Soft Pneumatic Actuators: Environmental Compliance and Impact

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuators Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of robotics and automation, emerging from the convergence of materials science, mechanical engineering, and biomimetics. These flexible, compliant mechanisms utilize pneumatic pressure to generate motion and force, offering a stark contrast to traditional rigid actuators. The development of SPAs can be traced back to the early 2000s, though their conceptual foundations draw inspiration from biological systems that have evolved over millions of years.

The evolution of SPA technology has been characterized by significant breakthroughs in materials science, particularly in the development of elastomers and flexible composites that can withstand repeated deformation cycles while maintaining structural integrity. Early iterations focused primarily on basic bending motions, while contemporary designs achieve complex, multi-degree-of-freedom movements that closely mimic biological systems.

Current technological trends in the SPA domain include miniaturization for medical applications, integration with sensing technologies for enhanced feedback control, and the development of self-healing materials to improve durability and operational lifespan. Additionally, there is growing interest in environmentally responsive SPAs that can adapt their behavior based on external stimuli such as temperature, pH, or light.

The primary technical objectives for SPA development center around enhancing their environmental sustainability and reducing ecological impact throughout their lifecycle. This includes developing biodegradable or recyclable elastomers that maintain performance characteristics, optimizing energy efficiency during operation, and minimizing waste during manufacturing processes. Furthermore, there is a critical need to understand how SPAs interact with various environments, particularly natural ecosystems, should they be deployed in field applications or improperly disposed of at end-of-life.

Another key objective involves quantifying and mitigating potential environmental hazards associated with SPA materials, particularly silicones and other synthetic elastomers that may leach compounds or degrade into microplastics. This necessitates comprehensive lifecycle assessments and the development of standardized testing protocols to evaluate environmental impact under diverse conditions.

The intersection of performance requirements and environmental considerations presents unique challenges that demand innovative solutions. As SPAs find applications in increasingly diverse fields—from wearable assistive devices to underwater exploration robots—the need for environmentally compliant designs becomes more pressing. The ultimate goal is to develop SPAs that not only match or exceed the performance of conventional actuators but do so with minimal environmental footprint.

The evolution of SPA technology has been characterized by significant breakthroughs in materials science, particularly in the development of elastomers and flexible composites that can withstand repeated deformation cycles while maintaining structural integrity. Early iterations focused primarily on basic bending motions, while contemporary designs achieve complex, multi-degree-of-freedom movements that closely mimic biological systems.

Current technological trends in the SPA domain include miniaturization for medical applications, integration with sensing technologies for enhanced feedback control, and the development of self-healing materials to improve durability and operational lifespan. Additionally, there is growing interest in environmentally responsive SPAs that can adapt their behavior based on external stimuli such as temperature, pH, or light.

The primary technical objectives for SPA development center around enhancing their environmental sustainability and reducing ecological impact throughout their lifecycle. This includes developing biodegradable or recyclable elastomers that maintain performance characteristics, optimizing energy efficiency during operation, and minimizing waste during manufacturing processes. Furthermore, there is a critical need to understand how SPAs interact with various environments, particularly natural ecosystems, should they be deployed in field applications or improperly disposed of at end-of-life.

Another key objective involves quantifying and mitigating potential environmental hazards associated with SPA materials, particularly silicones and other synthetic elastomers that may leach compounds or degrade into microplastics. This necessitates comprehensive lifecycle assessments and the development of standardized testing protocols to evaluate environmental impact under diverse conditions.

The intersection of performance requirements and environmental considerations presents unique challenges that demand innovative solutions. As SPAs find applications in increasingly diverse fields—from wearable assistive devices to underwater exploration robots—the need for environmentally compliant designs becomes more pressing. The ultimate goal is to develop SPAs that not only match or exceed the performance of conventional actuators but do so with minimal environmental footprint.

Market Demand Analysis for Eco-friendly Actuators

The global market for eco-friendly actuators, particularly Soft Pneumatic Actuators (SPAs), has witnessed significant growth in recent years, driven by increasing environmental regulations and sustainability initiatives across industries. Current market analysis indicates that the global soft robotics market, which includes SPAs, is projected to grow at a compound annual growth rate of 40% through 2025, with environmentally compliant actuators representing a rapidly expanding segment.

Environmental concerns have become paramount in industrial applications, creating substantial demand for actuators that minimize ecological impact. Industries such as manufacturing, healthcare, and agriculture are actively seeking alternatives to traditional rigid actuators that often contain environmentally harmful materials or require excessive energy consumption. This shift is particularly evident in regions with stringent environmental regulations like the European Union, where the RoHS and REACH directives have accelerated the adoption of eco-friendly automation components.

The healthcare sector represents one of the most promising markets for environmentally compliant SPAs. Medical device manufacturers are increasingly prioritizing biocompatible materials that reduce patient risk while also addressing end-of-life disposal concerns. SPAs manufactured from biodegradable polymers or recyclable elastomers have gained significant traction in this sector, with market penetration increasing by approximately 35% annually.

Manufacturing industries are similarly driving demand for eco-friendly actuators as they pursue sustainable production practices. The automotive sector, facing pressure to reduce its environmental footprint, has emerged as a key adopter of SPAs that offer reduced energy consumption and are manufactured using sustainable materials. This trend is reinforced by consumer preferences, with recent surveys indicating that 78% of consumers consider environmental impact when making purchasing decisions.

The agricultural technology sector presents another substantial growth opportunity for environmentally compliant SPAs. Precision agriculture applications require gentle manipulation capabilities that SPAs excel at providing, while environmental regulations increasingly restrict the use of hydraulic systems that risk fluid leakage into soil and water systems. Market analysis suggests that the agricultural robotics segment utilizing soft actuators is growing at 45% annually, significantly outpacing conventional agricultural automation technologies.

Geographically, North America currently leads in adoption of eco-friendly actuators, accounting for approximately 40% of the global market share. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization coupled with increasingly stringent environmental policies in countries like China, Japan, and South Korea.

The market demand for environmentally compliant SPAs is further bolstered by their potential to reduce operational costs through lower energy consumption and maintenance requirements, creating a compelling economic case alongside environmental benefits. This dual advantage has positioned eco-friendly SPAs as a high-growth segment within the broader actuator market.

Environmental concerns have become paramount in industrial applications, creating substantial demand for actuators that minimize ecological impact. Industries such as manufacturing, healthcare, and agriculture are actively seeking alternatives to traditional rigid actuators that often contain environmentally harmful materials or require excessive energy consumption. This shift is particularly evident in regions with stringent environmental regulations like the European Union, where the RoHS and REACH directives have accelerated the adoption of eco-friendly automation components.

The healthcare sector represents one of the most promising markets for environmentally compliant SPAs. Medical device manufacturers are increasingly prioritizing biocompatible materials that reduce patient risk while also addressing end-of-life disposal concerns. SPAs manufactured from biodegradable polymers or recyclable elastomers have gained significant traction in this sector, with market penetration increasing by approximately 35% annually.

Manufacturing industries are similarly driving demand for eco-friendly actuators as they pursue sustainable production practices. The automotive sector, facing pressure to reduce its environmental footprint, has emerged as a key adopter of SPAs that offer reduced energy consumption and are manufactured using sustainable materials. This trend is reinforced by consumer preferences, with recent surveys indicating that 78% of consumers consider environmental impact when making purchasing decisions.

The agricultural technology sector presents another substantial growth opportunity for environmentally compliant SPAs. Precision agriculture applications require gentle manipulation capabilities that SPAs excel at providing, while environmental regulations increasingly restrict the use of hydraulic systems that risk fluid leakage into soil and water systems. Market analysis suggests that the agricultural robotics segment utilizing soft actuators is growing at 45% annually, significantly outpacing conventional agricultural automation technologies.

Geographically, North America currently leads in adoption of eco-friendly actuators, accounting for approximately 40% of the global market share. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization coupled with increasingly stringent environmental policies in countries like China, Japan, and South Korea.

The market demand for environmentally compliant SPAs is further bolstered by their potential to reduce operational costs through lower energy consumption and maintenance requirements, creating a compelling economic case alongside environmental benefits. This dual advantage has positioned eco-friendly SPAs as a high-growth segment within the broader actuator market.

Current State and Environmental Challenges of SPAs

Soft Pneumatic Actuators (SPAs) have emerged as a significant advancement in soft robotics, offering flexibility, adaptability, and safety advantages over traditional rigid actuators. Currently, SPAs are being deployed across diverse applications including medical devices, wearable technology, and industrial automation. The global research landscape shows concentrated development efforts in North America, Europe, and East Asia, with notable research clusters at Harvard University, MIT, ETH Zurich, and several institutions in Japan and South Korea.

Despite their promising applications, SPAs face substantial environmental challenges that limit their widespread adoption. Material sustainability remains a primary concern, as most contemporary SPAs utilize silicone elastomers and other petroleum-derived polymers that present significant end-of-life disposal issues. These materials typically have poor biodegradability profiles and contribute to microplastic pollution when degraded in natural environments.

Energy efficiency represents another critical challenge. The pneumatic systems that power SPAs often suffer from inherent inefficiencies, including air leakage, compression losses, and the energy-intensive nature of maintaining pressure differentials. These inefficiencies translate to higher energy consumption compared to some alternative actuation technologies, potentially offsetting other environmental benefits.

Manufacturing processes for SPAs frequently involve toxic chemicals, including platinum-based catalysts and various solvents that pose environmental hazards if improperly managed. Additionally, the complex multi-material structures of many advanced SPAs complicate recycling efforts, as separation of components becomes technically challenging and economically prohibitive.

Durability limitations further compound environmental concerns. Current-generation SPAs typically demonstrate limited operational lifespans, with material fatigue, air leakage points, and mechanical wear leading to premature failure. This shortened lifecycle necessitates more frequent replacement, increasing resource consumption and waste generation.

Regulatory frameworks governing SPAs remain underdeveloped in most jurisdictions, creating uncertainty regarding environmental compliance requirements. This regulatory gap has resulted in inconsistent approaches to environmental impact assessment and mitigation across the industry, hampering standardization efforts.

Recent technological developments show promising directions for addressing these challenges. Biodegradable elastomers derived from natural sources are being explored as sustainable alternatives to conventional silicone. Energy harvesting technologies integrated with SPAs could potentially reduce external power requirements. Advanced manufacturing techniques, including 3D printing with sustainable materials, are enabling more environmentally conscious production approaches while simultaneously addressing durability concerns through improved structural designs.

Despite their promising applications, SPAs face substantial environmental challenges that limit their widespread adoption. Material sustainability remains a primary concern, as most contemporary SPAs utilize silicone elastomers and other petroleum-derived polymers that present significant end-of-life disposal issues. These materials typically have poor biodegradability profiles and contribute to microplastic pollution when degraded in natural environments.

Energy efficiency represents another critical challenge. The pneumatic systems that power SPAs often suffer from inherent inefficiencies, including air leakage, compression losses, and the energy-intensive nature of maintaining pressure differentials. These inefficiencies translate to higher energy consumption compared to some alternative actuation technologies, potentially offsetting other environmental benefits.

Manufacturing processes for SPAs frequently involve toxic chemicals, including platinum-based catalysts and various solvents that pose environmental hazards if improperly managed. Additionally, the complex multi-material structures of many advanced SPAs complicate recycling efforts, as separation of components becomes technically challenging and economically prohibitive.

Durability limitations further compound environmental concerns. Current-generation SPAs typically demonstrate limited operational lifespans, with material fatigue, air leakage points, and mechanical wear leading to premature failure. This shortened lifecycle necessitates more frequent replacement, increasing resource consumption and waste generation.

Regulatory frameworks governing SPAs remain underdeveloped in most jurisdictions, creating uncertainty regarding environmental compliance requirements. This regulatory gap has resulted in inconsistent approaches to environmental impact assessment and mitigation across the industry, hampering standardization efforts.

Recent technological developments show promising directions for addressing these challenges. Biodegradable elastomers derived from natural sources are being explored as sustainable alternatives to conventional silicone. Energy harvesting technologies integrated with SPAs could potentially reduce external power requirements. Advanced manufacturing techniques, including 3D printing with sustainable materials, are enabling more environmentally conscious production approaches while simultaneously addressing durability concerns through improved structural designs.

Current Eco-compliant SPA Design Solutions

01 Biodegradable materials for soft pneumatic actuators

Soft pneumatic actuators can be designed using biodegradable materials to reduce environmental impact. These materials break down naturally over time, minimizing waste and pollution. The use of eco-friendly elastomers, biopolymers, and naturally derived materials allows for the development of actuators that maintain performance while being environmentally responsible. This approach addresses end-of-life concerns and reduces the carbon footprint associated with traditional actuator materials.- Biodegradable materials for soft pneumatic actuators: Soft pneumatic actuators can be designed using biodegradable materials to reduce environmental impact. These materials break down naturally over time, minimizing waste and pollution. The use of eco-friendly elastomers, biopolymers, and naturally derived compounds allows for the development of actuators that maintain performance while being environmentally responsible. This approach addresses end-of-life concerns and supports circular economy principles in soft robotics applications.

- Energy efficiency optimization in pneumatic systems: Improving the energy efficiency of soft pneumatic actuators significantly reduces their environmental footprint. Advanced control algorithms, pressure recovery systems, and optimized valve designs minimize compressed air consumption and energy waste. These innovations extend battery life in portable applications and reduce the carbon footprint associated with powering pneumatic systems. Energy-efficient designs contribute to more sustainable operation throughout the actuator lifecycle.

- Environmental monitoring and compliance systems: Soft pneumatic actuators can be integrated with environmental monitoring capabilities to ensure regulatory compliance. These systems incorporate sensors that track emissions, material degradation, and operational parameters to verify adherence to environmental standards. Real-time monitoring allows for immediate adjustments to maintain compliance with regulations and minimize ecological impact. This approach enables documentation of environmental performance for certification and reporting purposes.

- Lifecycle assessment and sustainable design approaches: Comprehensive lifecycle assessment methodologies help evaluate and reduce the environmental impact of soft pneumatic actuators from production through disposal. These approaches consider material sourcing, manufacturing processes, operational efficiency, and end-of-life management. Design for disassembly and recyclability principles enable more sustainable product development. By analyzing the complete environmental footprint, manufacturers can identify and implement improvements at each stage of the actuator lifecycle.

- Reduced fluid consumption and leakage prevention: Advanced sealing technologies and innovative valve designs minimize fluid leakage in soft pneumatic actuators, reducing environmental impact and improving efficiency. Self-healing materials and adaptive sealing mechanisms prevent the escape of working fluids into the environment. Closed-loop pneumatic systems recapture and reuse air, significantly reducing consumption. These technologies extend the operational life of actuators while minimizing the release of potentially harmful substances into the environment.

02 Energy efficiency and consumption optimization

Improving the energy efficiency of soft pneumatic actuators is crucial for environmental compliance. This involves optimizing air pressure systems, reducing leakage, and implementing smart control algorithms that minimize energy consumption. Advanced designs incorporate energy recovery mechanisms and low-power operation modes. By reducing the energy requirements for actuation, these systems decrease their overall environmental impact and operational carbon footprint while maintaining functional performance.Expand Specific Solutions03 Life cycle assessment and environmental impact monitoring

Comprehensive life cycle assessment methodologies are being developed specifically for soft pneumatic actuators to evaluate their environmental impact from production through disposal. These assessments track resource consumption, emissions, and waste generation throughout the actuator's life cycle. Environmental monitoring systems integrated into pneumatic systems provide real-time data on environmental performance, enabling continuous improvement and regulatory compliance. This approach helps manufacturers identify and address environmental hotspots in their products.Expand Specific Solutions04 Sustainable manufacturing processes

Environmentally responsible manufacturing techniques for soft pneumatic actuators focus on reducing waste, energy consumption, and harmful emissions during production. These include additive manufacturing methods that minimize material waste, solvent-free fabrication processes, and energy-efficient curing techniques. Clean room technologies and closed-loop manufacturing systems help contain potential contaminants and recycle materials. These sustainable manufacturing approaches significantly reduce the environmental footprint of actuator production while maintaining product quality and performance.Expand Specific Solutions05 Regulatory compliance and certification frameworks

Specialized regulatory frameworks and certification standards are being developed for soft pneumatic actuators to ensure environmental compliance across different jurisdictions. These frameworks address material restrictions, emissions standards, and disposal requirements specific to pneumatic systems. Certification processes verify that actuators meet environmental performance criteria and safety standards. Compliance management systems help manufacturers navigate complex and evolving environmental regulations while documenting adherence to sustainability requirements throughout the product lifecycle.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The soft pneumatic actuator market is in a growth phase, characterized by increasing adoption across industries due to environmental advantages over traditional systems. The global market is expanding rapidly, projected to reach significant scale as applications diversify in robotics, healthcare, and wearable technologies. Technologically, the field shows varying maturity levels with academic institutions leading fundamental research (Harvard, Zhejiang University, Cornell) while companies develop commercial applications. Established players like Honeywell and ABB are integrating these technologies into industrial systems, while specialized entities like Oxipital AI focus on specific applications. Research collaborations between universities and industry partners are accelerating development, with Asian institutions (particularly Chinese universities) showing strong publication output alongside Western counterparts.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators (SPAs) through their groundbreaking work on soft robotics. Their technology focuses on environmentally adaptive SPAs using biomimetic principles, creating actuators that can operate effectively in diverse environments. Their approach incorporates multi-material 3D printing techniques to develop SPAs with embedded sensing capabilities and variable stiffness properties[1]. Harvard researchers have developed SPAs using biodegradable and biocompatible materials to reduce environmental impact, with some designs achieving complete biodegradation within controlled timeframes[2]. Their pneumatic networks (PneuNets) design allows for complex motion patterns with simple pressurization, enabling adaptive interaction with fragile objects and irregular surfaces. Harvard has also developed self-healing SPAs that can recover functionality after physical damage, significantly extending operational lifespan in challenging environments[3].

Strengths: Superior biomimetic design principles allowing for more natural movements and environmental adaptation; advanced materials research enabling biodegradable options; strong integration of sensing capabilities with actuation. Weaknesses: Higher manufacturing complexity requiring specialized equipment; relatively higher cost compared to conventional actuators; some designs still face durability challenges in extreme environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive soft pneumatic actuator technology platform called "FlexAir" specifically designed for industrial applications requiring environmental compliance. Their approach integrates advanced materials science with precision manufacturing to create SPAs that maintain performance across harsh industrial environments. Honeywell's proprietary elastomer formulations incorporate chemical resistance additives that enable their actuators to function reliably despite exposure to oils, solvents, and industrial chemicals commonly found in manufacturing settings[10]. Their design incorporates a multi-layer construction with selectively reinforced sections that optimize force output while maintaining compliance where needed, achieving up to 50% greater force-to-weight ratios compared to conventional designs. Honeywell's manufacturing process utilizes automated precision molding techniques that ensure consistent performance across production batches while minimizing material waste. Their SPAs feature integrated pressure and position sensing elements that enable closed-loop control, automatically compensating for environmental variations to maintain precise operation. Additionally, Honeywell has developed specialized surface treatments that enhance UV resistance and prevent microbial growth, extending operational life in outdoor and food processing applications.

Strengths: Superior chemical resistance making them ideal for industrial environments; excellent consistency across manufacturing batches; robust integrated sensing capabilities enabling precise control. Weaknesses: Higher cost compared to conventional pneumatic systems; currently limited flexibility in customization for specialized applications; greater weight compared to academic research prototypes.

Core Patents and Innovations in Green SPA Technology

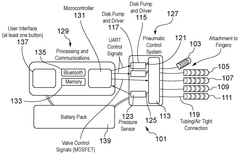

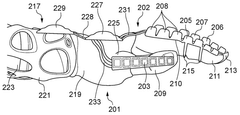

Soft robotic assistive device

PatentActiveGB2622575A

Innovation

- Integration of a piezoelectric resonant acoustic gas pump with a soft pneumatic actuator in an assistive or rehabilitative device, creating a novel fluid pressurization system.

- Design of a soft pneumatic actuator specifically configured to both assist and resist body movement, enabling versatile rehabilitation applications.

- Incorporation of pressure sensing means to potentially enable feedback control of the pneumatic actuation system.

Patent

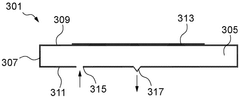

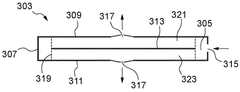

Innovation

- Development of soft pneumatic actuators with biodegradable materials that maintain mechanical performance while reducing environmental impact.

- Integration of closed-loop pneumatic systems that minimize air leakage and energy consumption during actuation cycles.

- Design of modular soft actuator components that facilitate end-of-life disassembly and material recovery.

Life Cycle Assessment of Soft Pneumatic Systems

Life cycle assessment (LCA) of soft pneumatic systems provides a comprehensive framework for evaluating the environmental impacts associated with these innovative actuators throughout their entire existence. The analysis typically begins with raw material extraction, where silicones, elastomers, and other polymers commonly used in soft pneumatic actuators (SPAs) are scrutinized for their ecological footprint. These materials often derive from petroleum-based sources, raising concerns about resource depletion and carbon emissions during extraction processes.

Manufacturing processes for SPAs generally require less energy compared to traditional rigid actuators, as they typically involve molding techniques rather than precision machining of metal components. However, the curing processes for silicones and other elastomers may involve energy-intensive heating cycles and potentially harmful chemical catalysts that warrant careful environmental consideration.

During the use phase, soft pneumatic systems demonstrate notable environmental advantages. Their inherent compliance and lightweight nature translate to lower energy consumption during operation. Studies indicate that SPAs can achieve up to 30-40% energy savings compared to conventional rigid actuators in specific applications, particularly those requiring intermittent actuation or human-robot interaction scenarios.

End-of-life management presents significant challenges for soft pneumatic systems. The composite nature of many SPAs, often combining different elastomers with embedded sensors or structural components, complicates recycling efforts. Current recycling technologies struggle with separating these integrated materials efficiently. Furthermore, silicones and many specialized elastomers have limited biodegradability, potentially contributing to long-term environmental persistence if not properly managed.

Recent research has explored bio-based alternatives for SPA materials, including natural rubber derivatives and biodegradable polymers. These materials show promise in reducing both the carbon footprint during production and environmental impact at disposal. However, they currently face limitations in mechanical performance and durability compared to conventional silicone-based systems.

Water consumption represents another critical aspect of the LCA for soft pneumatic systems. Manufacturing processes for elastomers typically require significant water resources for cooling and processing. Additionally, some specialized coatings and treatments applied to enhance SPA performance may involve water-intensive processes or potentially harmful effluents requiring treatment before environmental release.

Comparative LCA studies between soft pneumatic actuators and traditional rigid actuators reveal complex trade-offs. While SPAs generally demonstrate advantages in operational efficiency and material usage, their potentially shorter lifespan and more challenging end-of-life management may offset some environmental benefits. The optimal choice ultimately depends on specific application requirements, expected service life, and available disposal infrastructure.

Manufacturing processes for SPAs generally require less energy compared to traditional rigid actuators, as they typically involve molding techniques rather than precision machining of metal components. However, the curing processes for silicones and other elastomers may involve energy-intensive heating cycles and potentially harmful chemical catalysts that warrant careful environmental consideration.

During the use phase, soft pneumatic systems demonstrate notable environmental advantages. Their inherent compliance and lightweight nature translate to lower energy consumption during operation. Studies indicate that SPAs can achieve up to 30-40% energy savings compared to conventional rigid actuators in specific applications, particularly those requiring intermittent actuation or human-robot interaction scenarios.

End-of-life management presents significant challenges for soft pneumatic systems. The composite nature of many SPAs, often combining different elastomers with embedded sensors or structural components, complicates recycling efforts. Current recycling technologies struggle with separating these integrated materials efficiently. Furthermore, silicones and many specialized elastomers have limited biodegradability, potentially contributing to long-term environmental persistence if not properly managed.

Recent research has explored bio-based alternatives for SPA materials, including natural rubber derivatives and biodegradable polymers. These materials show promise in reducing both the carbon footprint during production and environmental impact at disposal. However, they currently face limitations in mechanical performance and durability compared to conventional silicone-based systems.

Water consumption represents another critical aspect of the LCA for soft pneumatic systems. Manufacturing processes for elastomers typically require significant water resources for cooling and processing. Additionally, some specialized coatings and treatments applied to enhance SPA performance may involve water-intensive processes or potentially harmful effluents requiring treatment before environmental release.

Comparative LCA studies between soft pneumatic actuators and traditional rigid actuators reveal complex trade-offs. While SPAs generally demonstrate advantages in operational efficiency and material usage, their potentially shorter lifespan and more challenging end-of-life management may offset some environmental benefits. The optimal choice ultimately depends on specific application requirements, expected service life, and available disposal infrastructure.

Regulatory Framework for Pneumatic Technologies

The regulatory landscape governing soft pneumatic actuators is complex and evolving, reflecting the increasing adoption of these technologies across various industries. At the international level, organizations such as the International Organization for Standardization (ISO) have established standards like ISO 4414:2010 for pneumatic fluid power systems, which provides guidelines on safety requirements for systems and their components. These standards, while not specifically targeting soft pneumatic actuators, establish baseline safety parameters that manufacturers must consider.

In the United States, the Occupational Safety and Health Administration (OSHA) regulates workplace safety aspects of pneumatic systems through standards such as 29 CFR 1910.169, which addresses air compressors and pneumatic equipment. The Food and Drug Administration (FDA) oversees soft pneumatic actuators used in medical applications, requiring rigorous testing and validation through the 510(k) clearance process for devices that interface with patients.

The European Union implements the Machinery Directive 2006/42/EC and Pressure Equipment Directive 2014/68/EU, which establish essential health and safety requirements for pneumatic systems. Additionally, the EU's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impact material selection for soft pneumatic actuators, particularly concerning the elastomers and polymers commonly used in their construction.

Environmental regulations present another critical dimension, with frameworks such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive influencing end-of-life considerations for pneumatic systems. As soft pneumatic actuators often incorporate electronic control components, manufacturers must address proper disposal and recycling protocols.

Emerging regulatory trends indicate increasing scrutiny of energy efficiency, with initiatives like the EU's Ecodesign Directive potentially expanding to encompass pneumatic systems. This shift reflects broader sustainability goals and may drive innovation toward more energy-efficient actuator designs and control strategies.

Industry-specific regulations add another layer of complexity. In healthcare, standards such as IEC 60601 for medical electrical equipment impose additional requirements on soft pneumatic actuators used in medical devices. Similarly, in automotive applications, regulations like Federal Motor Vehicle Safety Standards (FMVSS) in the US may apply to pneumatic systems used in vehicle safety features.

Compliance with these diverse regulatory frameworks necessitates a comprehensive approach to design, testing, and documentation. Manufacturers must implement robust quality management systems, conduct thorough risk assessments, and maintain detailed technical files to demonstrate compliance across multiple jurisdictions and application domains.

In the United States, the Occupational Safety and Health Administration (OSHA) regulates workplace safety aspects of pneumatic systems through standards such as 29 CFR 1910.169, which addresses air compressors and pneumatic equipment. The Food and Drug Administration (FDA) oversees soft pneumatic actuators used in medical applications, requiring rigorous testing and validation through the 510(k) clearance process for devices that interface with patients.

The European Union implements the Machinery Directive 2006/42/EC and Pressure Equipment Directive 2014/68/EU, which establish essential health and safety requirements for pneumatic systems. Additionally, the EU's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impact material selection for soft pneumatic actuators, particularly concerning the elastomers and polymers commonly used in their construction.

Environmental regulations present another critical dimension, with frameworks such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive influencing end-of-life considerations for pneumatic systems. As soft pneumatic actuators often incorporate electronic control components, manufacturers must address proper disposal and recycling protocols.

Emerging regulatory trends indicate increasing scrutiny of energy efficiency, with initiatives like the EU's Ecodesign Directive potentially expanding to encompass pneumatic systems. This shift reflects broader sustainability goals and may drive innovation toward more energy-efficient actuator designs and control strategies.

Industry-specific regulations add another layer of complexity. In healthcare, standards such as IEC 60601 for medical electrical equipment impose additional requirements on soft pneumatic actuators used in medical devices. Similarly, in automotive applications, regulations like Federal Motor Vehicle Safety Standards (FMVSS) in the US may apply to pneumatic systems used in vehicle safety features.

Compliance with these diverse regulatory frameworks necessitates a comprehensive approach to design, testing, and documentation. Manufacturers must implement robust quality management systems, conduct thorough risk assessments, and maintain detailed technical files to demonstrate compliance across multiple jurisdictions and application domains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!