What Are the Key Materials for Soft Pneumatic Actuators

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Materials Background and Objectives

Soft pneumatic actuators (SPAs) have emerged as a revolutionary technology in the field of robotics and biomedical engineering over the past two decades. These actuators, characterized by their flexibility, compliance, and biomimetic properties, represent a significant departure from traditional rigid actuators. The evolution of SPA technology can be traced back to the early 2000s, with pioneering work in pneumatic artificial muscles, but has seen exponential growth in research interest since 2010 with the advent of soft robotics as a distinct discipline.

The material science underpinning SPAs has evolved from simple elastomers to sophisticated composite structures. Initially, researchers primarily utilized silicone-based elastomers such as polydimethylsiloxane (PDMS) and Ecoflex due to their accessibility and ease of fabrication. The technical trajectory has since expanded to incorporate advanced materials including thermoplastic polyurethanes (TPUs), hydrogels, and various elastomer composites with enhanced mechanical and functional properties.

Current technical trends in SPA materials research focus on addressing key limitations including material fatigue, response time, actuation force, and environmental adaptability. The integration of smart materials such as shape memory polymers, electroactive polymers, and magnetically responsive composites represents a significant frontier in enhancing SPA capabilities. Additionally, there is growing emphasis on developing sustainable and biocompatible materials to expand application domains into medical devices and environmental monitoring.

The primary technical objectives for SPA material development include achieving higher actuation forces while maintaining compliance, improving energy efficiency, enhancing durability through cycle life extension, and developing materials with tunable mechanical properties. Researchers aim to create materials that can withstand millions of actuation cycles without significant performance degradation, operate across wider temperature ranges, and provide more precise control over deformation characteristics.

Another critical objective is the development of manufacturing techniques compatible with advanced SPA materials. This includes exploring 3D printing methodologies for multi-material structures, improved molding techniques for complex geometries, and scalable fabrication processes for industrial applications. The ultimate goal is to establish material systems and associated manufacturing processes that enable reliable, cost-effective production of SPAs with consistent performance characteristics.

The convergence of material science, mechanical engineering, and robotics in this field presents unique interdisciplinary challenges and opportunities. As SPA technology continues to mature, material innovation remains the fundamental enabler for expanding functional capabilities and application domains, from wearable assistive devices to industrial soft manipulators and beyond.

The material science underpinning SPAs has evolved from simple elastomers to sophisticated composite structures. Initially, researchers primarily utilized silicone-based elastomers such as polydimethylsiloxane (PDMS) and Ecoflex due to their accessibility and ease of fabrication. The technical trajectory has since expanded to incorporate advanced materials including thermoplastic polyurethanes (TPUs), hydrogels, and various elastomer composites with enhanced mechanical and functional properties.

Current technical trends in SPA materials research focus on addressing key limitations including material fatigue, response time, actuation force, and environmental adaptability. The integration of smart materials such as shape memory polymers, electroactive polymers, and magnetically responsive composites represents a significant frontier in enhancing SPA capabilities. Additionally, there is growing emphasis on developing sustainable and biocompatible materials to expand application domains into medical devices and environmental monitoring.

The primary technical objectives for SPA material development include achieving higher actuation forces while maintaining compliance, improving energy efficiency, enhancing durability through cycle life extension, and developing materials with tunable mechanical properties. Researchers aim to create materials that can withstand millions of actuation cycles without significant performance degradation, operate across wider temperature ranges, and provide more precise control over deformation characteristics.

Another critical objective is the development of manufacturing techniques compatible with advanced SPA materials. This includes exploring 3D printing methodologies for multi-material structures, improved molding techniques for complex geometries, and scalable fabrication processes for industrial applications. The ultimate goal is to establish material systems and associated manufacturing processes that enable reliable, cost-effective production of SPAs with consistent performance characteristics.

The convergence of material science, mechanical engineering, and robotics in this field presents unique interdisciplinary challenges and opportunities. As SPA technology continues to mature, material innovation remains the fundamental enabler for expanding functional capabilities and application domains, from wearable assistive devices to industrial soft manipulators and beyond.

Market Analysis for Soft Robotics Applications

The global soft robotics market is experiencing significant growth, projected to reach $5.25 billion by 2027, with a compound annual growth rate (CAGR) of 40.5% from 2021. This remarkable expansion is driven by increasing demand across multiple sectors, with soft pneumatic actuators representing a critical component of this emerging technology landscape.

Healthcare applications currently dominate the soft robotics market, accounting for approximately 35% of total market share. The demand for minimally invasive surgical tools, rehabilitation devices, and prosthetics is creating substantial opportunities for soft pneumatic actuator technologies. Particularly noteworthy is the growing adoption in elderly care applications, where the inherent safety of soft actuators addresses critical concerns regarding human-robot interaction.

Manufacturing represents the second-largest application segment, with an estimated 28% market share. Industries are increasingly implementing soft robotic solutions for delicate material handling, assembly of fragile components, and operations requiring adaptive gripping. The food processing industry specifically has shown 45% year-over-year growth in soft robotics adoption, primarily utilizing pneumatic actuation systems.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 47% annually, driven by rapid industrial automation initiatives in China, Japan, and South Korea, along with increasing healthcare expenditures.

Consumer demand trends indicate a strong preference for lightweight, energy-efficient, and environmentally sustainable robotic solutions. This has created a market pull for advanced materials in soft pneumatic actuators, with 72% of industry stakeholders identifying material innovation as the primary factor influencing purchasing decisions.

Market challenges include cost barriers, with current soft pneumatic actuator systems priced 30-40% higher than traditional rigid alternatives. Additionally, durability concerns and standardization issues remain significant market constraints, with 65% of potential industrial adopters citing reliability as their primary hesitation factor.

Emerging application areas showing promising growth include agriculture (22% annual growth), underwater exploration (18% growth), and wearable assistance devices (37% growth). These sectors represent significant diversification opportunities for soft pneumatic actuator technologies, potentially expanding the addressable market by an estimated $1.8 billion by 2030.

Healthcare applications currently dominate the soft robotics market, accounting for approximately 35% of total market share. The demand for minimally invasive surgical tools, rehabilitation devices, and prosthetics is creating substantial opportunities for soft pneumatic actuator technologies. Particularly noteworthy is the growing adoption in elderly care applications, where the inherent safety of soft actuators addresses critical concerns regarding human-robot interaction.

Manufacturing represents the second-largest application segment, with an estimated 28% market share. Industries are increasingly implementing soft robotic solutions for delicate material handling, assembly of fragile components, and operations requiring adaptive gripping. The food processing industry specifically has shown 45% year-over-year growth in soft robotics adoption, primarily utilizing pneumatic actuation systems.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 47% annually, driven by rapid industrial automation initiatives in China, Japan, and South Korea, along with increasing healthcare expenditures.

Consumer demand trends indicate a strong preference for lightweight, energy-efficient, and environmentally sustainable robotic solutions. This has created a market pull for advanced materials in soft pneumatic actuators, with 72% of industry stakeholders identifying material innovation as the primary factor influencing purchasing decisions.

Market challenges include cost barriers, with current soft pneumatic actuator systems priced 30-40% higher than traditional rigid alternatives. Additionally, durability concerns and standardization issues remain significant market constraints, with 65% of potential industrial adopters citing reliability as their primary hesitation factor.

Emerging application areas showing promising growth include agriculture (22% annual growth), underwater exploration (18% growth), and wearable assistance devices (37% growth). These sectors represent significant diversification opportunities for soft pneumatic actuator technologies, potentially expanding the addressable market by an estimated $1.8 billion by 2030.

Current Material Limitations and Technical Challenges

Despite significant advancements in soft pneumatic actuator technology, several material limitations and technical challenges continue to impede broader implementation and optimal performance. Current elastomeric materials predominantly used in soft actuators, such as silicone rubbers (PDMS, Ecoflex) and polyurethanes, exhibit inherent trade-offs between flexibility, durability, and response characteristics that restrict their application potential.

The mechanical property limitations represent a primary challenge. Most available elastomers demonstrate either excellent elasticity with insufficient strength or adequate strength with limited elasticity. This fundamental contradiction creates difficulties in designing actuators that can simultaneously achieve high force output and large deformation capabilities. Additionally, material fatigue and hysteresis effects lead to performance degradation over repeated actuation cycles, significantly reducing operational lifespan.

Permeability issues present another critical challenge. Current elastomeric materials exhibit varying degrees of gas permeability, resulting in pressure loss during operation. This necessitates continuous pressure maintenance and reduces energy efficiency. The permeability characteristics also limit the types of working fluids that can be effectively utilized, constraining design flexibility and application environments.

Manufacturing inconsistencies further complicate material selection and implementation. Batch-to-batch variations in commercially available elastomers lead to unpredictable performance characteristics, making standardization difficult. The curing processes for many elastomers are highly sensitive to environmental conditions, introducing additional variables that affect material properties and actuator performance.

Temperature sensitivity represents a significant limitation for existing materials. Most elastomers demonstrate substantial property changes across operational temperature ranges, restricting their use in extreme environments. The glass transition temperature of many elastomers limits low-temperature applications, while material softening and degradation constrain high-temperature scenarios.

Biocompatibility and environmental concerns also present challenges for specific applications. Materials suitable for medical or food-handling applications must meet stringent regulatory requirements, significantly narrowing the available material options. Additionally, many high-performance elastomers have poor biodegradability profiles, raising environmental sustainability concerns.

The integration of functional properties presents perhaps the most forward-looking challenge. Current materials typically serve primarily structural roles, lacking inherent sensing capabilities, self-healing properties, or adaptive responses. This limitation necessitates complex multi-material designs and additional components, increasing system complexity and potential failure points.

The mechanical property limitations represent a primary challenge. Most available elastomers demonstrate either excellent elasticity with insufficient strength or adequate strength with limited elasticity. This fundamental contradiction creates difficulties in designing actuators that can simultaneously achieve high force output and large deformation capabilities. Additionally, material fatigue and hysteresis effects lead to performance degradation over repeated actuation cycles, significantly reducing operational lifespan.

Permeability issues present another critical challenge. Current elastomeric materials exhibit varying degrees of gas permeability, resulting in pressure loss during operation. This necessitates continuous pressure maintenance and reduces energy efficiency. The permeability characteristics also limit the types of working fluids that can be effectively utilized, constraining design flexibility and application environments.

Manufacturing inconsistencies further complicate material selection and implementation. Batch-to-batch variations in commercially available elastomers lead to unpredictable performance characteristics, making standardization difficult. The curing processes for many elastomers are highly sensitive to environmental conditions, introducing additional variables that affect material properties and actuator performance.

Temperature sensitivity represents a significant limitation for existing materials. Most elastomers demonstrate substantial property changes across operational temperature ranges, restricting their use in extreme environments. The glass transition temperature of many elastomers limits low-temperature applications, while material softening and degradation constrain high-temperature scenarios.

Biocompatibility and environmental concerns also present challenges for specific applications. Materials suitable for medical or food-handling applications must meet stringent regulatory requirements, significantly narrowing the available material options. Additionally, many high-performance elastomers have poor biodegradability profiles, raising environmental sustainability concerns.

The integration of functional properties presents perhaps the most forward-looking challenge. Current materials typically serve primarily structural roles, lacking inherent sensing capabilities, self-healing properties, or adaptive responses. This limitation necessitates complex multi-material designs and additional components, increasing system complexity and potential failure points.

State-of-the-Art Material Solutions

01 Design and fabrication of soft pneumatic actuators

Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air. These actuators typically consist of chambers or channels within elastomeric materials that expand or contract when air pressure is applied. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal air channels and external structure. These design approaches enable the creation of actuators with various motion capabilities including bending, twisting, and elongation.- Design and fabrication of soft pneumatic actuators: Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract in response to pressure changes. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the complex internal structures necessary for controlled deformation and movement.

- Applications in robotics and automation: Soft pneumatic actuators are widely used in robotics and automation systems where gentle interaction with objects or environments is required. These applications include soft robotic grippers for handling delicate items, wearable assistive devices, and biomimetic robots that can navigate complex terrains. The inherent compliance of these actuators makes them particularly suitable for human-robot interaction scenarios and environments where traditional rigid robots would be unsuitable.

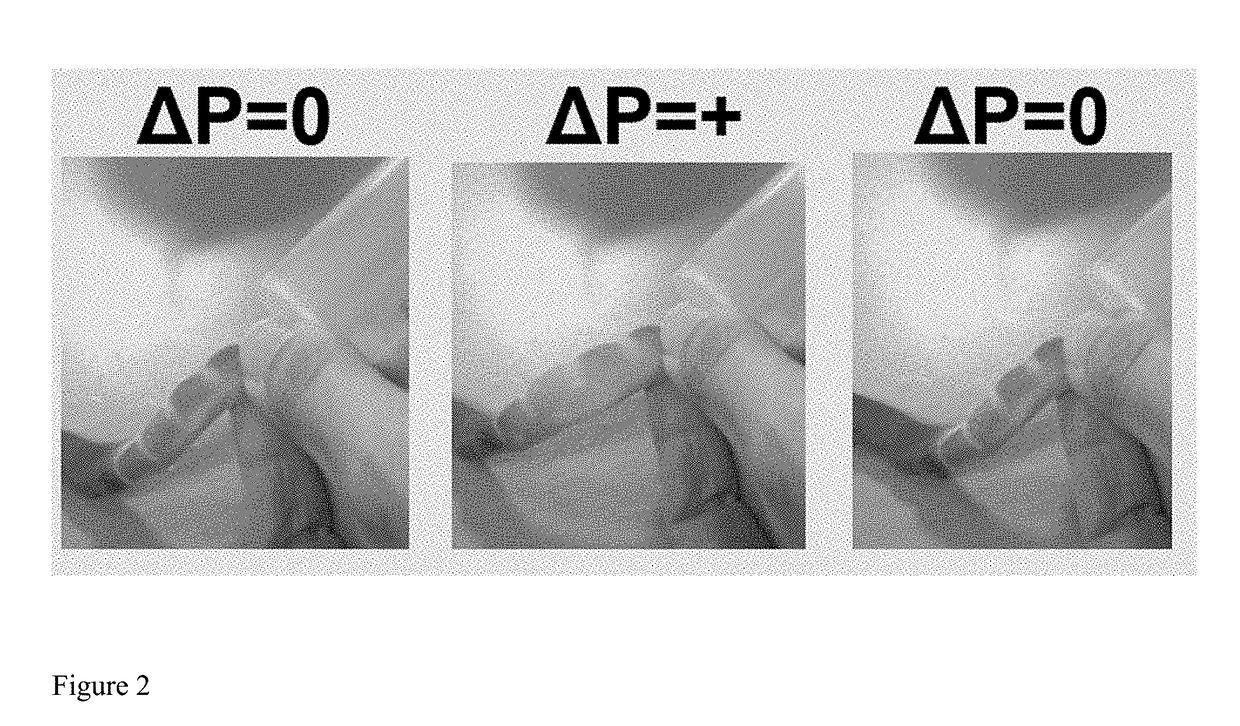

- Control systems and sensing integration: Advanced control systems are essential for precise operation of soft pneumatic actuators. These systems often incorporate pressure sensors, position feedback mechanisms, and machine learning algorithms to achieve accurate movement and force control. Integration of sensing elements directly into the soft structure allows for closed-loop control and adaptive behavior, enabling the actuators to respond to environmental changes and varying loads during operation.

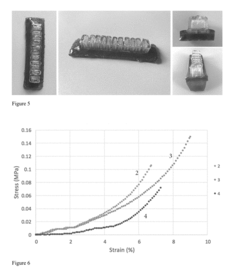

- Material innovations for enhanced performance: Novel materials are being developed to enhance the performance characteristics of soft pneumatic actuators. These include composite structures that combine elastomers with reinforcing fibers or particles, stimuli-responsive materials that change properties under specific conditions, and self-healing materials that can recover from damage. These material innovations aim to improve durability, force output, response time, and energy efficiency of the actuators.

- Multi-functional and reconfigurable designs: Recent advancements focus on developing multi-functional and reconfigurable soft pneumatic actuators that can adapt to different tasks. These designs incorporate modular components, variable stiffness mechanisms, and multi-chamber architectures that enable the actuator to change its behavior based on the application requirements. Some designs also integrate multiple actuation modes, combining pneumatic pressure with other stimuli such as electrical or thermal inputs for enhanced functionality.

02 Applications in robotics and automation

Soft pneumatic actuators are widely used in robotics and automation systems where gentle interaction with the environment is required. These applications include soft robotic grippers for handling delicate objects, wearable assistive devices, and biomimetic robots that mimic natural movements. The inherent compliance of these actuators makes them suitable for human-robot interaction scenarios, medical applications, and environments where traditional rigid robots would be unsuitable. Their ability to conform to irregular shapes makes them particularly valuable in adaptive manipulation tasks.Expand Specific Solutions03 Control systems and sensing integration

Advanced control systems are essential for precise operation of soft pneumatic actuators. These systems typically involve pressure regulation, valve control, and feedback mechanisms to achieve desired movements. Integration of sensors within the soft structure allows for closed-loop control and improved performance. Various sensing technologies including pressure sensors, strain sensors, and position tracking systems can be embedded within the actuator structure to provide real-time feedback about the actuator's state, enabling more sophisticated control strategies and autonomous operation.Expand Specific Solutions04 Material innovations for enhanced performance

Novel materials are being developed to enhance the performance of soft pneumatic actuators. These include specialized elastomers with improved durability, stretchability, and response characteristics. Composite materials that combine flexible substrates with reinforcing elements allow for directional control of deformation and increased force output. Smart materials that respond to various stimuli can be incorporated to create multi-functional actuators. These material innovations address challenges such as fatigue resistance, energy efficiency, and operational lifespan of soft pneumatic systems.Expand Specific Solutions05 Specialized configurations for specific motions

Various specialized configurations of soft pneumatic actuators have been developed to achieve specific types of motion. These include bellows-type actuators for linear extension, fiber-reinforced designs for controlled bending, and multi-chamber systems for complex movements. Origami and kirigami-inspired folding patterns can be incorporated to create predetermined deformation paths. These specialized designs enable tailored motion profiles suitable for specific applications, from simple linear actuation to complex multi-degree-of-freedom movements that mimic biological systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The soft pneumatic actuator materials market is in a growth phase, characterized by increasing research intensity and expanding applications across robotics, healthcare, and automation. The market size is projected to grow significantly due to rising demand for flexible, lightweight actuators in soft robotics. From a technological maturity perspective, academic institutions like Cornell University, MIT, and Harvard lead fundamental research, while companies such as Hitachi, DENSO, and Toyota Motor Corp. focus on commercial applications and manufacturing scalability. Research centers at universities are developing novel materials with enhanced properties, while industrial players like ContiTech Vibration Control and RESONAC are working on production techniques and system integration. The competitive landscape shows a collaborative ecosystem between academia and industry, with increasing patent activity indicating technology commercialization potential.

Cornell University

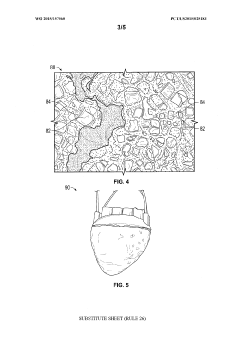

Technical Solution: Cornell University has made significant contributions to soft pneumatic actuator materials through their Organic Robotics Lab. Their research focuses on developing elastomeric foams with tailored porosity that can be pneumatically actuated with lower pressure requirements than traditional systems. Cornell researchers pioneered the use of liquid crystal elastomers (LCEs) in pneumatic systems, creating materials with anisotropic mechanical properties that enable complex, programmable deformations[5]. They've developed a proprietary manufacturing technique called Fiber-Reinforced Elastomeric Encapsulation (FREE) that allows precise control over the deformation modes of pneumatic actuators. Cornell has also created biodegradable elastomers for environmentally friendly soft robotics applications, addressing sustainability concerns in the field. Their recent innovations include self-healing silicone composites that incorporate microcapsules containing healing agents, automatically repairing small tears or punctures that would otherwise cause pneumatic failure[6]. Additionally, they've developed stretchable optical waveguides integrated into pneumatic networks for combined sensing and actuation capabilities.

Strengths: Leading research in biodegradable elastomers for sustainable soft robotics; innovative fiber-reinforced elastomeric encapsulation techniques; integration of optical sensing within pneumatic networks. Weaknesses: Some specialized materials require complex synthesis procedures; certain biodegradable formulations show reduced mechanical performance compared to traditional elastomers; scaling production remains challenging.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators through their groundbreaking work on soft robotics. Their key material innovation focuses on elastomeric composites with embedded pneumatic networks that enable complex motions when inflated. Their proprietary technology includes fiber-reinforced elastomers that prevent ballooning while enabling directional bending, and multi-material 3D printing techniques that create integrated pneumatic circuits within soft structures. Harvard researchers developed a manufacturing approach called Embedded 3D Printing (EMB3D) that enables the creation of complex internal channels within elastomeric matrices[1]. They've also developed strain-limiting layers using fabric or paper embedded within silicone elastomers to create anisotropic bending responses. Their recent work includes self-healing elastomers that can recover from punctures, critical for practical soft pneumatic applications[2].

Strengths: Industry-leading expertise in multi-material fabrication techniques; pioneered fiber-reinforced soft actuators that prevent ballooning while enabling directional bending; strong intellectual property portfolio. Weaknesses: Materials still face challenges in durability for long-term cyclic loading; manufacturing techniques remain relatively complex and difficult to scale for mass production.

Key Patents and Technical Literature Analysis

Soft actuator and methods of fabrication

PatentWO2015157560A1

Innovation

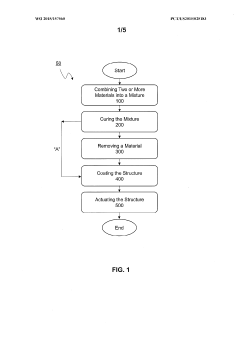

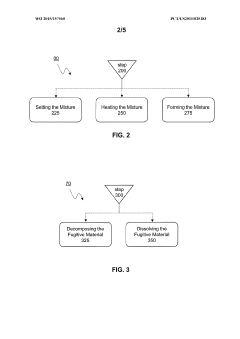

- Soft actuators are fabricated using a combination of elastomer materials and fugitive or foaming agent materials, which are cured to form an open-celled architecture that can be manipulated by inflation/deflation, allowing for controlled movement and actuation through the use of pressure from a power source, such as pneumatic pressure.

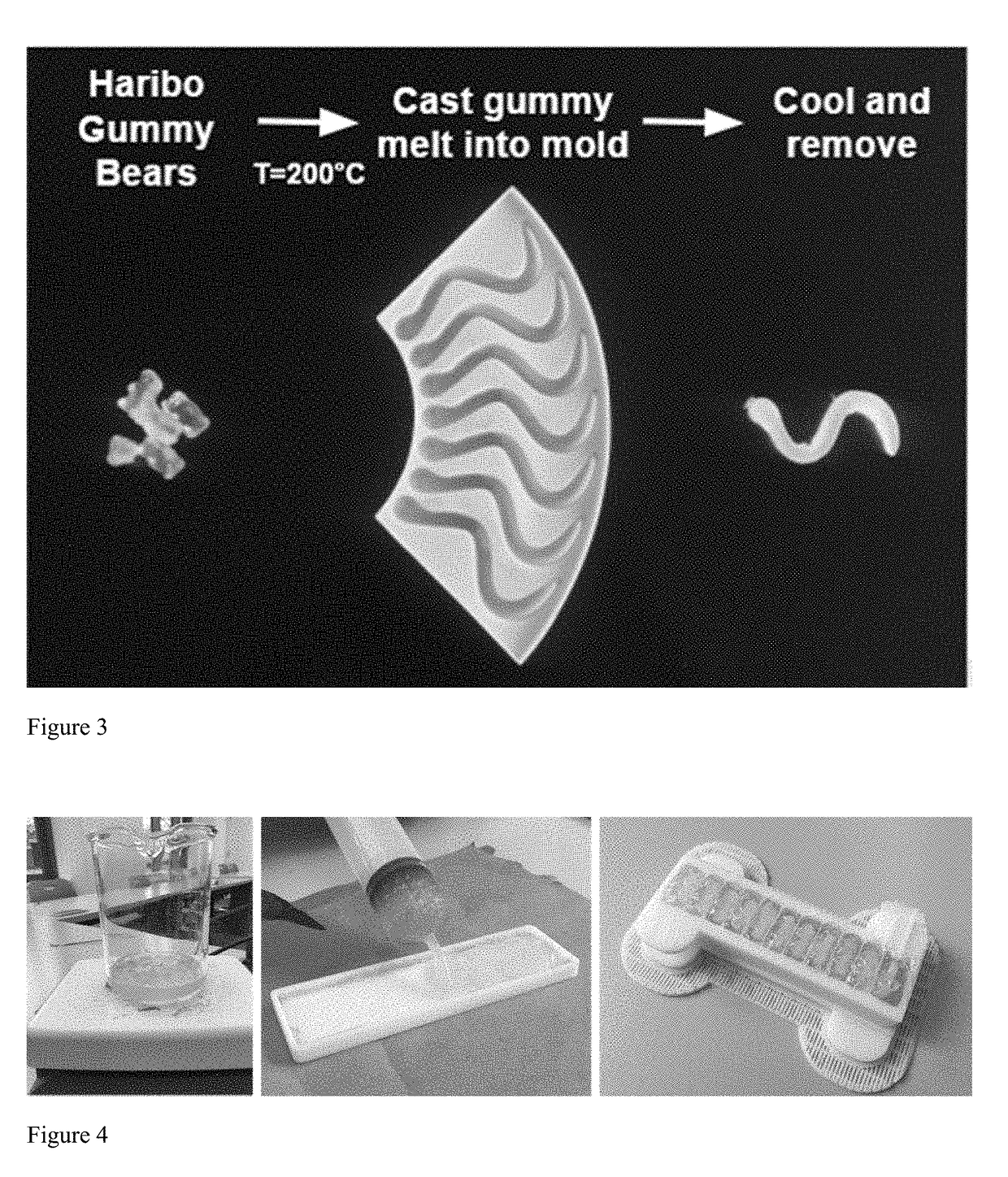

Edible Pneumatic Soft Robotic Actuators

PatentInactiveUS20180353870A1

Innovation

- A biocompatible and digestible material composed of a gelatin and corn syrup composite is developed, which is used to create edible pneumatic soft robotic actuators, allowing for the fabrication of soft body devices that are elastic, extensible, and degradable, with improved mechanical properties and processability.

Sustainability and Recyclability Considerations

The sustainability and recyclability of soft pneumatic actuators represent critical considerations in their development and deployment, particularly as environmental concerns gain prominence across industries. Current soft pneumatic actuators predominantly utilize silicone elastomers, which present significant end-of-life challenges due to their limited biodegradability and recycling potential. These materials typically persist in the environment for hundreds of years, contributing to mounting waste management issues.

Recent research has begun exploring biodegradable alternatives for soft actuator construction. Promising developments include the use of natural rubber derivatives, cellulose-based composites, and biodegradable polyesters such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). These materials offer comparable mechanical properties while significantly reducing environmental persistence. For instance, PHA-based actuators have demonstrated decomposition rates of 85-90% within 180 days under controlled composting conditions, compared to negligible degradation for silicone counterparts.

Material selection strategies increasingly incorporate life cycle assessment (LCA) methodologies to quantify environmental impacts across production, use, and disposal phases. Studies indicate that manufacturing processes for conventional elastomers consume 2.5-3 times more energy than those for biodegradable alternatives, with correspondingly higher carbon footprints. However, durability remains a challenge, as biodegradable materials typically exhibit shorter functional lifespans, necessitating more frequent replacement.

Design for disassembly represents another important approach, wherein actuator components are engineered for easy separation at end-of-life. This facilitates the recovery and recycling of specific materials, particularly metal components and specialized sensors that may be incorporated into more complex soft robotic systems. Modular designs further enhance sustainability by allowing for the replacement of individual components rather than entire actuator systems.

Several research groups have developed closed-loop manufacturing systems for soft actuators, where post-consumer materials are reclaimed and reprocessed into new components. These systems have demonstrated the potential to reduce virgin material requirements by up to 40% while maintaining acceptable performance characteristics. Thermoplastic elastomers show particular promise in this regard, as they can be melted and reformed multiple times without significant property degradation.

Economic barriers to sustainable material adoption remain significant, with biodegradable alternatives typically commanding price premiums of 30-200% over conventional elastomers. However, regulatory trends suggest increasing pressure toward extended producer responsibility, which may alter cost-benefit calculations for manufacturers in the coming years. Industry-academic partnerships are actively working to scale production of sustainable materials to achieve price parity with conventional options.

Recent research has begun exploring biodegradable alternatives for soft actuator construction. Promising developments include the use of natural rubber derivatives, cellulose-based composites, and biodegradable polyesters such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). These materials offer comparable mechanical properties while significantly reducing environmental persistence. For instance, PHA-based actuators have demonstrated decomposition rates of 85-90% within 180 days under controlled composting conditions, compared to negligible degradation for silicone counterparts.

Material selection strategies increasingly incorporate life cycle assessment (LCA) methodologies to quantify environmental impacts across production, use, and disposal phases. Studies indicate that manufacturing processes for conventional elastomers consume 2.5-3 times more energy than those for biodegradable alternatives, with correspondingly higher carbon footprints. However, durability remains a challenge, as biodegradable materials typically exhibit shorter functional lifespans, necessitating more frequent replacement.

Design for disassembly represents another important approach, wherein actuator components are engineered for easy separation at end-of-life. This facilitates the recovery and recycling of specific materials, particularly metal components and specialized sensors that may be incorporated into more complex soft robotic systems. Modular designs further enhance sustainability by allowing for the replacement of individual components rather than entire actuator systems.

Several research groups have developed closed-loop manufacturing systems for soft actuators, where post-consumer materials are reclaimed and reprocessed into new components. These systems have demonstrated the potential to reduce virgin material requirements by up to 40% while maintaining acceptable performance characteristics. Thermoplastic elastomers show particular promise in this regard, as they can be melted and reformed multiple times without significant property degradation.

Economic barriers to sustainable material adoption remain significant, with biodegradable alternatives typically commanding price premiums of 30-200% over conventional elastomers. However, regulatory trends suggest increasing pressure toward extended producer responsibility, which may alter cost-benefit calculations for manufacturers in the coming years. Industry-academic partnerships are actively working to scale production of sustainable materials to achieve price parity with conventional options.

Manufacturing Processes and Scalability Assessment

The manufacturing processes for soft pneumatic actuators (SPAs) present unique challenges due to the complex geometries and material properties required. Traditional manufacturing methods include molding, casting, and 3D printing, each with distinct advantages for different applications. Molding techniques, particularly silicone molding, remain dominant due to their reliability and cost-effectiveness for mass production. This process typically involves creating a negative mold, pouring liquid elastomer, curing, and demolding. However, this method faces limitations in producing complex internal channels necessary for advanced actuator designs.

3D printing has emerged as a revolutionary approach for SPA manufacturing, offering unprecedented design freedom and rapid prototyping capabilities. Direct ink writing and digital light processing (DLP) have shown particular promise, enabling the creation of intricate pneumatic networks that would be impossible with conventional methods. Recent advancements in multi-material 3D printing further allow for gradient material properties within a single actuator, enhancing performance characteristics.

Scalability remains a critical challenge in SPA production. While laboratory-scale manufacturing has advanced significantly, transitioning to industrial-scale production presents several obstacles. Material consistency across large production batches, curing time optimization, and quality control procedures require substantial refinement. Current industrial applications typically employ semi-automated production lines that combine manual assembly with automated molding and curing processes.

Cost analysis indicates that material expenses represent approximately 30-40% of total production costs, with labor and equipment depreciation accounting for the remainder. Economies of scale can reduce unit costs by 40-60% when production volumes increase from prototype quantities to medium-scale manufacturing. However, the specialized nature of many SPA applications often limits production volumes, creating a challenging economic environment for manufacturers.

Emerging manufacturing technologies show promise for improving scalability. Continuous liquid interface production (CLIP) offers significantly faster printing speeds than conventional methods, while automated assembly systems are beginning to address the labor-intensive aspects of production. Additionally, innovations in rapid curing techniques using specialized catalysts and UV-activation systems have reduced production cycle times by up to 70% in laboratory settings.

Quality control processes for SPA manufacturing require specialized testing protocols. Pressure resistance, actuation force consistency, and cycle life testing are essential metrics that must be standardized across the industry. Non-destructive testing methods, including optical coherence tomography and pneumatic performance testing, are increasingly being integrated into production lines to ensure consistent actuator performance.

3D printing has emerged as a revolutionary approach for SPA manufacturing, offering unprecedented design freedom and rapid prototyping capabilities. Direct ink writing and digital light processing (DLP) have shown particular promise, enabling the creation of intricate pneumatic networks that would be impossible with conventional methods. Recent advancements in multi-material 3D printing further allow for gradient material properties within a single actuator, enhancing performance characteristics.

Scalability remains a critical challenge in SPA production. While laboratory-scale manufacturing has advanced significantly, transitioning to industrial-scale production presents several obstacles. Material consistency across large production batches, curing time optimization, and quality control procedures require substantial refinement. Current industrial applications typically employ semi-automated production lines that combine manual assembly with automated molding and curing processes.

Cost analysis indicates that material expenses represent approximately 30-40% of total production costs, with labor and equipment depreciation accounting for the remainder. Economies of scale can reduce unit costs by 40-60% when production volumes increase from prototype quantities to medium-scale manufacturing. However, the specialized nature of many SPA applications often limits production volumes, creating a challenging economic environment for manufacturers.

Emerging manufacturing technologies show promise for improving scalability. Continuous liquid interface production (CLIP) offers significantly faster printing speeds than conventional methods, while automated assembly systems are beginning to address the labor-intensive aspects of production. Additionally, innovations in rapid curing techniques using specialized catalysts and UV-activation systems have reduced production cycle times by up to 70% in laboratory settings.

Quality control processes for SPA manufacturing require specialized testing protocols. Pressure resistance, actuation force consistency, and cycle life testing are essential metrics that must be standardized across the industry. Non-destructive testing methods, including optical coherence tomography and pneumatic performance testing, are increasingly being integrated into production lines to ensure consistent actuator performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!