Review of Patents in Emerging Soft Pneumatic Actuator Technologies

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Technology Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of robotics and automation, emerging as a significant alternative to traditional rigid actuators. The evolution of this technology can be traced back to the early 2000s, when researchers began exploring compliant materials for robotic applications. The fundamental concept behind SPAs involves the use of elastomeric materials that deform when pressurized with air or fluid, creating controlled movement without rigid components.

The technological trajectory of SPAs has been characterized by progressive improvements in material science, manufacturing techniques, and control systems. Initially limited by material constraints and fabrication challenges, recent breakthroughs in silicone elastomers, thermoplastic polyurethanes, and advanced manufacturing methods like 3D printing have significantly expanded the capabilities and applications of these devices.

Current research trends indicate a growing focus on biomimetic designs, where SPAs are engineered to replicate the movement and functionality of biological systems such as muscles, tentacles, and other natural actuators. This bio-inspired approach has proven particularly effective in creating more efficient and adaptable soft robotic systems.

The primary technical objectives in SPA development center around addressing several key challenges. First, enhancing the force-to-weight ratio to make these actuators more powerful while maintaining their inherent compliance. Second, improving response time and precision control to enable more complex and coordinated movements. Third, developing more durable materials that can withstand repeated actuation cycles without degradation or failure.

Another critical objective involves the integration of sensing capabilities directly into the soft actuator structure, creating what researchers term as "sensorized" SPAs. This integration aims to provide real-time feedback about the actuator's position, force exertion, and interaction with the environment, enabling more sophisticated control algorithms and autonomous operation.

Energy efficiency represents another significant goal, as current pneumatic systems often suffer from inefficiencies in air compression and distribution. Researchers are exploring alternative actuation methods, including chemical reactions, phase-change materials, and electrically activated polymers to overcome these limitations.

The long-term vision for SPA technology encompasses the development of fully integrated soft robotic systems capable of safe human-robot interaction, adaptive manipulation of delicate objects, and deployment in challenging environments where traditional rigid robots cannot operate effectively. This includes medical applications, disaster response scenarios, and industrial settings requiring gentle handling of sensitive materials.

The technological trajectory of SPAs has been characterized by progressive improvements in material science, manufacturing techniques, and control systems. Initially limited by material constraints and fabrication challenges, recent breakthroughs in silicone elastomers, thermoplastic polyurethanes, and advanced manufacturing methods like 3D printing have significantly expanded the capabilities and applications of these devices.

Current research trends indicate a growing focus on biomimetic designs, where SPAs are engineered to replicate the movement and functionality of biological systems such as muscles, tentacles, and other natural actuators. This bio-inspired approach has proven particularly effective in creating more efficient and adaptable soft robotic systems.

The primary technical objectives in SPA development center around addressing several key challenges. First, enhancing the force-to-weight ratio to make these actuators more powerful while maintaining their inherent compliance. Second, improving response time and precision control to enable more complex and coordinated movements. Third, developing more durable materials that can withstand repeated actuation cycles without degradation or failure.

Another critical objective involves the integration of sensing capabilities directly into the soft actuator structure, creating what researchers term as "sensorized" SPAs. This integration aims to provide real-time feedback about the actuator's position, force exertion, and interaction with the environment, enabling more sophisticated control algorithms and autonomous operation.

Energy efficiency represents another significant goal, as current pneumatic systems often suffer from inefficiencies in air compression and distribution. Researchers are exploring alternative actuation methods, including chemical reactions, phase-change materials, and electrically activated polymers to overcome these limitations.

The long-term vision for SPA technology encompasses the development of fully integrated soft robotic systems capable of safe human-robot interaction, adaptive manipulation of delicate objects, and deployment in challenging environments where traditional rigid robots cannot operate effectively. This includes medical applications, disaster response scenarios, and industrial settings requiring gentle handling of sensitive materials.

Market Applications and Demand Analysis for Soft Robotics

The soft robotics market is experiencing significant growth driven by increasing demand across multiple sectors. Healthcare applications represent one of the most promising areas, with soft pneumatic actuators enabling the development of rehabilitation devices, surgical tools, and prosthetics that can interact safely with human tissue. The inherent compliance and adaptability of soft actuators make them ideal for patient-specific applications, addressing a market estimated to reach $25 billion by 2025 for medical robotics overall.

Manufacturing industries are increasingly adopting soft robotic solutions for handling delicate or irregularly shaped objects. Traditional rigid grippers often damage products or fail to effectively manipulate certain materials, creating a substantial market opportunity for soft pneumatic actuators. This segment is projected to grow at a compound annual growth rate of 35% through 2027, particularly in food processing, electronics assembly, and pharmaceutical manufacturing.

The aging population in developed economies is driving demand for assistive technologies where soft robotics offers unique advantages. Wearable soft robotic exoskeletons and mobility aids represent a rapidly expanding market segment with significant investment from both private and public sectors. Consumer surveys indicate over 70% of elderly individuals express interest in soft robotic assistive devices that could help maintain independence.

Environmental monitoring and exploration constitute another emerging application area. Soft robots can navigate challenging terrains and confined spaces without causing environmental damage, making them valuable for marine exploration, disaster response, and agricultural monitoring. The underwater soft robotics segment alone is expected to triple in market size over the next five years.

Despite this promising outlook, market adoption faces several challenges. Cost remains a significant barrier, with current manufacturing processes for soft pneumatic actuators being relatively expensive compared to traditional robotics. Additionally, standardization issues and the need for specialized knowledge to implement these systems limit widespread industrial adoption.

Regional analysis reveals that North America currently leads in soft robotics research and commercialization, followed closely by Europe and East Asia. However, the fastest growth is anticipated in emerging economies where manufacturing sectors are rapidly modernizing and seeking flexible automation solutions. China, in particular, has increased patent filings related to soft pneumatic actuators by over 200% in the past three years, indicating strong market interest.

Manufacturing industries are increasingly adopting soft robotic solutions for handling delicate or irregularly shaped objects. Traditional rigid grippers often damage products or fail to effectively manipulate certain materials, creating a substantial market opportunity for soft pneumatic actuators. This segment is projected to grow at a compound annual growth rate of 35% through 2027, particularly in food processing, electronics assembly, and pharmaceutical manufacturing.

The aging population in developed economies is driving demand for assistive technologies where soft robotics offers unique advantages. Wearable soft robotic exoskeletons and mobility aids represent a rapidly expanding market segment with significant investment from both private and public sectors. Consumer surveys indicate over 70% of elderly individuals express interest in soft robotic assistive devices that could help maintain independence.

Environmental monitoring and exploration constitute another emerging application area. Soft robots can navigate challenging terrains and confined spaces without causing environmental damage, making them valuable for marine exploration, disaster response, and agricultural monitoring. The underwater soft robotics segment alone is expected to triple in market size over the next five years.

Despite this promising outlook, market adoption faces several challenges. Cost remains a significant barrier, with current manufacturing processes for soft pneumatic actuators being relatively expensive compared to traditional robotics. Additionally, standardization issues and the need for specialized knowledge to implement these systems limit widespread industrial adoption.

Regional analysis reveals that North America currently leads in soft robotics research and commercialization, followed closely by Europe and East Asia. However, the fastest growth is anticipated in emerging economies where manufacturing sectors are rapidly modernizing and seeking flexible automation solutions. China, in particular, has increased patent filings related to soft pneumatic actuators by over 200% in the past three years, indicating strong market interest.

Current Technical Challenges in Soft Pneumatic Actuators

Despite significant advancements in soft pneumatic actuator (SPA) technologies, several critical technical challenges continue to impede their widespread adoption and optimal performance. One of the primary obstacles remains the inherent trade-off between flexibility and force generation capacity. Current SPAs struggle to deliver high force outputs while maintaining the compliance and adaptability that make them valuable for human-robot interaction and delicate manipulation tasks.

Material limitations represent another significant hurdle. Most contemporary SPAs utilize silicone elastomers which, while flexible, suffer from durability issues including tear propagation, fatigue failure, and environmental degradation. These materials also exhibit nonlinear mechanical behaviors that complicate precise control and modeling efforts. The search for alternative materials with improved durability while maintaining necessary elasticity continues to challenge researchers.

Pneumatic control systems for SPAs face substantial miniaturization constraints. Current valve technologies, pressure regulators, and air supply systems remain bulky relative to the actuators themselves, limiting the development of truly portable and self-contained soft robotic systems. The energy efficiency of pneumatic systems also lags behind their electrical counterparts, with significant energy losses occurring during air compression and transmission.

Manufacturing inconsistencies present persistent challenges to scalability and reproducibility. Current fabrication methods, primarily molding and casting techniques, introduce variability between supposedly identical actuators. This inconsistency complicates control algorithms and hampers performance predictability, particularly problematic for applications requiring precise movements or force control.

Sensing integration remains underdeveloped in SPA systems. The incorporation of proprioceptive and exteroceptive sensing capabilities without compromising the actuator's compliance or performance characteristics continues to challenge designers. Current sensing solutions often add bulk, reduce flexibility, or create weak points in the structure.

Modeling and control algorithms for SPAs lack the sophistication of their rigid counterparts. The hyperelastic, nonlinear nature of soft materials makes accurate mathematical modeling exceptionally difficult. Real-time control systems struggle to account for material hysteresis, viscoelastic behaviors, and environmental interactions, resulting in less precise positioning and force control compared to conventional actuators.

Lastly, scalability issues persist across the size spectrum. Miniaturization efforts face challenges in maintaining functionality at reduced scales, while larger SPAs struggle with pressure distribution, response time, and structural integrity concerns. These multi-scale design challenges limit the application range of current SPA technologies.

Material limitations represent another significant hurdle. Most contemporary SPAs utilize silicone elastomers which, while flexible, suffer from durability issues including tear propagation, fatigue failure, and environmental degradation. These materials also exhibit nonlinear mechanical behaviors that complicate precise control and modeling efforts. The search for alternative materials with improved durability while maintaining necessary elasticity continues to challenge researchers.

Pneumatic control systems for SPAs face substantial miniaturization constraints. Current valve technologies, pressure regulators, and air supply systems remain bulky relative to the actuators themselves, limiting the development of truly portable and self-contained soft robotic systems. The energy efficiency of pneumatic systems also lags behind their electrical counterparts, with significant energy losses occurring during air compression and transmission.

Manufacturing inconsistencies present persistent challenges to scalability and reproducibility. Current fabrication methods, primarily molding and casting techniques, introduce variability between supposedly identical actuators. This inconsistency complicates control algorithms and hampers performance predictability, particularly problematic for applications requiring precise movements or force control.

Sensing integration remains underdeveloped in SPA systems. The incorporation of proprioceptive and exteroceptive sensing capabilities without compromising the actuator's compliance or performance characteristics continues to challenge designers. Current sensing solutions often add bulk, reduce flexibility, or create weak points in the structure.

Modeling and control algorithms for SPAs lack the sophistication of their rigid counterparts. The hyperelastic, nonlinear nature of soft materials makes accurate mathematical modeling exceptionally difficult. Real-time control systems struggle to account for material hysteresis, viscoelastic behaviors, and environmental interactions, resulting in less precise positioning and force control compared to conventional actuators.

Lastly, scalability issues persist across the size spectrum. Miniaturization efforts face challenges in maintaining functionality at reduced scales, while larger SPAs struggle with pressure distribution, response time, and structural integrity concerns. These multi-scale design challenges limit the application range of current SPA technologies.

Current Patent Landscape and Technical Solutions

01 Design and structure of soft pneumatic actuators

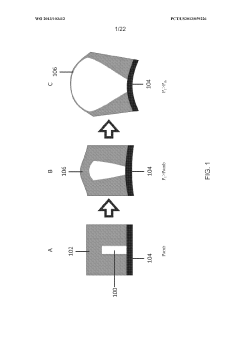

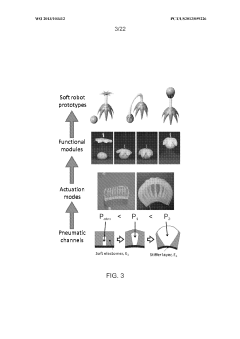

Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers, channels, or bellows that expand or contract to create movement. The design may incorporate reinforcement elements to control the direction of deformation and enhance performance. Various geometrical configurations can be employed to achieve different types of motion, such as bending, twisting, or extending.- Design and structure of soft pneumatic actuators: Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers or channels that expand in predetermined directions when inflated, creating controlled movement. The design may incorporate various geometries, reinforcement patterns, and material combinations to achieve specific motion characteristics such as bending, twisting, or extending. These structural considerations are fundamental to the functionality and performance of soft pneumatic actuators in various applications.

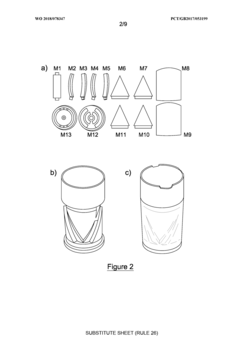

- Manufacturing techniques for soft pneumatic actuators: Various manufacturing methods are employed to create soft pneumatic actuators, including molding, 3D printing, and layered fabrication. These techniques allow for the creation of complex internal channels and chambers necessary for pneumatic operation. Advanced manufacturing approaches enable the integration of different materials with varying properties in a single actuator, as well as the embedding of sensors or other functional components. The manufacturing process significantly influences the actuator's performance characteristics, durability, and cost-effectiveness.

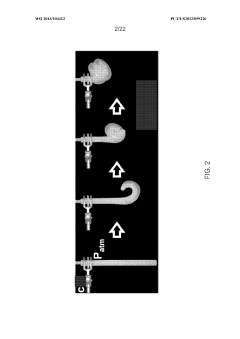

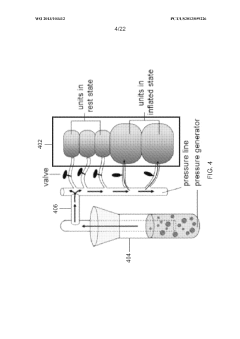

- Control systems and sensing for soft pneumatic actuators: Control systems for soft pneumatic actuators involve pressure regulation, valve control, and feedback mechanisms to achieve precise movements. These systems may incorporate various sensors to monitor parameters such as pressure, position, and deformation. Advanced control strategies include machine learning algorithms and model-based approaches to compensate for the nonlinear behavior inherent in soft materials. The integration of sensing and control enables more sophisticated applications requiring accurate positioning or force control.

- Applications of soft pneumatic actuators in robotics and biomechanics: Soft pneumatic actuators are increasingly used in fields such as soft robotics, wearable devices, and biomedical applications. Their compliant nature makes them ideal for safe human-robot interaction, assistive devices, and rehabilitation equipment. In robotics, they enable grippers that can handle delicate or irregularly shaped objects. Medical applications include surgical tools, artificial muscles, and therapeutic devices. The inherent safety and adaptability of these actuators make them particularly valuable in environments where traditional rigid actuators would be unsuitable.

- Material innovations for enhanced soft pneumatic actuator performance: Material selection plays a crucial role in the performance of soft pneumatic actuators. Researchers are developing new elastomers, composites, and hybrid materials with properties such as high elasticity, durability, and environmental resistance. Smart materials that respond to stimuli beyond pneumatic pressure, such as temperature or electrical signals, are being integrated to create multi-modal actuation. Biomimetic materials inspired by natural structures are also being explored to improve efficiency and functionality. These material innovations aim to overcome limitations in force output, speed, and longevity of soft pneumatic actuators.

02 Materials for soft pneumatic actuators

The selection of materials is crucial for soft pneumatic actuators. Elastomers such as silicone rubber, polyurethane, and other flexible polymers are commonly used due to their elastic properties and ability to withstand repeated deformation. Some designs incorporate composite materials or fiber reinforcements to control deformation patterns and increase strength. Advanced materials may also include self-healing properties or responsive elements that change characteristics under different conditions.Expand Specific Solutions03 Control systems and sensing for soft actuators

Control systems for soft pneumatic actuators often include pressure regulators, valves, and sensors to monitor and adjust the actuator's performance. Feedback mechanisms may incorporate pressure sensors, position sensors, or force sensors to enable precise control. Advanced systems may use machine learning algorithms or model-based control strategies to improve response time and accuracy. Integration with electronic components allows for automated operation and coordination of multiple actuators in complex systems.Expand Specific Solutions04 Applications of soft pneumatic actuators

Soft pneumatic actuators find applications in various fields including robotics, medical devices, and industrial automation. In robotics, they enable safe human-robot interaction due to their inherent compliance. Medical applications include assistive devices, rehabilitation equipment, and minimally invasive surgical tools. Industrial uses range from gripping delicate objects to adaptive manufacturing processes. Their flexibility and adaptability make them suitable for environments where traditional rigid actuators would be impractical or unsafe.Expand Specific Solutions05 Fabrication methods for soft pneumatic actuators

Various fabrication techniques are employed to create soft pneumatic actuators, including molding, 3D printing, and layered manufacturing. Molding processes often involve creating a negative mold into which elastomer materials are poured and cured. Advanced manufacturing methods may include multi-material printing or embedded components during fabrication. Some techniques focus on creating seamless structures to improve durability and performance, while others emphasize scalability for mass production or miniaturization for specialized applications.Expand Specific Solutions

Leading Companies and Research Institutions in Soft Robotics

The soft pneumatic actuator technology landscape is currently in a growth phase, with market size expanding due to increasing applications in robotics, healthcare, and industrial automation. The technology is approaching maturity with significant advancements from key players. Harvard University leads academic research with pioneering contributions, while companies like Toyota Motor Corp. and Hyundai Motor Co. are integrating these technologies into automotive applications. Specialized firms such as Artimus Robotics and RIVERFIELD Inc. are developing niche applications in medical robotics. Research institutions including Zhejiang University, National University of Singapore, and Cornell University are advancing fundamental technologies, while Meta Platforms and Boeing represent major corporations exploring industrial implementations. The competitive landscape shows a balanced ecosystem of academic institutions, specialized startups, and established corporations driving innovation.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators through their groundbreaking work on soft robotics. Their technology focuses on biomimetic designs using elastomeric materials with embedded pneumatic networks (PneuNets) that enable complex motions when inflated. These actuators feature multi-chamber designs with strain-limiting layers that create directional bending and movement. Harvard has developed manufacturing techniques including 3D printing, soft lithography, and molding processes that allow for rapid prototyping and customization of actuator geometries. Their patents cover fundamental architectures for soft pneumatic systems, including fiber-reinforced actuators that can achieve controlled motion patterns while maintaining compliance. Harvard researchers have also developed control systems specifically designed for the nonlinear behavior of soft actuators, enabling precise movement despite the inherent elasticity of the materials.

Strengths: Exceptional biomimetic designs that closely mimic natural movements; strong intellectual property portfolio covering fundamental soft robotics principles; advanced manufacturing techniques. Weaknesses: Higher production costs compared to traditional rigid actuators; challenges in scaling production for commercial applications; potential durability concerns in high-cycle applications.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed innovative soft pneumatic actuator technologies focusing on fiber-reinforced designs that enable precise control of motion constraints while maintaining flexibility. Their patented approach incorporates strategically placed fiber reinforcements within elastomeric structures to create programmable deformation patterns when pressurized. Michigan's research has yielded actuators capable of complex movements including extension, contraction, bending, and twisting through careful manipulation of fiber orientation and spacing. Their manufacturing process involves precision fiber winding techniques combined with multi-material molding to create integrated actuator systems. The university has also pioneered sensing integration within soft actuators, embedding flexible electronic components that provide real-time feedback on actuator state, position, and applied forces. This sensory capability enables closed-loop control systems that significantly improve performance in dynamic environments and human-robot interaction scenarios.

Strengths: Superior force-to-weight ratio compared to many competing designs; excellent motion control precision through fiber reinforcement; integrated sensing capabilities. Weaknesses: Complex manufacturing process requiring specialized equipment; higher material costs; potential limitations in extreme temperature environments.

Key Patent Analysis and Technical Innovations

Systems and methods for actuating soft robotic actuators

PatentWO2013103412A2

Innovation

- The development of soft robotic systems that utilize pressurized gas sources, including electrolyzers and self-powered chemical pumps, and explosive combustion for actuation, enabling flexible deformation and efficient energy release through pneumatic and explosive mechanisms.

Soft actuators

PatentWO2018078347A1

Innovation

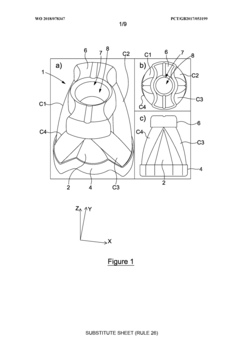

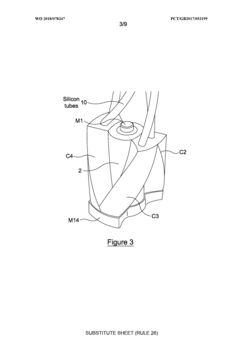

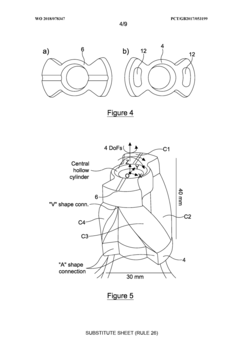

- A soft pneumatic actuator design featuring four inflatable chambers that are resiliently deformable, allowing for 4 DOFs motion by altering pressure within the chambers, enabling bending, twisting, and extension with a central core that supports the chambers and allows for precise control of motion.

Materials Science Advancements for Soft Actuators

The evolution of soft pneumatic actuators has been significantly influenced by advancements in materials science. Traditional rigid actuators constructed from metals and hard plastics have given way to compliant systems that utilize elastomeric and composite materials. This transition has been driven by the need for safer human-machine interactions and more biomimetic motion capabilities.

Silicone elastomers, particularly polydimethylsiloxane (PDMS) and silicone rubbers like Ecoflex and Dragon Skin, have emerged as primary materials for soft actuators due to their excellent elasticity, chemical stability, and ease of fabrication. Recent patents have focused on modifying these base materials to enhance specific properties such as strain capacity, response time, and durability under repeated actuation cycles.

Fiber-reinforced composites represent another significant advancement, combining elastomeric matrices with high-strength fibers to control deformation patterns and increase force output. Patents from Harvard University and Soft Robotics Inc. have demonstrated how strategic fiber placement can create programmable motion pathways while preventing balloon-like expansion under pressure.

Smart materials integration has opened new frontiers in soft actuator functionality. Shape memory alloys (SMAs), electroactive polymers (EAPs), and liquid crystal elastomers (LCEs) have been incorporated into hybrid designs to enable multi-modal actuation and sensing capabilities. A notable patent from Tokyo Institute of Technology describes a soft actuator with embedded SMA wires that provides both pneumatic and thermal actuation modes.

3D printable elastomers have revolutionized fabrication processes, allowing for complex internal channel geometries and gradient material properties. Recent patents from MIT and ETH Zurich detail novel printing techniques that enable single-step manufacturing of fully functional soft actuators with integrated sensing elements and variable stiffness regions.

Biomimetic materials inspired by natural structures have gained significant attention. Patents exploring hydrogel-based actuators that mimic plant movements and protein-based materials that replicate muscle tissue properties demonstrate the growing interest in nature-inspired design principles. These materials offer potential advantages in energy efficiency and environmental compatibility.

Self-healing capabilities represent the cutting edge of materials development for soft actuators. Recent patents describe elastomeric composites with microcapsules containing healing agents that can repair microtears during operation, significantly extending operational lifespan and reliability in demanding applications.

Silicone elastomers, particularly polydimethylsiloxane (PDMS) and silicone rubbers like Ecoflex and Dragon Skin, have emerged as primary materials for soft actuators due to their excellent elasticity, chemical stability, and ease of fabrication. Recent patents have focused on modifying these base materials to enhance specific properties such as strain capacity, response time, and durability under repeated actuation cycles.

Fiber-reinforced composites represent another significant advancement, combining elastomeric matrices with high-strength fibers to control deformation patterns and increase force output. Patents from Harvard University and Soft Robotics Inc. have demonstrated how strategic fiber placement can create programmable motion pathways while preventing balloon-like expansion under pressure.

Smart materials integration has opened new frontiers in soft actuator functionality. Shape memory alloys (SMAs), electroactive polymers (EAPs), and liquid crystal elastomers (LCEs) have been incorporated into hybrid designs to enable multi-modal actuation and sensing capabilities. A notable patent from Tokyo Institute of Technology describes a soft actuator with embedded SMA wires that provides both pneumatic and thermal actuation modes.

3D printable elastomers have revolutionized fabrication processes, allowing for complex internal channel geometries and gradient material properties. Recent patents from MIT and ETH Zurich detail novel printing techniques that enable single-step manufacturing of fully functional soft actuators with integrated sensing elements and variable stiffness regions.

Biomimetic materials inspired by natural structures have gained significant attention. Patents exploring hydrogel-based actuators that mimic plant movements and protein-based materials that replicate muscle tissue properties demonstrate the growing interest in nature-inspired design principles. These materials offer potential advantages in energy efficiency and environmental compatibility.

Self-healing capabilities represent the cutting edge of materials development for soft actuators. Recent patents describe elastomeric composites with microcapsules containing healing agents that can repair microtears during operation, significantly extending operational lifespan and reliability in demanding applications.

Standardization and Safety Considerations in Soft Robotics

The standardization and safety frameworks for soft robotics, particularly those involving pneumatic actuators, remain in nascent stages compared to traditional rigid robotics. As these technologies transition from research laboratories to commercial applications, establishing comprehensive safety protocols becomes increasingly critical. Current standardization efforts primarily focus on mechanical properties, material biocompatibility, and operational parameters of soft pneumatic systems.

International organizations such as ISO and IEEE have begun developing preliminary guidelines for soft robotic systems, though specific standards for pneumatic actuators are still evolving. The IEC 60601 series, while primarily focused on medical devices, provides valuable frameworks that can be adapted for soft pneumatic actuators in healthcare applications. Similarly, ISO 13482:2014 for personal care robots offers partial guidance but requires significant expansion to address the unique characteristics of soft systems.

Safety considerations for soft pneumatic actuators present unique challenges distinct from conventional robotics. The inherent compliance of these systems reduces certain risks associated with human-robot interaction but introduces new concerns regarding pressure regulation, material fatigue, and unexpected behavior under varying environmental conditions. Patent analysis reveals increasing attention to fail-safe mechanisms, including pressure relief valves, redundant control systems, and material innovations that prevent catastrophic failures.

Regulatory gaps persist in defining acceptable pressure thresholds, material degradation parameters, and testing methodologies specific to soft pneumatic technologies. This creates uncertainty for manufacturers and potentially impedes market adoption. Recent patent filings demonstrate growing interest in self-diagnostic capabilities that can detect material wear, pressure anomalies, or control system failures before they compromise safety.

The biocompatibility of materials used in soft pneumatic actuators represents another critical safety dimension, particularly for wearable applications or medical devices. Standards such as ISO 10993 provide guidance for material testing, but their application to the dynamic, cyclically-stressed materials in soft actuators requires further refinement. Several patents highlight novel approaches to encapsulation and material selection that address both performance and safety requirements.

As the field advances, standardization efforts must balance innovation enablement with appropriate safety guardrails. The development of testing protocols that accurately simulate real-world conditions and failure modes will be essential for establishing meaningful safety certifications. Industry consortia and academic-industrial partnerships are emerging as important vehicles for developing consensus-based standards that can keep pace with rapid technological evolution in this domain.

International organizations such as ISO and IEEE have begun developing preliminary guidelines for soft robotic systems, though specific standards for pneumatic actuators are still evolving. The IEC 60601 series, while primarily focused on medical devices, provides valuable frameworks that can be adapted for soft pneumatic actuators in healthcare applications. Similarly, ISO 13482:2014 for personal care robots offers partial guidance but requires significant expansion to address the unique characteristics of soft systems.

Safety considerations for soft pneumatic actuators present unique challenges distinct from conventional robotics. The inherent compliance of these systems reduces certain risks associated with human-robot interaction but introduces new concerns regarding pressure regulation, material fatigue, and unexpected behavior under varying environmental conditions. Patent analysis reveals increasing attention to fail-safe mechanisms, including pressure relief valves, redundant control systems, and material innovations that prevent catastrophic failures.

Regulatory gaps persist in defining acceptable pressure thresholds, material degradation parameters, and testing methodologies specific to soft pneumatic technologies. This creates uncertainty for manufacturers and potentially impedes market adoption. Recent patent filings demonstrate growing interest in self-diagnostic capabilities that can detect material wear, pressure anomalies, or control system failures before they compromise safety.

The biocompatibility of materials used in soft pneumatic actuators represents another critical safety dimension, particularly for wearable applications or medical devices. Standards such as ISO 10993 provide guidance for material testing, but their application to the dynamic, cyclically-stressed materials in soft actuators requires further refinement. Several patents highlight novel approaches to encapsulation and material selection that address both performance and safety requirements.

As the field advances, standardization efforts must balance innovation enablement with appropriate safety guardrails. The development of testing protocols that accurately simulate real-world conditions and failure modes will be essential for establishing meaningful safety certifications. Industry consortia and academic-industrial partnerships are emerging as important vehicles for developing consensus-based standards that can keep pace with rapid technological evolution in this domain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!