What Challenges Exist in Soft Pneumatic Actuator Scalability

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Evolution and Scalability Goals

Soft pneumatic actuators (SPAs) have evolved significantly since their inception in the 1950s, transitioning from rigid pneumatic systems to the flexible, compliant mechanisms we see today. The evolution began with McKibben artificial muscles, which utilized inflatable bladders constrained by braided mesh sleeves to generate contractile forces. This foundational design has influenced subsequent developments in the field, leading to the diverse array of soft actuators currently available.

The 1990s marked a pivotal shift with the emergence of biomimetic approaches, as researchers sought inspiration from natural systems like elephant trunks, octopus tentacles, and plant movements. This biological influence catalyzed innovation in material science and design methodologies, resulting in actuators with enhanced flexibility, adaptability, and efficiency. The introduction of silicone elastomers as primary construction materials in the early 2000s further accelerated development, enabling more sophisticated geometries and functionalities.

Recent technological advancements have focused on improving control precision, force output, and operational lifespan. The integration of embedded sensors, variable stiffness mechanisms, and multi-material fabrication techniques has expanded the capabilities of SPAs, allowing them to perform increasingly complex tasks in diverse environments. Parallel developments in computational modeling and simulation tools have facilitated more accurate prediction of actuator behavior, streamlining the design process.

Despite these advances, scalability remains a significant challenge in SPA technology. Current research aims to develop actuators that maintain performance across different size scales, from microscopic medical devices to large industrial applications. This scalability goal encompasses both dimensional scaling (maintaining functionality when changing physical size) and production scaling (enabling efficient mass manufacturing while preserving quality and performance).

Key technical objectives include establishing standardized design principles that apply across scales, developing materials with consistent properties regardless of fabrication volume, and creating modular architectures that facilitate both miniaturization and enlargement. Researchers are particularly focused on addressing the non-linear scaling of mechanical properties, which often results in diminished performance when simply scaling designs up or down.

The ultimate goal is to create a unified framework for SPA design that enables predictable performance across multiple scales, supported by scalable manufacturing processes. This would significantly expand application domains, potentially revolutionizing fields from minimally invasive surgery to assistive wearable technologies and soft robotics for human-machine interaction. Success in this endeavor requires interdisciplinary collaboration between material scientists, mechanical engineers, control theorists, and manufacturing specialists.

The 1990s marked a pivotal shift with the emergence of biomimetic approaches, as researchers sought inspiration from natural systems like elephant trunks, octopus tentacles, and plant movements. This biological influence catalyzed innovation in material science and design methodologies, resulting in actuators with enhanced flexibility, adaptability, and efficiency. The introduction of silicone elastomers as primary construction materials in the early 2000s further accelerated development, enabling more sophisticated geometries and functionalities.

Recent technological advancements have focused on improving control precision, force output, and operational lifespan. The integration of embedded sensors, variable stiffness mechanisms, and multi-material fabrication techniques has expanded the capabilities of SPAs, allowing them to perform increasingly complex tasks in diverse environments. Parallel developments in computational modeling and simulation tools have facilitated more accurate prediction of actuator behavior, streamlining the design process.

Despite these advances, scalability remains a significant challenge in SPA technology. Current research aims to develop actuators that maintain performance across different size scales, from microscopic medical devices to large industrial applications. This scalability goal encompasses both dimensional scaling (maintaining functionality when changing physical size) and production scaling (enabling efficient mass manufacturing while preserving quality and performance).

Key technical objectives include establishing standardized design principles that apply across scales, developing materials with consistent properties regardless of fabrication volume, and creating modular architectures that facilitate both miniaturization and enlargement. Researchers are particularly focused on addressing the non-linear scaling of mechanical properties, which often results in diminished performance when simply scaling designs up or down.

The ultimate goal is to create a unified framework for SPA design that enables predictable performance across multiple scales, supported by scalable manufacturing processes. This would significantly expand application domains, potentially revolutionizing fields from minimally invasive surgery to assistive wearable technologies and soft robotics for human-machine interaction. Success in this endeavor requires interdisciplinary collaboration between material scientists, mechanical engineers, control theorists, and manufacturing specialists.

Market Applications and Demand Analysis for Scalable SPAs

The market for Soft Pneumatic Actuators (SPAs) is experiencing significant growth across multiple industries, driven by their unique capabilities in mimicking natural movements and adaptability to various environments. The healthcare sector represents one of the most promising markets, with applications ranging from rehabilitation devices to surgical tools. Particularly in rehabilitation, scalable SPAs offer personalized therapy solutions that can adapt to different body sizes and therapeutic needs, addressing a market estimated to reach $25 billion globally by 2027.

Manufacturing and automation industries are increasingly adopting soft robotics technologies, including SPAs, to handle delicate objects and operate in collaborative environments with human workers. The demand for scalable SPAs in this sector stems from the need for versatile gripping solutions that can handle components of varying sizes and shapes without requiring complete system redesigns. This adaptability translates to significant cost savings and operational flexibility for manufacturers.

Consumer electronics and wearable technology represent emerging markets for scalable SPAs. The integration of these actuators into smart clothing, haptic feedback devices, and interactive consumer products requires solutions that can be efficiently manufactured at different scales while maintaining consistent performance characteristics. Market research indicates consumer acceptance of such technologies is growing, particularly when they offer enhanced comfort and natural interaction.

The aerospace and defense sectors are exploring SPAs for applications ranging from deployable structures to adaptive control surfaces. These applications demand actuators that can be scaled from centimeter to meter dimensions while maintaining reliability under extreme conditions. The specialized nature of these applications creates high-value market opportunities despite lower production volumes.

Analysis of market trends reveals a growing preference for modular and reconfigurable systems across industries. Scalable SPAs align perfectly with this trend, as they can be designed as building blocks for more complex systems. This modularity creates opportunities for standardized components that can serve multiple market segments, potentially reducing development costs and accelerating time-to-market.

Customer feedback from early adopters indicates that while there is strong interest in the capabilities of SPAs, concerns about reliability, control precision, and manufacturing consistency at different scales remain significant barriers to wider adoption. These market signals highlight the need for technical solutions that address scalability challenges while maintaining performance predictability across different dimensions.

The geographical distribution of demand shows particular strength in regions with advanced manufacturing capabilities and aging populations, notably North America, Europe, and East Asia. These regions combine the technical infrastructure to implement SPA-based solutions with pressing needs in healthcare and automation that these technologies can address.

Manufacturing and automation industries are increasingly adopting soft robotics technologies, including SPAs, to handle delicate objects and operate in collaborative environments with human workers. The demand for scalable SPAs in this sector stems from the need for versatile gripping solutions that can handle components of varying sizes and shapes without requiring complete system redesigns. This adaptability translates to significant cost savings and operational flexibility for manufacturers.

Consumer electronics and wearable technology represent emerging markets for scalable SPAs. The integration of these actuators into smart clothing, haptic feedback devices, and interactive consumer products requires solutions that can be efficiently manufactured at different scales while maintaining consistent performance characteristics. Market research indicates consumer acceptance of such technologies is growing, particularly when they offer enhanced comfort and natural interaction.

The aerospace and defense sectors are exploring SPAs for applications ranging from deployable structures to adaptive control surfaces. These applications demand actuators that can be scaled from centimeter to meter dimensions while maintaining reliability under extreme conditions. The specialized nature of these applications creates high-value market opportunities despite lower production volumes.

Analysis of market trends reveals a growing preference for modular and reconfigurable systems across industries. Scalable SPAs align perfectly with this trend, as they can be designed as building blocks for more complex systems. This modularity creates opportunities for standardized components that can serve multiple market segments, potentially reducing development costs and accelerating time-to-market.

Customer feedback from early adopters indicates that while there is strong interest in the capabilities of SPAs, concerns about reliability, control precision, and manufacturing consistency at different scales remain significant barriers to wider adoption. These market signals highlight the need for technical solutions that address scalability challenges while maintaining performance predictability across different dimensions.

The geographical distribution of demand shows particular strength in regions with advanced manufacturing capabilities and aging populations, notably North America, Europe, and East Asia. These regions combine the technical infrastructure to implement SPA-based solutions with pressing needs in healthcare and automation that these technologies can address.

Current Technical Limitations in SPA Scaling

Soft Pneumatic Actuators (SPAs) face significant scaling challenges that currently limit their widespread industrial adoption. The primary technical limitation is the non-linear relationship between size and performance. As SPAs scale up, their response time increases disproportionately due to the larger air volumes that must be pressurized or depressurized. This fundamental physical constraint creates a performance ceiling that becomes increasingly problematic at larger scales.

Material limitations represent another critical barrier to SPA scalability. Current elastomeric materials exhibit insufficient durability when subjected to repeated deformation cycles at larger scales. The mechanical stress concentrations at seams and connection points become more pronounced as size increases, leading to accelerated material fatigue and eventual failure. Additionally, larger SPAs require materials with consistent properties throughout their volume, which becomes increasingly difficult to achieve during manufacturing processes.

Manufacturing precision presents significant challenges when scaling SPAs. Current fabrication techniques like molding and 3D printing struggle to maintain consistent wall thicknesses and internal channel geometries at larger scales. These inconsistencies lead to unpredictable deformation patterns and pressure distribution, compromising both performance and reliability. The complexity of creating intricate internal pneumatic networks becomes exponentially more difficult as dimensions increase.

Power efficiency deteriorates substantially with increased SPA size. Larger actuators require greater volumes of compressed air, resulting in higher energy consumption and heat generation. The pneumatic infrastructure needed to support large-scale SPAs becomes increasingly complex and expensive, often negating the inherent cost advantages of soft robotics. This efficiency gap widens particularly when compared to conventional rigid actuators at similar scales.

Control precision represents perhaps the most significant technical limitation. The inherently non-linear behavior of soft materials becomes more pronounced at larger scales, making precise position and force control extremely challenging. Current sensing technologies struggle to provide accurate feedback from large-scale soft structures, and computational models fail to accurately predict deformation behaviors beyond certain size thresholds. This control limitation severely restricts applications requiring high precision.

Integration challenges also emerge when scaling SPAs. Interfacing large soft actuators with rigid components or other systems introduces complex mechanical coupling issues. The weight-to-force ratio becomes increasingly unfavorable as size increases, limiting practical applications. Furthermore, the thermal management requirements become more demanding, as larger volumes of compressed air generate more heat during operation, potentially degrading the elastomeric materials over time.

Material limitations represent another critical barrier to SPA scalability. Current elastomeric materials exhibit insufficient durability when subjected to repeated deformation cycles at larger scales. The mechanical stress concentrations at seams and connection points become more pronounced as size increases, leading to accelerated material fatigue and eventual failure. Additionally, larger SPAs require materials with consistent properties throughout their volume, which becomes increasingly difficult to achieve during manufacturing processes.

Manufacturing precision presents significant challenges when scaling SPAs. Current fabrication techniques like molding and 3D printing struggle to maintain consistent wall thicknesses and internal channel geometries at larger scales. These inconsistencies lead to unpredictable deformation patterns and pressure distribution, compromising both performance and reliability. The complexity of creating intricate internal pneumatic networks becomes exponentially more difficult as dimensions increase.

Power efficiency deteriorates substantially with increased SPA size. Larger actuators require greater volumes of compressed air, resulting in higher energy consumption and heat generation. The pneumatic infrastructure needed to support large-scale SPAs becomes increasingly complex and expensive, often negating the inherent cost advantages of soft robotics. This efficiency gap widens particularly when compared to conventional rigid actuators at similar scales.

Control precision represents perhaps the most significant technical limitation. The inherently non-linear behavior of soft materials becomes more pronounced at larger scales, making precise position and force control extremely challenging. Current sensing technologies struggle to provide accurate feedback from large-scale soft structures, and computational models fail to accurately predict deformation behaviors beyond certain size thresholds. This control limitation severely restricts applications requiring high precision.

Integration challenges also emerge when scaling SPAs. Interfacing large soft actuators with rigid components or other systems introduces complex mechanical coupling issues. The weight-to-force ratio becomes increasingly unfavorable as size increases, limiting practical applications. Furthermore, the thermal management requirements become more demanding, as larger volumes of compressed air generate more heat during operation, potentially degrading the elastomeric materials over time.

Existing Approaches to SPA Scalability Challenges

01 Design principles for scalable soft pneumatic actuators

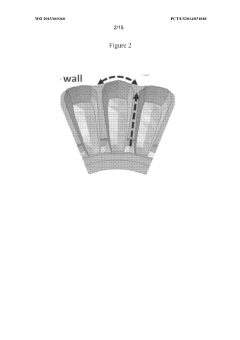

Scalability in soft pneumatic actuators can be achieved through specific design principles that allow for size adaptation while maintaining performance characteristics. These designs often incorporate modular components, flexible materials with consistent properties across different scales, and geometric configurations that preserve functionality when scaled. Key considerations include maintaining appropriate wall thickness-to-chamber size ratios and ensuring pressure distribution remains consistent across different actuator dimensions.- Design principles for scalable soft pneumatic actuators: Specific design principles can be applied to create scalable soft pneumatic actuators. These include modular designs that allow for easy size adjustment, geometric optimization for consistent performance across different scales, and material selection that maintains flexibility and durability regardless of actuator size. These design approaches enable soft pneumatic actuators to be effectively scaled up or down while maintaining their functional properties and performance characteristics.

- Manufacturing techniques for scalable soft actuators: Various manufacturing techniques enable the scalable production of soft pneumatic actuators. These include 3D printing methods that allow for precise control over actuator geometry, molding processes that can be adapted for different sizes, and automated assembly techniques that maintain consistency across production scales. These manufacturing approaches help overcome challenges related to material properties and structural integrity when scaling soft pneumatic actuators.

- Control systems for multi-scale pneumatic actuation: Specialized control systems are essential for managing soft pneumatic actuators across different scales. These systems incorporate pressure regulation mechanisms that adapt to actuator size, feedback sensors that monitor performance regardless of scale, and control algorithms that compensate for the non-linear behavior of soft materials. Advanced control architectures enable precise movement and force application for soft pneumatic actuators of varying dimensions.

- Material innovations for scale-independent performance: Novel materials play a crucial role in developing scalable soft pneumatic actuators. These include composite elastomers with tunable mechanical properties, reinforcement structures that maintain performance across scales, and smart materials that respond consistently to pneumatic pressure regardless of size. Material innovations help address challenges related to wall thickness, elasticity, and durability when scaling soft actuators up or down.

- Applications of scalable soft pneumatic actuators: Scalable soft pneumatic actuators find applications across various domains. In robotics, they enable the development of manipulators that can be sized according to task requirements. In medical devices, scalability allows for customization to patient anatomy. Industrial applications benefit from the ability to deploy soft actuators of appropriate dimensions for specific tasks. The scalability of these actuators also facilitates their use in wearable technologies and prosthetics that must adapt to different user sizes.

02 Manufacturing techniques for scalable soft actuators

Various manufacturing techniques enable the production of soft pneumatic actuators at different scales. These include molding processes, 3D printing, and composite fabrication methods that can be adapted for different sizes. Advanced manufacturing approaches allow for precise control of material properties and internal geometries, which is crucial for maintaining performance across scales. Techniques such as multi-material printing and embedded fabrication help address challenges in producing miniaturized or enlarged actuator systems.Expand Specific Solutions03 Material selection for scale-dependent performance

The selection of appropriate materials is critical for soft pneumatic actuators at different scales. Materials must maintain consistent mechanical properties such as elasticity, durability, and response to pressure across various dimensions. Elastomers with tunable properties, reinforced composites, and specialized polymers can be engineered to address scale-specific challenges. Material considerations include strain limitations, fatigue resistance, and pressure handling capabilities that may change with actuator size.Expand Specific Solutions04 Control systems for multi-scale soft actuators

Control systems for soft pneumatic actuators must be adaptable to different scales to maintain precision and responsiveness. These systems incorporate sensors, valves, and pressure regulators that can be sized appropriately for the actuator dimensions. Advanced control algorithms compensate for scale-dependent behaviors such as response time variations and pressure distribution differences. Feedback mechanisms and predictive models help maintain consistent performance across actuators of different sizes.Expand Specific Solutions05 Applications and integration of scalable soft actuators

Scalable soft pneumatic actuators enable diverse applications across multiple fields. These applications range from miniaturized medical devices to large-scale industrial automation systems. The ability to scale actuators allows for integration into various environments and systems while maintaining functional characteristics. Application areas include robotics, wearable devices, rehabilitation equipment, and adaptive structures, each benefiting from the ability to size actuators appropriately for specific use cases.Expand Specific Solutions

Leading Research Groups and Industrial Players in SPA Field

The soft pneumatic actuator (SPA) scalability landscape is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size is expanding, driven by applications in robotics, healthcare, and industrial automation, with projections suggesting substantial growth as technical barriers are overcome. Regarding technical maturity, academic institutions (Harvard College, Zhejiang University, Shanghai Jiao Tong University) lead fundamental research, while specialized companies (Artimus Robotics, Koganei Corp.) are beginning to commercialize solutions. Key challenges include material limitations, manufacturing complexity, and control precision at different scales. Established players like NASA and Canon are exploring integration possibilities, indicating growing industrial interest in this emerging technology domain.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered innovative approaches to soft pneumatic actuator scalability challenges through their foundational work on soft robotics. Their technical solution focuses on a multi-material 3D printing approach that enables the fabrication of complex, integrated soft pneumatic actuators with embedded pneumatic channels and varying material properties. This manufacturing technique allows precise control over material distribution and structural design, addressing the geometric complexity limitations of traditional molding methods. Harvard researchers have developed specialized silicone-based materials with tunable mechanical properties that maintain performance across different scales, and implemented hierarchical design principles that maintain functional properties when scaling actuators up or down. Their pneumatic control systems utilize miniaturized valves and distributed control architectures to manage air delivery efficiently across different actuator sizes[1][2]. The institute has also developed computational models that accurately predict mechanical behavior across scales, enabling optimization before physical prototyping.

Strengths: Harvard's approach excels in achieving precise control over material properties and internal geometries through advanced manufacturing techniques, allowing for complex, integrated designs impossible with traditional methods. Their computational modeling capabilities enable accurate prediction of performance across scales. Weaknesses: The multi-material 3D printing processes remain relatively slow and expensive for mass production, and the specialized materials developed may have limited commercial availability, potentially restricting widespread adoption.

The Regents of the University of California

Technical Solution: UC Berkeley's Embodied Intelligence Lab has developed a comprehensive technical solution addressing soft pneumatic actuator scalability challenges through their modular fabrication approach. Their system employs a standardized manufacturing platform that creates soft pneumatic actuator components with consistent material properties regardless of size. The platform utilizes a combination of 3D-printed molds and automated silicone casting processes that maintain precise wall thickness control—a critical factor when scaling actuators. Their technical innovation includes a novel fiber reinforcement technique that preserves force output proportionality when scaling actuators up or down, addressing the non-linear scaling issues that typically plague soft actuators[3]. UC researchers have also developed a pressure compensation algorithm that automatically adjusts pneumatic input based on actuator size to maintain consistent performance characteristics. This is complemented by their distributed pneumatic control architecture that uses miniaturized, digitally-controlled pneumatic regulators to precisely manage air delivery to actuators of varying sizes[4].

Strengths: UC Berkeley's modular approach enables consistent manufacturing quality across different scales while maintaining proportional performance characteristics. Their automated fabrication techniques significantly reduce production variability compared to manual methods. Weaknesses: The fiber reinforcement techniques add complexity to the manufacturing process and may limit certain motion patterns. Their pressure compensation systems require additional computational resources and sensing capabilities, potentially increasing system complexity and cost for simpler applications.

Key Patents and Research Breakthroughs in SPA Scaling

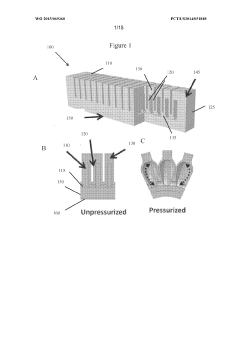

Low strain pneumatic networks for soft robots

PatentWO2015069360A1

Innovation

- Design of pneumatic network actuators with freestanding chambers and a strain limiting base, where interior walls are more compliant than exterior walls, reducing strain and energy loss, and allowing for rapid actuation and increased cycle durability.

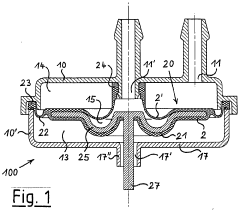

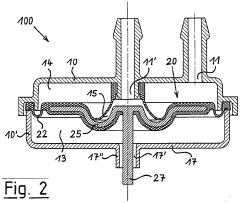

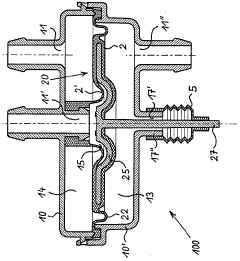

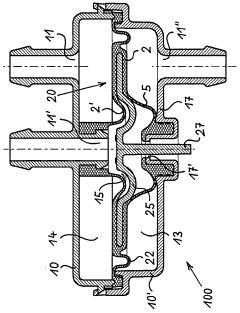

Pneumatic actuator and method for producing a component therefor, said component comprising a regulating membrane and a membrane-carrying body

PatentWO2005088416A1

Innovation

- A pneumatic actuator design featuring three diaphragm chambers, where the control diaphragm and a separating diaphragm are sealingly connected to each other and the housing, allowing for simultaneous action of multiple control pressures without the need for complex housing modifications or additional coupling components, and using a membrane support body to enhance rigidity and simplify production.

Materials Science Advancements for SPA Scalability

Recent advancements in materials science have opened new pathways for addressing the scalability challenges in Soft Pneumatic Actuators (SPAs). Traditional elastomeric materials like silicone rubber, while offering excellent flexibility, often struggle with durability and performance consistency when scaled. Research has now focused on developing composite materials that maintain elasticity while enhancing structural integrity across different size scales.

Fiber-reinforced elastomers represent a significant breakthrough, incorporating high-strength fibers such as carbon, glass, or aramid into elastomeric matrices. These composites demonstrate superior resistance to deformation under pressure while maintaining the flexibility essential for SPA functionality. Studies indicate that strategically oriented fiber reinforcement can increase pressure tolerance by up to 300% compared to non-reinforced counterparts, enabling larger actuators to operate at higher pressures without failure.

Gradient materials with variable stiffness properties are emerging as another promising direction. These materials feature controlled transitions between rigid and flexible regions, allowing designers to reinforce high-stress areas while maintaining overall compliance. This approach has proven particularly effective for addressing the non-uniform stress distribution that occurs when scaling SPAs to larger dimensions.

Self-healing elastomers represent perhaps the most revolutionary development in the field. These materials incorporate microcapsules containing healing agents or utilize dynamic chemical bonds that reform after rupture. When implemented in SPAs, these materials can autonomously repair minor damage caused by repeated actuation cycles or excessive pressure, potentially extending operational lifespans by 40-60% according to laboratory testing.

Nanomaterial-enhanced polymers are also showing promise for SPA applications. The incorporation of nanomaterials such as graphene, carbon nanotubes, or nanocellulose into elastomeric matrices has demonstrated improvements in mechanical properties without significant compromises to flexibility. These nanocomposites exhibit enhanced tear resistance and reduced gas permeability—critical factors for maintaining pneumatic efficiency at various scales.

Manufacturing techniques have evolved alongside these material innovations. Advanced 3D printing methods now enable multi-material fabrication with precisely controlled material gradients and reinforcement patterns. This manufacturing precision allows for optimized material distribution that can be tailored to specific scaling requirements, effectively addressing the mechanical challenges that emerge at different size scales.

Fiber-reinforced elastomers represent a significant breakthrough, incorporating high-strength fibers such as carbon, glass, or aramid into elastomeric matrices. These composites demonstrate superior resistance to deformation under pressure while maintaining the flexibility essential for SPA functionality. Studies indicate that strategically oriented fiber reinforcement can increase pressure tolerance by up to 300% compared to non-reinforced counterparts, enabling larger actuators to operate at higher pressures without failure.

Gradient materials with variable stiffness properties are emerging as another promising direction. These materials feature controlled transitions between rigid and flexible regions, allowing designers to reinforce high-stress areas while maintaining overall compliance. This approach has proven particularly effective for addressing the non-uniform stress distribution that occurs when scaling SPAs to larger dimensions.

Self-healing elastomers represent perhaps the most revolutionary development in the field. These materials incorporate microcapsules containing healing agents or utilize dynamic chemical bonds that reform after rupture. When implemented in SPAs, these materials can autonomously repair minor damage caused by repeated actuation cycles or excessive pressure, potentially extending operational lifespans by 40-60% according to laboratory testing.

Nanomaterial-enhanced polymers are also showing promise for SPA applications. The incorporation of nanomaterials such as graphene, carbon nanotubes, or nanocellulose into elastomeric matrices has demonstrated improvements in mechanical properties without significant compromises to flexibility. These nanocomposites exhibit enhanced tear resistance and reduced gas permeability—critical factors for maintaining pneumatic efficiency at various scales.

Manufacturing techniques have evolved alongside these material innovations. Advanced 3D printing methods now enable multi-material fabrication with precisely controlled material gradients and reinforcement patterns. This manufacturing precision allows for optimized material distribution that can be tailored to specific scaling requirements, effectively addressing the mechanical challenges that emerge at different size scales.

Manufacturing Processes and Fabrication Techniques for SPAs

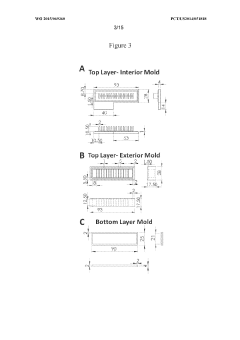

The manufacturing of Soft Pneumatic Actuators (SPAs) presents significant challenges that directly impact their scalability. Traditional fabrication methods for SPAs typically involve multi-step molding processes that are labor-intensive and time-consuming. These processes often include creating molds, mixing and pouring elastomeric materials, curing, demolding, and assembly of various components. Such manual processes introduce variability in the final products and limit production throughput, creating a substantial barrier to mass production.

Material selection represents another critical aspect of SPA manufacturing. Most SPAs utilize silicone elastomers such as PDMS, Ecoflex, or Dragon Skin, which offer excellent flexibility but present challenges in processing. The viscosity of these materials before curing affects their ability to fill complex mold geometries, particularly when scaling down to micro-actuators. Conversely, when scaling up, ensuring uniform material properties throughout larger structures becomes problematic due to curing inconsistencies and air bubble formation.

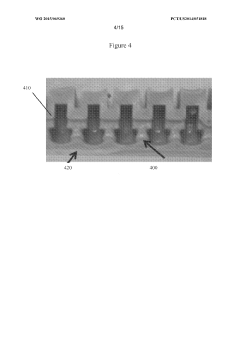

Advanced manufacturing techniques have emerged to address some of these challenges. 3D printing technologies, including fused deposition modeling (FDM) and digital light processing (DLP), offer promising alternatives for SPA fabrication. These methods enable the creation of complex internal channels and chambers without the need for assembly. However, current 3D printing technologies face limitations in material compatibility, resolution, and surface finish quality that affect actuator performance.

Injection molding presents a potential solution for mass production of SPAs, but requires significant initial investment in tooling and equipment. The process also faces challenges in creating the complex internal geometries necessary for pneumatic networks without introducing weak points or seams. Multi-material manufacturing remains particularly challenging, as many SPAs require regions of varying stiffness to achieve directional actuation.

Surface treatment and bonding processes represent another manufacturing hurdle. Creating reliable seals between different components is essential for preventing air leakage, which becomes increasingly difficult as the size of actuators decreases. Current bonding techniques often rely on chemical adhesives or plasma treatment, which may not scale efficiently for mass production.

Quality control and consistency in manufacturing present ongoing challenges. The performance of SPAs depends heavily on wall thickness, channel dimensions, and material properties, all of which can vary during fabrication. Developing standardized testing protocols and in-line quality control methods remains an area requiring significant development to enable reliable mass production of SPAs with predictable performance characteristics.

Material selection represents another critical aspect of SPA manufacturing. Most SPAs utilize silicone elastomers such as PDMS, Ecoflex, or Dragon Skin, which offer excellent flexibility but present challenges in processing. The viscosity of these materials before curing affects their ability to fill complex mold geometries, particularly when scaling down to micro-actuators. Conversely, when scaling up, ensuring uniform material properties throughout larger structures becomes problematic due to curing inconsistencies and air bubble formation.

Advanced manufacturing techniques have emerged to address some of these challenges. 3D printing technologies, including fused deposition modeling (FDM) and digital light processing (DLP), offer promising alternatives for SPA fabrication. These methods enable the creation of complex internal channels and chambers without the need for assembly. However, current 3D printing technologies face limitations in material compatibility, resolution, and surface finish quality that affect actuator performance.

Injection molding presents a potential solution for mass production of SPAs, but requires significant initial investment in tooling and equipment. The process also faces challenges in creating the complex internal geometries necessary for pneumatic networks without introducing weak points or seams. Multi-material manufacturing remains particularly challenging, as many SPAs require regions of varying stiffness to achieve directional actuation.

Surface treatment and bonding processes represent another manufacturing hurdle. Creating reliable seals between different components is essential for preventing air leakage, which becomes increasingly difficult as the size of actuators decreases. Current bonding techniques often rely on chemical adhesives or plasma treatment, which may not scale efficiently for mass production.

Quality control and consistency in manufacturing present ongoing challenges. The performance of SPAs depends heavily on wall thickness, channel dimensions, and material properties, all of which can vary during fabrication. Developing standardized testing protocols and in-line quality control methods remains an area requiring significant development to enable reliable mass production of SPAs with predictable performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!