Comparative Study of Actuator Control Systems

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Actuator Control Systems Evolution and Objectives

Actuator control systems have evolved significantly over the past several decades, transforming from simple mechanical devices to sophisticated electromechanical systems with advanced control algorithms. The journey began with basic hydraulic and pneumatic actuators in the early 20th century, which relied on fluid pressure to generate motion. These systems, while revolutionary for their time, offered limited precision and responsiveness.

The introduction of electric motors in the mid-20th century marked a significant advancement, enabling more precise control and greater efficiency. By the 1970s, the integration of electronic components and microprocessors facilitated the development of servo motors and stepper motors, which dramatically improved positioning accuracy and speed control capabilities.

The 1990s witnessed the emergence of digital control systems, incorporating feedback mechanisms and PID (Proportional-Integral-Derivative) controllers that could adapt to changing conditions and maintain optimal performance. This period also saw the miniaturization of actuators, making them suitable for a wider range of applications, from industrial automation to consumer electronics.

In recent years, the field has experienced exponential growth with the advent of smart actuators featuring embedded intelligence, network connectivity, and self-diagnostic capabilities. These modern systems can communicate with other devices, adjust their parameters autonomously, and predict maintenance needs, aligning perfectly with Industry 4.0 principles.

The primary objectives of contemporary actuator control system development include enhancing energy efficiency, improving response time and precision, extending operational lifespan, and reducing maintenance requirements. Researchers are particularly focused on developing systems that can operate reliably in extreme environments and adapt to varying load conditions without human intervention.

Another critical goal is the seamless integration of actuators with IoT (Internet of Things) ecosystems, enabling remote monitoring and control. This connectivity facilitates data collection for predictive maintenance and performance optimization, ultimately reducing downtime and operational costs.

The comparative study of actuator control systems aims to evaluate different technologies across various performance metrics, including power consumption, response time, positioning accuracy, force output, durability, and cost-effectiveness. By understanding the strengths and limitations of each approach, engineers can make informed decisions about which actuator technology best suits specific applications, from precision manufacturing to autonomous vehicles and robotic surgery.

The introduction of electric motors in the mid-20th century marked a significant advancement, enabling more precise control and greater efficiency. By the 1970s, the integration of electronic components and microprocessors facilitated the development of servo motors and stepper motors, which dramatically improved positioning accuracy and speed control capabilities.

The 1990s witnessed the emergence of digital control systems, incorporating feedback mechanisms and PID (Proportional-Integral-Derivative) controllers that could adapt to changing conditions and maintain optimal performance. This period also saw the miniaturization of actuators, making them suitable for a wider range of applications, from industrial automation to consumer electronics.

In recent years, the field has experienced exponential growth with the advent of smart actuators featuring embedded intelligence, network connectivity, and self-diagnostic capabilities. These modern systems can communicate with other devices, adjust their parameters autonomously, and predict maintenance needs, aligning perfectly with Industry 4.0 principles.

The primary objectives of contemporary actuator control system development include enhancing energy efficiency, improving response time and precision, extending operational lifespan, and reducing maintenance requirements. Researchers are particularly focused on developing systems that can operate reliably in extreme environments and adapt to varying load conditions without human intervention.

Another critical goal is the seamless integration of actuators with IoT (Internet of Things) ecosystems, enabling remote monitoring and control. This connectivity facilitates data collection for predictive maintenance and performance optimization, ultimately reducing downtime and operational costs.

The comparative study of actuator control systems aims to evaluate different technologies across various performance metrics, including power consumption, response time, positioning accuracy, force output, durability, and cost-effectiveness. By understanding the strengths and limitations of each approach, engineers can make informed decisions about which actuator technology best suits specific applications, from precision manufacturing to autonomous vehicles and robotic surgery.

Market Demand Analysis for Advanced Actuator Controls

The global market for advanced actuator control systems is experiencing robust growth, driven primarily by increasing automation across multiple industries. Current market analysis indicates that the industrial automation sector represents the largest demand segment, with manufacturing facilities worldwide implementing sophisticated actuator systems to enhance precision, efficiency, and production capabilities. This trend is particularly evident in automotive manufacturing, where high-precision actuators are essential for robotic assembly lines and quality control systems.

The aerospace and defense sectors constitute another significant market segment, with demand for highly reliable and precise actuator control systems continuing to rise. These industries require actuators capable of operating under extreme conditions while maintaining exceptional performance standards. Market research indicates that the aerospace actuator control systems market alone is projected to grow at a compound annual growth rate exceeding 5% through 2028.

Healthcare and medical device manufacturing represent emerging high-value markets for advanced actuator controls. The increasing adoption of robotic-assisted surgery systems, automated laboratory equipment, and advanced prosthetics has created substantial demand for miniaturized, high-precision actuator systems. This segment is expected to demonstrate the fastest growth rate among all application areas over the next five years.

Geographically, North America and Europe currently dominate the market for advanced actuator control systems, accounting for approximately two-thirds of global market share. However, the Asia-Pacific region, particularly China, South Korea, and India, is witnessing the most rapid growth in demand, fueled by accelerating industrial automation initiatives and manufacturing sector expansion.

Consumer demand trends indicate increasing preference for energy-efficient actuator systems, particularly in building automation and automotive applications. This shift is driven by both regulatory requirements for reduced energy consumption and corporate sustainability initiatives. Market analysis shows that manufacturers offering actuator systems with demonstrable energy efficiency improvements command premium pricing and gain market share advantages.

The market is also experiencing growing demand for smart actuator systems featuring integrated sensors, diagnostic capabilities, and network connectivity. This trend aligns with broader Industry 4.0 initiatives and the increasing implementation of predictive maintenance strategies across industrial sectors. End-users increasingly prioritize actuator systems that provide operational data and can integrate with facility-wide monitoring systems.

Supply chain considerations are significantly influencing market dynamics, with customers increasingly valuing manufacturing partners who can ensure component availability and technical support. Recent global supply chain disruptions have heightened awareness of these factors, creating competitive advantages for actuator control system providers with robust supply networks and regional manufacturing capabilities.

The aerospace and defense sectors constitute another significant market segment, with demand for highly reliable and precise actuator control systems continuing to rise. These industries require actuators capable of operating under extreme conditions while maintaining exceptional performance standards. Market research indicates that the aerospace actuator control systems market alone is projected to grow at a compound annual growth rate exceeding 5% through 2028.

Healthcare and medical device manufacturing represent emerging high-value markets for advanced actuator controls. The increasing adoption of robotic-assisted surgery systems, automated laboratory equipment, and advanced prosthetics has created substantial demand for miniaturized, high-precision actuator systems. This segment is expected to demonstrate the fastest growth rate among all application areas over the next five years.

Geographically, North America and Europe currently dominate the market for advanced actuator control systems, accounting for approximately two-thirds of global market share. However, the Asia-Pacific region, particularly China, South Korea, and India, is witnessing the most rapid growth in demand, fueled by accelerating industrial automation initiatives and manufacturing sector expansion.

Consumer demand trends indicate increasing preference for energy-efficient actuator systems, particularly in building automation and automotive applications. This shift is driven by both regulatory requirements for reduced energy consumption and corporate sustainability initiatives. Market analysis shows that manufacturers offering actuator systems with demonstrable energy efficiency improvements command premium pricing and gain market share advantages.

The market is also experiencing growing demand for smart actuator systems featuring integrated sensors, diagnostic capabilities, and network connectivity. This trend aligns with broader Industry 4.0 initiatives and the increasing implementation of predictive maintenance strategies across industrial sectors. End-users increasingly prioritize actuator systems that provide operational data and can integrate with facility-wide monitoring systems.

Supply chain considerations are significantly influencing market dynamics, with customers increasingly valuing manufacturing partners who can ensure component availability and technical support. Recent global supply chain disruptions have heightened awareness of these factors, creating competitive advantages for actuator control system providers with robust supply networks and regional manufacturing capabilities.

Current Technological Landscape and Challenges

The actuator control systems landscape is currently experiencing a significant transformation driven by advancements in digital technologies, materials science, and artificial intelligence. Traditional hydraulic and pneumatic actuators continue to dominate industrial applications due to their reliability and high power density, but they face increasing competition from newer technologies. Electromechanical actuators have gained substantial market share, particularly in aerospace, automotive, and precision manufacturing sectors, owing to their improved efficiency, controllability, and reduced maintenance requirements.

A major challenge in the current actuator control landscape is the integration of disparate systems across different operational environments. Many industrial facilities operate with legacy hydraulic systems alongside newer electric actuators, creating compatibility issues and increasing system complexity. This heterogeneity often results in suboptimal performance and higher maintenance costs, particularly in industries undergoing digital transformation.

Energy efficiency remains a critical concern across all actuator technologies. Hydraulic systems, while powerful, typically operate at 20-30% efficiency, with significant energy losses through heat generation. Pneumatic systems fare slightly better but still suffer from compressed air leakage and inefficient pressure regulation. Modern electromechanical actuators achieve efficiencies of 60-80%, but their adoption is hindered by higher initial costs and power density limitations in certain applications.

The miniaturization trend presents both opportunities and challenges for actuator technologies. Micro-electromechanical systems (MEMS) and piezoelectric actuators enable unprecedented precision at microscale, but scaling these technologies for industrial applications remains problematic. Conversely, traditional actuators struggle to meet the size and weight constraints of emerging applications in robotics, medical devices, and portable equipment.

Control system architecture has evolved significantly, with distributed control systems (DCS) and programmable logic controllers (PLCs) being supplemented or replaced by more sophisticated digital control platforms. The integration of real-time monitoring, predictive maintenance capabilities, and adaptive control algorithms represents the cutting edge of actuator control technology, though implementation varies widely across industries and regions.

Geographically, actuator technology development shows distinct patterns. North America and Europe lead in high-precision electromechanical and smart actuator technologies, while Asia, particularly China and Japan, dominates in manufacturing scale and cost-effective implementation. Emerging economies are primarily consumers rather than developers of advanced actuator technologies, creating potential market opportunities but also technological dependencies.

Regulatory frameworks and sustainability requirements increasingly influence actuator technology adoption. Stricter emissions standards and energy efficiency regulations favor electric actuators over fluid power systems in many applications, though safety-critical systems often maintain hydraulic redundancy due to reliability concerns and regulatory requirements.

A major challenge in the current actuator control landscape is the integration of disparate systems across different operational environments. Many industrial facilities operate with legacy hydraulic systems alongside newer electric actuators, creating compatibility issues and increasing system complexity. This heterogeneity often results in suboptimal performance and higher maintenance costs, particularly in industries undergoing digital transformation.

Energy efficiency remains a critical concern across all actuator technologies. Hydraulic systems, while powerful, typically operate at 20-30% efficiency, with significant energy losses through heat generation. Pneumatic systems fare slightly better but still suffer from compressed air leakage and inefficient pressure regulation. Modern electromechanical actuators achieve efficiencies of 60-80%, but their adoption is hindered by higher initial costs and power density limitations in certain applications.

The miniaturization trend presents both opportunities and challenges for actuator technologies. Micro-electromechanical systems (MEMS) and piezoelectric actuators enable unprecedented precision at microscale, but scaling these technologies for industrial applications remains problematic. Conversely, traditional actuators struggle to meet the size and weight constraints of emerging applications in robotics, medical devices, and portable equipment.

Control system architecture has evolved significantly, with distributed control systems (DCS) and programmable logic controllers (PLCs) being supplemented or replaced by more sophisticated digital control platforms. The integration of real-time monitoring, predictive maintenance capabilities, and adaptive control algorithms represents the cutting edge of actuator control technology, though implementation varies widely across industries and regions.

Geographically, actuator technology development shows distinct patterns. North America and Europe lead in high-precision electromechanical and smart actuator technologies, while Asia, particularly China and Japan, dominates in manufacturing scale and cost-effective implementation. Emerging economies are primarily consumers rather than developers of advanced actuator technologies, creating potential market opportunities but also technological dependencies.

Regulatory frameworks and sustainability requirements increasingly influence actuator technology adoption. Stricter emissions standards and energy efficiency regulations favor electric actuators over fluid power systems in many applications, though safety-critical systems often maintain hydraulic redundancy due to reliability concerns and regulatory requirements.

Contemporary Control Architectures and Methodologies

01 Automotive actuator control systems

Control systems for automotive applications that manage various actuators in vehicles. These systems include technologies for controlling vehicle dynamics, autonomous driving features, and safety mechanisms. They integrate sensors, processors, and actuators to enable precise control of vehicle functions such as steering, braking, and acceleration. These control systems often incorporate feedback mechanisms to ensure accurate and responsive operation in different driving conditions.- Automotive actuator control systems: Control systems for automotive actuators that manage vehicle functions such as steering, braking, and throttle control. These systems often incorporate feedback mechanisms to ensure precise control and safety features to prevent malfunctions. Advanced automotive actuator control systems may include adaptive algorithms that adjust to different driving conditions and user preferences, enhancing overall vehicle performance and safety.

- Electronic control units for actuators: Electronic control units (ECUs) designed specifically for managing actuator operations in various applications. These units process input signals, execute control algorithms, and generate appropriate output signals to drive actuators with precision. Modern ECUs often feature microprocessors with advanced computational capabilities, allowing for complex control strategies and integration with other systems through communication protocols.

- Feedback control systems for actuators: Systems that utilize feedback mechanisms to monitor and adjust actuator performance in real-time. These control systems compare desired outputs with actual outputs and make continuous adjustments to minimize errors. Feedback control systems for actuators may incorporate various sensors to measure position, velocity, force, or other parameters, enabling precise control even in the presence of disturbances or system variations.

- Networked actuator control systems: Control systems that manage multiple actuators through networked architectures, allowing for coordinated operation and centralized monitoring. These systems typically employ communication protocols to exchange data between controllers and actuators, enabling synchronized movements and distributed control. Networked actuator control systems are particularly valuable in complex applications requiring the coordination of numerous actuators across different subsystems.

- Adaptive and intelligent actuator control: Advanced control systems that incorporate adaptive algorithms, machine learning, or artificial intelligence to optimize actuator performance. These systems can learn from past operations, predict future requirements, and automatically adjust control parameters to improve efficiency and reliability. Intelligent actuator control systems may also include self-diagnostic capabilities to detect potential failures before they occur, enhancing system robustness and reducing maintenance needs.

02 Electronic control units for actuator management

Electronic control units (ECUs) designed specifically for managing actuators in various applications. These units process input signals from sensors, apply control algorithms, and generate appropriate output signals to drive actuators. They often include microprocessors, memory components, and communication interfaces to interact with other systems. Advanced ECUs may incorporate adaptive control strategies, fault detection mechanisms, and diagnostic capabilities to ensure reliable actuator operation.Expand Specific Solutions03 Networked actuator control systems

Control systems that manage multiple actuators through networked architectures. These systems enable coordinated control of distributed actuators across complex environments or machinery. They typically utilize communication protocols to synchronize actuator operations and share data between control nodes. Networked actuator systems may incorporate cloud computing, edge processing, or distributed intelligence to optimize performance and reliability while reducing latency in control operations.Expand Specific Solutions04 Precision actuator control for industrial applications

Control systems designed for high-precision actuator management in industrial settings. These systems enable accurate positioning, force control, and motion profiles for manufacturing, robotics, and automation applications. They often incorporate advanced control algorithms such as PID, adaptive control, or model predictive control to achieve the required precision. Features may include vibration compensation, backlash elimination, and thermal drift correction to maintain accuracy under varying operating conditions.Expand Specific Solutions05 Intelligent actuator monitoring and diagnostics

Systems that provide real-time monitoring, diagnostics, and predictive maintenance for actuators. These technologies track actuator performance parameters, detect anomalies, and predict potential failures before they occur. They may incorporate machine learning algorithms to analyze patterns in actuator behavior and identify degradation trends. Such systems help optimize maintenance schedules, reduce downtime, and extend actuator service life through condition-based maintenance approaches.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The actuator control systems market is currently in a growth phase, characterized by increasing demand across automotive, aerospace, and industrial sectors. The market size is estimated to be substantial, driven by automation trends and technological advancements. In terms of technical maturity, established players like Robert Bosch, Siemens, and Honeywell lead with comprehensive solutions, while aerospace specialists such as Boeing, Airbus Operations, and Nabtesco Aerospace focus on high-precision flight control actuators. Automotive leaders including Mercedes-Benz and Caterpillar are advancing electromechanical actuator technologies. The competitive landscape shows a mix of diversified industrial conglomerates (Eaton, Omron) and specialized manufacturers (Phoenix Contact, Balluff), with emerging competition in smart actuator systems from technology companies like Qualcomm and Intel, indicating a market transitioning toward more integrated, intelligent control solutions.

Robert Bosch GmbH

Technical Solution: Bosch has developed sophisticated electrohydraulic actuator control systems that combine traditional hydraulic power with electronic precision control. Their systems utilize proprietary valve technology with response times under 10ms and pressure control accuracy of ±1%. Bosch's actuator control architecture employs a multi-layer approach with dedicated microcontrollers handling different aspects of the control loop, from sensor data acquisition to output signal processing. Their systems feature adaptive control algorithms that automatically compensate for temperature variations and component wear, maintaining consistent performance throughout the actuator's lifecycle. Bosch has implemented advanced diagnostic capabilities that continuously monitor system parameters and can predict potential failures before they occur, with demonstrated reduction in unplanned downtime of up to 25% in automotive manufacturing applications.

Strengths: Exceptional durability in harsh environments; high power density for compact applications; precise control even under variable load conditions; comprehensive self-diagnostic capabilities. Weaknesses: Higher energy consumption compared to pure electric systems; more complex maintenance requirements due to hydraulic components; limited scalability for very small precision applications.

The Boeing Co.

Technical Solution: Boeing has developed advanced fly-by-wire actuator control systems for aerospace applications that represent the cutting edge of reliability and precision. Their actuator control architecture employs quadruple-redundant channels with dissimilar hardware and software implementations to achieve failure rates below 10^-9 per flight hour. Boeing's systems utilize proprietary control algorithms that compensate for aerodynamic effects and structural flexing in real-time, maintaining positioning accuracy within ±0.05 degrees even under extreme flight conditions. Their actuator control technology incorporates active damping mechanisms that reduce mechanical stress and vibration, extending component life by up to 40% compared to conventional systems. Boeing has pioneered the integration of health monitoring systems that continuously analyze actuator performance parameters and can predict maintenance requirements with 95% accuracy up to 500 flight hours in advance.

Strengths: Unmatched reliability and redundancy features; exceptional precision under variable environmental conditions; comprehensive built-in test capabilities; sophisticated fault isolation and recovery mechanisms. Weaknesses: Extremely high implementation costs; significant weight penalties compared to simpler systems; complex certification requirements limiting modification flexibility.

Key Patents and Technical Innovations

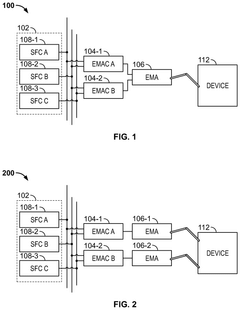

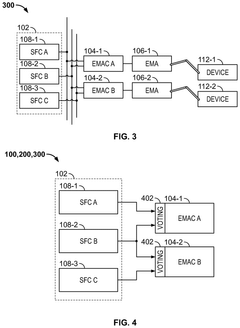

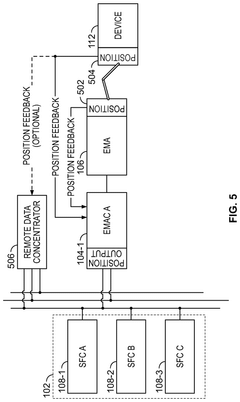

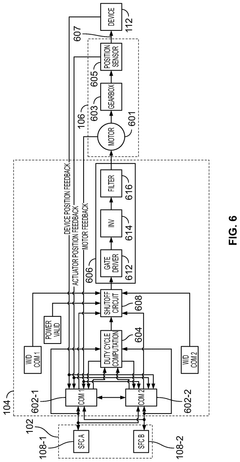

High-integrity actuator controller and control systems

PatentActiveUS12244258B2

Innovation

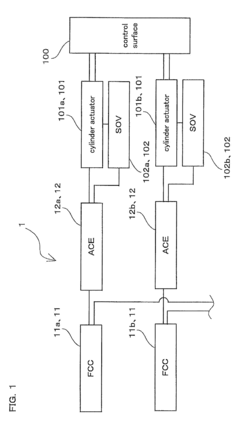

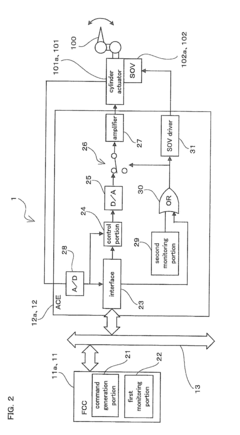

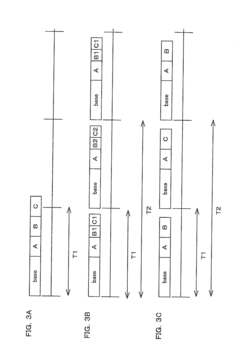

- A high-integrity electromechanical actuator control system is designed with redundant function control channels, actuator controllers implementing a command voting scheme, and electromechanical actuators receiving position commands from multiple controllers, ensuring integrity and redundancy while reducing weight and complexity.

Actuator control system

PatentActiveUS20110160876A1

Innovation

- The actuator control system includes an operation control apparatus with a command generation portion and a first monitoring portion that monitors abnormalities, and an actuator control apparatus with a control portion and a second monitoring portion that monitors different types of abnormalities, allowing for distributed monitoring and reducing the load on the actuator control apparatus, thereby simplifying the configuration and eliminating the need for a backup control portion.

Performance Metrics and Benchmarking Standards

In the rapidly evolving field of actuator control systems, establishing standardized performance metrics and benchmarking standards is crucial for objective evaluation and comparison. Current industry standards primarily focus on five key performance indicators: response time, precision, energy efficiency, reliability, and system integration capabilities. Response time measures the delay between command input and actuator movement, with state-of-the-art systems achieving sub-millisecond responses in high-performance applications. Precision metrics evaluate positioning accuracy and repeatability, typically measured in micrometers or angular degrees depending on the actuator type.

Energy efficiency benchmarks have gained significant importance with the global push toward sustainable technologies. The industry now commonly uses metrics such as power consumption per unit force/torque and standby power requirements. The IEEE Standard 1512-2020 provides a comprehensive framework for evaluating energy efficiency in electromechanical actuator systems, while ISO 15066:2016 establishes performance standards specifically for collaborative robot actuators.

Reliability testing protocols incorporate mean time between failures (MTBF), operational lifetime under specified conditions, and performance degradation rates. These metrics are particularly critical in aerospace, medical, and industrial safety applications where actuator failure could have catastrophic consequences. The SAE ARP6461 standard offers industry-accepted methodologies for reliability testing of flight control actuators that have been adapted for broader applications.

System integration capabilities are evaluated through standardized communication protocol compliance, response to network latency, and fault tolerance. The increasing implementation of Industry 4.0 principles has elevated the importance of these metrics, with OPC UA and EtherCAT emerging as dominant communication standards for actuator control systems.

Recent developments in benchmarking include the creation of standardized test environments that simulate real-world operating conditions. The Actuator Performance Index (API), developed by a consortium of research institutions and industry leaders, provides a composite score based on weighted performance across multiple metrics. This index has gained acceptance as a comprehensive benchmarking tool, though regional variations exist in its implementation.

Challenges in standardization persist due to application-specific requirements and the rapid pace of technological advancement. The emergence of soft robotics and smart materials has necessitated the development of new metrics beyond traditional mechanical parameters, including material deformation characteristics and adaptive response capabilities. Industry stakeholders are currently working through ISO Technical Committee 299 to establish updated standards that address these emerging technologies.

Energy efficiency benchmarks have gained significant importance with the global push toward sustainable technologies. The industry now commonly uses metrics such as power consumption per unit force/torque and standby power requirements. The IEEE Standard 1512-2020 provides a comprehensive framework for evaluating energy efficiency in electromechanical actuator systems, while ISO 15066:2016 establishes performance standards specifically for collaborative robot actuators.

Reliability testing protocols incorporate mean time between failures (MTBF), operational lifetime under specified conditions, and performance degradation rates. These metrics are particularly critical in aerospace, medical, and industrial safety applications where actuator failure could have catastrophic consequences. The SAE ARP6461 standard offers industry-accepted methodologies for reliability testing of flight control actuators that have been adapted for broader applications.

System integration capabilities are evaluated through standardized communication protocol compliance, response to network latency, and fault tolerance. The increasing implementation of Industry 4.0 principles has elevated the importance of these metrics, with OPC UA and EtherCAT emerging as dominant communication standards for actuator control systems.

Recent developments in benchmarking include the creation of standardized test environments that simulate real-world operating conditions. The Actuator Performance Index (API), developed by a consortium of research institutions and industry leaders, provides a composite score based on weighted performance across multiple metrics. This index has gained acceptance as a comprehensive benchmarking tool, though regional variations exist in its implementation.

Challenges in standardization persist due to application-specific requirements and the rapid pace of technological advancement. The emergence of soft robotics and smart materials has necessitated the development of new metrics beyond traditional mechanical parameters, including material deformation characteristics and adaptive response capabilities. Industry stakeholders are currently working through ISO Technical Committee 299 to establish updated standards that address these emerging technologies.

Energy Efficiency and Sustainability Considerations

Energy efficiency has emerged as a critical factor in the design and implementation of actuator control systems, driven by both economic imperatives and environmental sustainability goals. Modern actuator systems consume significant energy during operation, particularly in industrial applications where continuous motion control is required. Research indicates that optimizing control algorithms can reduce energy consumption by 15-30% without compromising performance parameters. Regenerative braking technologies, which capture and reuse kinetic energy during deceleration phases, have demonstrated energy savings of up to 40% in certain applications, particularly in servo motor systems and hydraulic actuators.

Material selection plays a crucial role in sustainability considerations for actuator systems. Advanced composite materials and rare earth magnets have improved the power-to-weight ratio of electromagnetic actuators, reducing both energy requirements and material consumption. However, the environmental impact of mining and processing these materials presents a sustainability challenge that must be addressed through responsible sourcing and recycling initiatives.

Lifecycle assessment studies reveal that the operational phase accounts for approximately 80% of an actuator system's total environmental impact, with manufacturing and disposal comprising the remainder. This underscores the importance of energy-efficient control strategies that optimize duty cycles and minimize idle power consumption. Adaptive control systems that automatically adjust power usage based on load requirements have shown particular promise, reducing energy waste by up to 25% compared to traditional fixed-parameter controllers.

Thermal management represents another significant aspect of energy efficiency in actuator systems. Heat generation not only wastes energy but also accelerates component degradation, reducing system lifespan. Advanced cooling techniques and thermal modeling have enabled more efficient heat dissipation, allowing actuators to operate at higher power densities without compromising reliability or energy efficiency.

The integration of renewable energy sources with actuator systems presents promising opportunities for sustainability. Solar-powered actuators for building automation and water management systems demonstrate the feasibility of self-sufficient control systems in appropriate applications. Additionally, smart grid compatibility enables demand-response functionality, where actuator systems can adjust their operation based on grid conditions, contributing to overall energy system stability while reducing operational costs.

Standardization efforts are increasingly incorporating energy efficiency metrics into actuator performance specifications. The development of internationally recognized efficiency classes for actuators, similar to those established for electric motors, would provide valuable guidance for system designers and end-users seeking to optimize energy performance. Such standards would facilitate meaningful comparisons between different actuator technologies and control strategies, driving continuous improvement in the industry.

Material selection plays a crucial role in sustainability considerations for actuator systems. Advanced composite materials and rare earth magnets have improved the power-to-weight ratio of electromagnetic actuators, reducing both energy requirements and material consumption. However, the environmental impact of mining and processing these materials presents a sustainability challenge that must be addressed through responsible sourcing and recycling initiatives.

Lifecycle assessment studies reveal that the operational phase accounts for approximately 80% of an actuator system's total environmental impact, with manufacturing and disposal comprising the remainder. This underscores the importance of energy-efficient control strategies that optimize duty cycles and minimize idle power consumption. Adaptive control systems that automatically adjust power usage based on load requirements have shown particular promise, reducing energy waste by up to 25% compared to traditional fixed-parameter controllers.

Thermal management represents another significant aspect of energy efficiency in actuator systems. Heat generation not only wastes energy but also accelerates component degradation, reducing system lifespan. Advanced cooling techniques and thermal modeling have enabled more efficient heat dissipation, allowing actuators to operate at higher power densities without compromising reliability or energy efficiency.

The integration of renewable energy sources with actuator systems presents promising opportunities for sustainability. Solar-powered actuators for building automation and water management systems demonstrate the feasibility of self-sufficient control systems in appropriate applications. Additionally, smart grid compatibility enables demand-response functionality, where actuator systems can adjust their operation based on grid conditions, contributing to overall energy system stability while reducing operational costs.

Standardization efforts are increasingly incorporating energy efficiency metrics into actuator performance specifications. The development of internationally recognized efficiency classes for actuators, similar to those established for electric motors, would provide valuable guidance for system designers and end-users seeking to optimize energy performance. Such standards would facilitate meaningful comparisons between different actuator technologies and control strategies, driving continuous improvement in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!