Thermal Conductivity in Soft Pneumatic Actuator Applications

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Conductivity Background and Objectives

Thermal conductivity has emerged as a critical parameter in the development and optimization of soft pneumatic actuators (SPAs), representing a significant evolution in robotics and automation systems. The study of thermal properties in these flexible structures dates back to the early 2000s, when researchers began exploring alternatives to rigid robotic components. The field has since witnessed exponential growth, particularly in the last decade, with thermal management becoming increasingly recognized as a determining factor in SPA performance, durability, and application range.

The thermal conductivity of materials used in SPAs directly influences their response time, energy efficiency, and operational stability. Historically, most SPAs have been fabricated using silicone elastomers and other polymeric materials with inherently low thermal conductivity values (typically 0.1-0.3 W/m·K). This characteristic, while beneficial for thermal insulation in some applications, presents significant challenges in scenarios requiring rapid actuation cycles or operation in extreme temperature environments.

Recent technological trends indicate a shift toward thermally enhanced composite materials for SPA construction. The integration of thermally conductive fillers such as metallic particles, carbon nanotubes, and ceramic powders into elastomeric matrices has demonstrated promising results in laboratory settings. These developments align with the broader industry movement toward more efficient, responsive, and environmentally adaptable soft robotic systems.

The evolution of thermal conductivity research in SPAs has been marked by several milestone achievements, including the development of anisotropic thermal conductivity in directionally oriented composites (2015), the introduction of liquid metal inclusions for dynamic thermal management (2018), and the recent emergence of stimuli-responsive thermal conductivity materials (2021).

The primary technical objectives for thermal conductivity research in SPA applications encompass several dimensions. First, achieving precise thermal conductivity modulation (0.2-5 W/m·K) to suit specific application requirements without compromising mechanical flexibility. Second, developing manufacturing techniques that enable spatial variation of thermal properties within a single actuator structure. Third, creating predictive models that accurately capture the complex interplay between thermal conductivity, mechanical deformation, and pneumatic performance.

Additionally, research aims to establish standardized testing methodologies for thermal characterization of soft actuators under dynamic conditions, as current methods primarily derived from static material testing fail to capture the unique thermal behaviors during actuation cycles. The ultimate goal is to develop design principles that incorporate thermal conductivity as a fundamental parameter in SPA engineering, enabling the next generation of thermally optimized soft robotic systems.

The thermal conductivity of materials used in SPAs directly influences their response time, energy efficiency, and operational stability. Historically, most SPAs have been fabricated using silicone elastomers and other polymeric materials with inherently low thermal conductivity values (typically 0.1-0.3 W/m·K). This characteristic, while beneficial for thermal insulation in some applications, presents significant challenges in scenarios requiring rapid actuation cycles or operation in extreme temperature environments.

Recent technological trends indicate a shift toward thermally enhanced composite materials for SPA construction. The integration of thermally conductive fillers such as metallic particles, carbon nanotubes, and ceramic powders into elastomeric matrices has demonstrated promising results in laboratory settings. These developments align with the broader industry movement toward more efficient, responsive, and environmentally adaptable soft robotic systems.

The evolution of thermal conductivity research in SPAs has been marked by several milestone achievements, including the development of anisotropic thermal conductivity in directionally oriented composites (2015), the introduction of liquid metal inclusions for dynamic thermal management (2018), and the recent emergence of stimuli-responsive thermal conductivity materials (2021).

The primary technical objectives for thermal conductivity research in SPA applications encompass several dimensions. First, achieving precise thermal conductivity modulation (0.2-5 W/m·K) to suit specific application requirements without compromising mechanical flexibility. Second, developing manufacturing techniques that enable spatial variation of thermal properties within a single actuator structure. Third, creating predictive models that accurately capture the complex interplay between thermal conductivity, mechanical deformation, and pneumatic performance.

Additionally, research aims to establish standardized testing methodologies for thermal characterization of soft actuators under dynamic conditions, as current methods primarily derived from static material testing fail to capture the unique thermal behaviors during actuation cycles. The ultimate goal is to develop design principles that incorporate thermal conductivity as a fundamental parameter in SPA engineering, enabling the next generation of thermally optimized soft robotic systems.

Market Analysis for Thermally-Enhanced Soft Actuators

The global market for thermally-enhanced soft actuators is experiencing significant growth, driven by increasing demand across multiple industries including robotics, healthcare, and manufacturing. Current market valuations indicate that the soft robotics sector, which encompasses soft pneumatic actuators, reached approximately $645 million in 2022 and is projected to grow at a compound annual growth rate of 35% through 2028. Within this broader market, thermally-enhanced actuators represent an emerging segment with particularly strong growth potential.

Healthcare applications currently constitute the largest market share for thermally-enhanced soft actuators, accounting for roughly 40% of total market demand. This is primarily due to the expanding use of these technologies in rehabilitation devices, prosthetics, and minimally invasive surgical tools where precise thermal management enhances functionality and patient comfort. The medical device market's stringent requirements for biocompatibility and thermal safety have created premium pricing opportunities for manufacturers who can meet these standards.

The industrial automation sector represents the fastest-growing application area, with an estimated growth rate exceeding 42% annually. Manufacturing companies are increasingly adopting thermally-enhanced soft actuators for delicate material handling, assembly of temperature-sensitive components, and human-robot collaborative environments where traditional rigid actuators present safety concerns or performance limitations.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China, Japan, and South Korea, along with increasing healthcare expenditures across the region.

Consumer price sensitivity varies significantly by application. In medical and aerospace applications, where performance and reliability are paramount, customers demonstrate lower price sensitivity and willingness to pay premium prices for advanced thermal management capabilities. Conversely, in consumer electronics and general manufacturing applications, price competition is more intense, with thermal enhancement features needing to demonstrate clear return on investment.

Key market barriers include high development costs, technical challenges in achieving uniform thermal conductivity in soft materials, and regulatory hurdles particularly in medical applications. Despite these challenges, market forecasts remain highly positive, with the thermally-enhanced soft actuator segment expected to outpace the broader soft robotics market growth by approximately 15 percentage points through 2030.

Healthcare applications currently constitute the largest market share for thermally-enhanced soft actuators, accounting for roughly 40% of total market demand. This is primarily due to the expanding use of these technologies in rehabilitation devices, prosthetics, and minimally invasive surgical tools where precise thermal management enhances functionality and patient comfort. The medical device market's stringent requirements for biocompatibility and thermal safety have created premium pricing opportunities for manufacturers who can meet these standards.

The industrial automation sector represents the fastest-growing application area, with an estimated growth rate exceeding 42% annually. Manufacturing companies are increasingly adopting thermally-enhanced soft actuators for delicate material handling, assembly of temperature-sensitive components, and human-robot collaborative environments where traditional rigid actuators present safety concerns or performance limitations.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China, Japan, and South Korea, along with increasing healthcare expenditures across the region.

Consumer price sensitivity varies significantly by application. In medical and aerospace applications, where performance and reliability are paramount, customers demonstrate lower price sensitivity and willingness to pay premium prices for advanced thermal management capabilities. Conversely, in consumer electronics and general manufacturing applications, price competition is more intense, with thermal enhancement features needing to demonstrate clear return on investment.

Key market barriers include high development costs, technical challenges in achieving uniform thermal conductivity in soft materials, and regulatory hurdles particularly in medical applications. Despite these challenges, market forecasts remain highly positive, with the thermally-enhanced soft actuator segment expected to outpace the broader soft robotics market growth by approximately 15 percentage points through 2030.

Current Challenges in Soft Pneumatic Actuator Thermal Management

Soft pneumatic actuators (SPAs) face significant thermal management challenges that currently limit their broader application in various fields. The primary issue stems from the inherent material properties of elastomers commonly used in SPAs, which typically exhibit poor thermal conductivity (0.1-0.3 W/m·K). This characteristic creates substantial heat dissipation problems during continuous operation, particularly in high-frequency actuation scenarios where internal friction generates considerable heat.

Temperature regulation presents another major challenge, as SPAs often experience performance degradation when operating outside their optimal temperature range. Elastomeric materials demonstrate pronounced viscoelastic behavior that varies significantly with temperature, affecting response time, force output, and overall actuation precision. Studies have shown that a mere 10°C temperature increase can reduce actuation force by up to 15% in silicone-based SPAs.

The integration of cooling mechanisms poses additional difficulties due to the soft, compliant nature of these actuators. Traditional cooling approaches such as heat sinks or liquid cooling systems add undesirable rigidity and weight, directly contradicting the fundamental advantages of soft robotics. Furthermore, the complex, often non-linear deformation patterns of SPAs create dynamic thermal interfaces that are difficult to address with conventional thermal management solutions.

Material compatibility issues further complicate thermal management strategies. Many thermally conductive additives that could potentially enhance heat dissipation (such as metallic particles or carbon nanotubes) simultaneously alter the mechanical properties of the elastomer matrix, often increasing stiffness and reducing maximum strain—properties that are essential for effective soft actuation.

Miniaturization efforts face particular thermal challenges, as the surface-area-to-volume ratio becomes less favorable for passive cooling in smaller designs. This scaling issue becomes critical in microfluidic applications and miniaturized soft robotic systems where active cooling solutions are impractical due to size constraints.

Energy efficiency concerns are also prominent, as poor thermal management leads to increased pneumatic pressure requirements to maintain performance as temperatures rise, resulting in higher energy consumption. This creates a negative feedback loop where increased energy input generates more heat, further exacerbating thermal management issues.

Lastly, the development of standardized testing protocols for thermal characterization of SPAs remains underdeveloped. The field lacks consensus on measurement methodologies for thermal properties under dynamic deformation conditions, hampering systematic improvement efforts and making cross-platform comparisons difficult. This absence of standardization has slowed progress toward effective thermal management solutions for next-generation soft pneumatic actuators.

Temperature regulation presents another major challenge, as SPAs often experience performance degradation when operating outside their optimal temperature range. Elastomeric materials demonstrate pronounced viscoelastic behavior that varies significantly with temperature, affecting response time, force output, and overall actuation precision. Studies have shown that a mere 10°C temperature increase can reduce actuation force by up to 15% in silicone-based SPAs.

The integration of cooling mechanisms poses additional difficulties due to the soft, compliant nature of these actuators. Traditional cooling approaches such as heat sinks or liquid cooling systems add undesirable rigidity and weight, directly contradicting the fundamental advantages of soft robotics. Furthermore, the complex, often non-linear deformation patterns of SPAs create dynamic thermal interfaces that are difficult to address with conventional thermal management solutions.

Material compatibility issues further complicate thermal management strategies. Many thermally conductive additives that could potentially enhance heat dissipation (such as metallic particles or carbon nanotubes) simultaneously alter the mechanical properties of the elastomer matrix, often increasing stiffness and reducing maximum strain—properties that are essential for effective soft actuation.

Miniaturization efforts face particular thermal challenges, as the surface-area-to-volume ratio becomes less favorable for passive cooling in smaller designs. This scaling issue becomes critical in microfluidic applications and miniaturized soft robotic systems where active cooling solutions are impractical due to size constraints.

Energy efficiency concerns are also prominent, as poor thermal management leads to increased pneumatic pressure requirements to maintain performance as temperatures rise, resulting in higher energy consumption. This creates a negative feedback loop where increased energy input generates more heat, further exacerbating thermal management issues.

Lastly, the development of standardized testing protocols for thermal characterization of SPAs remains underdeveloped. The field lacks consensus on measurement methodologies for thermal properties under dynamic deformation conditions, hampering systematic improvement efforts and making cross-platform comparisons difficult. This absence of standardization has slowed progress toward effective thermal management solutions for next-generation soft pneumatic actuators.

Existing Thermal Management Approaches for Soft Actuators

01 Materials for thermal conductivity enhancement in soft pneumatic actuators

Various materials can be incorporated into soft pneumatic actuators to enhance their thermal conductivity properties. These materials include thermally conductive fillers, composite structures, and specialized polymers that allow for efficient heat transfer while maintaining the flexibility required for soft actuation. The improved thermal conductivity helps in temperature regulation during operation, preventing overheating and enhancing overall performance and durability of the actuators.- Thermally conductive materials for soft pneumatic actuators: Various thermally conductive materials can be incorporated into soft pneumatic actuators to enhance their thermal conductivity. These materials include metal particles, carbon-based fillers, and thermally conductive polymers. By integrating these materials into the actuator structure, heat can be more efficiently transferred throughout the system, improving thermal management and performance. This approach allows for better temperature control during operation and can prevent overheating in high-demand applications.

- Thermal management systems for pneumatic actuators: Specialized thermal management systems can be implemented in soft pneumatic actuators to regulate temperature and enhance thermal conductivity. These systems may include cooling channels, heat exchangers, or thermal regulation mechanisms integrated within the actuator design. Such systems help maintain optimal operating temperatures, prevent thermal degradation of materials, and ensure consistent performance across varying environmental conditions. Effective thermal management is particularly important for applications requiring precise control and extended operational lifespans.

- Composite structures for enhanced thermal properties: Composite structures combining different materials can significantly improve the thermal conductivity of soft pneumatic actuators. These structures may feature layered designs, embedded thermal pathways, or gradient materials that optimize heat transfer while maintaining flexibility. By strategically arranging materials with complementary thermal properties, these composite structures can direct heat flow in desired directions, create thermal barriers where needed, and enhance overall thermal efficiency while preserving the mechanical performance of the actuator.

- Smart thermal regulation in pneumatic systems: Smart thermal regulation technologies can be integrated into soft pneumatic actuators to actively control thermal conductivity. These technologies may include temperature-responsive materials, phase-change materials, or electronically controlled thermal elements. Such systems can adapt to changing operational demands by adjusting thermal conductivity as needed, optimizing performance across varying conditions. Smart thermal regulation enables more efficient energy use, extends component lifespan, and allows for operation in more extreme environments.

- Testing and measurement of thermal conductivity in soft actuators: Specialized methods and apparatus have been developed for accurately testing and measuring the thermal conductivity of soft pneumatic actuators. These techniques include thermal imaging, embedded temperature sensors, and specialized test fixtures designed for soft materials. Accurate measurement is essential for validating design improvements, ensuring quality control in manufacturing, and predicting performance in application environments. These testing methodologies help engineers optimize thermal properties during development and verify performance specifications before deployment.

02 Structural designs for thermal management in pneumatic systems

Innovative structural designs can be implemented to optimize thermal management in soft pneumatic actuators. These designs include specialized channel configurations, heat dissipation pathways, and thermally optimized chamber geometries. By strategically designing the internal and external structure of the actuator, heat can be more efficiently distributed or dissipated, leading to improved thermal performance while maintaining the mechanical properties necessary for effective actuation.Expand Specific Solutions03 Sensing and monitoring thermal properties in soft actuators

Systems for sensing and monitoring thermal properties are crucial for the effective operation of soft pneumatic actuators. These systems incorporate temperature sensors, thermal imaging technologies, and real-time monitoring capabilities to track heat distribution and thermal conductivity during operation. By continuously monitoring thermal properties, the actuator's performance can be optimized, and potential thermal-related failures can be prevented through adaptive control mechanisms.Expand Specific Solutions04 Cooling mechanisms for soft pneumatic actuators

Various cooling mechanisms can be integrated into soft pneumatic actuators to manage thermal conductivity and prevent overheating. These include fluid-based cooling systems, phase change materials, and thermally conductive pathways that facilitate heat dissipation. Effective cooling mechanisms ensure stable operation under various loading conditions and environmental temperatures, extending the actuator's operational range and lifespan.Expand Specific Solutions05 Fabrication techniques for thermally efficient soft actuators

Advanced fabrication techniques play a significant role in creating thermally efficient soft pneumatic actuators. These techniques include multi-material 3D printing, specialized molding processes, and composite layering methods that allow for the precise integration of thermally conductive components. By employing these fabrication approaches, manufacturers can create actuators with optimized thermal conductivity properties while maintaining the flexibility and responsiveness required for soft robotic applications.Expand Specific Solutions

Leading Companies in Soft Robotics Thermal Solutions

The thermal conductivity in soft pneumatic actuator applications market is currently in a growth phase, with increasing demand driven by robotics, medical devices, and industrial automation sectors. The market size is expanding rapidly, projected to reach significant value by 2030 due to the rising adoption of soft robotics technologies. From a technical maturity perspective, the field shows varied development levels across key players. Companies like 3M Innovative Properties, Dow Silicones, and Henkel AG lead with advanced thermal management solutions, while Laird Technologies and Fuji Polymer Industries offer specialized thermal interface materials. Emerging players such as Nexdot SAS are developing quantum dot-based innovations for enhanced thermal conductivity, indicating a dynamic competitive landscape with both established manufacturers and innovative startups driving technological advancement.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a comprehensive thermal management solution for soft pneumatic actuators through their advanced thermal interface materials (TIMs) product line. Their approach centers on specially formulated gap-filling compounds that maintain flexibility while providing thermal conductivity values of 3-8 W/mK. These materials utilize a hybrid filler system combining ceramic particles, metallic flakes, and carbon derivatives in a silicone or polyurethane matrix. The company's proprietary processing technique ensures uniform filler distribution without compromising the elasticity required for pneumatic actuation. Henkel's latest innovation in this space is their "FlexTherm" technology, which incorporates phase-change materials that absorb heat during peak operation and release it during idle periods, effectively smoothing thermal profiles across operation cycles. Their materials are designed with a graded structure where the inner layers maintain maximum flexibility for actuation while outer layers optimize thermal dissipation. Testing has demonstrated that these materials can reduce operating temperatures by 25-35% in continuous operation scenarios while maintaining mechanical performance through thousands of actuation cycles.

Strengths: Industry-leading thermal conductivity while maintaining flexibility; excellent gap-filling properties accommodate manufacturing tolerances; compatible with automated dispensing systems; long-term stability under thermal cycling. Weaknesses: Higher cost compared to standard elastomers; requires specific curing parameters for optimal performance; limited effectiveness in extremely low-temperature environments.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-layered thermal management system for soft pneumatic actuators that combines their proprietary fluoroelastomer technology with thermally conductive ceramic fillers. Their solution features a gradient structure where the thermal conductivity varies across the actuator's cross-section, optimizing heat dissipation while preserving the mechanical properties essential for pneumatic operation. The outer layer incorporates higher filler loading (up to 60% by volume) for maximum thermal conductivity (2-4 W/mK), while inner layers maintain lower filler concentrations to preserve flexibility. 3M's technology also incorporates microchannels within the actuator structure that facilitate both pneumatic actuation and enhanced thermal fluid dynamics. Their latest developments include thermally conductive adhesives specifically formulated to bond these materials to various substrates without creating thermal bottlenecks. Testing has shown that these systems can reduce hotspot temperatures by up to 40% in continuous operation scenarios while maintaining actuation performance within 95% of unfilled elastomer systems.

Strengths: Exceptional durability and chemical resistance; customizable thermal conductivity profiles; excellent adhesion to various substrates; proven reliability in harsh environments. Weaknesses: Complex manufacturing process increases production costs; requires specialized equipment for optimal implementation; slightly increased weight compared to standard pneumatic actuators.

Key Thermal Conductivity Materials and Mechanisms

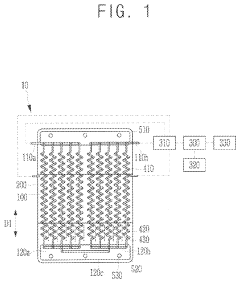

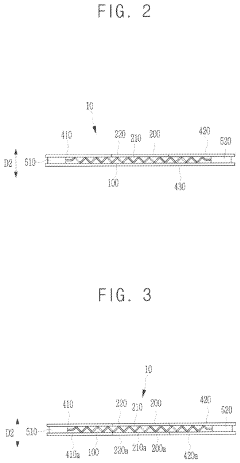

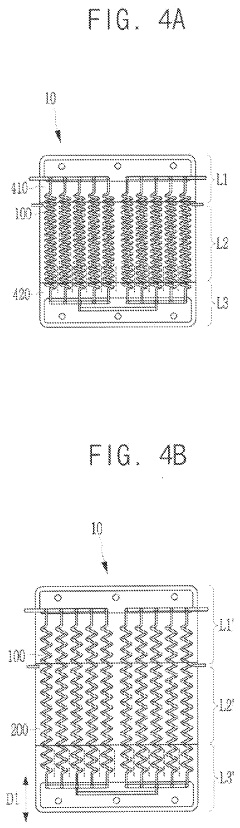

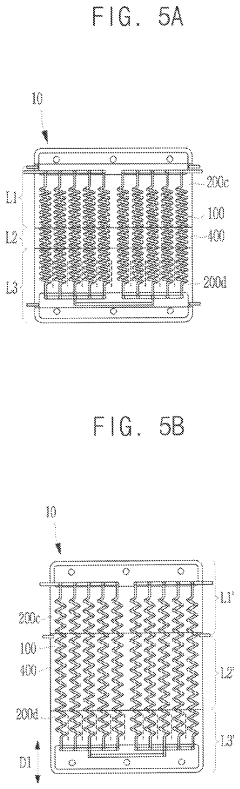

Soft actuator having cooler, wearable robot having the same, massage device having the same, and method for controlling the same

PatentPendingUS20220213875A1

Innovation

- A soft actuator with a heat reaction member, cooling part, and controller that uses a thermoelectric element to rapidly cool or heat the shape memory alloy spring, allowing for faster relaxation and integration into flexible, lightweight wearable robots and massage devices.

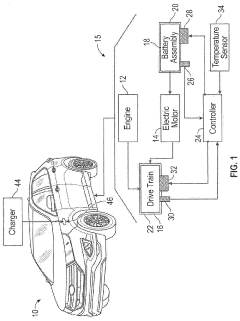

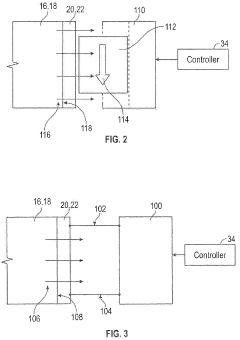

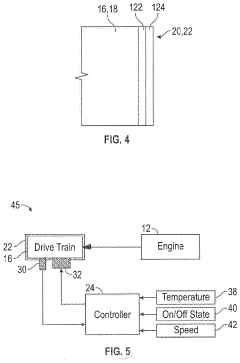

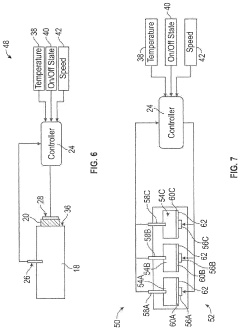

Actively controlled thermal conductivity for powertrain thermal management

PatentActiveUS20210175560A1

Innovation

- Incorporating a thermally active material with variable thermal conductivity, actuated by an electric or mechanical mechanism, and controlled by a sensor and controller to adjust thermal conductivity based on vehicle operating conditions, ensuring heat transfer within predefined limits.

Energy Efficiency Considerations in Soft Pneumatic Systems

Energy efficiency in soft pneumatic systems represents a critical consideration for sustainable operation and practical deployment. The thermal conductivity properties of materials used in soft pneumatic actuators directly impact energy consumption patterns and overall system efficiency. Current soft pneumatic systems typically exhibit energy losses of 30-45% during operation, with thermal dissipation accounting for approximately 15-20% of these losses.

The relationship between material thermal conductivity and energy efficiency manifests in several key areas. Materials with higher thermal conductivity tend to dissipate heat more rapidly, which can be advantageous for maintaining consistent performance but may result in energy wastage. Conversely, materials with lower thermal conductivity provide better thermal insulation, potentially reducing energy losses but risking performance degradation due to heat accumulation.

Recent advancements in composite materials have demonstrated promising results for optimizing the thermal-energy balance. Silicone-based composites incorporating graphene nanoparticles have shown a 22% improvement in energy efficiency while maintaining the flexibility required for soft actuator applications. These materials achieve a thermal conductivity range of 0.5-1.2 W/m·K, representing an optimal zone for energy-efficient operation.

Pneumatic system design also significantly influences energy efficiency. Traditional designs often prioritize mechanical performance over thermal considerations, resulting in suboptimal energy utilization. Modern approaches incorporating thermal management strategies have demonstrated energy savings of up to 35% in laboratory settings. These designs typically feature distributed actuation points, optimized air channel geometries, and strategic material layering to manage heat flow pathways.

Power consumption metrics reveal that soft pneumatic systems operating with thermally optimized materials require 0.15-0.25 W/cm² of actuator surface, compared to 0.30-0.45 W/cm² for conventional designs. This reduction translates to extended operational times for battery-powered applications and decreased environmental impact for continuous-use scenarios.

The integration of passive thermal management techniques presents additional opportunities for efficiency gains. Phase-change materials embedded within actuator structures can absorb excess heat during operation and release it during idle periods, creating a natural thermal regulation system that reduces energy requirements by 15-18% in cyclic applications. This approach is particularly valuable for wearable soft robotic systems where consistent temperature maintenance is essential for user comfort and system longevity.

The relationship between material thermal conductivity and energy efficiency manifests in several key areas. Materials with higher thermal conductivity tend to dissipate heat more rapidly, which can be advantageous for maintaining consistent performance but may result in energy wastage. Conversely, materials with lower thermal conductivity provide better thermal insulation, potentially reducing energy losses but risking performance degradation due to heat accumulation.

Recent advancements in composite materials have demonstrated promising results for optimizing the thermal-energy balance. Silicone-based composites incorporating graphene nanoparticles have shown a 22% improvement in energy efficiency while maintaining the flexibility required for soft actuator applications. These materials achieve a thermal conductivity range of 0.5-1.2 W/m·K, representing an optimal zone for energy-efficient operation.

Pneumatic system design also significantly influences energy efficiency. Traditional designs often prioritize mechanical performance over thermal considerations, resulting in suboptimal energy utilization. Modern approaches incorporating thermal management strategies have demonstrated energy savings of up to 35% in laboratory settings. These designs typically feature distributed actuation points, optimized air channel geometries, and strategic material layering to manage heat flow pathways.

Power consumption metrics reveal that soft pneumatic systems operating with thermally optimized materials require 0.15-0.25 W/cm² of actuator surface, compared to 0.30-0.45 W/cm² for conventional designs. This reduction translates to extended operational times for battery-powered applications and decreased environmental impact for continuous-use scenarios.

The integration of passive thermal management techniques presents additional opportunities for efficiency gains. Phase-change materials embedded within actuator structures can absorb excess heat during operation and release it during idle periods, creating a natural thermal regulation system that reduces energy requirements by 15-18% in cyclic applications. This approach is particularly valuable for wearable soft robotic systems where consistent temperature maintenance is essential for user comfort and system longevity.

Biocompatibility of Thermal Materials for Wearable Applications

The biocompatibility of thermal materials represents a critical consideration in the development of wearable soft pneumatic actuators. These materials must maintain intimate contact with human skin while efficiently managing heat transfer without causing adverse biological reactions. Current biocompatible thermal materials include medical-grade silicones, thermoplastic polyurethanes (TPUs), and hydrogels, each offering unique properties for thermal conductivity applications.

Medical-grade silicones demonstrate excellent biocompatibility with minimal inflammatory responses and cytotoxicity, making them ideal for extended skin contact. Their thermal conductivity can be enhanced through the incorporation of thermally conductive fillers like boron nitride or aluminum oxide while maintaining biocompatibility profiles. Recent studies have shown that silicone composites with 20-30% filler content can achieve thermal conductivity values of 1-2 W/mK without compromising biocompatibility.

TPUs offer flexibility and durability alongside good thermal properties, with recent developments focusing on biodegradable variants that maintain thermal conductivity. These materials show promising results in cytotoxicity and skin sensitization tests, with minimal adverse reactions in clinical evaluations. The integration of graphene or carbon nanotubes into TPU matrices has yielded biocompatible composites with thermal conductivities reaching 3-5 W/mK.

Hydrogels present a unique approach to biocompatible thermal materials, mimicking human tissue properties while providing excellent thermal transfer capabilities. Their high water content facilitates heat dissipation, though this can present challenges for long-term stability. Recent innovations include thermally conductive nanocomposite hydrogels incorporating gold nanoparticles or graphene oxide, which maintain biocompatibility while achieving thermal conductivity values of 0.8-1.5 W/mK.

Regulatory frameworks for these materials include ISO 10993 standards for biological evaluation of medical devices and FDA guidelines for skin-contacting materials. Compliance with these standards requires rigorous testing protocols including cytotoxicity, sensitization, and irritation assessments. Materials must demonstrate minimal biological reactivity while maintaining their thermal properties under physiological conditions.

Future developments in biocompatible thermal materials focus on responsive systems that adapt their thermal conductivity based on physiological needs. These include phase-change materials that respond to temperature fluctuations and biomimetic structures that optimize heat transfer while maintaining compatibility with biological tissues. The integration of these advanced materials into soft pneumatic actuators promises to enhance both performance and safety in next-generation wearable technologies.

Medical-grade silicones demonstrate excellent biocompatibility with minimal inflammatory responses and cytotoxicity, making them ideal for extended skin contact. Their thermal conductivity can be enhanced through the incorporation of thermally conductive fillers like boron nitride or aluminum oxide while maintaining biocompatibility profiles. Recent studies have shown that silicone composites with 20-30% filler content can achieve thermal conductivity values of 1-2 W/mK without compromising biocompatibility.

TPUs offer flexibility and durability alongside good thermal properties, with recent developments focusing on biodegradable variants that maintain thermal conductivity. These materials show promising results in cytotoxicity and skin sensitization tests, with minimal adverse reactions in clinical evaluations. The integration of graphene or carbon nanotubes into TPU matrices has yielded biocompatible composites with thermal conductivities reaching 3-5 W/mK.

Hydrogels present a unique approach to biocompatible thermal materials, mimicking human tissue properties while providing excellent thermal transfer capabilities. Their high water content facilitates heat dissipation, though this can present challenges for long-term stability. Recent innovations include thermally conductive nanocomposite hydrogels incorporating gold nanoparticles or graphene oxide, which maintain biocompatibility while achieving thermal conductivity values of 0.8-1.5 W/mK.

Regulatory frameworks for these materials include ISO 10993 standards for biological evaluation of medical devices and FDA guidelines for skin-contacting materials. Compliance with these standards requires rigorous testing protocols including cytotoxicity, sensitization, and irritation assessments. Materials must demonstrate minimal biological reactivity while maintaining their thermal properties under physiological conditions.

Future developments in biocompatible thermal materials focus on responsive systems that adapt their thermal conductivity based on physiological needs. These include phase-change materials that respond to temperature fluctuations and biomimetic structures that optimize heat transfer while maintaining compatibility with biological tissues. The integration of these advanced materials into soft pneumatic actuators promises to enhance both performance and safety in next-generation wearable technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!