Technical Evaluation of Soft Pneumatic Actuator Designs

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of robotics and automation, emerging from the convergence of materials science, mechanical engineering, and biomimetics. These flexible, compliant mechanisms harness pneumatic pressure to generate motion and force, offering a stark contrast to traditional rigid actuators. The evolution of SPAs can be traced back to the early 2000s, when researchers began exploring alternatives to conventional hard robotics, inspired by biological systems such as elephant trunks, octopus tentacles, and human muscles.

The technological trajectory of SPAs has been characterized by significant innovations in materials, fabrication techniques, and control strategies. Early designs utilized simple elastomeric structures with embedded air chambers, while contemporary approaches incorporate advanced composite materials, multi-material 3D printing, and sophisticated pneumatic networks. This progression has enabled increasingly complex motions and functionalities, expanding the potential applications of soft robotics across various industries.

Current research trends in SPA technology focus on enhancing performance metrics such as force-to-weight ratio, response time, and operational lifespan. Additionally, there is growing interest in developing self-sensing capabilities, integrating embedded sensors, and creating modular designs that can be easily customized for specific applications. The miniaturization of SPAs and the development of untethered systems represent other significant trends that are shaping the future of this technology.

The primary objectives of SPA technology development are multifaceted. First, to create safer human-robot interaction systems by leveraging the inherent compliance and adaptability of soft materials. Second, to enable operation in unstructured or delicate environments where traditional rigid robots would be unsuitable. Third, to develop more energy-efficient actuators that can perform complex movements with minimal pneumatic input. Fourth, to achieve biomimetic capabilities that replicate the versatility and dexterity of biological systems.

From a technical standpoint, researchers aim to overcome several key challenges, including nonlinear behavior prediction, material fatigue, fabrication scalability, and precise control. The ultimate goal is to establish a comprehensive framework for designing, modeling, and controlling SPAs that can be readily applied across diverse applications, from medical devices and assistive technologies to industrial automation and exploration robotics.

As SPAs continue to mature as a technology, they promise to bridge the gap between rigid, high-precision traditional robotics and the adaptable, safe interaction capabilities required for next-generation applications in human-centric environments.

The technological trajectory of SPAs has been characterized by significant innovations in materials, fabrication techniques, and control strategies. Early designs utilized simple elastomeric structures with embedded air chambers, while contemporary approaches incorporate advanced composite materials, multi-material 3D printing, and sophisticated pneumatic networks. This progression has enabled increasingly complex motions and functionalities, expanding the potential applications of soft robotics across various industries.

Current research trends in SPA technology focus on enhancing performance metrics such as force-to-weight ratio, response time, and operational lifespan. Additionally, there is growing interest in developing self-sensing capabilities, integrating embedded sensors, and creating modular designs that can be easily customized for specific applications. The miniaturization of SPAs and the development of untethered systems represent other significant trends that are shaping the future of this technology.

The primary objectives of SPA technology development are multifaceted. First, to create safer human-robot interaction systems by leveraging the inherent compliance and adaptability of soft materials. Second, to enable operation in unstructured or delicate environments where traditional rigid robots would be unsuitable. Third, to develop more energy-efficient actuators that can perform complex movements with minimal pneumatic input. Fourth, to achieve biomimetic capabilities that replicate the versatility and dexterity of biological systems.

From a technical standpoint, researchers aim to overcome several key challenges, including nonlinear behavior prediction, material fatigue, fabrication scalability, and precise control. The ultimate goal is to establish a comprehensive framework for designing, modeling, and controlling SPAs that can be readily applied across diverse applications, from medical devices and assistive technologies to industrial automation and exploration robotics.

As SPAs continue to mature as a technology, they promise to bridge the gap between rigid, high-precision traditional robotics and the adaptable, safe interaction capabilities required for next-generation applications in human-centric environments.

Market Applications and Demand Analysis

The soft pneumatic actuator (SPA) market is experiencing significant growth driven by increasing demand across multiple industries seeking flexible, lightweight, and safe automation solutions. The global market for soft robotics, which includes SPAs, is projected to reach $3.27 billion by 2026, with a compound annual growth rate of 35.1% from 2021. This remarkable growth trajectory reflects the expanding applications and market acceptance of soft actuator technologies.

Healthcare represents one of the most promising markets for soft pneumatic actuators, with applications ranging from rehabilitation devices to surgical assistants. The aging population in developed countries has created substantial demand for assistive technologies that can safely interact with humans. SPAs offer the compliance and gentle interaction capabilities essential for patient care, making them ideal for exoskeletons, prosthetics, and physical therapy devices. The medical robotics segment alone is expected to contribute approximately $1.2 billion to the soft robotics market by 2025.

Manufacturing and industrial automation constitute another significant market segment. Traditional rigid robots present safety concerns and operational limitations when working alongside human operators. Soft pneumatic actuators address these challenges by providing inherently safer human-machine interaction capabilities. The collaborative robotics sector, where SPAs play an increasingly important role, is growing at 41.2% annually, highlighting the industrial demand for flexible automation solutions.

Consumer electronics and wearable technology represent emerging markets with substantial growth potential. The tactile feedback capabilities of SPAs make them valuable for haptic interfaces, virtual reality equipment, and next-generation user interface devices. This segment is expected to grow as immersive technologies become more mainstream, with market analysts predicting a 28% annual growth rate for haptic technology applications.

The logistics and e-commerce sectors have shown increasing interest in soft gripping technologies for handling diverse and delicate objects. The ability of SPAs to conform to irregular shapes while applying controlled force makes them ideal for automated picking and packing operations. With e-commerce continuing its double-digit growth globally, the demand for adaptive gripping solutions is projected to increase proportionally.

Agricultural applications represent an untapped market with significant potential, particularly for delicate crop handling and automated harvesting. The global agricultural robotics market is expected to reach $20.6 billion by 2025, with soft actuator technologies positioned to capture a growing share of this market as farmers seek solutions for labor shortages and sustainable farming practices.

Healthcare represents one of the most promising markets for soft pneumatic actuators, with applications ranging from rehabilitation devices to surgical assistants. The aging population in developed countries has created substantial demand for assistive technologies that can safely interact with humans. SPAs offer the compliance and gentle interaction capabilities essential for patient care, making them ideal for exoskeletons, prosthetics, and physical therapy devices. The medical robotics segment alone is expected to contribute approximately $1.2 billion to the soft robotics market by 2025.

Manufacturing and industrial automation constitute another significant market segment. Traditional rigid robots present safety concerns and operational limitations when working alongside human operators. Soft pneumatic actuators address these challenges by providing inherently safer human-machine interaction capabilities. The collaborative robotics sector, where SPAs play an increasingly important role, is growing at 41.2% annually, highlighting the industrial demand for flexible automation solutions.

Consumer electronics and wearable technology represent emerging markets with substantial growth potential. The tactile feedback capabilities of SPAs make them valuable for haptic interfaces, virtual reality equipment, and next-generation user interface devices. This segment is expected to grow as immersive technologies become more mainstream, with market analysts predicting a 28% annual growth rate for haptic technology applications.

The logistics and e-commerce sectors have shown increasing interest in soft gripping technologies for handling diverse and delicate objects. The ability of SPAs to conform to irregular shapes while applying controlled force makes them ideal for automated picking and packing operations. With e-commerce continuing its double-digit growth globally, the demand for adaptive gripping solutions is projected to increase proportionally.

Agricultural applications represent an untapped market with significant potential, particularly for delicate crop handling and automated harvesting. The global agricultural robotics market is expected to reach $20.6 billion by 2025, with soft actuator technologies positioned to capture a growing share of this market as farmers seek solutions for labor shortages and sustainable farming practices.

Current Challenges in Soft Pneumatic Actuator Technology

Despite significant advancements in soft pneumatic actuator (SPA) technology, several critical challenges continue to impede widespread industrial adoption and optimal performance. Material limitations represent one of the most significant barriers, as current elastomers used in SPAs often exhibit contradictory property requirements. These materials must simultaneously demonstrate high elasticity for deformation while maintaining sufficient strength to withstand repeated pressurization cycles. Additionally, most commercially available elastomers suffer from hysteresis, stress relaxation, and fatigue issues that compromise long-term reliability.

Manufacturing inconsistencies present another substantial challenge. Traditional fabrication methods like molding and casting frequently introduce variability in wall thickness and material properties, resulting in unpredictable performance across supposedly identical actuators. More advanced techniques such as 3D printing offer improved precision but remain limited in material selection and often produce actuators with anisotropic properties that affect mechanical performance.

Pressure control and distribution systems for SPAs lack the sophistication found in conventional rigid actuators. Current pneumatic systems struggle to deliver precise, responsive pressure modulation necessary for complex motion profiles. The inherent compliance of soft systems introduces delays and nonlinearities in the pressure-deformation relationship, complicating control algorithms and limiting dynamic performance capabilities.

Modeling and simulation tools for SPAs remain underdeveloped compared to those available for traditional rigid systems. The hyperelastic, nonlinear behavior of soft materials presents significant computational challenges, with existing finite element models often failing to accurately predict real-world performance. This modeling gap hinders design optimization and increases development cycles as engineers must rely heavily on physical prototyping and empirical testing.

Scalability issues persist across the SPA field. Miniaturization efforts face challenges in maintaining functional pressure chambers and distribution channels at small scales, while larger SPAs struggle with pressure containment and achieving uniform actuation across their structure. This limits application potential at both ends of the size spectrum.

Energy efficiency represents another critical concern, as SPAs typically exhibit poor energy return due to viscoelastic losses and air compressibility. The need for continuous pressurization to maintain position further reduces efficiency compared to self-locking rigid actuators, presenting significant barriers for mobile or portable applications with limited power resources.

Integration challenges with conventional robotic systems and standardization issues further complicate adoption. The lack of established performance metrics, testing protocols, and design standards makes comparison between different SPA technologies difficult and slows industry-wide progress toward solving these fundamental challenges.

Manufacturing inconsistencies present another substantial challenge. Traditional fabrication methods like molding and casting frequently introduce variability in wall thickness and material properties, resulting in unpredictable performance across supposedly identical actuators. More advanced techniques such as 3D printing offer improved precision but remain limited in material selection and often produce actuators with anisotropic properties that affect mechanical performance.

Pressure control and distribution systems for SPAs lack the sophistication found in conventional rigid actuators. Current pneumatic systems struggle to deliver precise, responsive pressure modulation necessary for complex motion profiles. The inherent compliance of soft systems introduces delays and nonlinearities in the pressure-deformation relationship, complicating control algorithms and limiting dynamic performance capabilities.

Modeling and simulation tools for SPAs remain underdeveloped compared to those available for traditional rigid systems. The hyperelastic, nonlinear behavior of soft materials presents significant computational challenges, with existing finite element models often failing to accurately predict real-world performance. This modeling gap hinders design optimization and increases development cycles as engineers must rely heavily on physical prototyping and empirical testing.

Scalability issues persist across the SPA field. Miniaturization efforts face challenges in maintaining functional pressure chambers and distribution channels at small scales, while larger SPAs struggle with pressure containment and achieving uniform actuation across their structure. This limits application potential at both ends of the size spectrum.

Energy efficiency represents another critical concern, as SPAs typically exhibit poor energy return due to viscoelastic losses and air compressibility. The need for continuous pressurization to maintain position further reduces efficiency compared to self-locking rigid actuators, presenting significant barriers for mobile or portable applications with limited power resources.

Integration challenges with conventional robotic systems and standardization issues further complicate adoption. The lack of established performance metrics, testing protocols, and design standards makes comparison between different SPA technologies difficult and slows industry-wide progress toward solving these fundamental challenges.

Current Design Solutions and Architectures

01 Materials and fabrication techniques for soft pneumatic actuators

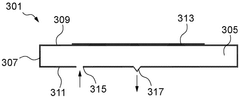

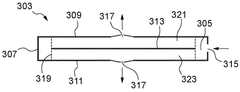

Various materials and fabrication techniques are employed in the design of soft pneumatic actuators. These include the use of elastomeric materials such as silicone rubber, which provides flexibility and resilience. Advanced manufacturing methods like 3D printing and molding processes enable the creation of complex geometries and internal channels necessary for pneumatic operation. The selection of appropriate materials and fabrication methods is crucial for achieving desired performance characteristics such as flexibility, durability, and response time.- Materials and fabrication techniques for soft pneumatic actuators: Various materials and fabrication techniques are employed in the design of soft pneumatic actuators. These include elastomeric materials like silicone rubber that provide flexibility and resilience, and manufacturing methods such as molding, 3D printing, and lamination processes. The selection of appropriate materials and fabrication techniques is crucial for achieving desired performance characteristics such as flexibility, durability, and response time in soft pneumatic actuators.

- Structural designs for enhanced performance: Different structural designs can enhance the performance of soft pneumatic actuators. These include bellows structures, fiber-reinforced designs, and multi-chamber configurations that allow for complex movements and improved force output. The geometry and arrangement of chambers within the actuator significantly influence its motion capabilities, such as bending, twisting, or extending. Strategic placement of reinforcement elements can constrain expansion in specific directions, enabling more controlled and predictable movements.

- Control systems and sensing integration: Advanced control systems and integrated sensing capabilities are essential for precise operation of soft pneumatic actuators. These systems may incorporate pressure sensors, position feedback mechanisms, and sophisticated algorithms to regulate air flow and pressure. Machine learning approaches can be used to improve the responsiveness and adaptability of the actuators. Integration of embedded sensors allows for real-time monitoring of actuator state, enabling closed-loop control for more accurate and repeatable movements.

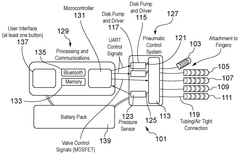

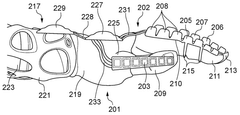

- Application-specific designs for robotics and biomechanics: Soft pneumatic actuators are designed with specific applications in mind, particularly in robotics and biomechanical systems. These designs may focus on mimicking biological movements, such as those of fingers, arms, or tentacles, or on addressing particular industrial or medical needs. For wearable applications, actuators may be designed to conform to the human body while providing assistance or rehabilitation functions. In robotic grippers, designs often emphasize gentle yet secure handling of delicate or irregularly shaped objects.

- Energy efficiency and portable pneumatic systems: Improving energy efficiency is a key consideration in soft pneumatic actuator design. This includes developing lightweight, portable pneumatic systems with efficient air distribution networks and minimal leakage. Some designs incorporate energy recovery mechanisms or alternative actuation methods to reduce compressed air consumption. Miniaturization of pneumatic components and integration of compact air supply systems enable the development of portable and autonomous soft robotic systems with reduced energy requirements.

02 Geometric designs and structural configurations

The geometric design and structural configuration of soft pneumatic actuators significantly influence their performance. Various designs include bellows-type structures, pleated chambers, and fiber-reinforced configurations. These designs determine the direction and type of movement when pressurized, such as bending, twisting, or extending. Strategic placement of reinforcement elements and varying wall thicknesses can be used to control deformation patterns and enhance actuation capabilities.Expand Specific Solutions03 Control systems and pressure regulation

Effective control systems and pressure regulation mechanisms are essential for precise operation of soft pneumatic actuators. These systems may include pressure sensors, valves, and electronic controllers that modulate air flow and pressure distribution. Advanced control algorithms can compensate for the nonlinear behavior of soft materials, enabling more accurate positioning and movement. Integration with feedback mechanisms allows for adaptive responses to changing environmental conditions or task requirements.Expand Specific Solutions04 Multi-chamber and modular actuator designs

Multi-chamber and modular designs enhance the versatility and functionality of soft pneumatic actuators. By incorporating multiple independently controllable chambers within a single actuator, complex movements and force distributions can be achieved. Modular approaches allow for the assembly of actuators into larger systems with increased degrees of freedom. These designs facilitate adaptability to different applications and enable more sophisticated manipulation capabilities compared to single-chamber actuators.Expand Specific Solutions05 Application-specific actuator optimizations

Soft pneumatic actuators can be optimized for specific applications across various fields. In medical devices, actuators may be designed with biocompatible materials and gentle interaction forces for safe patient contact. For robotic grippers, designs focus on conformable grasping surfaces and controlled force distribution. In wearable devices, actuators are optimized for lightweight construction and ergonomic integration with the human body. These application-specific optimizations involve tailoring the actuator's size, force output, response time, and other parameters to meet particular requirements.Expand Specific Solutions

Leading Companies and Research Institutions

The soft pneumatic actuator market is in a growth phase characterized by increasing adoption across robotics, healthcare, and industrial automation sectors. Market size is expanding rapidly, projected to reach significant value by 2030 due to demand for compliant, lightweight actuation systems. Technologically, the field shows varying maturity levels with academic institutions leading fundamental research (Harvard, MIT, Zhejiang University) while specialized companies develop commercial applications. Established players like Boeing and Toyota explore integration possibilities, while innovative startups such as Artimus Robotics and Oxipital AI focus on specialized applications. Research institutions like KIMM and CSIR contribute to technological advancement, creating a competitive landscape balanced between academic innovation and industrial implementation, with growing cross-sector collaboration accelerating development.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered innovative soft pneumatic actuator (SPA) designs through their work on soft robotics. Their approach focuses on biomimetic designs that utilize elastomeric materials with embedded pneumatic networks (PneuNets). These actuators feature complex internal channel structures that enable controlled deformation when pressurized with air. Harvard researchers have developed multi-gait soft robots using these actuators, capable of undulating, crawling, and even navigating challenging terrains. Their technical solution incorporates silicone-based materials with varying shore hardness to create actuators with programmable motion patterns. The team has also advanced fabrication techniques, including 3D printing and soft lithography methods, to create increasingly sophisticated pneumatic networks. Recent developments include the integration of sensing capabilities through embedded conductive materials and the creation of hybrid actuators that combine pneumatic actuation with other modalities such as electrical or chemical stimulation for enhanced functionality and control precision[1][3].

Strengths: Superior biomimetic capabilities allowing complex, natural movements; excellent adaptability to unstructured environments; inherent safety for human interaction due to compliant materials. Weaknesses: Lower force output compared to rigid actuators; challenges in precise position control; potential durability issues with repeated cycling of elastomeric materials.

Cornell University

Technical Solution: Cornell University's Organic Robotics Lab has developed a distinctive approach to soft pneumatic actuators through their Fiber-Reinforced Elastomeric Enclosures (FREEs) technology. Their technical solution involves embedding fiber reinforcements in specific patterns within elastomeric materials to create programmable deformation patterns when pressurized. This method allows for precise control over expansion, contraction, twisting, and bending motions. Cornell researchers have particularly focused on creating actuators with anisotropic properties by strategically placing inextensible fibers at specific angles relative to the actuator's longitudinal axis. Their innovations include multi-chamber designs that enable complex motion sequences and variable stiffness capabilities through antagonistic chamber arrangements. The lab has also pioneered rapid manufacturing techniques for these actuators, including automated fiber winding processes and multi-material 3D printing that integrates both rigid and flexible components in a single fabrication process. Recent advancements include the development of self-sensing actuators that incorporate conductive materials to provide proprioceptive feedback during operation[2][5].

Strengths: Highly customizable motion patterns through fiber reinforcement design; excellent force-to-weight ratio compared to other soft actuators; scalable from micro to macro applications. Weaknesses: Manufacturing complexity due to fiber placement requirements; potential failure points at fiber-elastomer interfaces; limited operational lifespan under high-pressure conditions.

Key Patents and Technical Innovations

Soft robotic assistive device

PatentActiveGB2622575A

Innovation

- Integration of a piezoelectric resonant acoustic gas pump with a soft pneumatic actuator in an assistive or rehabilitative device, creating a novel pneumatic actuation system.

- Dual functionality of the soft pneumatic actuator to both assist and resist body movement, enabling comprehensive rehabilitation capabilities in a single device.

- Inclusion of pressure sensing means to monitor and potentially regulate the pneumatic system's performance during rehabilitation exercises.

Materials Science Considerations

The selection of materials for soft pneumatic actuators represents a critical factor in determining their performance characteristics, durability, and application suitability. Elastomeric materials such as silicone rubber (PDMS, Ecoflex), thermoplastic polyurethanes (TPU), and natural rubber derivatives form the foundation of most contemporary soft actuator designs. These materials offer varying degrees of elasticity, with Young's modulus typically ranging from 0.1 MPa to 10 MPa, enabling the controlled deformation necessary for actuation.

Material properties directly influence the mechanical behavior of soft pneumatic actuators, particularly in terms of response time, force output, and operational lifespan. Silicone-based materials generally provide excellent flexibility and rapid response times but may suffer from air permeability issues that reduce pressure maintenance capabilities. Conversely, TPU offers superior air retention properties while sacrificing some degree of elasticity, resulting in different actuation dynamics.

Fabrication considerations must account for material processability, with silicones typically requiring molding and curing processes, while TPUs can be utilized in additive manufacturing approaches such as fused deposition modeling. The interface between different materials within multi-material actuator designs presents significant challenges, particularly regarding delamination under repeated stress cycles. Recent advances in surface treatment technologies and chemical bonding methods have improved these interfaces, enhancing overall system reliability.

Environmental stability represents another crucial consideration, as material properties can vary significantly with temperature fluctuations. Most elastomers exhibit glass transition temperatures below room temperature, but their mechanical properties may still change appreciably within operational temperature ranges. Additionally, exposure to UV radiation, ozone, and various chemicals can accelerate material degradation, necessitating protective measures for applications in harsh environments.

Biocompatibility becomes essential for medical and wearable applications, with medical-grade silicones offering advantages for direct human contact scenarios. However, these materials often command premium prices and may require specialized processing techniques. The development of bio-derived elastomers represents an emerging trend, addressing both biocompatibility concerns and sustainability objectives.

Material fatigue characteristics ultimately determine actuator longevity, with most elastomers exhibiting hysteresis and stress softening (Mullins effect) during initial cycling. This necessitates pre-conditioning protocols for applications requiring precise force control. Recent research has focused on self-healing elastomers that can recover from microdamage, potentially extending operational lifespans significantly beyond current limitations.

Material properties directly influence the mechanical behavior of soft pneumatic actuators, particularly in terms of response time, force output, and operational lifespan. Silicone-based materials generally provide excellent flexibility and rapid response times but may suffer from air permeability issues that reduce pressure maintenance capabilities. Conversely, TPU offers superior air retention properties while sacrificing some degree of elasticity, resulting in different actuation dynamics.

Fabrication considerations must account for material processability, with silicones typically requiring molding and curing processes, while TPUs can be utilized in additive manufacturing approaches such as fused deposition modeling. The interface between different materials within multi-material actuator designs presents significant challenges, particularly regarding delamination under repeated stress cycles. Recent advances in surface treatment technologies and chemical bonding methods have improved these interfaces, enhancing overall system reliability.

Environmental stability represents another crucial consideration, as material properties can vary significantly with temperature fluctuations. Most elastomers exhibit glass transition temperatures below room temperature, but their mechanical properties may still change appreciably within operational temperature ranges. Additionally, exposure to UV radiation, ozone, and various chemicals can accelerate material degradation, necessitating protective measures for applications in harsh environments.

Biocompatibility becomes essential for medical and wearable applications, with medical-grade silicones offering advantages for direct human contact scenarios. However, these materials often command premium prices and may require specialized processing techniques. The development of bio-derived elastomers represents an emerging trend, addressing both biocompatibility concerns and sustainability objectives.

Material fatigue characteristics ultimately determine actuator longevity, with most elastomers exhibiting hysteresis and stress softening (Mullins effect) during initial cycling. This necessitates pre-conditioning protocols for applications requiring precise force control. Recent research has focused on self-healing elastomers that can recover from microdamage, potentially extending operational lifespans significantly beyond current limitations.

Performance Metrics and Evaluation Methods

The evaluation of soft pneumatic actuators requires comprehensive performance metrics and standardized testing methodologies to ensure objective comparison across different designs. Force generation capability stands as a primary metric, typically measured using force sensors at various inflation pressures, with particular attention to the maximum force output and force-to-weight ratio. These measurements provide critical insights into the actuator's potential applications and efficiency.

Displacement and range of motion represent equally important parameters, quantified through optical tracking systems or embedded sensors. The relationship between input pressure and resulting displacement, often expressed as displacement curves, helps engineers understand the actuator's mechanical behavior under varying conditions. For applications requiring precise movement control, hysteresis measurement becomes essential, as it reveals the difference between extension and contraction paths during pressure cycling.

Response time metrics capture the actuator's dynamic performance, measuring both inflation and deflation speeds at different pressure levels. This data proves particularly valuable for applications requiring rapid movement or precise timing. Complementing this, cycle life testing evaluates durability by subjecting actuators to repeated inflation-deflation cycles until failure or significant performance degradation occurs.

Energy efficiency assessment involves calculating the ratio of mechanical work output to pneumatic energy input, providing insights into the actuator's overall efficiency. This metric becomes increasingly important in portable or energy-constrained applications. For actuators intended for specific environments, environmental resistance testing evaluates performance under extreme temperatures, humidity levels, or chemical exposure.

Standardized testing protocols have emerged to facilitate meaningful comparisons between different soft actuator designs. These include the blocked force test (measuring force output when movement is constrained), free displacement test (measuring movement range without external loads), and load-displacement curves (mapping performance across various loading conditions). Advanced evaluation methods incorporate finite element analysis and computational fluid dynamics to predict performance before physical prototyping.

The integration of embedded sensing technologies has revolutionized performance evaluation, enabling real-time monitoring of actuator state, pressure distribution, and deformation patterns. These advancements support more sophisticated control strategies and provide valuable data for design optimization. As the field matures, establishing industry-wide standardized testing methodologies remains crucial for accelerating development and facilitating meaningful comparisons across different soft pneumatic actuator designs.

Displacement and range of motion represent equally important parameters, quantified through optical tracking systems or embedded sensors. The relationship between input pressure and resulting displacement, often expressed as displacement curves, helps engineers understand the actuator's mechanical behavior under varying conditions. For applications requiring precise movement control, hysteresis measurement becomes essential, as it reveals the difference between extension and contraction paths during pressure cycling.

Response time metrics capture the actuator's dynamic performance, measuring both inflation and deflation speeds at different pressure levels. This data proves particularly valuable for applications requiring rapid movement or precise timing. Complementing this, cycle life testing evaluates durability by subjecting actuators to repeated inflation-deflation cycles until failure or significant performance degradation occurs.

Energy efficiency assessment involves calculating the ratio of mechanical work output to pneumatic energy input, providing insights into the actuator's overall efficiency. This metric becomes increasingly important in portable or energy-constrained applications. For actuators intended for specific environments, environmental resistance testing evaluates performance under extreme temperatures, humidity levels, or chemical exposure.

Standardized testing protocols have emerged to facilitate meaningful comparisons between different soft actuator designs. These include the blocked force test (measuring force output when movement is constrained), free displacement test (measuring movement range without external loads), and load-displacement curves (mapping performance across various loading conditions). Advanced evaluation methods incorporate finite element analysis and computational fluid dynamics to predict performance before physical prototyping.

The integration of embedded sensing technologies has revolutionized performance evaluation, enabling real-time monitoring of actuator state, pressure distribution, and deformation patterns. These advancements support more sophisticated control strategies and provide valuable data for design optimization. As the field matures, establishing industry-wide standardized testing methodologies remains crucial for accelerating development and facilitating meaningful comparisons across different soft pneumatic actuator designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!