Soft Pneumatic Actuators in Assistive Human Technologies

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuators Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of assistive human technologies, marking a significant departure from traditional rigid actuators. These flexible, compliant devices utilize pneumatic pressure to generate controlled motion and force, offering unprecedented potential for human-machine interaction. The evolution of SPAs can be traced back to the early 2000s, when researchers began exploring alternatives to conventional rigid robotics, seeking solutions that could safely interface with the human body.

The technological trajectory of SPAs has been characterized by continuous innovation in materials science, manufacturing techniques, and control systems. Initially limited by rudimentary materials and fabrication methods, modern SPAs now leverage advanced elastomers, multi-material 3D printing, and sophisticated embedded sensing technologies. This progression has enabled increasingly complex and functional designs that can more effectively mimic natural biological movements.

Current research trends indicate a growing focus on biomimetic approaches, where SPAs are designed to replicate the functionality and efficiency of natural muscular systems. This bio-inspired direction has proven particularly valuable in assistive technologies, where natural movement patterns and human-like responses are essential for user acceptance and effectiveness.

The primary technical objectives in SPA development for assistive human technologies encompass several critical dimensions. First, enhancing force-to-weight ratios to deliver sufficient power while maintaining lightweight profiles suitable for wearable applications. Second, improving response times and control precision to enable more natural and intuitive assistance. Third, developing robust and reliable systems capable of extended operation in diverse environments without performance degradation.

Energy efficiency represents another crucial objective, as many assistive devices must operate for extended periods on limited power sources. Researchers are actively pursuing innovations in pneumatic system design, valve miniaturization, and control algorithms to minimize air consumption while maintaining performance parameters.

Biocompatibility and user comfort objectives have driven significant research into skin-friendly materials, ergonomic designs, and adaptive interfaces that can accommodate individual anatomical variations. These considerations are paramount for technologies intended for prolonged contact with human users, particularly in medical rehabilitation and disability assistance applications.

The ultimate goal of SPA research in assistive human technologies is to create seamless human-machine interfaces that augment human capabilities without imposing unnatural constraints or discomfort. This vision encompasses not only physical assistance but also intuitive control systems that can interpret user intent through minimal conscious effort, potentially leveraging advances in neural interfaces and machine learning to create truly responsive assistive systems.

The technological trajectory of SPAs has been characterized by continuous innovation in materials science, manufacturing techniques, and control systems. Initially limited by rudimentary materials and fabrication methods, modern SPAs now leverage advanced elastomers, multi-material 3D printing, and sophisticated embedded sensing technologies. This progression has enabled increasingly complex and functional designs that can more effectively mimic natural biological movements.

Current research trends indicate a growing focus on biomimetic approaches, where SPAs are designed to replicate the functionality and efficiency of natural muscular systems. This bio-inspired direction has proven particularly valuable in assistive technologies, where natural movement patterns and human-like responses are essential for user acceptance and effectiveness.

The primary technical objectives in SPA development for assistive human technologies encompass several critical dimensions. First, enhancing force-to-weight ratios to deliver sufficient power while maintaining lightweight profiles suitable for wearable applications. Second, improving response times and control precision to enable more natural and intuitive assistance. Third, developing robust and reliable systems capable of extended operation in diverse environments without performance degradation.

Energy efficiency represents another crucial objective, as many assistive devices must operate for extended periods on limited power sources. Researchers are actively pursuing innovations in pneumatic system design, valve miniaturization, and control algorithms to minimize air consumption while maintaining performance parameters.

Biocompatibility and user comfort objectives have driven significant research into skin-friendly materials, ergonomic designs, and adaptive interfaces that can accommodate individual anatomical variations. These considerations are paramount for technologies intended for prolonged contact with human users, particularly in medical rehabilitation and disability assistance applications.

The ultimate goal of SPA research in assistive human technologies is to create seamless human-machine interfaces that augment human capabilities without imposing unnatural constraints or discomfort. This vision encompasses not only physical assistance but also intuitive control systems that can interpret user intent through minimal conscious effort, potentially leveraging advances in neural interfaces and machine learning to create truly responsive assistive systems.

Market Analysis for Assistive Human Technologies

The global market for assistive human technologies is experiencing significant growth, driven by aging populations, increasing prevalence of disabilities, and advancements in technological capabilities. The market for soft pneumatic actuators specifically within this sector represents a promising segment with substantial growth potential. Current market valuations indicate that the global assistive devices market exceeds $25 billion, with projections suggesting annual growth rates of 6-8% through 2030.

Soft pneumatic actuators address critical needs in rehabilitation, mobility assistance, and daily living aids. The rehabilitation robotics segment, where these actuators find significant application, is expanding at approximately 20% annually, outpacing many other healthcare technology sectors. This growth is particularly pronounced in developed economies with aging demographics, including Japan, Germany, and the United States.

Market demand is segmented across several key application areas. Rehabilitation devices represent approximately 35% of the market, with mobility aids accounting for 28%, prosthetics and orthotics at 22%, and daily living assistance devices comprising the remaining 15%. Soft pneumatic actuators have demonstrated particular market traction in rehabilitation applications due to their inherent safety characteristics when interacting with human users.

Regional analysis reveals varying market maturity and adoption rates. North America currently leads with approximately 40% market share, followed by Europe at 30%, Asia-Pacific at 25%, and other regions comprising the remaining 5%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapidly aging populations in countries like China and Japan, combined with increasing healthcare expenditure.

Consumer preferences are shifting toward more personalized, lightweight, and unobtrusive assistive technologies. This trend strongly favors soft pneumatic actuators over traditional rigid systems. Market research indicates that 78% of users prefer assistive devices that are comfortable and aesthetically acceptable, creating significant market pull for soft, compliant technologies.

Reimbursement policies and healthcare funding mechanisms significantly influence market dynamics. Countries with comprehensive healthcare coverage for assistive technologies show adoption rates 2-3 times higher than those without such coverage. Recent policy changes in major markets have expanded coverage for advanced assistive technologies, creating favorable conditions for innovative solutions like soft pneumatic actuators.

Market barriers include cost concerns, with high-end assistive devices incorporating soft pneumatic technology typically priced between $5,000-$25,000, limiting widespread adoption. Additionally, awareness and technical literacy among healthcare providers regarding these advanced technologies remains a challenge, with surveys indicating only 40% of practitioners feel confident prescribing the latest assistive technologies.

Soft pneumatic actuators address critical needs in rehabilitation, mobility assistance, and daily living aids. The rehabilitation robotics segment, where these actuators find significant application, is expanding at approximately 20% annually, outpacing many other healthcare technology sectors. This growth is particularly pronounced in developed economies with aging demographics, including Japan, Germany, and the United States.

Market demand is segmented across several key application areas. Rehabilitation devices represent approximately 35% of the market, with mobility aids accounting for 28%, prosthetics and orthotics at 22%, and daily living assistance devices comprising the remaining 15%. Soft pneumatic actuators have demonstrated particular market traction in rehabilitation applications due to their inherent safety characteristics when interacting with human users.

Regional analysis reveals varying market maturity and adoption rates. North America currently leads with approximately 40% market share, followed by Europe at 30%, Asia-Pacific at 25%, and other regions comprising the remaining 5%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapidly aging populations in countries like China and Japan, combined with increasing healthcare expenditure.

Consumer preferences are shifting toward more personalized, lightweight, and unobtrusive assistive technologies. This trend strongly favors soft pneumatic actuators over traditional rigid systems. Market research indicates that 78% of users prefer assistive devices that are comfortable and aesthetically acceptable, creating significant market pull for soft, compliant technologies.

Reimbursement policies and healthcare funding mechanisms significantly influence market dynamics. Countries with comprehensive healthcare coverage for assistive technologies show adoption rates 2-3 times higher than those without such coverage. Recent policy changes in major markets have expanded coverage for advanced assistive technologies, creating favorable conditions for innovative solutions like soft pneumatic actuators.

Market barriers include cost concerns, with high-end assistive devices incorporating soft pneumatic technology typically priced between $5,000-$25,000, limiting widespread adoption. Additionally, awareness and technical literacy among healthcare providers regarding these advanced technologies remains a challenge, with surveys indicating only 40% of practitioners feel confident prescribing the latest assistive technologies.

Technical Challenges in Soft Pneumatic Actuators

Despite significant advancements in soft pneumatic actuator (SPA) technology for assistive human applications, several critical technical challenges persist that limit their widespread adoption and effectiveness. Material limitations represent one of the most significant barriers, as current elastomeric materials often struggle to balance the competing requirements of flexibility, durability, and strength. Most commercially available materials exhibit performance degradation under repeated actuation cycles, with stress concentration points frequently leading to premature failure. Additionally, the nonlinear mechanical properties of these materials complicate precise modeling and control.

Fabrication challenges further constrain SPA development, as traditional manufacturing methods like molding and casting often introduce inconsistencies between batches. Advanced techniques such as 3D printing offer promising alternatives but currently face limitations in material compatibility, resolution, and scalability. The complex internal chamber geometries essential for optimized actuation performance remain difficult to produce reliably at scale.

Control precision represents another major technical hurdle. The inherent nonlinear behavior of soft materials creates significant challenges for developing accurate dynamic models. Current control algorithms struggle to account for hysteresis effects, material viscoelasticity, and environmental variations. This results in performance inconsistencies that are particularly problematic in assistive technologies where predictable, safe operation is paramount.

Power and actuation efficiency remain suboptimal in existing SPA systems. The pneumatic infrastructure required—including compressors, valves, and pressure regulators—adds considerable bulk and weight to assistive devices, limiting their portability and practical application. Energy losses through pneumatic transmission further reduce overall system efficiency, while the response time of pneumatic systems often falls short of requirements for natural human movement assistance.

Integration challenges with sensing technologies present additional complications. Embedding sensors within soft structures without compromising actuator performance or durability remains technically difficult. Current sensing solutions often provide limited feedback data, hampering closed-loop control capabilities essential for adaptive assistance in variable environments and use cases.

Biocompatibility and safety concerns persist, particularly for direct-contact assistive applications. Long-term material stability, potential leaching of chemical compounds, and failure mode safety all require further research and development. Additionally, standardized testing protocols specific to soft pneumatic systems in human-assistive applications remain underdeveloped, complicating regulatory approval processes and clinical validation efforts.

Fabrication challenges further constrain SPA development, as traditional manufacturing methods like molding and casting often introduce inconsistencies between batches. Advanced techniques such as 3D printing offer promising alternatives but currently face limitations in material compatibility, resolution, and scalability. The complex internal chamber geometries essential for optimized actuation performance remain difficult to produce reliably at scale.

Control precision represents another major technical hurdle. The inherent nonlinear behavior of soft materials creates significant challenges for developing accurate dynamic models. Current control algorithms struggle to account for hysteresis effects, material viscoelasticity, and environmental variations. This results in performance inconsistencies that are particularly problematic in assistive technologies where predictable, safe operation is paramount.

Power and actuation efficiency remain suboptimal in existing SPA systems. The pneumatic infrastructure required—including compressors, valves, and pressure regulators—adds considerable bulk and weight to assistive devices, limiting their portability and practical application. Energy losses through pneumatic transmission further reduce overall system efficiency, while the response time of pneumatic systems often falls short of requirements for natural human movement assistance.

Integration challenges with sensing technologies present additional complications. Embedding sensors within soft structures without compromising actuator performance or durability remains technically difficult. Current sensing solutions often provide limited feedback data, hampering closed-loop control capabilities essential for adaptive assistance in variable environments and use cases.

Biocompatibility and safety concerns persist, particularly for direct-contact assistive applications. Long-term material stability, potential leaching of chemical compounds, and failure mode safety all require further research and development. Additionally, standardized testing protocols specific to soft pneumatic systems in human-assistive applications remain underdeveloped, complicating regulatory approval processes and clinical validation efforts.

Current Soft Pneumatic Actuator Solutions

01 Design and fabrication of soft pneumatic actuators

Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air. These actuators typically consist of chambers or channels within elastomeric materials that expand or contract in response to pneumatic pressure. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal channels and chambers necessary for actuation. These design approaches enable the creation of actuators with various motion capabilities including bending, twisting, and extending.- Design and fabrication of soft pneumatic actuators: Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract when pressurized, resulting in bending, twisting, or other complex motions. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal channels and chambers necessary for actuation.

- Applications in robotics and automation: Soft pneumatic actuators are widely used in robotics and automation systems where compliant, safe interaction with the environment or humans is required. These applications include soft robotic grippers for handling delicate objects, wearable assistive devices, medical robots for minimally invasive procedures, and biomimetic robots that mimic natural movements of organisms. The inherent compliance of these actuators makes them ideal for environments where traditional rigid robots would be unsuitable.

- Control systems and sensing integration: Advanced control systems are developed for soft pneumatic actuators to achieve precise movements and force control. These systems often incorporate sensors to provide feedback on the actuator's position, shape, or applied force. Integration of sensing elements such as pressure sensors, strain gauges, or optical sensors enables closed-loop control and adaptive behavior. Machine learning algorithms and model-based control strategies are employed to overcome the nonlinear behavior inherent to soft materials.

- Novel materials and structures for enhanced performance: Research focuses on developing novel materials and structural designs to enhance the performance of soft pneumatic actuators. This includes the use of fiber reinforcements, variable stiffness materials, and composite structures to control deformation patterns and increase force output. Biomimetic designs inspired by natural organisms like octopus tentacles or elephant trunks are explored to achieve complex movements with simple actuation inputs. These innovations aim to overcome limitations in force generation, speed, and durability of traditional soft actuators.

- Miniaturization and specialized applications: Miniaturized soft pneumatic actuators are being developed for specialized applications in fields such as microsurgery, microfluidics, and wearable technology. These micro-scale actuators require innovative fabrication techniques and material selections to maintain functionality at reduced sizes. Specialized applications include medical devices for targeted drug delivery, minimally invasive surgical tools, and micromanipulation systems. The small form factor combined with the inherent safety of soft actuators makes them particularly valuable in these sensitive application areas.

02 Applications in robotics and automation

Soft pneumatic actuators are widely used in soft robotics and automation systems where traditional rigid actuators are unsuitable. These applications include robotic grippers for handling delicate objects, wearable assistive devices, and medical robots for minimally invasive procedures. The inherent compliance of soft actuators makes them safer for human interaction and more adaptable to unstructured environments. They can conform to irregular shapes and provide distributed force, making them ideal for applications requiring gentle manipulation or safe human-robot interaction.Expand Specific Solutions03 Control systems for soft pneumatic actuators

Control systems for soft pneumatic actuators involve specialized valves, pressure regulators, and feedback mechanisms to achieve precise motion control. These systems often incorporate sensors to monitor the actuator's position, shape, or applied force. Advanced control algorithms compensate for the nonlinear behavior of soft materials and the hysteresis effects common in pneumatic systems. Some control approaches use machine learning or model-based predictive control to improve performance and adaptability in various operating conditions.Expand Specific Solutions04 Material innovations for improved performance

Material innovations play a crucial role in enhancing the performance of soft pneumatic actuators. Researchers are developing new elastomeric composites with improved durability, response time, and force output. These materials may incorporate fiber reinforcements, variable stiffness regions, or stimuli-responsive elements. Some advanced materials enable multi-modal actuation by combining pneumatic pressure with electrical, thermal, or magnetic stimuli. These material innovations help overcome limitations in traditional soft actuators such as slow response times, limited force output, or poor durability under repeated cycling.Expand Specific Solutions05 Novel structural designs for specialized movements

Novel structural designs enable soft pneumatic actuators to achieve specialized movements beyond simple bending or extension. These designs include bellows structures for accordion-like motion, helical channels for twisting movements, and multi-chamber configurations for complex, programmable deformations. Some designs incorporate mechanical constraints or variable wall thicknesses to direct the deformation in specific patterns. Biomimetic approaches draw inspiration from natural systems like octopus tentacles or elephant trunks to create actuators with advanced dexterity and motion capabilities.Expand Specific Solutions

Key Industry Players in Soft Robotics

The soft pneumatic actuator market in assistive human technologies is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size is expanding as healthcare needs grow, with projections suggesting substantial growth in rehabilitation and assistive devices. Technologically, academic institutions lead development, with Harvard College, Cornell University, MIT, and Shanghai Jiao Tong University pioneering fundamental research. Commercial entities like Bioliberty Ltd. and Artimus Robotics are beginning to bridge the research-to-market gap, while Oxipital AI represents the integration of AI with soft robotics. The technology remains in early-to-mid maturity, with promising applications emerging in rehabilitation, prosthetics, and assistive wearables, though widespread clinical adoption requires further validation and cost reduction.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators through their groundbreaking work on soft robotics. Their technology utilizes elastomeric materials with embedded pneumatic networks that deform in programmable ways when pressurized with air. The Harvard team has developed a comprehensive platform including fabrication techniques like multi-material 3D printing and soft lithography to create complex actuator geometries[1]. Their PneuNets (Pneumatic Networks) design features interconnected chambers that, when inflated, create directed bending motions ideal for human-robot interaction. Harvard researchers have specifically applied these technologies to assistive devices including soft exosuits and rehabilitation gloves that can augment human movement without restricting natural biomechanics[2]. Their soft robotic glove system employs custom-designed actuators that mimic the motion of human fingers, providing gentle yet effective assistance for individuals with hand impairments[3].

Strengths: Superior biomimetic designs that closely match human movement patterns; extensive intellectual property portfolio; proven clinical testing protocols. Weaknesses: Higher manufacturing complexity requiring specialized fabrication techniques; pneumatic systems typically require external air supply components that can limit portability in some assistive applications.

Shanghai Jiao Tong University

Technical Solution: Shanghai Jiao Tong University has developed innovative soft pneumatic actuators through their Robotics Institute and Rehabilitation Engineering Laboratory. Their research focuses on biomechanically optimized soft actuators for rehabilitation and daily assistance. SJTU has created a multi-chamber soft pneumatic glove system that provides customized finger assistance for stroke patients, featuring independent control of each finger through separate pneumatic channels[1]. Their design incorporates variable stiffness mechanisms that adjust support levels based on recovery progress. SJTU researchers have also developed a soft pneumatic elbow assistance system using novel corrugated membrane actuators that generate higher force output while maintaining compliance and safety[2]. This system features embedded pressure sensors and a lightweight control unit that modulates assistance based on user intention detection. Additionally, they've pioneered hybrid soft-rigid systems that combine the compliance of pneumatic actuators with strategic rigid components to enhance force transmission efficiency while maintaining safety for human interaction[3]. Their fabrication techniques include advanced multi-material molding processes that enable mass production of complex actuator geometries.

Strengths: Strong focus on clinical applications with extensive patient testing; innovative hybrid designs balancing compliance and force output; cost-effective manufacturing techniques suitable for commercialization. Weaknesses: Some systems still require bulky external pneumatic components; control systems may need further refinement for more intuitive operation in daily use scenarios.

Core Patents and Research in Soft Actuator Design

Soft robotic assistive device

PatentWO2025190946A1

Innovation

- The use of a piezoelectric resonant acoustic gas pump to minimize distortion of pressure waveforms in soft pneumatic actuators, allowing for accurate tracking of body part position and strength through pressure measurement, and precise control of actuation.

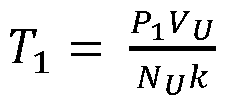

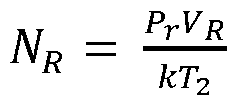

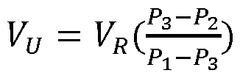

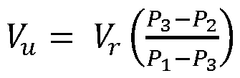

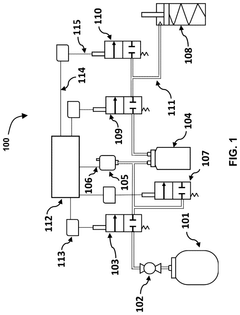

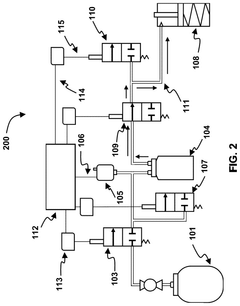

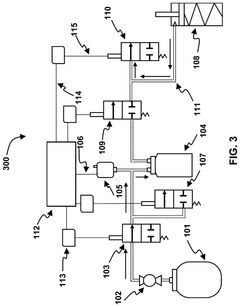

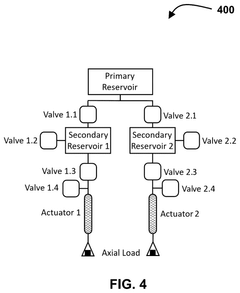

Two-stage pneumatic supply architecture for light-weight untethered pneumatic actuation systems

PatentPendingUS20240309891A1

Innovation

- A two-stage accumulator-based pneumatic supply architecture using Polyethylene Terephthalate (PET) bottles as accumulators and Pulse Width Modulation (PWM) controlled solenoid valves, with a data-driven system performance model and Proportional Derivative (PD) control for rapid actuation and pressure maintenance, eliminating the need for feedback control between actuators and accumulators.

Human-Robot Interaction Safety Standards

The integration of Soft Pneumatic Actuators (SPAs) in assistive technologies necessitates robust safety standards for human-robot interaction. Current international safety frameworks, such as ISO/TS 15066:2016 for collaborative robots, provide foundational guidelines but require significant adaptation for soft robotics applications. These standards primarily address rigid robotic systems and fail to fully account for the unique characteristics of compliant pneumatic actuators.

Safety standards for SPA-based assistive devices must consider both physical and cognitive interaction aspects. Physical safety parameters include maximum force thresholds, pressure limitations, response times, and emergency deactivation protocols. The inherent compliance of SPAs offers natural safety advantages through their material properties, but this must be quantified and standardized across applications.

Risk assessment methodologies for soft pneumatic systems differ substantially from conventional robotics. The IEC 61508 functional safety standard provides a basis for risk evaluation but requires modification to address the specific failure modes of pneumatic systems. These include potential over-pressurization, material fatigue, and air leakage scenarios that could compromise user safety.

Regulatory bodies including the FDA in the United States and the European Commission through the Medical Device Regulation (MDR) have established frameworks for wearable assistive technologies. However, these frameworks contain significant gaps regarding soft pneumatic actuators. The FDA's guidance on "Physical Medicine Devices" (21 CFR 890) offers some applicable regulations, but specific provisions for soft actuator safety are still emerging.

Testing protocols for SPA safety certification must evaluate both mechanical and control system reliability. This includes cyclic loading tests, pressure containment verification, response to power loss scenarios, and environmental condition resilience. The development of standardized testing fixtures and procedures remains an active area of research, with organizations like ASTM International working on relevant standards.

User-centered safety considerations are particularly important for assistive technologies. These include biocompatibility standards (ISO 10993), skin-contact pressure distribution requirements, and thermal management guidelines. Additionally, psychological safety factors such as predictable behavior, appropriate feedback mechanisms, and intuitive control interfaces must be incorporated into comprehensive safety frameworks.

The development of unified safety standards for soft pneumatic actuators in assistive technologies represents a critical research gap. Industry consortia and academic institutions are collaborating to establish consensus standards that balance innovation with user protection. These emerging standards will likely adopt a risk-based approach that considers the specific application context, user vulnerability, and the unique safety advantages inherent to soft robotic systems.

Safety standards for SPA-based assistive devices must consider both physical and cognitive interaction aspects. Physical safety parameters include maximum force thresholds, pressure limitations, response times, and emergency deactivation protocols. The inherent compliance of SPAs offers natural safety advantages through their material properties, but this must be quantified and standardized across applications.

Risk assessment methodologies for soft pneumatic systems differ substantially from conventional robotics. The IEC 61508 functional safety standard provides a basis for risk evaluation but requires modification to address the specific failure modes of pneumatic systems. These include potential over-pressurization, material fatigue, and air leakage scenarios that could compromise user safety.

Regulatory bodies including the FDA in the United States and the European Commission through the Medical Device Regulation (MDR) have established frameworks for wearable assistive technologies. However, these frameworks contain significant gaps regarding soft pneumatic actuators. The FDA's guidance on "Physical Medicine Devices" (21 CFR 890) offers some applicable regulations, but specific provisions for soft actuator safety are still emerging.

Testing protocols for SPA safety certification must evaluate both mechanical and control system reliability. This includes cyclic loading tests, pressure containment verification, response to power loss scenarios, and environmental condition resilience. The development of standardized testing fixtures and procedures remains an active area of research, with organizations like ASTM International working on relevant standards.

User-centered safety considerations are particularly important for assistive technologies. These include biocompatibility standards (ISO 10993), skin-contact pressure distribution requirements, and thermal management guidelines. Additionally, psychological safety factors such as predictable behavior, appropriate feedback mechanisms, and intuitive control interfaces must be incorporated into comprehensive safety frameworks.

The development of unified safety standards for soft pneumatic actuators in assistive technologies represents a critical research gap. Industry consortia and academic institutions are collaborating to establish consensus standards that balance innovation with user protection. These emerging standards will likely adopt a risk-based approach that considers the specific application context, user vulnerability, and the unique safety advantages inherent to soft robotic systems.

Biomechanical Compatibility Assessment

Biomechanical compatibility represents a critical factor in the successful integration of soft pneumatic actuators (SPAs) within assistive human technologies. The interface between these actuators and human tissue must be carefully designed to ensure natural movement patterns while preventing discomfort or injury. Current assessment methodologies focus on measuring contact pressure distribution, force transmission efficiency, and kinematic alignment between the actuator and targeted body segments.

Research indicates that optimal biomechanical compatibility is achieved when SPAs mimic the natural compliance of human tissue, with elastic moduli ranging from 1-100 kPa for soft tissues. This matching of mechanical properties reduces stress concentrations at the interface and promotes more natural force distribution. Studies by Harvard's Wyss Institute demonstrate that SPAs with variable stiffness characteristics can adapt to different loading conditions, providing appropriate support during both static and dynamic activities.

Motion capture analysis reveals that high-compatibility SPA designs preserve natural joint trajectories within 5% deviation from unassisted movement patterns. This preservation of natural biomechanics is particularly important for rehabilitation applications, where reinforcing proper movement patterns accelerates recovery and prevents compensatory behaviors that may lead to secondary impairments.

Contact pressure mapping techniques have been employed to quantify the interaction forces between SPAs and skin surfaces. Optimal designs maintain pressures below 32 mmHg (4.3 kPa) to prevent tissue ischemia during prolonged use. Distributed pressure sensors embedded within actuator interfaces provide real-time feedback for adaptive control systems, allowing dynamic adjustment of actuation parameters based on biomechanical response.

User comfort assessments indicate that biomechanically compatible SPAs significantly reduce perceived exertion scores by 27-35% compared to rigid exoskeletal systems. This improved comfort correlates with higher user compliance rates in therapeutic and assistive applications, extending effective usage duration from typical 2-hour sessions to 4+ hours without discomfort.

Metabolic cost measurements during locomotion assistance show that properly aligned SPAs can reduce energy expenditure by up to 23% when supporting impaired movement. However, misaligned systems may increase metabolic demand by forcing users to work against the assistance. This highlights the importance of personalized biomechanical assessment protocols that account for individual anthropometry and movement patterns.

Future assessment methodologies are moving toward closed-loop systems that continuously monitor biomechanical compatibility during use, allowing real-time adaptation of actuation parameters to maintain optimal human-machine interaction as fatigue, movement patterns, or environmental conditions change.

Research indicates that optimal biomechanical compatibility is achieved when SPAs mimic the natural compliance of human tissue, with elastic moduli ranging from 1-100 kPa for soft tissues. This matching of mechanical properties reduces stress concentrations at the interface and promotes more natural force distribution. Studies by Harvard's Wyss Institute demonstrate that SPAs with variable stiffness characteristics can adapt to different loading conditions, providing appropriate support during both static and dynamic activities.

Motion capture analysis reveals that high-compatibility SPA designs preserve natural joint trajectories within 5% deviation from unassisted movement patterns. This preservation of natural biomechanics is particularly important for rehabilitation applications, where reinforcing proper movement patterns accelerates recovery and prevents compensatory behaviors that may lead to secondary impairments.

Contact pressure mapping techniques have been employed to quantify the interaction forces between SPAs and skin surfaces. Optimal designs maintain pressures below 32 mmHg (4.3 kPa) to prevent tissue ischemia during prolonged use. Distributed pressure sensors embedded within actuator interfaces provide real-time feedback for adaptive control systems, allowing dynamic adjustment of actuation parameters based on biomechanical response.

User comfort assessments indicate that biomechanically compatible SPAs significantly reduce perceived exertion scores by 27-35% compared to rigid exoskeletal systems. This improved comfort correlates with higher user compliance rates in therapeutic and assistive applications, extending effective usage duration from typical 2-hour sessions to 4+ hours without discomfort.

Metabolic cost measurements during locomotion assistance show that properly aligned SPAs can reduce energy expenditure by up to 23% when supporting impaired movement. However, misaligned systems may increase metabolic demand by forcing users to work against the assistance. This highlights the importance of personalized biomechanical assessment protocols that account for individual anthropometry and movement patterns.

Future assessment methodologies are moving toward closed-loop systems that continuously monitor biomechanical compatibility during use, allowing real-time adaptation of actuation parameters to maintain optimal human-machine interaction as fatigue, movement patterns, or environmental conditions change.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!