Soft Pneumatic Actuators in Surgical Device Enhancements

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuators Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of medical robotics, particularly in surgical applications. These actuators, characterized by their compliant nature and biomimetic properties, have evolved significantly over the past three decades. Initially developed in the 1990s as simple inflatable structures, SPAs have transformed into sophisticated, precisely controllable components that can mimic complex biological movements.

The evolution of SPAs has been driven by the convergence of materials science, robotics, and surgical needs. Early iterations faced challenges with durability, precision, and biocompatibility. However, breakthroughs in elastomeric materials, manufacturing techniques like 3D printing, and computational modeling have accelerated their development. The introduction of fiber-reinforced designs in the early 2000s marked a pivotal advancement, enabling greater force generation while maintaining compliance.

Recent technological trends show a clear movement toward multi-material SPAs with embedded sensing capabilities, allowing for closed-loop control systems that can adapt to varying tissue interactions during surgical procedures. The integration of machine learning algorithms has further enhanced their responsiveness and precision, making them increasingly suitable for delicate surgical tasks.

The primary objective of SPA research in surgical applications is to develop actuators that can safely interact with human tissues while providing surgeons with enhanced dexterity and tactile feedback. This includes creating systems capable of navigating through confined anatomical spaces with minimal trauma, performing complex manipulations in hard-to-reach areas, and delivering controlled forces appropriate for various tissue types.

Another critical goal is miniaturization without compromising functionality, enabling less invasive surgical approaches. Researchers aim to develop SPAs that can be deployed through small incisions or natural orifices, potentially revolutionizing minimally invasive surgery paradigms.

Sustainability and cost-effectiveness represent additional objectives, with efforts focused on developing manufacturing processes that can scale economically while maintaining precision and reliability. The ultimate vision is to create surgical tools that combine the precision of robotics with the gentleness and adaptability of human touch.

The field is now at an inflection point where theoretical advances are increasingly being translated into practical applications. Collaborative efforts between engineers, materials scientists, and surgical specialists are essential to address remaining challenges and fully realize the potential of soft pneumatic actuators in transforming surgical capabilities and patient outcomes.

The evolution of SPAs has been driven by the convergence of materials science, robotics, and surgical needs. Early iterations faced challenges with durability, precision, and biocompatibility. However, breakthroughs in elastomeric materials, manufacturing techniques like 3D printing, and computational modeling have accelerated their development. The introduction of fiber-reinforced designs in the early 2000s marked a pivotal advancement, enabling greater force generation while maintaining compliance.

Recent technological trends show a clear movement toward multi-material SPAs with embedded sensing capabilities, allowing for closed-loop control systems that can adapt to varying tissue interactions during surgical procedures. The integration of machine learning algorithms has further enhanced their responsiveness and precision, making them increasingly suitable for delicate surgical tasks.

The primary objective of SPA research in surgical applications is to develop actuators that can safely interact with human tissues while providing surgeons with enhanced dexterity and tactile feedback. This includes creating systems capable of navigating through confined anatomical spaces with minimal trauma, performing complex manipulations in hard-to-reach areas, and delivering controlled forces appropriate for various tissue types.

Another critical goal is miniaturization without compromising functionality, enabling less invasive surgical approaches. Researchers aim to develop SPAs that can be deployed through small incisions or natural orifices, potentially revolutionizing minimally invasive surgery paradigms.

Sustainability and cost-effectiveness represent additional objectives, with efforts focused on developing manufacturing processes that can scale economically while maintaining precision and reliability. The ultimate vision is to create surgical tools that combine the precision of robotics with the gentleness and adaptability of human touch.

The field is now at an inflection point where theoretical advances are increasingly being translated into practical applications. Collaborative efforts between engineers, materials scientists, and surgical specialists are essential to address remaining challenges and fully realize the potential of soft pneumatic actuators in transforming surgical capabilities and patient outcomes.

Market Demand Analysis for Advanced Surgical Devices

The global market for advanced surgical devices is experiencing robust growth, driven by increasing demand for minimally invasive procedures and technological innovations in surgical techniques. The integration of soft pneumatic actuators into surgical devices represents a significant advancement in this field, addressing critical needs for precision, safety, and improved patient outcomes. Current market projections indicate that the global surgical robotics market, which encompasses pneumatic actuation technologies, is expected to grow at a compound annual growth rate of 21.6% through 2027, reaching a market value of $16.77 billion.

Healthcare providers worldwide are increasingly seeking surgical solutions that reduce patient trauma, minimize recovery time, and enhance surgical precision. This trend is particularly evident in complex procedures such as neurosurgery, cardiovascular interventions, and microsurgery, where traditional rigid instruments present limitations in accessing confined anatomical spaces. Market research indicates that hospitals and ambulatory surgical centers are willing to invest in advanced surgical technologies that demonstrate clear improvements in clinical outcomes and operational efficiency.

Demographic shifts, particularly aging populations in developed economies, are amplifying the demand for minimally invasive surgical procedures. With age-related conditions requiring surgical intervention on the rise, there is growing pressure on healthcare systems to adopt technologies that reduce hospitalization periods and post-operative complications. Soft pneumatic actuators address these needs by enabling gentler tissue manipulation and reducing the risk of iatrogenic injuries during procedures.

Geographical analysis reveals varying adoption rates across regions. North America currently leads the market for advanced surgical technologies, followed by Europe and Asia-Pacific. However, emerging economies in Asia and Latin America are showing accelerated growth rates in adoption, driven by improving healthcare infrastructure and increasing healthcare expenditure. These markets present significant expansion opportunities for innovative surgical device technologies.

Reimbursement policies and regulatory frameworks significantly influence market penetration of new surgical technologies. Recent positive shifts in insurance coverage for minimally invasive procedures utilizing advanced actuation systems have created favorable market conditions. Additionally, healthcare facilities are increasingly evaluating technologies based on their total economic impact, including reduced complication rates, shorter hospital stays, and improved surgical throughput.

The COVID-19 pandemic has accelerated certain market trends, particularly the adoption of technologies that reduce procedure time and minimize hospital stays. This has created an unexpected catalyst for the adoption of advanced surgical devices incorporating soft pneumatic actuators, as healthcare systems worldwide seek to optimize resource utilization while maintaining high standards of care.

Healthcare providers worldwide are increasingly seeking surgical solutions that reduce patient trauma, minimize recovery time, and enhance surgical precision. This trend is particularly evident in complex procedures such as neurosurgery, cardiovascular interventions, and microsurgery, where traditional rigid instruments present limitations in accessing confined anatomical spaces. Market research indicates that hospitals and ambulatory surgical centers are willing to invest in advanced surgical technologies that demonstrate clear improvements in clinical outcomes and operational efficiency.

Demographic shifts, particularly aging populations in developed economies, are amplifying the demand for minimally invasive surgical procedures. With age-related conditions requiring surgical intervention on the rise, there is growing pressure on healthcare systems to adopt technologies that reduce hospitalization periods and post-operative complications. Soft pneumatic actuators address these needs by enabling gentler tissue manipulation and reducing the risk of iatrogenic injuries during procedures.

Geographical analysis reveals varying adoption rates across regions. North America currently leads the market for advanced surgical technologies, followed by Europe and Asia-Pacific. However, emerging economies in Asia and Latin America are showing accelerated growth rates in adoption, driven by improving healthcare infrastructure and increasing healthcare expenditure. These markets present significant expansion opportunities for innovative surgical device technologies.

Reimbursement policies and regulatory frameworks significantly influence market penetration of new surgical technologies. Recent positive shifts in insurance coverage for minimally invasive procedures utilizing advanced actuation systems have created favorable market conditions. Additionally, healthcare facilities are increasingly evaluating technologies based on their total economic impact, including reduced complication rates, shorter hospital stays, and improved surgical throughput.

The COVID-19 pandemic has accelerated certain market trends, particularly the adoption of technologies that reduce procedure time and minimize hospital stays. This has created an unexpected catalyst for the adoption of advanced surgical devices incorporating soft pneumatic actuators, as healthcare systems worldwide seek to optimize resource utilization while maintaining high standards of care.

Current State and Challenges in Soft Robotics for Surgery

Soft robotics has emerged as a transformative field in surgical applications, offering unprecedented flexibility, safety, and adaptability compared to traditional rigid robotic systems. Currently, the global landscape of soft robotics for surgery demonstrates significant advancements, with research centers across North America, Europe, and Asia making substantial contributions. The Harvard Biodesign Lab, Stanford's Biomimetics Lab, and ETH Zurich stand as pioneers in developing pneumatically-driven soft actuators specifically tailored for minimally invasive procedures.

Despite these advancements, several critical challenges persist in the implementation of soft pneumatic actuators in surgical environments. Material biocompatibility remains a primary concern, as materials must simultaneously meet mechanical performance requirements while ensuring patient safety during prolonged tissue contact. Current silicone elastomers, while promising, still face limitations in durability during repeated sterilization cycles and extended surgical procedures.

Precision control represents another significant hurdle. Unlike rigid systems with well-established kinematics, soft actuators exhibit non-linear deformation behaviors that complicate accurate positioning and force application. This unpredictability becomes particularly problematic during delicate tissue manipulation where millimeter-level precision is essential. Current control algorithms struggle to account for material hysteresis and environmental variations within the surgical field.

Miniaturization constraints further challenge implementation, as pneumatic systems traditionally require external pumps and control hardware that limit portability. Recent innovations in microfluidics and embedded pneumatic networks have shown promise, but complete system integration remains elusive for many applications requiring multiple degrees of freedom in confined anatomical spaces.

Regulatory approval pathways present additional obstacles. The novel nature of soft robotic surgical tools means limited precedent exists for safety validation protocols. Regulatory bodies like the FDA and European Medicines Agency are still developing appropriate frameworks to evaluate these technologies, creating uncertainty for developers and potentially extending commercialization timelines.

Energy efficiency and response time limitations also constrain current implementations. Pneumatic systems inherently suffer from compressibility effects that reduce actuation speed compared to their rigid counterparts. This limitation becomes particularly evident in applications requiring rapid movements or precise timing synchronization with physiological events such as heartbeats or respiration cycles.

Cross-disciplinary collaboration gaps between materials scientists, roboticists, and practicing surgeons further impede progress. The specialized knowledge required across these domains often results in solutions that excel technically but fail to address practical clinical requirements or workflow integration needs in operating theaters.

Despite these advancements, several critical challenges persist in the implementation of soft pneumatic actuators in surgical environments. Material biocompatibility remains a primary concern, as materials must simultaneously meet mechanical performance requirements while ensuring patient safety during prolonged tissue contact. Current silicone elastomers, while promising, still face limitations in durability during repeated sterilization cycles and extended surgical procedures.

Precision control represents another significant hurdle. Unlike rigid systems with well-established kinematics, soft actuators exhibit non-linear deformation behaviors that complicate accurate positioning and force application. This unpredictability becomes particularly problematic during delicate tissue manipulation where millimeter-level precision is essential. Current control algorithms struggle to account for material hysteresis and environmental variations within the surgical field.

Miniaturization constraints further challenge implementation, as pneumatic systems traditionally require external pumps and control hardware that limit portability. Recent innovations in microfluidics and embedded pneumatic networks have shown promise, but complete system integration remains elusive for many applications requiring multiple degrees of freedom in confined anatomical spaces.

Regulatory approval pathways present additional obstacles. The novel nature of soft robotic surgical tools means limited precedent exists for safety validation protocols. Regulatory bodies like the FDA and European Medicines Agency are still developing appropriate frameworks to evaluate these technologies, creating uncertainty for developers and potentially extending commercialization timelines.

Energy efficiency and response time limitations also constrain current implementations. Pneumatic systems inherently suffer from compressibility effects that reduce actuation speed compared to their rigid counterparts. This limitation becomes particularly evident in applications requiring rapid movements or precise timing synchronization with physiological events such as heartbeats or respiration cycles.

Cross-disciplinary collaboration gaps between materials scientists, roboticists, and practicing surgeons further impede progress. The specialized knowledge required across these domains often results in solutions that excel technically but fail to address practical clinical requirements or workflow integration needs in operating theaters.

Current Soft Pneumatic Solutions for Surgical Applications

01 Design and structure of soft pneumatic actuators

Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers, channels, or bellows that expand or contract to create movement. The design may incorporate various geometries and reinforcement patterns to control the direction and type of motion, enabling bending, twisting, or linear actuation depending on the application requirements.- Design and structure of soft pneumatic actuators: Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers or channels that expand in predetermined directions when inflated, creating controlled movement. The design may incorporate various geometries, reinforcement patterns, and material combinations to achieve specific motion characteristics such as bending, twisting, or extending. These structural considerations are fundamental to creating effective soft actuators for various applications.

- Materials for soft pneumatic actuators: The selection of materials is crucial for soft pneumatic actuator performance. Elastomers like silicone rubber and thermoplastic polyurethanes are commonly used due to their flexibility, durability, and ability to withstand repeated inflation cycles. Some designs incorporate fiber reinforcements, fabric layers, or composite structures to control deformation patterns and enhance mechanical properties. Advanced materials may also feature self-healing capabilities or stimuli-responsive characteristics to improve functionality and longevity of the actuators.

- Control systems for soft pneumatic actuators: Control systems for soft pneumatic actuators typically involve pressure regulation, valve systems, and feedback mechanisms. These systems may incorporate sensors to monitor actuator position, pressure, or deformation state. Advanced control approaches include machine learning algorithms, model-based control strategies, and distributed control architectures for coordinating multiple actuators. The integration of electronic components with the soft structures presents unique challenges that require specialized solutions for reliable operation in various environments.

- Applications of soft pneumatic actuators in robotics: Soft pneumatic actuators are increasingly used in robotics applications where safe human-robot interaction is essential. They enable the development of soft grippers that can handle delicate objects without damage, wearable assistive devices that conform to the human body, and bio-inspired robots that mimic natural movements of organisms. These actuators provide advantages in unstructured environments where traditional rigid robots struggle, offering compliance, adaptability, and inherent safety features that make them suitable for healthcare, manufacturing, and exploration applications.

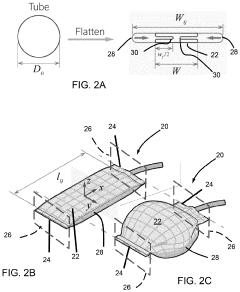

- Manufacturing techniques for soft pneumatic actuators: Various manufacturing techniques are employed to create soft pneumatic actuators, including molding, 3D printing, and hybrid fabrication approaches. Molding processes often use multi-step casting of elastomers around sacrificial cores to create internal channels. Advanced additive manufacturing methods allow for complex internal geometries and gradient material properties. Some techniques incorporate embedded components during fabrication, such as sensors or rigid elements, to enhance functionality. These manufacturing approaches continue to evolve to improve repeatability, scalability, and integration capabilities.

02 Materials for soft pneumatic actuators

The selection of materials is crucial for soft pneumatic actuators, with elastomers like silicone rubber being commonly used due to their flexibility and durability. These materials need to withstand repeated inflation and deflation cycles while maintaining their mechanical properties. Some advanced actuators incorporate composite materials or fiber reinforcements to enhance performance characteristics such as force output, response time, and operational lifespan.Expand Specific Solutions03 Control systems for soft pneumatic actuators

Control systems for soft pneumatic actuators typically include pressure regulators, valves, sensors, and electronic controllers that work together to manage air flow and pressure. These systems may employ feedback mechanisms to monitor and adjust actuator performance in real-time. Advanced control strategies might incorporate machine learning algorithms or model-based approaches to achieve precise movements and adapt to changing conditions or tasks.Expand Specific Solutions04 Applications of soft pneumatic actuators in robotics

Soft pneumatic actuators are increasingly used in robotics applications where safe human-robot interaction is essential. These actuators enable the development of soft robotic grippers that can handle delicate objects without damage, wearable assistive devices that conform to the human body, and bio-inspired robots that mimic natural movements. Their inherent compliance makes them particularly suitable for unstructured environments and tasks requiring adaptability.Expand Specific Solutions05 Manufacturing techniques for soft pneumatic actuators

Various manufacturing techniques are employed to produce soft pneumatic actuators, including molding, 3D printing, and lamination processes. These methods allow for the creation of complex internal structures and the integration of multiple materials. Advanced fabrication approaches may incorporate embedded sensors or variable stiffness elements to enhance functionality. The manufacturing process often involves careful consideration of material curing conditions and bonding techniques to ensure reliable performance.Expand Specific Solutions

Key Industry Players in Surgical Robotics

The soft pneumatic actuator market for surgical device enhancements is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market is projected to expand significantly as minimally invasive surgical techniques gain prominence, with an estimated value reaching several hundred million dollars by 2030. Leading academic institutions (Harvard, MIT, Cornell, Yale) are driving fundamental research, while established medical device companies like Ethicon Endo-Surgery and CONMED are integrating these technologies into commercial products. Emerging players such as Bioliberty and Artimus Robotics are developing specialized applications, focusing on wearable rehabilitation devices and custom actuator solutions. The technology is transitioning from laboratory research to clinical validation, with increasing focus on biocompatibility, precision control, and integration with surgical workflows.

Ethicon Endo-Surgery, Inc.

Technical Solution: Ethicon Endo-Surgery has developed an advanced soft pneumatic actuator platform specifically designed for next-generation surgical instruments. Their technology focuses on enhancing minimally invasive procedures through articulating instruments with improved dexterity and tissue interaction capabilities. Ethicon's soft pneumatic actuators utilize multi-chamber designs with differential pressure control to achieve complex articulation patterns necessary for navigating confined anatomical spaces[8]. Their proprietary manufacturing process creates seamless elastomeric structures with embedded reinforcement fibers that prevent ballooning while maintaining flexibility. For endoscopic applications, Ethicon has developed ultra-thin pneumatic actuators that can be integrated into sub-5mm instruments while providing sufficient force for tissue manipulation. Their technology includes specialized pressure regulation systems that maintain consistent actuator performance regardless of external forces or instrument orientation. Ethicon has also pioneered hybrid actuator designs that combine pneumatic chambers with traditional mechanical articulation, creating surgical instruments with enhanced degrees of freedom while maintaining compatibility with existing surgical systems[10]. Recent innovations include smart pneumatic actuators with embedded sensors that can detect tissue contact forces and provide real-time feedback to surgeons, significantly improving safety during delicate procedures.

Strengths: Extensive clinical experience and regulatory expertise enabling faster path to market; seamless integration with existing surgical workflows and equipment; robust manufacturing capabilities ensuring consistent quality and performance. Weaknesses: More conservative design approach may limit revolutionary capabilities compared to academic research; proprietary systems may lack compatibility with other manufacturers' equipment; focus on commercial viability sometimes prioritizes reliability over cutting-edge performance.

President & Fellows of Harvard College

Technical Solution: Harvard's research on soft pneumatic actuators for surgical applications has centered around their groundbreaking work in soft robotics. Their Wyss Institute has developed a comprehensive platform for creating biomimetic soft actuators specifically designed for minimally invasive surgery. Harvard's approach utilizes novel fabrication methods including molding, 3D printing, and lamination techniques to create pneumatic networks embedded within elastomeric materials[2]. Their signature contribution is the development of Fluidic Elastomer Actuators (FEAs) that can achieve complex motions through pressurization of embedded channels. For surgical applications, Harvard researchers have created multi-chamber actuators capable of omnidirectional bending, enabling precise navigation through tortuous anatomical pathways[4]. Their PneuNets (Pneumatic Networks) technology allows for rapid actuation with minimal pressure requirements, making them suitable for delicate tissue manipulation. Harvard has also pioneered soft robotic grippers with variable stiffness capabilities that can safely grasp and manipulate organs without causing damage[6]. Recent innovations include pressure-adaptive actuators with integrated sensing that can detect tissue properties and adjust gripping force accordingly, significantly reducing the risk of tissue damage during surgical procedures.

Strengths: World-leading expertise in soft materials and fabrication techniques; highly adaptable designs that can be customized for specific surgical applications; excellent force distribution properties minimizing tissue trauma. Weaknesses: Some designs face challenges with response speed compared to traditional rigid actuators; potential durability concerns in high-cycle surgical applications; current limitations in achieving high precision positioning under variable loads.

Core Technical Innovations in Soft Pneumatic Actuators

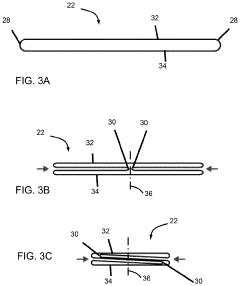

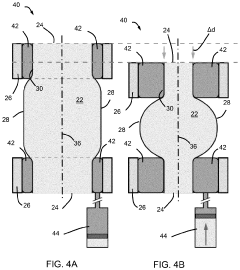

Pneumatic soft actuators with tunable force-displacement relation and methods and machines therefor

PatentPendingUS20230373082A1

Innovation

- A pneumatic soft actuator with an inflatable pouch featuring symmetrical folds at its ends, allowing for active modification of the end geometry through a branched tendon and spool mechanism, enabling adjustment of the force-strain relationship and range of motion without altering the pouch's composition or structure.

Biocompatibility and Safety Considerations

The biocompatibility of materials used in soft pneumatic actuators (SPAs) represents a critical consideration for surgical applications. Medical-grade silicones such as polydimethylsiloxane (PDMS) and platinum-cured silicones have emerged as primary materials due to their established biocompatibility profiles and compliance with ISO 10993 standards. These materials demonstrate minimal inflammatory responses and reduced risk of adverse tissue reactions when in contact with human organs and tissues during surgical procedures.

Safety considerations extend beyond material selection to encompass the pneumatic control systems that power these actuators. Pressure regulation mechanisms must incorporate redundant safety features to prevent excessive force application during surgical interventions. Recent developments include pressure-limiting valves and electronic monitoring systems that can detect and respond to abnormal pressure conditions within milliseconds, significantly reducing the risk of tissue damage.

Sterilization compatibility presents another crucial challenge for SPA implementation in surgical settings. Materials must withstand standard medical sterilization processes such as ethylene oxide treatment, gamma irradiation, or autoclave procedures without degrading mechanical properties or releasing toxic compounds. Research indicates that specialized formulations of silicone elastomers can maintain their performance characteristics after multiple sterilization cycles, though this remains an active area of investigation.

The risk of particulate generation during actuation cycles requires careful evaluation, as microparticles could potentially enter the surgical field. Advanced manufacturing techniques, including multi-material 3D printing and precision molding processes, have demonstrated significant reductions in particulate shedding compared to earlier fabrication methods. Surface treatment technologies such as parylene coating further minimize friction and associated particle generation.

Electrical safety considerations become paramount when integrating sensors and control electronics with pneumatic systems. Isolation barriers between pneumatic and electronic components must prevent fluid ingress while maintaining system functionality. Low-voltage operation and optical isolation techniques have proven effective in minimizing electrical hazards in wet surgical environments.

Long-term implantation scenarios introduce additional biocompatibility challenges related to material degradation and host response. Encapsulation strategies using biocompatible barrier materials have shown promise in preventing adverse tissue reactions during extended contact periods. Recent studies have explored bioresorbable pneumatic actuators that gradually dissolve after completing their surgical function, potentially eliminating the need for removal procedures and associated risks.

Safety considerations extend beyond material selection to encompass the pneumatic control systems that power these actuators. Pressure regulation mechanisms must incorporate redundant safety features to prevent excessive force application during surgical interventions. Recent developments include pressure-limiting valves and electronic monitoring systems that can detect and respond to abnormal pressure conditions within milliseconds, significantly reducing the risk of tissue damage.

Sterilization compatibility presents another crucial challenge for SPA implementation in surgical settings. Materials must withstand standard medical sterilization processes such as ethylene oxide treatment, gamma irradiation, or autoclave procedures without degrading mechanical properties or releasing toxic compounds. Research indicates that specialized formulations of silicone elastomers can maintain their performance characteristics after multiple sterilization cycles, though this remains an active area of investigation.

The risk of particulate generation during actuation cycles requires careful evaluation, as microparticles could potentially enter the surgical field. Advanced manufacturing techniques, including multi-material 3D printing and precision molding processes, have demonstrated significant reductions in particulate shedding compared to earlier fabrication methods. Surface treatment technologies such as parylene coating further minimize friction and associated particle generation.

Electrical safety considerations become paramount when integrating sensors and control electronics with pneumatic systems. Isolation barriers between pneumatic and electronic components must prevent fluid ingress while maintaining system functionality. Low-voltage operation and optical isolation techniques have proven effective in minimizing electrical hazards in wet surgical environments.

Long-term implantation scenarios introduce additional biocompatibility challenges related to material degradation and host response. Encapsulation strategies using biocompatible barrier materials have shown promise in preventing adverse tissue reactions during extended contact periods. Recent studies have explored bioresorbable pneumatic actuators that gradually dissolve after completing their surgical function, potentially eliminating the need for removal procedures and associated risks.

Regulatory Approval Pathways for Surgical Innovations

The regulatory landscape for soft pneumatic actuators in surgical devices presents a complex pathway that developers must navigate carefully. In the United States, the FDA classifies most surgical devices incorporating pneumatic actuator technology as Class II medical devices, requiring a 510(k) premarket notification unless the technology represents a significant departure from existing predicate devices. For truly novel applications of soft pneumatic actuators, a De Novo classification request or Premarket Approval (PMA) pathway may be necessary, substantially increasing development timelines and costs.

European market access requires conformity with the Medical Device Regulation (MDR), which has implemented more stringent requirements since its full application in 2021. Soft pneumatic actuators in surgical applications typically fall under Class IIa or IIb, depending on their specific function and duration of use. The conformity assessment procedure necessitates involvement of a Notified Body and comprehensive technical documentation demonstrating safety and performance.

Japan's Pharmaceuticals and Medical Devices Agency (PMDA) follows a risk-based classification system similar to other major markets but may require additional local clinical data for novel pneumatic actuator technologies. China's National Medical Products Administration (NMPA) has recently streamlined its approval process but maintains strict requirements for innovative surgical technologies.

Clinical evidence requirements vary significantly across regulatory jurisdictions. For soft pneumatic actuators, bench testing demonstrating mechanical reliability, biocompatibility testing per ISO 10993, and sterilization validation are universally required. However, the extent of clinical investigation depends on the claimed benefits and potential risks. Minimally invasive surgical applications may benefit from the FDA's Breakthrough Devices Program or equivalent expedited pathways in other regions if they address unmet clinical needs.

Regulatory strategies for soft pneumatic actuator technologies should consider a phased approach, potentially beginning with less invasive applications to establish safety data before pursuing more complex surgical implementations. Early engagement with regulatory bodies through pre-submission meetings (FDA), scientific advice consultations (EMA), or their equivalents in other markets is highly recommended to align development plans with regulatory expectations.

Standards compliance represents another critical aspect of the regulatory pathway. ISO 13485 for quality management systems, IEC 60601 for electrical safety, and specific standards related to particular surgical applications provide a framework for demonstrating conformity. Emerging standards specific to soft robotics and pneumatic systems in medical applications are under development but not yet fully established, creating both challenges and opportunities for early market entrants.

European market access requires conformity with the Medical Device Regulation (MDR), which has implemented more stringent requirements since its full application in 2021. Soft pneumatic actuators in surgical applications typically fall under Class IIa or IIb, depending on their specific function and duration of use. The conformity assessment procedure necessitates involvement of a Notified Body and comprehensive technical documentation demonstrating safety and performance.

Japan's Pharmaceuticals and Medical Devices Agency (PMDA) follows a risk-based classification system similar to other major markets but may require additional local clinical data for novel pneumatic actuator technologies. China's National Medical Products Administration (NMPA) has recently streamlined its approval process but maintains strict requirements for innovative surgical technologies.

Clinical evidence requirements vary significantly across regulatory jurisdictions. For soft pneumatic actuators, bench testing demonstrating mechanical reliability, biocompatibility testing per ISO 10993, and sterilization validation are universally required. However, the extent of clinical investigation depends on the claimed benefits and potential risks. Minimally invasive surgical applications may benefit from the FDA's Breakthrough Devices Program or equivalent expedited pathways in other regions if they address unmet clinical needs.

Regulatory strategies for soft pneumatic actuator technologies should consider a phased approach, potentially beginning with less invasive applications to establish safety data before pursuing more complex surgical implementations. Early engagement with regulatory bodies through pre-submission meetings (FDA), scientific advice consultations (EMA), or their equivalents in other markets is highly recommended to align development plans with regulatory expectations.

Standards compliance represents another critical aspect of the regulatory pathway. ISO 13485 for quality management systems, IEC 60601 for electrical safety, and specific standards related to particular surgical applications provide a framework for demonstrating conformity. Emerging standards specific to soft robotics and pneumatic systems in medical applications are under development but not yet fully established, creating both challenges and opportunities for early market entrants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!