The Role of Elastomers in Soft Pneumatic Actuator Performance

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Elastomer Technology Background and Objectives

Elastomers have been fundamental components in the evolution of soft robotics, particularly in the development of soft pneumatic actuators (SPAs). The history of elastomer application in this field traces back to the 1950s when Joseph McKibben developed the first pneumatic artificial muscles using rubber tubes encased in braided mesh. However, the systematic exploration of elastomers specifically for soft robotics gained momentum only in the early 2000s, coinciding with the broader emergence of soft robotics as a distinct discipline.

The technological evolution of elastomers has been characterized by continuous improvements in material properties, manufacturing techniques, and application methodologies. Traditional elastomers such as silicone rubbers (PDMS, Ecoflex), polyurethanes, and natural rubber have been progressively supplemented by advanced formulations featuring enhanced mechanical properties, improved durability, and specialized characteristics such as self-healing capabilities and stimuli-responsiveness.

Current research objectives in elastomer technology for SPAs focus on several critical aspects. Primary among these is the development of materials with precisely tailored mechanical properties, particularly modulus of elasticity, elongation at break, and hysteresis characteristics. These properties directly influence the force generation, displacement range, and response time of actuators. Additionally, there is significant interest in enhancing the fatigue resistance of elastomers to extend the operational lifespan of SPAs under repeated cycling.

Another key objective is the creation of multi-material elastomer systems that can provide spatially varying mechanical properties within a single actuator structure. This approach enables more complex and biomimetic motion patterns that more closely resemble natural muscular systems. Researchers are also pursuing elastomers with embedded functionality, such as integrated sensing capabilities or electro-active properties that can complement pneumatic actuation.

From a manufacturing perspective, the field aims to develop elastomer formulations compatible with advanced fabrication techniques, including 3D printing, micro-molding, and automated assembly processes. These manufacturing considerations are crucial for transitioning SPAs from laboratory prototypes to commercially viable products.

The overarching technological goal is to establish a comprehensive understanding of the relationship between elastomer material properties and actuator performance metrics. This includes developing predictive models that can accurately correlate material characteristics with functional outcomes such as force generation, speed, precision, and energy efficiency. Such models would significantly accelerate the design process for application-specific SPAs and reduce the current reliance on empirical testing and iterative prototyping.

The technological evolution of elastomers has been characterized by continuous improvements in material properties, manufacturing techniques, and application methodologies. Traditional elastomers such as silicone rubbers (PDMS, Ecoflex), polyurethanes, and natural rubber have been progressively supplemented by advanced formulations featuring enhanced mechanical properties, improved durability, and specialized characteristics such as self-healing capabilities and stimuli-responsiveness.

Current research objectives in elastomer technology for SPAs focus on several critical aspects. Primary among these is the development of materials with precisely tailored mechanical properties, particularly modulus of elasticity, elongation at break, and hysteresis characteristics. These properties directly influence the force generation, displacement range, and response time of actuators. Additionally, there is significant interest in enhancing the fatigue resistance of elastomers to extend the operational lifespan of SPAs under repeated cycling.

Another key objective is the creation of multi-material elastomer systems that can provide spatially varying mechanical properties within a single actuator structure. This approach enables more complex and biomimetic motion patterns that more closely resemble natural muscular systems. Researchers are also pursuing elastomers with embedded functionality, such as integrated sensing capabilities or electro-active properties that can complement pneumatic actuation.

From a manufacturing perspective, the field aims to develop elastomer formulations compatible with advanced fabrication techniques, including 3D printing, micro-molding, and automated assembly processes. These manufacturing considerations are crucial for transitioning SPAs from laboratory prototypes to commercially viable products.

The overarching technological goal is to establish a comprehensive understanding of the relationship between elastomer material properties and actuator performance metrics. This includes developing predictive models that can accurately correlate material characteristics with functional outcomes such as force generation, speed, precision, and energy efficiency. Such models would significantly accelerate the design process for application-specific SPAs and reduce the current reliance on empirical testing and iterative prototyping.

Market Applications for Soft Pneumatic Actuators

Soft pneumatic actuators (SPAs) have emerged as a transformative technology across multiple industries due to their unique properties of flexibility, adaptability, and safe human interaction. The market applications for these innovative devices span several key sectors, each leveraging specific advantages of soft robotics technology.

In healthcare and medical devices, SPAs are revolutionizing patient care through rehabilitation devices, surgical tools, and assistive technologies. Rehabilitation gloves and exoskeletons utilizing soft pneumatic systems provide gentle, controlled force for physical therapy while adapting to individual patient anatomy. Minimally invasive surgical tools incorporating SPAs offer surgeons enhanced dexterity in confined spaces while reducing trauma to surrounding tissues.

The manufacturing sector has begun integrating SPAs into collaborative robots (cobots) designed to work alongside human operators. These soft robotic systems can handle delicate objects without damage and operate safely in shared workspaces without the need for protective barriers. Applications include precision assembly of electronic components, handling of fragile items, and ergonomic assistance for workers in repetitive tasks.

Consumer electronics represents another growing market for SPAs, particularly in haptic feedback systems and interactive devices. Virtual reality controllers, gaming peripherals, and touchscreen interfaces enhanced with pneumatic feedback provide users with more immersive and intuitive experiences. The tactile sensations created by these systems significantly enhance user engagement across digital platforms.

The agricultural sector has found valuable applications for SPAs in automated harvesting systems for delicate crops. Soft grippers can adapt to irregular shapes and varying firmness of fruits and vegetables, reducing damage and waste during harvesting operations. These systems are particularly valuable for high-value crops where mechanical damage directly impacts market value.

Aerospace and automotive industries are exploring SPAs for specialized applications including deployable structures, adaptive aerodynamic surfaces, and customizable interior components. The lightweight nature of these systems offers fuel efficiency benefits while their adaptability provides new design possibilities for vehicle comfort and functionality.

Wearable technology represents one of the fastest-growing application areas, with SPAs being integrated into smart clothing, performance-enhancing garments, and health monitoring systems. These devices can provide targeted compression, posture correction, or physiological monitoring while maintaining comfort and mobility for users.

AI-driven soft robotics systems are emerging as a premium market segment, combining machine learning algorithms with adaptive pneumatic structures to create increasingly autonomous and responsive devices across all these application areas.

In healthcare and medical devices, SPAs are revolutionizing patient care through rehabilitation devices, surgical tools, and assistive technologies. Rehabilitation gloves and exoskeletons utilizing soft pneumatic systems provide gentle, controlled force for physical therapy while adapting to individual patient anatomy. Minimally invasive surgical tools incorporating SPAs offer surgeons enhanced dexterity in confined spaces while reducing trauma to surrounding tissues.

The manufacturing sector has begun integrating SPAs into collaborative robots (cobots) designed to work alongside human operators. These soft robotic systems can handle delicate objects without damage and operate safely in shared workspaces without the need for protective barriers. Applications include precision assembly of electronic components, handling of fragile items, and ergonomic assistance for workers in repetitive tasks.

Consumer electronics represents another growing market for SPAs, particularly in haptic feedback systems and interactive devices. Virtual reality controllers, gaming peripherals, and touchscreen interfaces enhanced with pneumatic feedback provide users with more immersive and intuitive experiences. The tactile sensations created by these systems significantly enhance user engagement across digital platforms.

The agricultural sector has found valuable applications for SPAs in automated harvesting systems for delicate crops. Soft grippers can adapt to irregular shapes and varying firmness of fruits and vegetables, reducing damage and waste during harvesting operations. These systems are particularly valuable for high-value crops where mechanical damage directly impacts market value.

Aerospace and automotive industries are exploring SPAs for specialized applications including deployable structures, adaptive aerodynamic surfaces, and customizable interior components. The lightweight nature of these systems offers fuel efficiency benefits while their adaptability provides new design possibilities for vehicle comfort and functionality.

Wearable technology represents one of the fastest-growing application areas, with SPAs being integrated into smart clothing, performance-enhancing garments, and health monitoring systems. These devices can provide targeted compression, posture correction, or physiological monitoring while maintaining comfort and mobility for users.

AI-driven soft robotics systems are emerging as a premium market segment, combining machine learning algorithms with adaptive pneumatic structures to create increasingly autonomous and responsive devices across all these application areas.

Current Elastomer Limitations in Pneumatic Systems

Despite significant advancements in soft pneumatic actuator technology, current elastomers present several critical limitations that impede optimal performance. The viscoelastic nature of commonly used elastomers such as silicone rubber (PDMS), thermoplastic polyurethanes (TPUs), and natural rubber introduces time-dependent mechanical behaviors, resulting in hysteresis during actuation cycles. This phenomenon manifests as differences between inflation and deflation pathways, compromising precision in applications requiring exact positional control.

Material fatigue represents another significant challenge, with elastomers exhibiting performance degradation after repeated actuation cycles. This degradation typically manifests as permanent deformation, decreased force output, and increased response time, ultimately shortening the operational lifespan of soft pneumatic actuators. The fatigue resistance varies considerably across elastomer types, with some materials showing significant performance decline after just hundreds of cycles.

Temperature sensitivity further complicates elastomer performance in pneumatic systems. Most elastomers demonstrate substantial mechanical property variations across operational temperature ranges, with stiffness typically increasing at lower temperatures and decreasing at higher temperatures. This thermal dependence creates inconsistent actuation behavior in environments with temperature fluctuations, limiting deployment in extreme conditions or applications requiring thermal stability.

Permeability issues also plague current elastomer technologies. Gas molecules gradually diffuse through elastomer walls, causing pressure loss over time and necessitating continuous pressure compensation. This permeability varies significantly between elastomer types and depends on factors including material thickness, crosslinking density, and the specific gas used for actuation.

Manufacturing consistency presents additional challenges, with batch-to-batch variations in elastomer properties affecting actuator performance reproducibility. These variations stem from differences in curing conditions, raw material quality, and processing parameters, making standardization difficult across production runs.

Environmental degradation further limits elastomer longevity in pneumatic systems. Exposure to UV radiation, ozone, oxygen, and various chemicals accelerates material breakdown, particularly in outdoor or harsh industrial environments. This degradation manifests as surface cracking, discoloration, and mechanical property deterioration, significantly reducing operational lifespan.

Finally, the inherent trade-off between elasticity and strength represents a fundamental limitation. Highly elastic materials typically offer lower tensile strength and tear resistance, while stronger elastomers generally provide reduced flexibility and strain capacity. This inverse relationship constrains design options, forcing engineers to compromise between actuation range and durability based on application requirements.

Material fatigue represents another significant challenge, with elastomers exhibiting performance degradation after repeated actuation cycles. This degradation typically manifests as permanent deformation, decreased force output, and increased response time, ultimately shortening the operational lifespan of soft pneumatic actuators. The fatigue resistance varies considerably across elastomer types, with some materials showing significant performance decline after just hundreds of cycles.

Temperature sensitivity further complicates elastomer performance in pneumatic systems. Most elastomers demonstrate substantial mechanical property variations across operational temperature ranges, with stiffness typically increasing at lower temperatures and decreasing at higher temperatures. This thermal dependence creates inconsistent actuation behavior in environments with temperature fluctuations, limiting deployment in extreme conditions or applications requiring thermal stability.

Permeability issues also plague current elastomer technologies. Gas molecules gradually diffuse through elastomer walls, causing pressure loss over time and necessitating continuous pressure compensation. This permeability varies significantly between elastomer types and depends on factors including material thickness, crosslinking density, and the specific gas used for actuation.

Manufacturing consistency presents additional challenges, with batch-to-batch variations in elastomer properties affecting actuator performance reproducibility. These variations stem from differences in curing conditions, raw material quality, and processing parameters, making standardization difficult across production runs.

Environmental degradation further limits elastomer longevity in pneumatic systems. Exposure to UV radiation, ozone, oxygen, and various chemicals accelerates material breakdown, particularly in outdoor or harsh industrial environments. This degradation manifests as surface cracking, discoloration, and mechanical property deterioration, significantly reducing operational lifespan.

Finally, the inherent trade-off between elasticity and strength represents a fundamental limitation. Highly elastic materials typically offer lower tensile strength and tear resistance, while stronger elastomers generally provide reduced flexibility and strain capacity. This inverse relationship constrains design options, forcing engineers to compromise between actuation range and durability based on application requirements.

Current Elastomer Solutions for Actuator Performance

01 Elastomer composition and properties

Elastomers can be formulated with specific compositions to enhance their performance characteristics. These compositions often include various polymers, fillers, and additives that contribute to the elastomer's mechanical properties such as tensile strength, elongation, and resilience. The proper selection and combination of these components can significantly improve the overall performance of elastomers in various applications.- Elastomer composition and formulation: Elastomer compositions can be formulated with various additives to enhance performance characteristics. These formulations typically include base elastomers combined with fillers, plasticizers, vulcanizing agents, and other additives to achieve desired properties. The specific combination of ingredients affects mechanical properties such as tensile strength, elongation, and resilience. Advanced formulations may incorporate specialized additives to improve specific performance attributes like heat resistance or chemical stability.

- Elastomer processing techniques: Processing techniques significantly impact elastomer performance. Methods such as extrusion, molding, calendering, and vulcanization affect the final properties of elastomeric products. Temperature control during processing is crucial for achieving optimal cross-linking and preventing degradation. Advanced processing techniques can enhance elastomer performance by improving molecular orientation, reducing defects, and ensuring uniform distribution of additives throughout the elastomer matrix.

- High-performance specialty elastomers: Specialty elastomers are designed for extreme conditions or specific applications requiring enhanced performance characteristics. These include fluoroelastomers for chemical resistance, silicone elastomers for temperature extremes, and hydrogenated nitrile rubbers for oil resistance. These materials often feature modified polymer structures or specialized copolymer systems to achieve superior performance in specific environments. Their unique molecular architecture provides properties that conventional elastomers cannot achieve.

- Elastomer reinforcement systems: Reinforcement systems significantly enhance elastomer performance through the incorporation of fillers and reinforcing agents. Carbon black, silica, and other particulate fillers improve tensile strength, tear resistance, and abrasion resistance. Nano-fillers can provide reinforcement at lower loading levels while maintaining processability. The interaction between the elastomer matrix and reinforcing agents at the molecular level is critical for performance enhancement, with surface treatments often used to optimize this interface.

- Elastomer durability and aging resistance: Enhancing elastomer durability involves incorporating stabilizers and antidegradants to protect against environmental factors. Antioxidants prevent oxidative degradation, while UV stabilizers protect against photodegradation. Anti-ozonants specifically target ozone attack, which can cause cracking in elastomers under tension. Proper selection of these protective additives based on the specific elastomer type and application environment is essential for extending service life and maintaining performance properties over time.

02 Thermal and chemical resistance of elastomers

Elastomers can be engineered to withstand extreme temperatures and harsh chemical environments. By incorporating specific additives and modifying the polymer structure, elastomers can maintain their performance properties even under challenging conditions. These improvements in thermal and chemical resistance extend the service life of elastomer products and expand their potential applications in industries such as automotive, aerospace, and chemical processing.Expand Specific Solutions03 Processing techniques for elastomer performance enhancement

Various processing techniques can be employed to enhance the performance of elastomers. These include vulcanization, compounding, and specific molding methods that affect the final properties of the elastomer products. Advanced processing techniques can improve the homogeneity of the elastomer mixture, reduce defects, and enhance the overall performance characteristics such as durability, flexibility, and resistance to environmental factors.Expand Specific Solutions04 Elastomer reinforcement systems

Reinforcement systems play a crucial role in enhancing elastomer performance. These systems typically involve the incorporation of fillers such as carbon black, silica, or fibers that interact with the elastomer matrix to improve mechanical properties. The type, size, distribution, and surface treatment of reinforcing materials significantly impact the performance characteristics of the final elastomer product, including tear resistance, abrasion resistance, and dynamic properties.Expand Specific Solutions05 Specialty elastomers for specific applications

Specialty elastomers are developed for specific applications with unique performance requirements. These elastomers are tailored to meet particular demands such as extreme flexibility, high precision, biocompatibility, or electrical properties. The formulation of specialty elastomers often involves innovative approaches to polymer design, compounding, and processing to achieve the desired performance characteristics for applications in medical devices, electronics, sealing systems, and other specialized fields.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The elastomers market for soft pneumatic actuators is currently in a growth phase, with increasing applications across robotics, medical devices, and automation. The global market size is expanding as these actuators offer advantages in compliant, lightweight, and safe human-machine interactions. Leading academic institutions including Harvard College, Cornell University, and Zhejiang University are driving technological innovation through fundamental research on material properties and actuator design. Commercial development is emerging with companies like Minebea Mitsumi and Huawei Technologies exploring industrial applications. The technology maturity varies across applications, with medical implementations (supported by Children's Medical Center) showing greater advancement than industrial automation solutions. Research collaboration between universities and industry partners is accelerating development toward commercial viability.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered innovative approaches to soft pneumatic actuators (SPAs) through their research on elastomeric materials. Their technology focuses on fiber-reinforced elastomeric enclosures that can be pressurized to produce complex motions. Harvard researchers have developed a comprehensive material selection framework that correlates elastomer properties with actuator performance metrics, including force output, speed, and efficiency. Their proprietary fabrication techniques involve multi-material molding processes that enable the creation of actuators with programmable motion patterns. Harvard's research has demonstrated that silicone elastomers with Shore A hardness between 20-40 provide optimal balance between flexibility and force transmission in SPAs[1]. They've also pioneered hybrid elastomer systems that combine high-elongation silicones with stiffer reinforcement materials to achieve both compliance and structural integrity. Recent developments include self-healing elastomers that can recover from puncture damage, extending actuator lifespan in challenging environments[3].

Strengths: Superior material characterization capabilities and systematic approach to elastomer selection; extensive fabrication expertise allowing complex geometries and multi-material integration. Weaknesses: Higher manufacturing complexity compared to simpler designs; some of their advanced elastomer formulations require specialized equipment and expertise for implementation in commercial applications.

Cornell University

Technical Solution: Cornell University has developed a distinctive approach to soft pneumatic actuators through their Organic Robotics Lab, focusing on elastomer customization for specific performance requirements. Their technology centers on liquid crystal elastomers (LCEs) that exhibit programmable mechanical anisotropy, allowing directional actuation when pneumatically pressurized. Cornell researchers have created a proprietary elastomer formulation process that enables precise control of crosslinking density and chain orientation, resulting in actuators with tailored stress-strain behaviors. Their fabrication methodology incorporates 3D printing of sacrificial molds combined with vacuum casting techniques to create complex internal channel architectures within elastomeric matrices. Cornell's research has demonstrated that incorporating nanoparticle fillers (5-10% by weight) into silicone elastomers can enhance mechanical properties while maintaining flexibility[2]. They've also pioneered temperature-responsive elastomer systems that can modify their stiffness characteristics during operation, enabling adaptive behavior in varying environmental conditions[4].

Strengths: Advanced material science approach with programmable mechanical properties; excellent integration of material science with fabrication techniques allowing for complex internal geometries. Weaknesses: Some of their specialized elastomer formulations have limited commercial availability; temperature-responsive systems require additional control mechanisms that increase system complexity.

Key Patents in Elastomer-Based Soft Actuators

Apparatus, system, and method for providing fabric-elastomer composites as pneumatic actuators

PatentActiveUS20150070904A1

Innovation

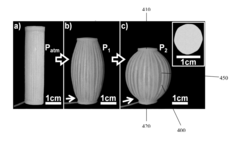

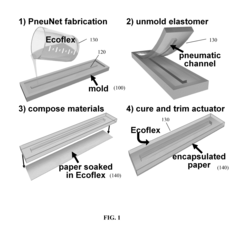

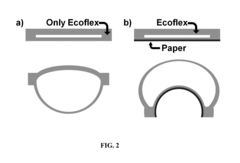

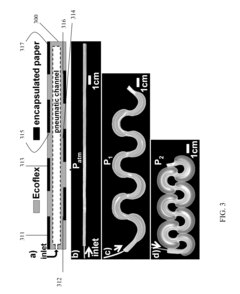

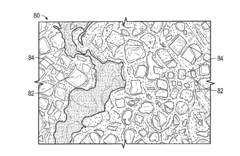

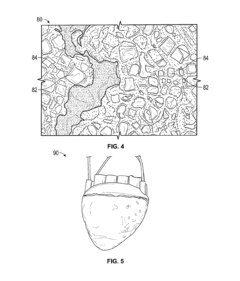

- The development of soft robotics using composite actuators made from elastomers and embedded flexible sheets, such as paper, which introduce controlled anisotropy to enable a range of motions including extension, contraction, twisting, and bending through pneumatic actuation, allowing for flexible control and practical design.

Soft actuator and methods of fabrication

PatentActiveUS20170029592A1

Innovation

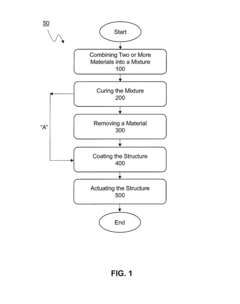

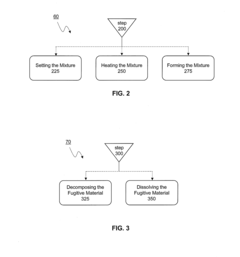

- Soft actuators are fabricated using a combination of elastomer materials and fugitive or foaming agent materials, which are cured to create an open-celled architecture that can be manipulated through inflation/deflation, allowing for controlled movement and actuation by applying pressure to select portions of the structure.

Sustainability Aspects of Elastomer Materials

The sustainability of elastomer materials in soft pneumatic actuators represents a critical consideration in their development and application. Traditional elastomers used in these systems, such as silicone rubbers and polyurethanes, often present significant environmental challenges throughout their lifecycle. The production processes for these materials typically involve petroleum-based feedstocks and energy-intensive manufacturing methods, contributing to carbon emissions and resource depletion.

End-of-life management poses another substantial sustainability concern. Most conventional elastomers demonstrate poor biodegradability, with decomposition timeframes extending to hundreds of years in natural environments. This persistence creates long-term waste management challenges, particularly as soft robotics applications expand across industries.

Recent research has focused on developing bio-based elastomer alternatives derived from renewable resources. Materials incorporating natural rubber, cellulose derivatives, and plant oils have shown promising mechanical properties while reducing environmental impact. For instance, elastomers derived from castor oil have demonstrated comparable performance to silicone-based counterparts in certain soft actuator applications, while offering improved biodegradability profiles.

Lifecycle assessment studies indicate that the environmental footprint of elastomer-based soft actuators can be significantly reduced through material selection and design optimization. Factors such as material durability, repairability, and recyclability play crucial roles in determining overall sustainability. Extended service life through self-healing elastomers represents a particularly promising approach, as these materials can autonomously repair minor damage, thereby reducing replacement frequency and associated waste.

Manufacturing innovations are also advancing sustainability objectives. Additive manufacturing techniques enable more precise material deposition, reducing waste compared to traditional molding processes. Additionally, these methods facilitate design optimization that can minimize material usage while maintaining performance characteristics.

Regulatory frameworks increasingly influence elastomer selection in soft robotics applications. Restrictions on certain chemical additives, such as phthalate plasticizers, have prompted research into safer alternatives that maintain the desired mechanical properties. This regulatory pressure, combined with growing consumer demand for environmentally responsible products, is accelerating the transition toward more sustainable elastomer formulations.

Cross-disciplinary collaboration between materials scientists, environmental engineers, and robotics specialists is essential for addressing these sustainability challenges comprehensively. The development of standardized sustainability metrics specific to soft robotics materials would further facilitate meaningful comparisons between different elastomer options and guide future research directions.

End-of-life management poses another substantial sustainability concern. Most conventional elastomers demonstrate poor biodegradability, with decomposition timeframes extending to hundreds of years in natural environments. This persistence creates long-term waste management challenges, particularly as soft robotics applications expand across industries.

Recent research has focused on developing bio-based elastomer alternatives derived from renewable resources. Materials incorporating natural rubber, cellulose derivatives, and plant oils have shown promising mechanical properties while reducing environmental impact. For instance, elastomers derived from castor oil have demonstrated comparable performance to silicone-based counterparts in certain soft actuator applications, while offering improved biodegradability profiles.

Lifecycle assessment studies indicate that the environmental footprint of elastomer-based soft actuators can be significantly reduced through material selection and design optimization. Factors such as material durability, repairability, and recyclability play crucial roles in determining overall sustainability. Extended service life through self-healing elastomers represents a particularly promising approach, as these materials can autonomously repair minor damage, thereby reducing replacement frequency and associated waste.

Manufacturing innovations are also advancing sustainability objectives. Additive manufacturing techniques enable more precise material deposition, reducing waste compared to traditional molding processes. Additionally, these methods facilitate design optimization that can minimize material usage while maintaining performance characteristics.

Regulatory frameworks increasingly influence elastomer selection in soft robotics applications. Restrictions on certain chemical additives, such as phthalate plasticizers, have prompted research into safer alternatives that maintain the desired mechanical properties. This regulatory pressure, combined with growing consumer demand for environmentally responsible products, is accelerating the transition toward more sustainable elastomer formulations.

Cross-disciplinary collaboration between materials scientists, environmental engineers, and robotics specialists is essential for addressing these sustainability challenges comprehensively. The development of standardized sustainability metrics specific to soft robotics materials would further facilitate meaningful comparisons between different elastomer options and guide future research directions.

Standardization and Testing Protocols

The standardization of testing protocols for soft pneumatic actuators (SPAs) represents a critical challenge in the field, particularly when evaluating elastomer performance. Current testing methodologies vary significantly across research institutions and industries, making direct comparisons between different elastomer-based actuators difficult and often unreliable. This inconsistency hampers technological advancement and commercial adoption of soft robotics technologies.

A comprehensive standardization framework must address multiple performance parameters simultaneously. Key metrics include force generation capacity, displacement range, response time, energy efficiency, and cycle durability—all of which are directly influenced by elastomer properties. The development of ISO-compliant testing procedures would enable meaningful benchmarking across different elastomer formulations and actuator designs.

Material characterization protocols specifically tailored for elastomers in pneumatic applications are essential components of standardization efforts. These should include standardized methods for measuring viscoelastic properties under dynamic loading conditions that simulate actual operational scenarios. Hyperelastic behavior characterization using standardized strain rates and temperature ranges would provide comparable data across different elastomer types used in SPAs.

Environmental testing represents another critical aspect of standardization. Protocols must specify standard conditions for evaluating elastomer performance across temperature ranges (-40°C to 85°C), humidity levels, and exposure to common chemicals and UV radiation. These environmental factors significantly impact elastomer mechanical properties and consequently actuator performance over time.

Fatigue testing protocols require particular attention, as elastomer degradation mechanisms directly influence SPA longevity. Standardized cyclic loading tests at specified pressures, frequencies, and duty cycles would enable reliable prediction of service life across different elastomer formulations. The establishment of accelerated aging protocols correlated with real-world performance would significantly reduce development timelines.

Non-destructive evaluation techniques must also be standardized to enable consistent quality control in manufacturing. Methods such as durometer hardness testing, optical strain mapping, and acoustic emission analysis should be codified with specific procedures and acceptance criteria. These techniques allow for ongoing monitoring of elastomer properties throughout the actuator lifecycle.

The implementation of these standardized testing protocols would facilitate more rapid innovation in elastomer formulation specifically optimized for soft pneumatic applications. By establishing common performance metrics and evaluation methodologies, researchers and manufacturers could more effectively communicate advances and accelerate the transition from laboratory prototypes to commercial soft robotic systems with predictable, reliable performance characteristics.

A comprehensive standardization framework must address multiple performance parameters simultaneously. Key metrics include force generation capacity, displacement range, response time, energy efficiency, and cycle durability—all of which are directly influenced by elastomer properties. The development of ISO-compliant testing procedures would enable meaningful benchmarking across different elastomer formulations and actuator designs.

Material characterization protocols specifically tailored for elastomers in pneumatic applications are essential components of standardization efforts. These should include standardized methods for measuring viscoelastic properties under dynamic loading conditions that simulate actual operational scenarios. Hyperelastic behavior characterization using standardized strain rates and temperature ranges would provide comparable data across different elastomer types used in SPAs.

Environmental testing represents another critical aspect of standardization. Protocols must specify standard conditions for evaluating elastomer performance across temperature ranges (-40°C to 85°C), humidity levels, and exposure to common chemicals and UV radiation. These environmental factors significantly impact elastomer mechanical properties and consequently actuator performance over time.

Fatigue testing protocols require particular attention, as elastomer degradation mechanisms directly influence SPA longevity. Standardized cyclic loading tests at specified pressures, frequencies, and duty cycles would enable reliable prediction of service life across different elastomer formulations. The establishment of accelerated aging protocols correlated with real-world performance would significantly reduce development timelines.

Non-destructive evaluation techniques must also be standardized to enable consistent quality control in manufacturing. Methods such as durometer hardness testing, optical strain mapping, and acoustic emission analysis should be codified with specific procedures and acceptance criteria. These techniques allow for ongoing monitoring of elastomer properties throughout the actuator lifecycle.

The implementation of these standardized testing protocols would facilitate more rapid innovation in elastomer formulation specifically optimized for soft pneumatic applications. By establishing common performance metrics and evaluation methodologies, researchers and manufacturers could more effectively communicate advances and accelerate the transition from laboratory prototypes to commercial soft robotic systems with predictable, reliable performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!