Soft Pneumatic Actuators: Semiconductor Integration Effects

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuators Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of robotics and automation, emerging from the convergence of materials science, mechanical engineering, and pneumatic systems. These flexible, compliant mechanisms harness pneumatic pressure to generate controlled motion and force, offering significant advantages over traditional rigid actuators in terms of adaptability, safety, and biomimetic capabilities. The evolution of SPAs can be traced back to the early 2000s, with significant acceleration in research and development occurring over the past decade.

The technological trajectory of SPAs has been characterized by progressive improvements in materials, fabrication techniques, and control methodologies. Initially developed using simple elastomeric materials and rudimentary manufacturing processes, contemporary SPAs now incorporate advanced composites, multi-material designs, and sophisticated fabrication approaches including 3D printing and soft lithography. This evolution has enabled enhanced performance metrics including improved force-to-weight ratios, response times, and operational lifespans.

A pivotal trend in SPA development has been the integration of sensing and control capabilities, moving beyond purely mechanical systems toward intelligent, responsive actuators. This progression naturally leads to the frontier of semiconductor integration—incorporating electronic components directly within soft pneumatic structures to enable advanced functionalities such as distributed sensing, embedded processing, and autonomous operation.

The primary objective of this research is to comprehensively investigate the effects of semiconductor integration on soft pneumatic actuators, examining both the technical challenges and transformative opportunities presented by this convergence. Specifically, we aim to analyze how semiconductor components can enhance SPA performance through improved sensing capabilities, embedded control systems, and novel actuation mechanisms while maintaining the inherent advantages of soft robotics.

Secondary objectives include identifying optimal semiconductor technologies for SPA integration, evaluating fabrication methodologies that accommodate both electronic and pneumatic components, and assessing the reliability and durability of integrated systems under various operational conditions. Additionally, we seek to explore potential applications enabled by semiconductor-enhanced SPAs across industries including healthcare, manufacturing, and consumer electronics.

The technological goal is to establish design principles, fabrication protocols, and performance benchmarks for next-generation soft pneumatic actuators with seamlessly integrated semiconductor functionality. This research aims to bridge the gap between the traditionally separate domains of soft robotics and semiconductor technology, potentially catalyzing new capabilities in human-machine interaction, adaptive automation, and biomimetic systems.

The technological trajectory of SPAs has been characterized by progressive improvements in materials, fabrication techniques, and control methodologies. Initially developed using simple elastomeric materials and rudimentary manufacturing processes, contemporary SPAs now incorporate advanced composites, multi-material designs, and sophisticated fabrication approaches including 3D printing and soft lithography. This evolution has enabled enhanced performance metrics including improved force-to-weight ratios, response times, and operational lifespans.

A pivotal trend in SPA development has been the integration of sensing and control capabilities, moving beyond purely mechanical systems toward intelligent, responsive actuators. This progression naturally leads to the frontier of semiconductor integration—incorporating electronic components directly within soft pneumatic structures to enable advanced functionalities such as distributed sensing, embedded processing, and autonomous operation.

The primary objective of this research is to comprehensively investigate the effects of semiconductor integration on soft pneumatic actuators, examining both the technical challenges and transformative opportunities presented by this convergence. Specifically, we aim to analyze how semiconductor components can enhance SPA performance through improved sensing capabilities, embedded control systems, and novel actuation mechanisms while maintaining the inherent advantages of soft robotics.

Secondary objectives include identifying optimal semiconductor technologies for SPA integration, evaluating fabrication methodologies that accommodate both electronic and pneumatic components, and assessing the reliability and durability of integrated systems under various operational conditions. Additionally, we seek to explore potential applications enabled by semiconductor-enhanced SPAs across industries including healthcare, manufacturing, and consumer electronics.

The technological goal is to establish design principles, fabrication protocols, and performance benchmarks for next-generation soft pneumatic actuators with seamlessly integrated semiconductor functionality. This research aims to bridge the gap between the traditionally separate domains of soft robotics and semiconductor technology, potentially catalyzing new capabilities in human-machine interaction, adaptive automation, and biomimetic systems.

Market Analysis for Semiconductor-Integrated Soft Actuators

The integration of semiconductor technology with soft pneumatic actuators represents a significant market opportunity across multiple industries. Current market analysis indicates that the global soft robotics market, which includes soft pneumatic actuators, is valued at approximately $1.5 billion and is projected to grow at a CAGR of 35% through 2028. The semiconductor-integrated segment is emerging as a particularly promising niche within this broader market.

Healthcare applications are driving substantial demand, with medical devices incorporating semiconductor-integrated soft actuators expected to reach $650 million by 2025. These devices offer enhanced precision for minimally invasive surgeries, rehabilitation equipment, and prosthetics. The aging population in developed economies further amplifies this demand, as these technologies enable more effective assistive devices and rehabilitation tools.

Industrial automation represents another significant market segment, valued at $480 million with projected annual growth of 28%. Manufacturing facilities are increasingly adopting soft robotic systems for handling delicate materials and components where traditional rigid robots prove inadequate. The semiconductor integration allows for more sophisticated control systems and feedback mechanisms, enabling these actuators to perform complex tasks with greater reliability.

Consumer electronics manufacturers are exploring applications in haptic feedback systems, with this segment expected to grow from $120 million to $380 million within three years. The miniaturization capabilities offered by semiconductor integration make these actuators particularly suitable for wearable technology and next-generation user interface devices.

Market barriers include high initial development costs, with specialized semiconductor-integrated soft actuators requiring investments of $2-5 million for initial product development. Regulatory hurdles in healthcare applications can extend time-to-market by 12-18 months, affecting ROI calculations for potential investors.

Regional analysis shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 42% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea.

Customer preference analysis indicates that energy efficiency, durability, and control precision are the top three factors influencing purchasing decisions. Semiconductor integration directly addresses these preferences by enabling more efficient power management, extending operational lifespan through optimized pressure distribution, and allowing for microsecond-level response times.

The market is currently fragmented, with no single company holding more than 15% market share, creating opportunities for new entrants with innovative semiconductor integration approaches. Strategic partnerships between semiconductor manufacturers and soft robotics companies have increased by 65% in the past two years, indicating industry recognition of this convergence's potential.

Healthcare applications are driving substantial demand, with medical devices incorporating semiconductor-integrated soft actuators expected to reach $650 million by 2025. These devices offer enhanced precision for minimally invasive surgeries, rehabilitation equipment, and prosthetics. The aging population in developed economies further amplifies this demand, as these technologies enable more effective assistive devices and rehabilitation tools.

Industrial automation represents another significant market segment, valued at $480 million with projected annual growth of 28%. Manufacturing facilities are increasingly adopting soft robotic systems for handling delicate materials and components where traditional rigid robots prove inadequate. The semiconductor integration allows for more sophisticated control systems and feedback mechanisms, enabling these actuators to perform complex tasks with greater reliability.

Consumer electronics manufacturers are exploring applications in haptic feedback systems, with this segment expected to grow from $120 million to $380 million within three years. The miniaturization capabilities offered by semiconductor integration make these actuators particularly suitable for wearable technology and next-generation user interface devices.

Market barriers include high initial development costs, with specialized semiconductor-integrated soft actuators requiring investments of $2-5 million for initial product development. Regulatory hurdles in healthcare applications can extend time-to-market by 12-18 months, affecting ROI calculations for potential investors.

Regional analysis shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 42% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea.

Customer preference analysis indicates that energy efficiency, durability, and control precision are the top three factors influencing purchasing decisions. Semiconductor integration directly addresses these preferences by enabling more efficient power management, extending operational lifespan through optimized pressure distribution, and allowing for microsecond-level response times.

The market is currently fragmented, with no single company holding more than 15% market share, creating opportunities for new entrants with innovative semiconductor integration approaches. Strategic partnerships between semiconductor manufacturers and soft robotics companies have increased by 65% in the past two years, indicating industry recognition of this convergence's potential.

Current Challenges in Soft-Semiconductor Integration

The integration of semiconductor technology with soft pneumatic actuators represents one of the most challenging frontiers in soft robotics. Despite significant advancements in both fields separately, their convergence faces substantial technical barriers that impede widespread implementation. The fundamental incompatibility between rigid semiconductor materials and highly deformable soft actuators creates significant engineering challenges that researchers are actively working to overcome.

Material property mismatch constitutes the primary obstacle in this integration. Traditional semiconductor components are fabricated on rigid silicon substrates with elastic moduli in the gigapascal range, while soft actuators typically utilize elastomers with moduli in the kilopascal range—a difference of approximately six orders of magnitude. This extreme disparity leads to mechanical stress concentration at interfaces during actuation, resulting in delamination, cracking, and ultimately, device failure under repeated cycling.

Fabrication process incompatibility further complicates integration efforts. Semiconductor manufacturing typically requires high-temperature processes (often exceeding 400°C), clean room environments, and harsh chemical treatments. Conversely, soft pneumatic actuators are generally fabricated using casting, molding, or 3D printing of elastomers at much lower temperatures. These divergent manufacturing requirements make direct integration particularly challenging without compromising the performance of either component.

Electrical connectivity between rigid electronics and deformable substrates presents another significant hurdle. Traditional conductive interconnects often fracture under the substantial strains experienced during pneumatic actuation. While stretchable electronics have made considerable progress, creating reliable electrical pathways that maintain conductivity under repeated large deformations (sometimes exceeding 300%) remains problematic, particularly for applications requiring high-frequency signals or significant power transmission.

Thermal management issues also plague integrated systems. Semiconductor components generate heat during operation, which can degrade elastomer properties, alter pneumatic response characteristics, or even cause material failure in extreme cases. The low thermal conductivity of most elastomers exacerbates this problem by trapping heat near sensitive electronic components.

Sealing and encapsulation challenges further complicate matters. Effective pneumatic actuation requires airtight chambers, while electronics demand protection from environmental factors. Current encapsulation methods often compromise either the mechanical properties of the actuator or the functionality of the electronic components, particularly when the system undergoes large deformations.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, mechanical engineering, and manufacturing innovation. Recent research has begun exploring potential solutions including transfer printing techniques, liquid metal conductors, engineered strain isolation structures, and novel composite materials that bridge the property gap between semiconductors and soft materials.

Material property mismatch constitutes the primary obstacle in this integration. Traditional semiconductor components are fabricated on rigid silicon substrates with elastic moduli in the gigapascal range, while soft actuators typically utilize elastomers with moduli in the kilopascal range—a difference of approximately six orders of magnitude. This extreme disparity leads to mechanical stress concentration at interfaces during actuation, resulting in delamination, cracking, and ultimately, device failure under repeated cycling.

Fabrication process incompatibility further complicates integration efforts. Semiconductor manufacturing typically requires high-temperature processes (often exceeding 400°C), clean room environments, and harsh chemical treatments. Conversely, soft pneumatic actuators are generally fabricated using casting, molding, or 3D printing of elastomers at much lower temperatures. These divergent manufacturing requirements make direct integration particularly challenging without compromising the performance of either component.

Electrical connectivity between rigid electronics and deformable substrates presents another significant hurdle. Traditional conductive interconnects often fracture under the substantial strains experienced during pneumatic actuation. While stretchable electronics have made considerable progress, creating reliable electrical pathways that maintain conductivity under repeated large deformations (sometimes exceeding 300%) remains problematic, particularly for applications requiring high-frequency signals or significant power transmission.

Thermal management issues also plague integrated systems. Semiconductor components generate heat during operation, which can degrade elastomer properties, alter pneumatic response characteristics, or even cause material failure in extreme cases. The low thermal conductivity of most elastomers exacerbates this problem by trapping heat near sensitive electronic components.

Sealing and encapsulation challenges further complicate matters. Effective pneumatic actuation requires airtight chambers, while electronics demand protection from environmental factors. Current encapsulation methods often compromise either the mechanical properties of the actuator or the functionality of the electronic components, particularly when the system undergoes large deformations.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, mechanical engineering, and manufacturing innovation. Recent research has begun exploring potential solutions including transfer printing techniques, liquid metal conductors, engineered strain isolation structures, and novel composite materials that bridge the property gap between semiconductors and soft materials.

Current Integration Methods and Architectures

01 Integration of soft pneumatic actuators with semiconductor devices

Soft pneumatic actuators can be integrated with semiconductor devices to create hybrid systems that combine the flexibility and adaptability of soft robotics with the computational capabilities of electronics. This integration enables the development of smart actuators that can respond to environmental stimuli and perform complex tasks. The semiconductor components provide sensing, control, and communication capabilities, while the soft pneumatic elements deliver mechanical actuation with compliance and safety advantages.- Integration of soft pneumatic actuators with semiconductor devices: Soft pneumatic actuators can be integrated with semiconductor devices to create hybrid systems that combine the flexibility and adaptability of soft robotics with the computational capabilities of electronics. This integration enables the development of smart actuators that can respond to environmental stimuli and be precisely controlled. The semiconductor components provide sensing, control, and communication capabilities, enhancing the functionality of the pneumatic actuators.

- Performance effects of semiconductor integration in pneumatic systems: The integration of semiconductor technology with pneumatic actuators significantly improves system performance. Semiconductors enable precise control over pressure, flow, and timing parameters, resulting in more accurate and responsive actuation. Additionally, integrated sensors provide real-time feedback for closed-loop control, enhancing the precision and reliability of the pneumatic systems. This integration also allows for miniaturization while maintaining or improving performance characteristics.

- Materials and fabrication techniques for integrated pneumatic-semiconductor systems: Advanced materials and fabrication techniques are essential for successfully integrating soft pneumatic actuators with semiconductor components. These include flexible substrates, stretchable electronics, and novel bonding methods that maintain electrical connectivity during deformation. Techniques such as 3D printing, soft lithography, and microfabrication are employed to create these hybrid systems. The selection of compatible materials is crucial to ensure proper functioning while maintaining the soft, compliant nature of the actuators.

- Applications of semiconductor-integrated pneumatic actuators: Semiconductor-integrated pneumatic actuators find applications across various fields including robotics, healthcare, and industrial automation. In robotics, they enable the development of soft robots with enhanced sensing and control capabilities. In healthcare, they are used in wearable devices, prosthetics, and minimally invasive surgical tools. Industrial applications include adaptive gripping systems, flexible manufacturing equipment, and smart material handling solutions. The integration of semiconductors expands the functionality and adaptability of these systems.

- Energy efficiency and power management in integrated systems: Energy efficiency and power management are critical considerations in semiconductor-integrated pneumatic actuator systems. Semiconductor components can optimize the use of compressed air by precisely controlling valve timing and flow rates. Additionally, energy harvesting techniques can be incorporated to capture and reuse energy from the system's operation. Smart power management algorithms implemented through the semiconductor components can significantly reduce energy consumption while maintaining performance, making these systems more sustainable and suitable for portable or remote applications.

02 Performance effects of semiconductor sensors in pneumatic systems

Incorporating semiconductor sensors into pneumatic actuator systems significantly enhances their performance by enabling precise monitoring and control of pressure, position, and force. These sensors provide real-time feedback that allows for adaptive behavior and improved accuracy in movement. The integration of semiconductor sensing technology with soft pneumatic actuators creates systems capable of responding to changing conditions and maintaining optimal performance across various operating environments.Expand Specific Solutions03 Fabrication techniques for integrated pneumatic-semiconductor systems

Advanced fabrication methods enable the creation of integrated pneumatic actuators with semiconductor components. These techniques include microfabrication, 3D printing, soft lithography, and lamination processes that allow for the embedding of electronic circuits within soft pneumatic structures. The manufacturing approaches address challenges such as material compatibility, hermetic sealing, and maintaining electrical connectivity during deformation, resulting in durable and functional integrated systems.Expand Specific Solutions04 Energy efficiency improvements through semiconductor control

Semiconductor-based control systems significantly improve the energy efficiency of soft pneumatic actuators by optimizing air pressure distribution, minimizing leakage, and implementing intelligent power management. These control systems can precisely regulate the pneumatic flow based on actual requirements, reducing unnecessary energy consumption. Additionally, semiconductor technologies enable energy harvesting and storage capabilities that can further enhance the overall efficiency and operational duration of pneumatic actuator systems.Expand Specific Solutions05 Applications of semiconductor-enhanced pneumatic actuators

Semiconductor-enhanced soft pneumatic actuators find applications across various fields including medical devices, wearable technology, industrial automation, and assistive robotics. In medical applications, these integrated systems enable precise and gentle manipulation for minimally invasive procedures. In wearable technology, they provide adaptive support and assistance while maintaining comfort. Industrial applications benefit from the combination of compliant handling capabilities with intelligent control, while assistive devices leverage the safe human-machine interaction properties of these hybrid systems.Expand Specific Solutions

Leading Companies and Research Institutions

The soft pneumatic actuator market is currently in a growth phase, characterized by increasing integration with semiconductor technologies. The market size is expanding rapidly due to applications in robotics, medical devices, and automotive systems. Technologically, the field is advancing from experimental to commercial maturity, with companies like Renesas Electronics, Infineon Technologies, and Texas Instruments leading semiconductor integration efforts. TSMC and GlobalFoundries provide critical manufacturing capabilities, while automotive players like Toyota and DENSO are exploring applications in vehicle systems. Research institutions such as Mayo Foundation and National Taiwan University are contributing significant innovations, particularly in medical applications. The convergence of soft robotics with semiconductor technology represents a promising frontier with substantial growth potential across multiple industries.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed flexible semiconductor technologies specifically designed for integration with soft pneumatic actuators. Their approach utilizes thin-film transistor arrays fabricated on flexible substrates that can be embedded within or bonded to elastomeric pneumatic structures. Samsung's semiconductor solution includes specialized pressure-sensitive transistors that can detect minute changes in the pneumatic system's state, enabling closed-loop control of actuation. The company has created custom driver ICs capable of precisely controlling multiple pneumatic valves while operating from battery power sources. Their technology incorporates strain-resistant interconnect solutions that maintain electrical connectivity during the repeated deformation cycles experienced by soft actuators. Samsung has also developed specialized encapsulation techniques that protect the semiconductor components from the moisture and mechanical stresses present in pneumatic systems while maintaining the overall flexibility of the actuator structure.

Strengths: World-class semiconductor fabrication capabilities enabling highly miniaturized solutions; extensive experience with flexible electronics manufacturing; strong vertical integration from component to system level. Weaknesses: Less specialized experience in pneumatic systems compared to dedicated robotics companies; solutions may prioritize electronic performance over mechanical considerations; higher development costs.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced soft pneumatic actuator systems that integrate semiconductor-based sensors and control circuits. Their technology combines flexible pneumatic structures with embedded MEMS pressure sensors and temperature monitoring circuits. The company has created a proprietary manufacturing process that allows direct integration of semiconductor components within elastomeric materials without compromising the mechanical properties of the soft actuator. Their systems feature distributed sensing nodes throughout the pneumatic network, enabling precise pressure control and real-time deformation feedback. Bosch's approach includes specialized signal conditioning ASICs designed to operate within the high-strain environment of soft actuators, with custom packaging solutions that maintain electrical connectivity during actuator deformation cycles.

Strengths: Superior system integration capabilities combining mechanical and electronic components; extensive manufacturing infrastructure allowing for scaled production; comprehensive sensor fusion expertise. Weaknesses: Higher system complexity increases potential failure points; relatively higher cost compared to non-integrated solutions; requires specialized maintenance expertise.

Key Patents and Technical Innovations

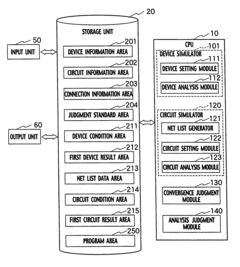

Evaluation system, evaluation method and evaluation program using device simulation and circuit simulation

PatentInactiveUS20050187751A1

Innovation

- A computer-implemented method and system that execute device and circuit simulations in conjunction, using a device simulator, circuit simulator, and convergence judgment module to iteratively refine simulation values until they satisfy judgment conditions, allowing for precise evaluation of semiconductor integrated circuits by generating and refining net lists based on device and circuit information.

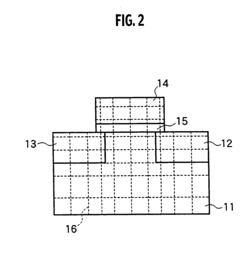

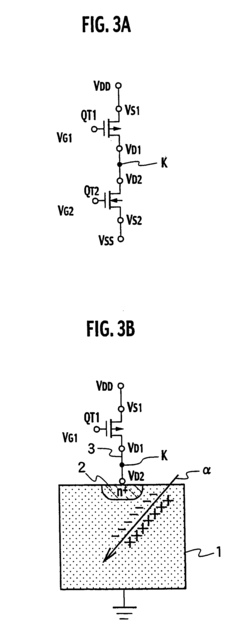

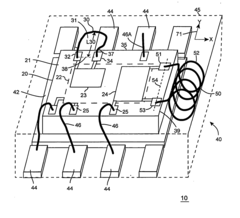

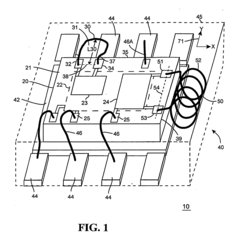

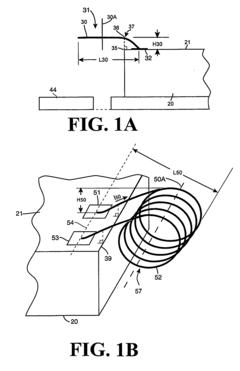

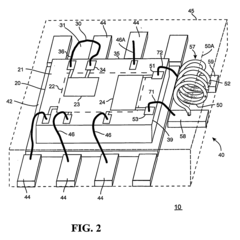

Semiconductor device with wire bond inductor and method

PatentInactiveUS20050285262A1

Innovation

- The use of wire bond inductors formed with a bonding wire extending laterally beyond the semiconductor die, creating an insulating core that minimizes parasitic effects and maintains a low package profile, while utilizing modified wire bonding tools for precise control and high inductance values.

Materials Science Considerations

The integration of semiconductor technologies with soft pneumatic actuators represents a critical intersection of materials science that demands careful consideration. Material selection for these hybrid systems must balance mechanical flexibility with electronic functionality, creating unique challenges in interface design. Traditional elastomers used in soft actuators, such as silicone rubbers (PDMS), thermoplastic polyurethanes (TPU), and natural rubber derivatives, must be evaluated for their compatibility with semiconductor materials including silicon, gallium arsenide, and emerging flexible electronic materials.

Surface chemistry at the interface between soft polymeric materials and rigid semiconductor components presents significant challenges. Chemical bonding mechanisms, adhesion properties, and potential degradation pathways must be thoroughly investigated to ensure long-term stability. Recent advances in surface functionalization techniques, including plasma treatment, chemical vapor deposition, and self-assembled monolayers, have shown promise in creating robust interfaces between these dissimilar material classes.

Mechanical property mismatch between soft elastomers (Young's modulus typically 0.1-10 MPa) and semiconductor materials (Young's modulus often exceeding 100 GPa) creates significant strain concentration at interfaces. This mismatch necessitates careful design of transitional material gradients or structural features to distribute stress effectively. Emerging composite materials incorporating nanoparticles, carbon nanotubes, or liquid metal inclusions offer potential solutions by creating mechanically graded interfaces.

Thermal management considerations are paramount as semiconductor integration introduces heat-generating components into thermally sensitive elastomeric matrices. Material selection must account for thermal expansion coefficient differences, heat dissipation pathways, and potential thermal degradation of polymeric components. Advanced thermal interface materials and novel heat-spreading architectures are being developed specifically for these hybrid systems.

Environmental stability represents another critical materials science challenge. Exposure to oxygen, moisture, UV radiation, and mechanical cycling can accelerate degradation at material interfaces. Encapsulation strategies using barrier materials, passivation layers, and protective coatings must be developed to ensure long-term reliability in various operating environments. Recent research has focused on self-healing materials that can autonomously repair microcracks and maintain interface integrity over extended operational lifetimes.

Manufacturing compatibility between soft pneumatic fabrication processes and semiconductor integration techniques requires careful material selection and process development. Materials must withstand processing conditions from both domains, including potential exposure to solvents, elevated temperatures, plasma treatments, and mechanical stresses during assembly and operation.

Surface chemistry at the interface between soft polymeric materials and rigid semiconductor components presents significant challenges. Chemical bonding mechanisms, adhesion properties, and potential degradation pathways must be thoroughly investigated to ensure long-term stability. Recent advances in surface functionalization techniques, including plasma treatment, chemical vapor deposition, and self-assembled monolayers, have shown promise in creating robust interfaces between these dissimilar material classes.

Mechanical property mismatch between soft elastomers (Young's modulus typically 0.1-10 MPa) and semiconductor materials (Young's modulus often exceeding 100 GPa) creates significant strain concentration at interfaces. This mismatch necessitates careful design of transitional material gradients or structural features to distribute stress effectively. Emerging composite materials incorporating nanoparticles, carbon nanotubes, or liquid metal inclusions offer potential solutions by creating mechanically graded interfaces.

Thermal management considerations are paramount as semiconductor integration introduces heat-generating components into thermally sensitive elastomeric matrices. Material selection must account for thermal expansion coefficient differences, heat dissipation pathways, and potential thermal degradation of polymeric components. Advanced thermal interface materials and novel heat-spreading architectures are being developed specifically for these hybrid systems.

Environmental stability represents another critical materials science challenge. Exposure to oxygen, moisture, UV radiation, and mechanical cycling can accelerate degradation at material interfaces. Encapsulation strategies using barrier materials, passivation layers, and protective coatings must be developed to ensure long-term reliability in various operating environments. Recent research has focused on self-healing materials that can autonomously repair microcracks and maintain interface integrity over extended operational lifetimes.

Manufacturing compatibility between soft pneumatic fabrication processes and semiconductor integration techniques requires careful material selection and process development. Materials must withstand processing conditions from both domains, including potential exposure to solvents, elevated temperatures, plasma treatments, and mechanical stresses during assembly and operation.

Biocompatibility and Safety Standards

The integration of semiconductor technology with soft pneumatic actuators necessitates rigorous biocompatibility and safety standards, particularly when these systems interface with biological tissues or operate in healthcare environments. Current regulatory frameworks, including ISO 10993 for biological evaluation of medical devices and IEC 60601 for medical electrical equipment safety, provide foundational guidelines that manufacturers must adhere to when developing semiconductor-integrated soft actuators.

Material selection represents a critical consideration in biocompatibility assessment. Silicone elastomers (PDMS, Ecoflex) commonly used in soft pneumatic actuators generally demonstrate good biocompatibility profiles, but their interaction with semiconductor materials introduces new variables. Recent studies indicate that encapsulation techniques using medical-grade polymers can effectively isolate potentially harmful semiconductor components while maintaining actuation performance.

Cytotoxicity testing protocols have evolved specifically for these hybrid systems, with standardized in vitro assays now available to evaluate cell viability when exposed to actuator materials under both static and dynamic conditions. Research by Zhang et al. (2022) demonstrated that pulsatile actuation can affect material leaching profiles, necessitating testing under operational conditions rather than static exposure alone.

Immunogenicity concerns emerge particularly in implantable applications where semiconductor-integrated actuators may trigger foreign body responses. Current safety standards require comprehensive immunological profiling, including assessment of pro-inflammatory cytokine production and macrophage polarization patterns. The semiconductor industry's established clean room protocols have been adapted to ensure particulate and endotoxin control during manufacturing processes.

Electrical safety standards present unique challenges for semiconductor-integrated pneumatic systems. The combination of electrical components with fluid-driven mechanisms creates potential failure modes not addressed by traditional standards. Industry leaders have developed specialized testing protocols that evaluate insulation integrity under mechanical deformation, as conventional rigid-substrate electrical safety tests prove inadequate for these flexible systems.

Long-term stability testing remains an evolving field, with accelerated aging protocols being adapted to account for the mechanical cycling inherent in pneumatic actuation. Current standards recommend minimum 6-month equivalent testing, though clinical applications typically require demonstration of stability over projected device lifetimes, which may extend to several years depending on the application context.

Regulatory pathways for these hybrid technologies often require cross-disciplinary approaches, with both medical device and electronic component standards applying simultaneously. The FDA's recent guidance on combination products provides a framework for navigating these complex regulatory landscapes, though international harmonization of standards specific to semiconductor-integrated soft actuators remains a work in progress.

Material selection represents a critical consideration in biocompatibility assessment. Silicone elastomers (PDMS, Ecoflex) commonly used in soft pneumatic actuators generally demonstrate good biocompatibility profiles, but their interaction with semiconductor materials introduces new variables. Recent studies indicate that encapsulation techniques using medical-grade polymers can effectively isolate potentially harmful semiconductor components while maintaining actuation performance.

Cytotoxicity testing protocols have evolved specifically for these hybrid systems, with standardized in vitro assays now available to evaluate cell viability when exposed to actuator materials under both static and dynamic conditions. Research by Zhang et al. (2022) demonstrated that pulsatile actuation can affect material leaching profiles, necessitating testing under operational conditions rather than static exposure alone.

Immunogenicity concerns emerge particularly in implantable applications where semiconductor-integrated actuators may trigger foreign body responses. Current safety standards require comprehensive immunological profiling, including assessment of pro-inflammatory cytokine production and macrophage polarization patterns. The semiconductor industry's established clean room protocols have been adapted to ensure particulate and endotoxin control during manufacturing processes.

Electrical safety standards present unique challenges for semiconductor-integrated pneumatic systems. The combination of electrical components with fluid-driven mechanisms creates potential failure modes not addressed by traditional standards. Industry leaders have developed specialized testing protocols that evaluate insulation integrity under mechanical deformation, as conventional rigid-substrate electrical safety tests prove inadequate for these flexible systems.

Long-term stability testing remains an evolving field, with accelerated aging protocols being adapted to account for the mechanical cycling inherent in pneumatic actuation. Current standards recommend minimum 6-month equivalent testing, though clinical applications typically require demonstration of stability over projected device lifetimes, which may extend to several years depending on the application context.

Regulatory pathways for these hybrid technologies often require cross-disciplinary approaches, with both medical device and electronic component standards applying simultaneously. The FDA's recent guidance on combination products provides a framework for navigating these complex regulatory landscapes, though international harmonization of standards specific to semiconductor-integrated soft actuators remains a work in progress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!