems utilize machine learning algorithms to recognize patterns in the user's movement intentions, gradually adapting to individual gait patterns, grip preferences, and movement styles. This personalization significantly reduces cognitive load during everyday activities, allowing users to focus less on controlling their prosthetic and more on the task at hand.

The sensory feedback mechanisms incorporated into modern soft pneumatic systems represent another breakthrough in user experience. By providing tactile and proprioceptive feedback through carefully calibrated pressure changes, users can "feel" interactions with objects and surfaces. This bidirectional communication creates a more embodied experience, helping to address the psychological disconnect many prosthetic users report between their physical self and their assistive device.

Control latency, a critical factor in user satisfaction, has been dramatically improved through advances in pneumatic valve technology and predictive algorithms. Modern systems can respond to neural or myoelectric signals within milliseconds, creating a near-instantaneous connection between intention and action. This responsiveness is particularly valuable during complex movements requiring precise timing, such as catching objects or navigating uneven terrain.

The customization capabilities of adaptive control systems extend beyond functional parameters to include user preferences for resistance, compliance, and energy expenditure. Users can adjust these settings based on different activities or environmental conditions, switching between modes optimized for precision tasks versus those designed for endurance or power. This flexibility contributes significantly to the integration of prosthetics into diverse aspects of users' lives.

Long-term adaptation represents perhaps the most promising aspect of these control systems. As the algorithms continue to learn from user behavior over months and years, the prosthetic becomes increasingly attuned to subtle changes in the user's physiology, preferences, and capabilities. This evolutionary relationship between user and device creates a truly personalized assistive technology that grows and adapts alongside its user.

Adaptive control systems paired with soft pneumatic actuators create a dynamic feedback loop between the user and the prosthetic device. These systems utilize machine learning algorithms to recognize patterns in the user's movement intentions, gradually adapting to individual gait patterns, grip preferences, and movement styles. This personalization significantly reduces cognitive load during everyday activities, allowing users to focus less on controlling their prosthetic and more on the task at hand.

The sensory feedback mechanisms incorporated into modern soft pneumatic systems represent another breakthrough in user experience. By providing tactile and proprioceptive feedback through carefully calibrated pressure changes, users can "feel" interactions with objects and surfaces. This bidirectional communication creates a more embodied experience, helping to address the psychological disconnect many prosthetic users report between their physical self and their assistive device.

Control latency, a critical factor in user satisfaction, has been dramatically improved through advances in pneumatic valve technology and predictive algorithms. Modern systems can respond to neural or myoelectric signals within milliseconds, creating a near-instantaneous connection between intention and action. This responsiveness is particularly valuable during complex movements requiring precise timing, such as catching objects or navigating uneven terrain.

The customization capabilities of adaptive control systems extend beyond functional parameters to include user preferences for resistance, compliance, and energy expenditure. Users can adjust these settings based on different activities or environmental conditions, switching between modes optimized for precision tasks versus those designed for endurance or power. This flexibility contributes significantly to the integration of prosthetics into diverse aspects of users' lives.

Long-term adaptation represents perhaps the most promising aspect of these control systems. As the algorithms continue to learn from user behavior over months and years, the prosthetic becomes increasingly attuned to subtle changes in the user's physiology, preferences, and capabilities. This evolutionary relationship between user and device creates a truly personalized assistive technology that grows and adapts alongside its user.

Materials Science Advancements for Pneumatic Prosthetics

Recent advancements in materials science have revolutionized the development of pneumatic prosthetic devices, particularly in the realm of soft pneumatic actuators. Traditional rigid materials used in prosthetics have been gradually supplemented or replaced by innovative soft, flexible, and adaptive materials that better mimic natural human tissue properties.

Elastomeric polymers, including silicone rubbers (PDMS), thermoplastic elastomers (TPEs), and polyurethanes, have emerged as primary materials for soft pneumatic actuators due to their excellent elasticity, durability, and biocompatibility. These materials can undergo significant deformation under pneumatic pressure while maintaining structural integrity through thousands of actuation cycles.

Composite materials combining soft polymers with reinforcing elements have addressed the challenge of controlled deformation. Fiber-reinforced elastomers, where high-strength fibers are embedded within soft matrices, enable anisotropic deformation patterns that can be precisely engineered to mimic specific muscle movements. This approach has significantly improved the biomimetic capabilities of pneumatic prosthetics.

Smart materials represent another frontier in pneumatic prosthetics development. Shape memory polymers (SMPs) that can change their mechanical properties in response to temperature or other stimuli allow for adaptive stiffness control. Meanwhile, self-healing materials incorporating microcapsules or dynamic chemical bonds can extend device lifespan by automatically repairing minor damage during operation.

Manufacturing techniques have evolved alongside material innovations. 3D printing technologies, particularly multi-material printing, enable the fabrication of complex pneumatic structures with varying material properties throughout a single component. Soft lithography and molding techniques have been refined to create intricate channel networks within elastomeric matrices, essential for pneumatic actuation systems.

Biomaterial interfaces have improved dramatically, with hypoallergenic and biocompatible coatings reducing rejection risks and enhancing comfort at the prosthetic-skin interface. These materials often incorporate antimicrobial properties to prevent infection at contact points, a critical consideration for long-term prosthetic use.

Sustainability concerns have also influenced material selection, with biodegradable elastomers and recyclable components becoming increasingly important in prosthetic design. These environmentally conscious materials maintain performance standards while reducing the ecological footprint of medical devices.

The integration of these material advances has collectively transformed pneumatic prosthetics from rigid, limited-function devices to sophisticated, biomimetic systems capable of nuanced movements and improved user comfort.

Elastomeric polymers, including silicone rubbers (PDMS), thermoplastic elastomers (TPEs), and polyurethanes, have emerged as primary materials for soft pneumatic actuators due to their excellent elasticity, durability, and biocompatibility. These materials can undergo significant deformation under pneumatic pressure while maintaining structural integrity through thousands of actuation cycles.

Composite materials combining soft polymers with reinforcing elements have addressed the challenge of controlled deformation. Fiber-reinforced elastomers, where high-strength fibers are embedded within soft matrices, enable anisotropic deformation patterns that can be precisely engineered to mimic specific muscle movements. This approach has significantly improved the biomimetic capabilities of pneumatic prosthetics.

Smart materials represent another frontier in pneumatic prosthetics development. Shape memory polymers (SMPs) that can change their mechanical properties in response to temperature or other stimuli allow for adaptive stiffness control. Meanwhile, self-healing materials incorporating microcapsules or dynamic chemical bonds can extend device lifespan by automatically repairing minor damage during operation.

Manufacturing techniques have evolved alongside material innovations. 3D printing technologies, particularly multi-material printing, enable the fabrication of complex pneumatic structures with varying material properties throughout a single component. Soft lithography and molding techniques have been refined to create intricate channel networks within elastomeric matrices, essential for pneumatic actuation systems.

Biomaterial interfaces have improved dramatically, with hypoallergenic and biocompatible coatings reducing rejection risks and enhancing comfort at the prosthetic-skin interface. These materials often incorporate antimicrobial properties to prevent infection at contact points, a critical consideration for long-term prosthetic use.

Sustainability concerns have also influenced material selection, with biodegradable elastomers and recyclable components becoming increasingly important in prosthetic design. These environmentally conscious materials maintain performance standards while reducing the ecological footprint of medical devices.

The integration of these material advances has collectively transformed pneumatic prosthetics from rigid, limited-function devices to sophisticated, biomimetic systems capable of nuanced movements and improved user comfort.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!