The Effect of Temperature on Soft Pneumatic Actuator Operation

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Temperature Sensitivity Background

Soft pneumatic actuators (SPAs) represent a significant advancement in the field of soft robotics, offering compliant and adaptable motion capabilities that traditional rigid actuators cannot provide. These actuators, typically fabricated from elastomeric materials, operate through the controlled inflation and deflation of chambers, resulting in predictable deformation patterns. Since their emergence in the early 2000s, SPAs have evolved from simple proof-of-concept designs to sophisticated components in various applications including medical devices, assistive technologies, and industrial automation.

The temperature sensitivity of SPAs constitutes a critical aspect of their operational characteristics that has gained increasing attention in recent years. Unlike conventional rigid actuators, the performance of SPAs is inherently linked to the thermomechanical properties of their constituent elastomers. These materials exhibit significant changes in stiffness, elasticity, and response time across different temperature ranges, directly impacting actuator functionality.

Historical development of SPA technology reveals that early research primarily focused on design optimization and fabrication techniques, with limited consideration for environmental factors such as temperature. The pioneering work by researchers at Harvard University and MIT around 2011-2014 established fundamental design principles but operated under controlled laboratory conditions where temperature effects were minimized or disregarded.

As SPAs transitioned from laboratory curiosities to practical applications, the limitations imposed by temperature variations became increasingly apparent. Field deployments in diverse environments exposed these actuators to temperature fluctuations that significantly altered their performance characteristics. This realization prompted a shift in research focus toward understanding and mitigating temperature-related effects.

The temperature sensitivity of SPAs manifests through several mechanisms. First, elastomer stiffness typically decreases with increasing temperature, resulting in reduced actuation forces but increased displacement at higher temperatures. Second, the viscous properties of elastomers are temperature-dependent, affecting response time and dynamic behavior. Third, thermal expansion of both the elastomer and the working fluid (typically air) introduces additional complexities in predicting actuator behavior across temperature gradients.

Recent technological trends indicate growing interest in developing temperature-compensated SPAs through material innovations, embedded sensing, and adaptive control strategies. The emergence of composite elastomers with tailored thermal properties and the integration of temperature sensors within actuator structures represent promising approaches to addressing these challenges.

The evolution of this field is now moving toward predictive modeling of temperature effects, with computational approaches incorporating thermomechanical coupling to enable more accurate simulation of SPA behavior under varying thermal conditions. This progression reflects the maturation of soft pneumatic actuation technology and its transition toward robust, environmentally resilient systems suitable for real-world deployment.

The temperature sensitivity of SPAs constitutes a critical aspect of their operational characteristics that has gained increasing attention in recent years. Unlike conventional rigid actuators, the performance of SPAs is inherently linked to the thermomechanical properties of their constituent elastomers. These materials exhibit significant changes in stiffness, elasticity, and response time across different temperature ranges, directly impacting actuator functionality.

Historical development of SPA technology reveals that early research primarily focused on design optimization and fabrication techniques, with limited consideration for environmental factors such as temperature. The pioneering work by researchers at Harvard University and MIT around 2011-2014 established fundamental design principles but operated under controlled laboratory conditions where temperature effects were minimized or disregarded.

As SPAs transitioned from laboratory curiosities to practical applications, the limitations imposed by temperature variations became increasingly apparent. Field deployments in diverse environments exposed these actuators to temperature fluctuations that significantly altered their performance characteristics. This realization prompted a shift in research focus toward understanding and mitigating temperature-related effects.

The temperature sensitivity of SPAs manifests through several mechanisms. First, elastomer stiffness typically decreases with increasing temperature, resulting in reduced actuation forces but increased displacement at higher temperatures. Second, the viscous properties of elastomers are temperature-dependent, affecting response time and dynamic behavior. Third, thermal expansion of both the elastomer and the working fluid (typically air) introduces additional complexities in predicting actuator behavior across temperature gradients.

Recent technological trends indicate growing interest in developing temperature-compensated SPAs through material innovations, embedded sensing, and adaptive control strategies. The emergence of composite elastomers with tailored thermal properties and the integration of temperature sensors within actuator structures represent promising approaches to addressing these challenges.

The evolution of this field is now moving toward predictive modeling of temperature effects, with computational approaches incorporating thermomechanical coupling to enable more accurate simulation of SPA behavior under varying thermal conditions. This progression reflects the maturation of soft pneumatic actuation technology and its transition toward robust, environmentally resilient systems suitable for real-world deployment.

Market Applications and Demand Analysis

The market for soft pneumatic actuators (SPAs) is experiencing significant growth driven by their unique capabilities and expanding applications across multiple industries. These actuators offer advantages in terms of flexibility, compliance, and safety compared to traditional rigid actuators, making them particularly valuable in human-machine interaction scenarios.

In the healthcare and medical devices sector, temperature-adaptive SPAs are increasingly sought after for rehabilitation devices, surgical tools, and prosthetics. The global medical robotics market, where these actuators play a crucial role, is projected to grow substantially as healthcare facilities seek solutions that can operate safely across varying temperature environments found in medical settings.

The robotics industry represents another major market segment, particularly for collaborative robots that work alongside humans. These applications demand actuators that maintain consistent performance across temperature fluctuations encountered in manufacturing environments. The soft robotics market is expanding rapidly as industries recognize the value of robots that can adapt to environmental changes while maintaining operational safety.

Wearable technology constitutes a growing application area where temperature-responsive SPAs are essential. These devices must function reliably against body heat and in varying external temperatures. The wearable technology market continues to expand beyond consumer applications into industrial safety and monitoring systems, creating additional demand for temperature-stable soft actuators.

The automotive and aerospace industries are increasingly incorporating soft actuators into their designs for applications ranging from haptic interfaces to adaptive structures. These environments present particularly challenging temperature ranges, from extreme cold at high altitudes to high heat in engine compartments, driving demand for SPAs with broad temperature tolerance.

Market analysis indicates that companies are actively seeking soft actuator solutions that can maintain consistent performance across temperature ranges from -20°C to +80°C without significant degradation in response time or force output. This requirement stems from the diverse deployment environments these actuators encounter in real-world applications.

Research institutions and industrial R&D departments are allocating substantial resources to address temperature-related challenges in SPA operation. This investment reflects market recognition that temperature compensation and adaptation represent critical barriers to widespread commercial adoption of soft pneumatic technologies across industries.

The geographical distribution of market demand shows concentration in regions with advanced manufacturing and healthcare infrastructure, particularly North America, Europe, and East Asia. However, emerging markets are showing increased interest as applications for temperature-resilient soft actuators expand into new sectors and use cases.

In the healthcare and medical devices sector, temperature-adaptive SPAs are increasingly sought after for rehabilitation devices, surgical tools, and prosthetics. The global medical robotics market, where these actuators play a crucial role, is projected to grow substantially as healthcare facilities seek solutions that can operate safely across varying temperature environments found in medical settings.

The robotics industry represents another major market segment, particularly for collaborative robots that work alongside humans. These applications demand actuators that maintain consistent performance across temperature fluctuations encountered in manufacturing environments. The soft robotics market is expanding rapidly as industries recognize the value of robots that can adapt to environmental changes while maintaining operational safety.

Wearable technology constitutes a growing application area where temperature-responsive SPAs are essential. These devices must function reliably against body heat and in varying external temperatures. The wearable technology market continues to expand beyond consumer applications into industrial safety and monitoring systems, creating additional demand for temperature-stable soft actuators.

The automotive and aerospace industries are increasingly incorporating soft actuators into their designs for applications ranging from haptic interfaces to adaptive structures. These environments present particularly challenging temperature ranges, from extreme cold at high altitudes to high heat in engine compartments, driving demand for SPAs with broad temperature tolerance.

Market analysis indicates that companies are actively seeking soft actuator solutions that can maintain consistent performance across temperature ranges from -20°C to +80°C without significant degradation in response time or force output. This requirement stems from the diverse deployment environments these actuators encounter in real-world applications.

Research institutions and industrial R&D departments are allocating substantial resources to address temperature-related challenges in SPA operation. This investment reflects market recognition that temperature compensation and adaptation represent critical barriers to widespread commercial adoption of soft pneumatic technologies across industries.

The geographical distribution of market demand shows concentration in regions with advanced manufacturing and healthcare infrastructure, particularly North America, Europe, and East Asia. However, emerging markets are showing increased interest as applications for temperature-resilient soft actuators expand into new sectors and use cases.

Current Thermal Challenges in Soft Pneumatic Systems

Soft pneumatic actuators (SPAs) face significant operational challenges related to temperature variations, which can substantially impact their performance, durability, and reliability. These thermal challenges represent a critical bottleneck in the widespread adoption of soft robotics technologies across various industries. The viscoelastic materials commonly used in SPAs, such as silicone elastomers and thermoplastic polyurethanes, exhibit pronounced temperature-dependent mechanical properties that directly affect actuation behavior.

At elevated temperatures, elastomeric materials typically experience decreased stiffness and increased compliance, resulting in reduced force output and precision control. Conversely, at lower temperatures, these materials become stiffer and less responsive, requiring higher actuation pressures and exhibiting slower response times. This temperature sensitivity creates significant challenges for applications requiring consistent performance across varying environmental conditions, such as outdoor robotics, medical devices, or industrial automation systems operating in non-controlled environments.

Thermal expansion and contraction of materials present another substantial challenge. Differential thermal expansion between various components of soft pneumatic systems can lead to structural deformation, seal failures, and air leakage at connection points. These issues are particularly problematic in multi-material systems where different thermal expansion coefficients create internal stresses that compromise system integrity and longevity.

The working fluid dynamics within pneumatic systems are also temperature-dependent. Gas laws dictate that air pressure varies with temperature, meaning that a system calibrated at one temperature may deliver significantly different pressures at another temperature, even with identical input parameters. This phenomenon necessitates complex compensation mechanisms or robust control systems that can adapt to changing thermal conditions.

Heat generation during operation represents another critical challenge. Repeated actuation cycles can generate heat through material hysteresis and friction, potentially leading to localized heating and accelerated material degradation. This self-heating effect can create a feedback loop where performance gradually deteriorates during extended operation, limiting the practical duty cycles of soft pneumatic systems.

Current thermal management solutions remain inadequate for many applications. Passive cooling strategies often cannot dissipate heat quickly enough during high-frequency operation, while active cooling systems add complexity, weight, and power requirements that contradict the inherent advantages of soft robotics. Additionally, thermal insulation approaches may protect against external temperature variations but exacerbate internal heat accumulation issues.

At elevated temperatures, elastomeric materials typically experience decreased stiffness and increased compliance, resulting in reduced force output and precision control. Conversely, at lower temperatures, these materials become stiffer and less responsive, requiring higher actuation pressures and exhibiting slower response times. This temperature sensitivity creates significant challenges for applications requiring consistent performance across varying environmental conditions, such as outdoor robotics, medical devices, or industrial automation systems operating in non-controlled environments.

Thermal expansion and contraction of materials present another substantial challenge. Differential thermal expansion between various components of soft pneumatic systems can lead to structural deformation, seal failures, and air leakage at connection points. These issues are particularly problematic in multi-material systems where different thermal expansion coefficients create internal stresses that compromise system integrity and longevity.

The working fluid dynamics within pneumatic systems are also temperature-dependent. Gas laws dictate that air pressure varies with temperature, meaning that a system calibrated at one temperature may deliver significantly different pressures at another temperature, even with identical input parameters. This phenomenon necessitates complex compensation mechanisms or robust control systems that can adapt to changing thermal conditions.

Heat generation during operation represents another critical challenge. Repeated actuation cycles can generate heat through material hysteresis and friction, potentially leading to localized heating and accelerated material degradation. This self-heating effect can create a feedback loop where performance gradually deteriorates during extended operation, limiting the practical duty cycles of soft pneumatic systems.

Current thermal management solutions remain inadequate for many applications. Passive cooling strategies often cannot dissipate heat quickly enough during high-frequency operation, while active cooling systems add complexity, weight, and power requirements that contradict the inherent advantages of soft robotics. Additionally, thermal insulation approaches may protect against external temperature variations but exacerbate internal heat accumulation issues.

Temperature Compensation Techniques

01 Temperature control systems for soft pneumatic actuators

Soft pneumatic actuators can be equipped with temperature control systems to maintain optimal operating conditions. These systems may include temperature sensors, heating elements, and cooling mechanisms that work together to regulate the temperature of the actuator. By controlling the temperature, the performance and lifespan of the soft pneumatic actuator can be improved, especially in environments with varying temperature conditions.- Temperature control systems for soft pneumatic actuators: Temperature control systems are essential for soft pneumatic actuators to maintain optimal performance across varying environmental conditions. These systems typically include temperature sensors, heating elements, and control algorithms that adjust the actuator's internal pressure and temperature. By regulating temperature, these systems prevent performance degradation and ensure consistent operation, particularly in applications requiring precise movements or force control.

- Temperature-responsive materials in soft pneumatic actuators: Incorporating temperature-responsive materials into soft pneumatic actuators enables enhanced functionality and adaptability. These materials can change their properties, such as stiffness or shape, in response to temperature variations. Examples include shape memory polymers, thermally responsive elastomers, and composite materials that exhibit controlled expansion or contraction with temperature changes. These materials allow actuators to perform complex movements or adapt to different environmental conditions without requiring additional mechanical components.

- Thermal management techniques for pneumatic actuation systems: Effective thermal management is crucial for maintaining the performance and longevity of soft pneumatic actuators. Techniques include passive cooling systems, active heat dissipation mechanisms, insulation layers, and thermal barriers. These approaches help prevent overheating during continuous operation, protect temperature-sensitive components, and maintain consistent actuation properties across varying ambient conditions. Advanced thermal management systems may incorporate phase-change materials or specialized cooling channels integrated into the actuator design.

- Temperature sensing and feedback control in pneumatic systems: Temperature sensing and feedback control mechanisms enable real-time monitoring and adjustment of soft pneumatic actuators. These systems typically include distributed temperature sensors, microcontrollers, and adaptive control algorithms that continuously monitor thermal conditions and adjust operating parameters accordingly. By implementing closed-loop control based on temperature feedback, these systems can compensate for thermal expansion, material property changes, and environmental variations, ensuring precise and reliable actuation performance.

- High-temperature applications of soft pneumatic actuators: Specialized soft pneumatic actuators designed for high-temperature environments incorporate heat-resistant materials, protective coatings, and thermal isolation strategies. These actuators can operate in extreme conditions such as industrial furnaces, engines, or space applications. Key design considerations include the use of silicone-based elastomers with high thermal stability, reinforcement structures that maintain integrity at elevated temperatures, and specialized sealing mechanisms that prevent leakage under thermal stress. These high-temperature actuators enable robotic applications in environments previously inaccessible to soft robotics.

02 Temperature-responsive materials in soft pneumatic actuators

Incorporating temperature-responsive materials in soft pneumatic actuators allows for enhanced functionality and control. These materials can change their properties, such as stiffness or shape, in response to temperature variations. This enables the development of actuators that can adapt to different environmental conditions or perform specific functions when exposed to certain temperature ranges, making them suitable for applications in robotics, medical devices, and other fields.Expand Specific Solutions03 Thermal management for high-performance soft pneumatic actuators

Effective thermal management is crucial for maintaining the performance of soft pneumatic actuators, especially in high-demand applications. This involves the use of heat dissipation techniques, insulation materials, and thermal barriers to prevent overheating or freezing. Advanced thermal management systems can help extend the operational range of soft pneumatic actuators in extreme temperature environments, ensuring consistent performance and reliability.Expand Specific Solutions04 Temperature sensing and feedback control in soft pneumatic systems

Integrating temperature sensing and feedback control mechanisms in soft pneumatic actuators enables real-time monitoring and adjustment of operating parameters. These systems use temperature sensors to collect data, which is then processed by control algorithms to adjust the pneumatic pressure, flow rate, or other variables. This closed-loop control approach ensures that the actuator maintains optimal performance despite temperature fluctuations in the environment or within the system itself.Expand Specific Solutions05 Temperature-based actuation mechanisms

Some soft pneumatic actuators utilize temperature changes as a primary or secondary actuation mechanism. These designs leverage thermal expansion, phase changes, or other temperature-dependent phenomena to generate or enhance movement. By combining pneumatic pressure with temperature-based actuation, these systems can achieve more complex movements, greater force output, or improved energy efficiency compared to conventional soft pneumatic actuators.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The soft pneumatic actuator market is in a growth phase, characterized by increasing applications across robotics, medical devices, and industrial automation. The market size is expanding rapidly due to the rising demand for flexible, lightweight actuation systems that can operate in diverse environments. Temperature effects on soft pneumatic actuators represent a critical technical challenge affecting performance reliability. Leading players in this space include established industrial giants like Toyota Motor Corp., Robert Bosch GmbH, and Rolls Royce PLC, who are leveraging their manufacturing expertise to develop temperature-resistant materials. Research institutions such as Fraunhofer-Gesellschaft, Korea Institute of Machinery & Materials, and Cornell University are advancing fundamental understanding of thermal effects on soft materials. Specialized companies like Schlumberger Technologies are developing application-specific solutions for extreme temperature environments, particularly in oil and gas sectors.

Korea Institute of Machinery & Materials

Technical Solution: Korea Institute of Machinery & Materials (KIMM) has developed advanced temperature-compensated soft pneumatic actuators (SPAs) that maintain consistent performance across varying thermal conditions. Their technology incorporates thermally responsive materials within the elastomeric structure that actively counteract expansion/contraction effects caused by temperature fluctuations. KIMM's solution includes a dual-layer design with different thermal expansion coefficients, creating a self-regulating mechanism that maintains consistent actuation force and displacement regardless of ambient temperature changes. Their research has demonstrated operational stability between -20°C and 80°C with less than 5% performance variation. Additionally, KIMM has implemented embedded temperature sensors and microcontrollers that dynamically adjust pneumatic pressure based on real-time temperature readings, ensuring precise motion control in industrial and medical applications.

Strengths: Superior temperature compensation across wide thermal ranges (-20°C to 80°C); integrated sensing and control systems for real-time adaptation; excellent performance consistency (less than 5% variation). Weaknesses: Higher manufacturing complexity due to multi-material construction; increased cost compared to standard SPAs; requires additional electronic components for full temperature compensation functionality.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered thermally-optimized soft pneumatic actuators through their proprietary material formulation and structural design approach. Their technology utilizes specially engineered silicone elastomers with temperature-stabilizing additives that significantly reduce thermal expansion coefficients while maintaining flexibility. These actuators incorporate a multi-chamber design with thermally insulating barriers between chambers, allowing for controlled heat distribution and minimizing performance variations across temperature gradients. Fraunhofer's research has yielded soft actuators capable of maintaining consistent force output (±7% variation) across temperatures ranging from 0°C to 60°C. Their design includes thermally conductive pathways that help dissipate heat during continuous operation, preventing performance degradation from internal heat buildup. Additionally, they've developed computational models that accurately predict actuator behavior under various thermal conditions, enabling application-specific optimization for industries ranging from medical devices to manufacturing automation.

Strengths: Advanced material science approach with proprietary elastomer formulations; excellent thermal stability through structural design; comprehensive modeling capabilities for application-specific optimization. Weaknesses: Higher initial development costs; more complex manufacturing process than standard SPAs; potential limitations in extreme temperature environments beyond tested ranges.

Key Thermal Management Patents and Research

Temperature Responsive Soft Actuator and Method for Manufacturing the Same

PatentActiveKR1020200050552A

Innovation

- A temperature-sensitive soft actuator is developed using a hydrogel laminate composed of a radiation-crosslinked hydrogel passive layer and a radiation-crosslinked temperature-sensitive hydrogel active layer, allowing for simultaneous crosslinking and sterilization without chemical catalysts, ensuring biocompatibility and consistent physical properties.

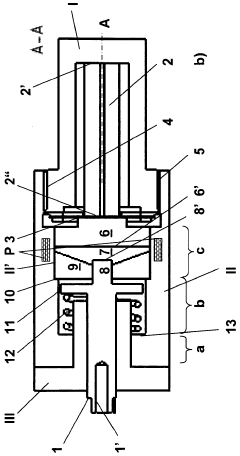

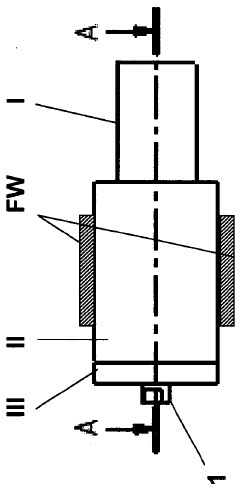

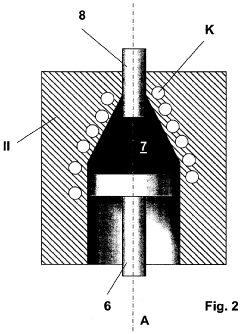

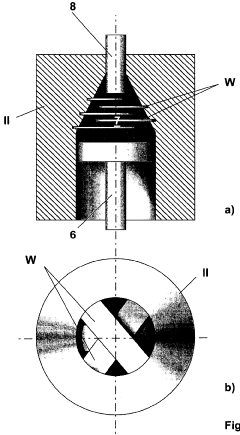

Operating unit having an actuator

PatentWO2011138026A1

Innovation

- The implementation of actively controllable or passive temperature control measures, such as coolant lines or thermoelectric components like Peltier elements, to manage and reduce heat generation within the actuating unit, ensuring stable operation without compromising the actuator's travel transmission principle.

Material Science Innovations for Thermal Stability

Recent advancements in material science have opened new frontiers for enhancing the thermal stability of soft pneumatic actuators (SPAs). Traditional elastomeric materials used in SPAs, such as silicone rubber and thermoplastic polyurethanes, exhibit significant performance variations across temperature ranges, limiting their operational reliability in extreme environments. The development of thermally stable composites represents a critical innovation path for expanding SPA applications.

Composite materials incorporating carbon nanotubes (CNTs) and graphene have demonstrated remarkable thermal conductivity properties, allowing for more uniform heat distribution throughout the actuator structure. These nanomaterials, when properly dispersed within elastomer matrices, create thermal pathways that mitigate localized heating effects that commonly lead to premature material degradation and performance inconsistencies in conventional SPAs.

Temperature-responsive polymers present another promising direction, with materials engineered to maintain consistent mechanical properties across wider temperature ranges. Recent research has focused on developing elastomers with minimal thermal expansion coefficients and reduced glass transition temperature sensitivity. These innovations help maintain dimensional stability and consistent actuation force generation regardless of ambient temperature fluctuations.

Cross-linking optimization techniques have emerged as effective methods for enhancing thermal resilience. Advanced curing processes that create temperature-resistant chemical bonds between polymer chains significantly improve material durability under thermal stress. Multi-stage curing protocols have been shown to increase the operational temperature range of silicone-based actuators by up to 40% compared to conventional single-stage curing methods.

Hybrid material systems combining organic elastomers with inorganic components offer superior thermal stability characteristics. Silica-reinforced elastomers and ceramic-polymer composites demonstrate enhanced resistance to thermal degradation while maintaining the flexibility required for pneumatic actuation. These hybrid materials effectively balance the competing requirements of mechanical compliance and thermal resilience.

Surface treatment innovations, including fluorination and plasma modification techniques, have proven effective in creating thermally resistant boundary layers on actuator surfaces. These treatments modify the surface chemistry of elastomers to reduce thermal oxidation processes that typically accelerate material aging at elevated temperatures, thereby extending operational lifespan in thermally challenging environments.

Biomimetic approaches drawing inspiration from heat-adapted organisms have led to novel material architectures with inherent thermal stability. Layered composite structures mimicking the heat-resistant properties of certain plant tissues and insect exoskeletons show promise for next-generation SPA designs intended for extreme temperature applications in aerospace, deep-sea exploration, and industrial automation sectors.

Composite materials incorporating carbon nanotubes (CNTs) and graphene have demonstrated remarkable thermal conductivity properties, allowing for more uniform heat distribution throughout the actuator structure. These nanomaterials, when properly dispersed within elastomer matrices, create thermal pathways that mitigate localized heating effects that commonly lead to premature material degradation and performance inconsistencies in conventional SPAs.

Temperature-responsive polymers present another promising direction, with materials engineered to maintain consistent mechanical properties across wider temperature ranges. Recent research has focused on developing elastomers with minimal thermal expansion coefficients and reduced glass transition temperature sensitivity. These innovations help maintain dimensional stability and consistent actuation force generation regardless of ambient temperature fluctuations.

Cross-linking optimization techniques have emerged as effective methods for enhancing thermal resilience. Advanced curing processes that create temperature-resistant chemical bonds between polymer chains significantly improve material durability under thermal stress. Multi-stage curing protocols have been shown to increase the operational temperature range of silicone-based actuators by up to 40% compared to conventional single-stage curing methods.

Hybrid material systems combining organic elastomers with inorganic components offer superior thermal stability characteristics. Silica-reinforced elastomers and ceramic-polymer composites demonstrate enhanced resistance to thermal degradation while maintaining the flexibility required for pneumatic actuation. These hybrid materials effectively balance the competing requirements of mechanical compliance and thermal resilience.

Surface treatment innovations, including fluorination and plasma modification techniques, have proven effective in creating thermally resistant boundary layers on actuator surfaces. These treatments modify the surface chemistry of elastomers to reduce thermal oxidation processes that typically accelerate material aging at elevated temperatures, thereby extending operational lifespan in thermally challenging environments.

Biomimetic approaches drawing inspiration from heat-adapted organisms have led to novel material architectures with inherent thermal stability. Layered composite structures mimicking the heat-resistant properties of certain plant tissues and insect exoskeletons show promise for next-generation SPA designs intended for extreme temperature applications in aerospace, deep-sea exploration, and industrial automation sectors.

Environmental Testing Standards and Protocols

Environmental testing standards for soft pneumatic actuators (SPAs) must follow rigorous protocols to ensure reliable performance across varying temperature conditions. The International Organization for Standardization (ISO) provides several relevant standards, including ISO 9022 for environmental testing of optical equipment and ISO 15189 for quality management in testing laboratories. These standards establish baseline requirements for temperature range testing, typically from -40°C to +85°C for industrial applications, with more extreme ranges for aerospace or cryogenic implementations.

ASTM International offers complementary standards such as ASTM D2240 for hardness testing of elastomers and ASTM D412 for tensile properties, both critical for evaluating temperature effects on SPA materials. These standards recommend controlled temperature ramping rates of 2-5°C per minute to prevent thermal shock during transitions between temperature extremes.

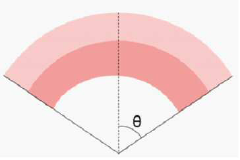

Testing protocols specifically designed for SPAs should include thermal cycling tests with a minimum of 1,000 cycles between operational temperature extremes. Each cycle should maintain dwell times of at least 30 minutes at temperature extremes to allow for complete thermal equilibration throughout the actuator structure. Performance metrics including actuation force, displacement, response time, and air consumption must be measured at standardized intervals during these cycles.

Humidity control represents another critical testing parameter, with standards recommending combined temperature-humidity testing according to IEC 60068-2-78. This protocol specifies maintaining relative humidity between 85-95% during high-temperature testing phases to simulate real-world operating conditions where moisture and heat often coexist.

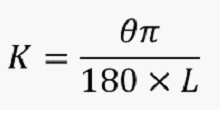

Accelerated aging tests should follow ASTM F1980 guidelines, with temperature acceleration factors calculated using the Arrhenius equation. For elastomeric materials common in SPAs, a 10°C increase typically accelerates aging by a factor of 2, allowing researchers to estimate long-term performance degradation within reasonable testing timeframes.

Data collection during environmental testing must adhere to metrological standards such as ISO/IEC 17025, ensuring measurement accuracy through calibrated instrumentation with documented uncertainty values. Testing reports should include detailed temperature profiles, measured performance metrics, and statistical analysis of variance across multiple test specimens to establish confidence intervals for operational parameters.

ASTM International offers complementary standards such as ASTM D2240 for hardness testing of elastomers and ASTM D412 for tensile properties, both critical for evaluating temperature effects on SPA materials. These standards recommend controlled temperature ramping rates of 2-5°C per minute to prevent thermal shock during transitions between temperature extremes.

Testing protocols specifically designed for SPAs should include thermal cycling tests with a minimum of 1,000 cycles between operational temperature extremes. Each cycle should maintain dwell times of at least 30 minutes at temperature extremes to allow for complete thermal equilibration throughout the actuator structure. Performance metrics including actuation force, displacement, response time, and air consumption must be measured at standardized intervals during these cycles.

Humidity control represents another critical testing parameter, with standards recommending combined temperature-humidity testing according to IEC 60068-2-78. This protocol specifies maintaining relative humidity between 85-95% during high-temperature testing phases to simulate real-world operating conditions where moisture and heat often coexist.

Accelerated aging tests should follow ASTM F1980 guidelines, with temperature acceleration factors calculated using the Arrhenius equation. For elastomeric materials common in SPAs, a 10°C increase typically accelerates aging by a factor of 2, allowing researchers to estimate long-term performance degradation within reasonable testing timeframes.

Data collection during environmental testing must adhere to metrological standards such as ISO/IEC 17025, ensuring measurement accuracy through calibrated instrumentation with documented uncertainty values. Testing reports should include detailed temperature profiles, measured performance metrics, and statistical analysis of variance across multiple test specimens to establish confidence intervals for operational parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!