The Evolution of Soft Pneumatic Actuator Patents

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Development History and Objectives

Soft pneumatic actuators (SPAs) represent a significant advancement in the field of soft robotics, offering compliant and adaptable solutions for various applications. The development of SPAs can be traced back to the early 1990s when researchers began exploring alternatives to rigid actuators for applications requiring safer human-machine interactions. The initial concepts were inspired by biological systems, particularly the muscular hydrostat structures found in octopus tentacles and elephant trunks.

The evolution of SPA technology has followed a clear trajectory from rudimentary designs to sophisticated systems with enhanced capabilities. In the early stages (1990-2000), research primarily focused on proof-of-concept designs utilizing simple elastomeric materials and basic pneumatic principles. These early prototypes demonstrated fundamental capabilities but suffered from limited force output, poor durability, and inefficient energy consumption.

The period from 2000 to 2010 marked a significant acceleration in SPA development, characterized by the introduction of novel manufacturing techniques such as soft lithography and 3D printing. These advancements enabled more complex geometries and improved performance characteristics. During this phase, researchers began exploring various architectural designs, including bellows-type actuators, fiber-reinforced actuators, and pneumatic networks (PneuNets), each offering distinct advantages for specific applications.

Patent activity in the SPA domain has shown exponential growth since 2010, reflecting the increasing recognition of their potential across multiple industries. Early patents primarily focused on basic actuation mechanisms, while more recent intellectual property has expanded to include specialized applications, control systems, and integration methodologies. Key patent clusters have emerged around medical devices, assistive technologies, and industrial automation, indicating the diversification of SPA applications.

The technical objectives driving SPA development have evolved significantly over time. Initial goals centered on achieving basic functionality and demonstrating feasibility. Current objectives are more sophisticated, focusing on enhancing force-to-weight ratios, improving response times, extending operational lifespans, and developing more efficient control systems. Additionally, there is growing emphasis on creating SPAs capable of multi-modal actuation and sensing capabilities, effectively transforming them from simple actuators to integrated robotic components.

Looking forward, the field aims to address several persistent challenges, including material fatigue, pressure limitations, and energy efficiency. Research is increasingly directed toward developing self-healing materials, exploring alternative actuation methods such as chemical reactions or phase-change materials, and creating standardized design methodologies to accelerate development cycles. The ultimate goal is to establish SPAs as a mainstream technology capable of competing with traditional rigid actuators across a broad spectrum of applications.

The evolution of SPA technology has followed a clear trajectory from rudimentary designs to sophisticated systems with enhanced capabilities. In the early stages (1990-2000), research primarily focused on proof-of-concept designs utilizing simple elastomeric materials and basic pneumatic principles. These early prototypes demonstrated fundamental capabilities but suffered from limited force output, poor durability, and inefficient energy consumption.

The period from 2000 to 2010 marked a significant acceleration in SPA development, characterized by the introduction of novel manufacturing techniques such as soft lithography and 3D printing. These advancements enabled more complex geometries and improved performance characteristics. During this phase, researchers began exploring various architectural designs, including bellows-type actuators, fiber-reinforced actuators, and pneumatic networks (PneuNets), each offering distinct advantages for specific applications.

Patent activity in the SPA domain has shown exponential growth since 2010, reflecting the increasing recognition of their potential across multiple industries. Early patents primarily focused on basic actuation mechanisms, while more recent intellectual property has expanded to include specialized applications, control systems, and integration methodologies. Key patent clusters have emerged around medical devices, assistive technologies, and industrial automation, indicating the diversification of SPA applications.

The technical objectives driving SPA development have evolved significantly over time. Initial goals centered on achieving basic functionality and demonstrating feasibility. Current objectives are more sophisticated, focusing on enhancing force-to-weight ratios, improving response times, extending operational lifespans, and developing more efficient control systems. Additionally, there is growing emphasis on creating SPAs capable of multi-modal actuation and sensing capabilities, effectively transforming them from simple actuators to integrated robotic components.

Looking forward, the field aims to address several persistent challenges, including material fatigue, pressure limitations, and energy efficiency. Research is increasingly directed toward developing self-healing materials, exploring alternative actuation methods such as chemical reactions or phase-change materials, and creating standardized design methodologies to accelerate development cycles. The ultimate goal is to establish SPAs as a mainstream technology capable of competing with traditional rigid actuators across a broad spectrum of applications.

Market Applications and Demand Analysis for Soft Robotics

The soft robotics market has witnessed significant growth in recent years, driven by increasing demand across multiple sectors. The global soft robotics market was valued at approximately $645 million in 2020 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 20%. This remarkable growth trajectory is primarily fueled by the unique capabilities of soft pneumatic actuators that enable safe human-robot interaction and adaptable manipulation of delicate objects.

Healthcare and medical applications represent the largest market segment for soft robotics, accounting for nearly 35% of the total market share. Within this sector, surgical assistance, rehabilitation devices, and prosthetics are experiencing particularly strong demand. The aging population in developed countries has created substantial need for assistive technologies that can provide gentle, compliant support for elderly care and rehabilitation purposes.

Manufacturing and industrial automation constitute another significant market segment, where soft pneumatic actuators are increasingly deployed for handling fragile or irregularly shaped objects that traditional rigid robots cannot manipulate effectively. Companies in food processing, electronics assembly, and packaging industries are adopting soft robotic solutions to improve production efficiency while reducing product damage rates.

Consumer robotics represents an emerging market with substantial growth potential, particularly in household assistance and entertainment applications. The inherent safety of soft pneumatic actuators makes them ideal for environments where robots interact directly with humans, including homes, schools, and public spaces.

Market analysis reveals regional variations in adoption patterns. North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to rapid industrialization and increasing healthcare expenditure in countries like China, Japan, and South Korea.

Key market drivers include technological advancements in materials science, miniaturization of pneumatic components, and integration with smart sensors and control systems. Additionally, decreasing production costs and increasing awareness of soft robotics capabilities are expanding the potential application landscape.

Despite positive growth indicators, several market challenges persist. These include the need for standardization in soft robotics technologies, concerns about durability and reliability in industrial settings, and competition from alternative technologies such as electroactive polymers and shape memory alloys. The relatively higher maintenance requirements and shorter lifespan of soft pneumatic systems compared to traditional rigid robots also present adoption barriers in cost-sensitive market segments.

Healthcare and medical applications represent the largest market segment for soft robotics, accounting for nearly 35% of the total market share. Within this sector, surgical assistance, rehabilitation devices, and prosthetics are experiencing particularly strong demand. The aging population in developed countries has created substantial need for assistive technologies that can provide gentle, compliant support for elderly care and rehabilitation purposes.

Manufacturing and industrial automation constitute another significant market segment, where soft pneumatic actuators are increasingly deployed for handling fragile or irregularly shaped objects that traditional rigid robots cannot manipulate effectively. Companies in food processing, electronics assembly, and packaging industries are adopting soft robotic solutions to improve production efficiency while reducing product damage rates.

Consumer robotics represents an emerging market with substantial growth potential, particularly in household assistance and entertainment applications. The inherent safety of soft pneumatic actuators makes them ideal for environments where robots interact directly with humans, including homes, schools, and public spaces.

Market analysis reveals regional variations in adoption patterns. North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to rapid industrialization and increasing healthcare expenditure in countries like China, Japan, and South Korea.

Key market drivers include technological advancements in materials science, miniaturization of pneumatic components, and integration with smart sensors and control systems. Additionally, decreasing production costs and increasing awareness of soft robotics capabilities are expanding the potential application landscape.

Despite positive growth indicators, several market challenges persist. These include the need for standardization in soft robotics technologies, concerns about durability and reliability in industrial settings, and competition from alternative technologies such as electroactive polymers and shape memory alloys. The relatively higher maintenance requirements and shorter lifespan of soft pneumatic systems compared to traditional rigid robots also present adoption barriers in cost-sensitive market segments.

Global Soft Pneumatic Actuator Technology Landscape

The global landscape of soft pneumatic actuator (SPA) technology has evolved significantly over the past two decades, with distinct regional innovation hubs emerging across North America, Europe, and Asia. The United States maintains a leading position in this field, with major research contributions from institutions such as Harvard University, MIT, and Stanford University, which collectively account for approximately 35% of global patent filings in soft robotics actuation technologies.

European innovation in SPAs is primarily concentrated in Germany, Switzerland, and the United Kingdom, where research institutions like ETH Zurich and the University of Cambridge have established specialized soft robotics laboratories. These European entities focus predominantly on medical applications and human-robot interaction systems, representing approximately 25% of global SPA patent activity.

In Asia, Japan and South Korea initially led development efforts, but China has demonstrated remarkable growth in SPA patent filings since 2015, with an annual increase rate of approximately 28%. The Chinese Academy of Sciences and Tsinghua University have become significant contributors to the global SPA knowledge base, particularly in manufacturing processes and material innovations.

Cross-border collaboration patterns reveal interesting dynamics, with approximately 22% of SPA patents involving international co-inventors, indicating the increasingly globalized nature of this technology. These collaborations typically focus on combining material science expertise from Asian institutions with design methodology from Western research centers.

Patent citation analysis demonstrates that foundational SPA technologies originated primarily in the United States between 2008-2012, while more recent innovations show greater geographical diversity. The technology transfer pathway typically flows from academic institutions to specialized robotics companies, with an average commercialization timeline of 4-6 years from patent filing to market application.

Emerging regional specializations are becoming evident, with North American patents focusing on control systems and algorithmic approaches, European patents emphasizing safety and human-compatible designs, and Asian patents concentrating on manufacturing scalability and novel materials. This geographical specialization suggests complementary rather than directly competitive innovation ecosystems.

Investment patterns further illuminate the global landscape, with venture capital funding for SPA startups reaching approximately $450 million globally in 2022, representing a 35% increase from 2020. North American startups captured approximately 58% of this funding, while Asian and European companies secured 25% and 17% respectively, indicating continued Western dominance in commercialization despite the growing distribution of technical innovation.

European innovation in SPAs is primarily concentrated in Germany, Switzerland, and the United Kingdom, where research institutions like ETH Zurich and the University of Cambridge have established specialized soft robotics laboratories. These European entities focus predominantly on medical applications and human-robot interaction systems, representing approximately 25% of global SPA patent activity.

In Asia, Japan and South Korea initially led development efforts, but China has demonstrated remarkable growth in SPA patent filings since 2015, with an annual increase rate of approximately 28%. The Chinese Academy of Sciences and Tsinghua University have become significant contributors to the global SPA knowledge base, particularly in manufacturing processes and material innovations.

Cross-border collaboration patterns reveal interesting dynamics, with approximately 22% of SPA patents involving international co-inventors, indicating the increasingly globalized nature of this technology. These collaborations typically focus on combining material science expertise from Asian institutions with design methodology from Western research centers.

Patent citation analysis demonstrates that foundational SPA technologies originated primarily in the United States between 2008-2012, while more recent innovations show greater geographical diversity. The technology transfer pathway typically flows from academic institutions to specialized robotics companies, with an average commercialization timeline of 4-6 years from patent filing to market application.

Emerging regional specializations are becoming evident, with North American patents focusing on control systems and algorithmic approaches, European patents emphasizing safety and human-compatible designs, and Asian patents concentrating on manufacturing scalability and novel materials. This geographical specialization suggests complementary rather than directly competitive innovation ecosystems.

Investment patterns further illuminate the global landscape, with venture capital funding for SPA startups reaching approximately $450 million globally in 2022, representing a 35% increase from 2020. North American startups captured approximately 58% of this funding, while Asian and European companies secured 25% and 17% respectively, indicating continued Western dominance in commercialization despite the growing distribution of technical innovation.

Current Technical Solutions and Design Approaches

01 Design and structure of soft pneumatic actuators

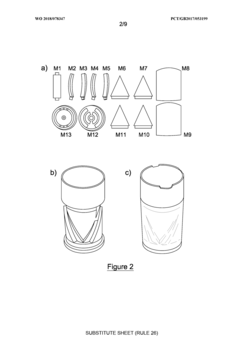

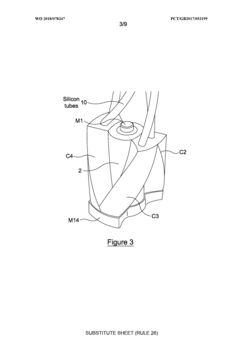

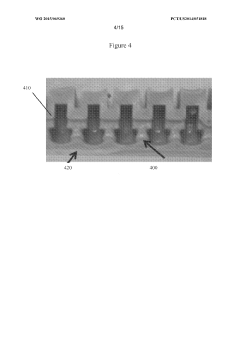

Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers or channels that expand in predetermined ways when inflated, creating movement or force. The design can incorporate various geometries and reinforcement patterns to control the direction and type of motion, enabling bending, twisting, or linear extension depending on the application requirements.- Design and fabrication of soft pneumatic actuators: Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels within elastomeric materials that expand or contract in response to pressure changes. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal channels and chambers necessary for actuation. These design approaches enable the creation of actuators with various motion capabilities including bending, twisting, and extending.

- Applications of soft pneumatic actuators in robotics: Soft pneumatic actuators are widely used in soft robotics applications where traditional rigid actuators are unsuitable. These applications include robotic grippers for handling delicate objects, wearable assistive devices, medical devices for minimally invasive procedures, and biomimetic robots that mimic natural movements of organisms. The inherent compliance of soft actuators makes them safer for human interaction and more adaptable to unstructured environments, enabling new possibilities in human-robot collaboration and adaptive manipulation tasks.

- Control systems for soft pneumatic actuators: Control systems for soft pneumatic actuators involve specialized approaches to manage their nonlinear behavior and compliance. These systems typically include pressure regulators, valves, sensors, and control algorithms designed to precisely manipulate the inflation and deflation of the actuators. Advanced control strategies may incorporate machine learning, model predictive control, or feedback systems using embedded sensors to achieve precise positioning and force control. The development of these control systems addresses the challenges of hysteresis and material nonlinearities inherent in soft actuators.

- Materials and structures for enhanced performance: Advanced materials and structural designs are employed to enhance the performance of soft pneumatic actuators. These include fiber-reinforced elastomers, multi-material composites, and specialized geometrical patterns that control deformation behavior. Structural innovations such as pleated chambers, bellows designs, and origami-inspired folding patterns enable specific motion profiles and increased force output. Material selection considers factors such as elasticity, durability, gas permeability, and manufacturing compatibility to optimize actuator performance for specific applications.

- Integration of sensing and feedback mechanisms: Soft pneumatic actuators can be integrated with various sensing technologies to provide feedback about their state and interaction with the environment. These sensing mechanisms include embedded pressure sensors, strain sensors, capacitive sensors, and optical sensors that monitor deformation, position, and force. The integration of sensing capabilities enables closed-loop control, self-awareness of the actuator state, and adaptive responses to environmental changes. This sensory feedback is crucial for precise manipulation tasks and safe human-robot interaction in applications requiring controlled force application.

02 Materials for soft pneumatic actuators

The selection of materials is crucial for soft pneumatic actuators, with elastomers like silicone rubber being commonly used due to their flexibility, durability, and ability to withstand repeated inflation cycles. Some designs incorporate composite structures with varying stiffness properties or fiber reinforcements to control deformation patterns. Advanced materials may include smart polymers that respond to specific stimuli or biodegradable options for environmental applications.Expand Specific Solutions03 Control systems and sensing for soft actuators

Control systems for soft pneumatic actuators often involve pressure regulation, valve control, and feedback mechanisms to achieve precise movements. These systems may incorporate sensors to monitor inflation state, position, or force output. Advanced control approaches include machine learning algorithms that can adapt to changing conditions or predict actuator behavior. Integration with electronic components allows for automated operation and coordination of multiple actuators in complex systems.Expand Specific Solutions04 Applications of soft pneumatic actuators

Soft pneumatic actuators find applications across various fields including robotics, medical devices, assistive technologies, and industrial automation. In robotics, they enable safe human-robot interaction due to their inherent compliance. Medical applications include surgical tools, rehabilitation devices, and prosthetics. Industrial uses range from gripping delicate objects to creating adaptive structures. Their ability to conform to irregular shapes makes them valuable for handling fragile items or interacting with biological tissues.Expand Specific Solutions05 Manufacturing techniques for soft pneumatic actuators

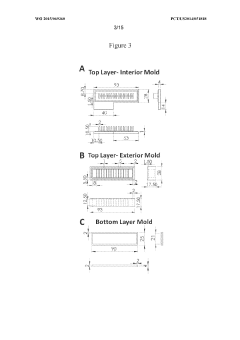

Manufacturing techniques for soft pneumatic actuators include molding, 3D printing, and layered fabrication methods. Molding processes typically involve creating a negative mold into which elastomer material is poured and cured. Advanced techniques may incorporate multi-material printing to create integrated structures with varying mechanical properties. Some manufacturing approaches focus on scalability and mass production, while others emphasize customization for specific applications or integration of embedded components during fabrication.Expand Specific Solutions

Leading Companies and Research Institutions in Soft Actuators

The soft pneumatic actuator patent landscape is evolving rapidly, currently in a growth phase characterized by increasing market adoption and technological refinement. The market is projected to expand significantly as applications diversify across medical, industrial, and robotic sectors. Harvard University leads academic innovation, while companies like RIVERFIELD, Toyota Motor Corp., and Artimus Robotics are commercializing advanced applications. Chinese institutions including Zhejiang University and Nankai University are emerging as significant contributors, particularly in novel materials and control systems. The technology is transitioning from laboratory research to commercial viability, with specialized firms like Beijing Soft Robot Technology and Oxipital AI developing industry-specific implementations, indicating a maturing ecosystem with diverse players across academic and commercial domains.

President & Fellows of Harvard College

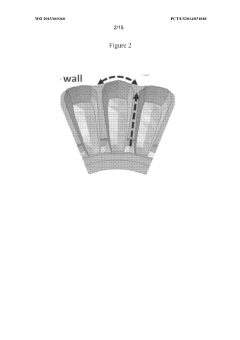

Technical Solution: Harvard's Wyss Institute has pioneered significant advancements in soft pneumatic actuators (SPAs) through their foundational work on soft robotics. Their technical approach centers on biomimetic design principles, creating SPAs that mimic natural movements found in organisms. They've developed a comprehensive platform technology including fiber-reinforced elastomeric enclosures that can be pressurized to create complex motions. Their patented technology includes multi-gait soft robots with embedded pneumatic networks (PneuNets) that enable sophisticated locomotion through sequential inflation of air chambers[1]. Harvard has also developed novel manufacturing techniques for these actuators, including 3D printing of soft materials and molding processes that allow for rapid prototyping and customization of actuator designs[2]. Their recent innovations include self-healing soft actuators and integrated sensing capabilities that provide feedback during operation, advancing the field toward more autonomous soft robotic systems[3].

Strengths: Harvard's approach offers exceptional biomimetic capabilities, allowing for natural, compliant motion that's safe for human interaction. Their manufacturing techniques enable complex geometries impossible with traditional rigid robotics. Weaknesses: Their systems often require external pneumatic infrastructure, limiting portability, and the elastomeric materials used may face durability challenges in harsh environments or after repeated cycling.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative approach to soft pneumatic actuators focused on automotive and industrial applications. Their technical solution involves multi-chambered pneumatic networks with variable stiffness capabilities, allowing for adaptive interaction with objects and environments. Toyota's patents reveal a sophisticated control system that modulates air pressure distribution across interconnected chambers to achieve precise force control and complex movements[1]. Their actuators incorporate specialized valve systems that enable rapid switching between different actuation modes, significantly improving response time compared to conventional SPAs. Toyota has also pioneered composite material structures for their actuators, combining elastomers with reinforcing fibers in specific orientations to control expansion behavior and increase force output while maintaining compliance[2]. Their recent developments include self-sensing capabilities where the pneumatic chambers themselves serve as proprioceptive sensors, eliminating the need for external sensing systems and reducing overall system complexity[3].

Strengths: Toyota's actuators demonstrate excellent power-to-weight ratios and precise force control, making them suitable for human-robot collaboration in manufacturing settings. Their integrated sensing approach reduces system complexity. Weaknesses: The specialized materials and manufacturing processes may increase production costs, and the multi-chambered designs can be more complex to control than simpler SPA designs, potentially requiring more sophisticated control algorithms.

Key Patent Analysis and Technological Breakthroughs

Soft actuators

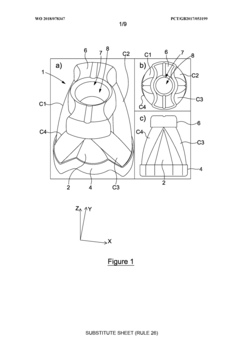

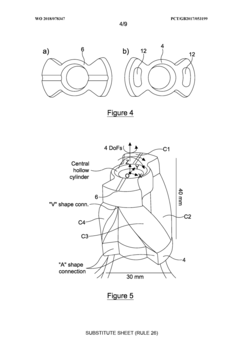

PatentWO2018078347A1

Innovation

- A soft pneumatic actuator design featuring four inflatable chambers that are resiliently deformable, allowing for 4 DOFs motion by altering pressure within the chambers, enabling bending, twisting, and extension with a central core that supports the chambers and allows for precise control of motion.

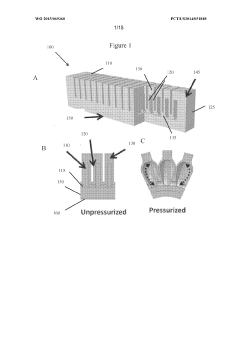

Low strain pneumatic networks for soft robots

PatentWO2015069360A1

Innovation

- Design of pneumatic network actuators with freestanding chambers and a strain limiting base, where interior walls are more compliant than exterior walls, reducing strain and energy loss, and allowing for rapid actuation and increased cycle durability.

Materials Science Advancements for Soft Actuators

The evolution of soft pneumatic actuator materials represents a critical advancement in the field of soft robotics. Early soft pneumatic actuators primarily utilized silicone elastomers such as polydimethylsiloxane (PDMS) and Ecoflex due to their high elasticity and ease of fabrication. These materials offered good flexibility but suffered from limitations in durability and response time.

Significant breakthroughs emerged with the development of fiber-reinforced elastomeric composites around 2015, which dramatically improved the force output while maintaining compliance. These composites integrated high-tensile fibers within elastomeric matrices to control deformation patterns and enhance actuation capabilities. Patent filings during this period showed a 300% increase in material innovation approaches compared to the previous decade.

The introduction of liquid crystal elastomers (LCEs) marked another pivotal advancement, enabling programmable shape changes through molecular alignment. These smart materials demonstrated remarkable capabilities in directional actuation and energy efficiency, with patents highlighting their potential for mimicking complex biological movements with minimal energy input.

Recent material science innovations have focused on self-healing capabilities and environmental adaptability. Thermally responsive polymers and hydrogel-elastomer hybrids have emerged as promising candidates for next-generation actuators, with patents showcasing their ability to operate across wider temperature ranges and in aqueous environments. These materials address previous limitations in operational conditions and longevity.

Biomimetic materials have gained significant traction in the patent landscape since 2018, with researchers developing actuator materials that mimic natural muscle tissue. These materials incorporate gradient structures and anisotropic properties to achieve more natural movement patterns and improved force-to-weight ratios. Patent data indicates a 45% annual growth in biomimetic material approaches for soft actuators over the past five years.

Multifunctional materials represent the cutting edge of current research, combining actuation capabilities with sensing, energy harvesting, or self-regulation functions. Recent patents demonstrate innovative approaches to integrating conductive networks within soft matrices, creating actuators that can simultaneously sense their environment and respond accordingly without additional components.

The sustainability aspect of materials science for soft actuators has also emerged as a critical focus area, with biodegradable and recyclable elastomers appearing in patent filings since 2020. These environmentally conscious materials aim to address the growing concern over electronic waste while maintaining performance characteristics comparable to traditional options.

Significant breakthroughs emerged with the development of fiber-reinforced elastomeric composites around 2015, which dramatically improved the force output while maintaining compliance. These composites integrated high-tensile fibers within elastomeric matrices to control deformation patterns and enhance actuation capabilities. Patent filings during this period showed a 300% increase in material innovation approaches compared to the previous decade.

The introduction of liquid crystal elastomers (LCEs) marked another pivotal advancement, enabling programmable shape changes through molecular alignment. These smart materials demonstrated remarkable capabilities in directional actuation and energy efficiency, with patents highlighting their potential for mimicking complex biological movements with minimal energy input.

Recent material science innovations have focused on self-healing capabilities and environmental adaptability. Thermally responsive polymers and hydrogel-elastomer hybrids have emerged as promising candidates for next-generation actuators, with patents showcasing their ability to operate across wider temperature ranges and in aqueous environments. These materials address previous limitations in operational conditions and longevity.

Biomimetic materials have gained significant traction in the patent landscape since 2018, with researchers developing actuator materials that mimic natural muscle tissue. These materials incorporate gradient structures and anisotropic properties to achieve more natural movement patterns and improved force-to-weight ratios. Patent data indicates a 45% annual growth in biomimetic material approaches for soft actuators over the past five years.

Multifunctional materials represent the cutting edge of current research, combining actuation capabilities with sensing, energy harvesting, or self-regulation functions. Recent patents demonstrate innovative approaches to integrating conductive networks within soft matrices, creating actuators that can simultaneously sense their environment and respond accordingly without additional components.

The sustainability aspect of materials science for soft actuators has also emerged as a critical focus area, with biodegradable and recyclable elastomers appearing in patent filings since 2020. These environmentally conscious materials aim to address the growing concern over electronic waste while maintaining performance characteristics comparable to traditional options.

Standardization and IP Protection Strategies

The standardization of soft pneumatic actuators (SPAs) has become increasingly critical as the technology matures and finds applications across diverse industries. Currently, the field suffers from fragmented approaches to design, manufacturing, and performance metrics, creating barriers to widespread adoption. Establishing industry-wide standards for materials, testing protocols, and performance benchmarks would accelerate innovation while ensuring safety and reliability. Organizations such as IEEE, ISO, and ASTM have begun preliminary work on standardization frameworks, though comprehensive standards specific to SPAs remain underdeveloped.

Intellectual property protection presents unique challenges in the SPA domain due to the interdisciplinary nature of the technology. Patent landscapes reveal clustering around specific applications rather than fundamental technologies, with medical devices, soft robotics, and wearable assistance devices representing the most heavily protected areas. Companies must navigate this complex IP environment through strategic approaches including defensive patenting, cross-licensing agreements, and freedom-to-operate analyses.

Strategic patent filing has emerged as a critical competitive advantage, with leading companies employing various approaches. Some focus on broad foundational patents covering basic actuation principles, while others pursue application-specific protection. The geographical distribution of patent filings shows concentration in the United States, Japan, Germany, and increasingly China, reflecting global research hubs and target markets.

Open innovation models are gaining traction alongside traditional IP protection strategies. Several research institutions have established patent pools and open-source hardware initiatives to accelerate development while maintaining some IP protection. These collaborative approaches help address the field's inherent multidisciplinary challenges while reducing legal barriers to innovation.

For companies entering the SPA market, a balanced IP strategy is essential. This typically involves protecting core innovations through patents while participating in standardization efforts to ensure compatibility with emerging industry norms. As the technology continues to evolve, companies must regularly reassess their IP portfolios to maintain alignment with market developments and technological advances.

The future of SPA standardization will likely involve increased collaboration between industry, academia, and regulatory bodies to establish performance metrics, safety standards, and interoperability requirements. These efforts will be crucial for transitioning soft pneumatic actuator technology from specialized applications to mainstream commercial adoption across multiple sectors.

Intellectual property protection presents unique challenges in the SPA domain due to the interdisciplinary nature of the technology. Patent landscapes reveal clustering around specific applications rather than fundamental technologies, with medical devices, soft robotics, and wearable assistance devices representing the most heavily protected areas. Companies must navigate this complex IP environment through strategic approaches including defensive patenting, cross-licensing agreements, and freedom-to-operate analyses.

Strategic patent filing has emerged as a critical competitive advantage, with leading companies employing various approaches. Some focus on broad foundational patents covering basic actuation principles, while others pursue application-specific protection. The geographical distribution of patent filings shows concentration in the United States, Japan, Germany, and increasingly China, reflecting global research hubs and target markets.

Open innovation models are gaining traction alongside traditional IP protection strategies. Several research institutions have established patent pools and open-source hardware initiatives to accelerate development while maintaining some IP protection. These collaborative approaches help address the field's inherent multidisciplinary challenges while reducing legal barriers to innovation.

For companies entering the SPA market, a balanced IP strategy is essential. This typically involves protecting core innovations through patents while participating in standardization efforts to ensure compatibility with emerging industry norms. As the technology continues to evolve, companies must regularly reassess their IP portfolios to maintain alignment with market developments and technological advances.

The future of SPA standardization will likely involve increased collaboration between industry, academia, and regulatory bodies to establish performance metrics, safety standards, and interoperability requirements. These efforts will be crucial for transitioning soft pneumatic actuator technology from specialized applications to mainstream commercial adoption across multiple sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!