Thermal Stability of Advanced Soft Pneumatic Actuators

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability Background and Objectives

Soft pneumatic actuators (SPAs) have emerged as a revolutionary technology in robotics and automation systems over the past two decades. These flexible, lightweight structures utilize pneumatic pressure to generate motion and force, offering advantages in safety, adaptability, and biomimetic capabilities compared to traditional rigid actuators. However, their thermal stability remains a critical challenge that limits broader industrial adoption and application versatility.

The evolution of SPA technology can be traced back to the early 2000s, with significant advancements occurring in the 2010s through the development of novel materials and fabrication techniques. Initially designed for room-temperature operations, these actuators have progressively been engineered to withstand more extreme conditions. The thermal stability of SPAs directly impacts their performance characteristics, including response time, force generation, durability, and operational lifespan.

Current research indicates that most commercially available SPAs experience significant performance degradation at temperatures exceeding 60°C, with catastrophic failure often occurring above 100°C. Conversely, extremely low temperatures can cause material embrittlement and reduced flexibility, compromising the fundamental advantages of soft robotics. This temperature sensitivity stems primarily from the elastomeric materials commonly used in SPA construction, such as silicone rubbers, polyurethanes, and various thermoplastic elastomers.

The global push toward automation in harsh environments—including deep-sea exploration, space applications, disaster response, and high-temperature manufacturing processes—has intensified the need for thermally stable SPAs. Market projections suggest that addressing thermal limitations could expand the soft robotics market by an estimated 35% within the next five years, particularly in aerospace, deep-sea operations, and advanced manufacturing sectors.

Our technical objectives for this research include: (1) comprehensive characterization of thermal degradation mechanisms in current SPA materials across the temperature range of -40°C to 200°C; (2) development of novel composite materials that maintain elasticity and performance across wider temperature ranges; (3) design of thermal management systems specifically adapted for soft robotic architectures; and (4) creation of predictive models for SPA performance under variable thermal conditions.

The ultimate goal is to develop next-generation SPAs capable of reliable operation in environments with temperature fluctuations between -60°C and 250°C without significant performance degradation, thereby enabling their deployment in previously inaccessible applications and substantially expanding their commercial viability across multiple industries.

The evolution of SPA technology can be traced back to the early 2000s, with significant advancements occurring in the 2010s through the development of novel materials and fabrication techniques. Initially designed for room-temperature operations, these actuators have progressively been engineered to withstand more extreme conditions. The thermal stability of SPAs directly impacts their performance characteristics, including response time, force generation, durability, and operational lifespan.

Current research indicates that most commercially available SPAs experience significant performance degradation at temperatures exceeding 60°C, with catastrophic failure often occurring above 100°C. Conversely, extremely low temperatures can cause material embrittlement and reduced flexibility, compromising the fundamental advantages of soft robotics. This temperature sensitivity stems primarily from the elastomeric materials commonly used in SPA construction, such as silicone rubbers, polyurethanes, and various thermoplastic elastomers.

The global push toward automation in harsh environments—including deep-sea exploration, space applications, disaster response, and high-temperature manufacturing processes—has intensified the need for thermally stable SPAs. Market projections suggest that addressing thermal limitations could expand the soft robotics market by an estimated 35% within the next five years, particularly in aerospace, deep-sea operations, and advanced manufacturing sectors.

Our technical objectives for this research include: (1) comprehensive characterization of thermal degradation mechanisms in current SPA materials across the temperature range of -40°C to 200°C; (2) development of novel composite materials that maintain elasticity and performance across wider temperature ranges; (3) design of thermal management systems specifically adapted for soft robotic architectures; and (4) creation of predictive models for SPA performance under variable thermal conditions.

The ultimate goal is to develop next-generation SPAs capable of reliable operation in environments with temperature fluctuations between -60°C and 250°C without significant performance degradation, thereby enabling their deployment in previously inaccessible applications and substantially expanding their commercial viability across multiple industries.

Market Analysis for Heat-Resistant Soft Actuators

The global market for heat-resistant soft actuators is experiencing significant growth, driven by increasing demand across multiple industries including robotics, healthcare, aerospace, and manufacturing. Current market valuation stands at approximately 2.3 billion USD with a projected compound annual growth rate of 12.7% over the next five years. This growth trajectory is particularly pronounced in regions with advanced manufacturing capabilities such as North America, Europe, and East Asia.

The healthcare sector represents the largest market segment, accounting for roughly 35% of total demand. Applications include surgical instruments, rehabilitation devices, and prosthetics where thermal stability during sterilization processes (typically 121-134°C) is critical. The ability of advanced soft pneumatic actuators to maintain performance integrity at these temperatures provides substantial value to medical device manufacturers.

Industrial automation constitutes the second-largest market segment at 28% of total demand. In this sector, heat-resistant actuators enable operation in high-temperature manufacturing environments such as foundries, glass production, and automotive assembly lines where temperatures can regularly exceed 100°C. The market is witnessing a shift from traditional rigid actuators to soft pneumatic alternatives due to their adaptability, safety advantages, and potential for energy efficiency.

Consumer electronics represents an emerging market with the fastest growth rate at 18.3% annually. Applications include haptic feedback systems, cooling mechanisms, and adaptive interfaces. The miniaturization trend in electronics has created demand for thermally stable micro-actuators that can function reliably despite heat generated by densely packed components.

Market analysis reveals several key customer requirements driving product development: temperature resistance range (typically 80-150°C for standard applications, 150-300°C for specialized uses), cycle durability under thermal stress, response time maintenance at elevated temperatures, and cost-effectiveness compared to traditional solutions. Customers increasingly demand materials that maintain elasticity and pneumatic responsiveness across wider temperature ranges.

Regional market distribution shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). However, the Asia-Pacific region demonstrates the highest growth potential due to rapid industrialization and increasing adoption of automation technologies in manufacturing hubs like China, South Korea, and Singapore.

Price sensitivity varies significantly by application, with healthcare applications commanding premium pricing due to regulatory requirements and performance demands, while industrial applications remain more cost-conscious despite requiring similar thermal performance specifications.

The healthcare sector represents the largest market segment, accounting for roughly 35% of total demand. Applications include surgical instruments, rehabilitation devices, and prosthetics where thermal stability during sterilization processes (typically 121-134°C) is critical. The ability of advanced soft pneumatic actuators to maintain performance integrity at these temperatures provides substantial value to medical device manufacturers.

Industrial automation constitutes the second-largest market segment at 28% of total demand. In this sector, heat-resistant actuators enable operation in high-temperature manufacturing environments such as foundries, glass production, and automotive assembly lines where temperatures can regularly exceed 100°C. The market is witnessing a shift from traditional rigid actuators to soft pneumatic alternatives due to their adaptability, safety advantages, and potential for energy efficiency.

Consumer electronics represents an emerging market with the fastest growth rate at 18.3% annually. Applications include haptic feedback systems, cooling mechanisms, and adaptive interfaces. The miniaturization trend in electronics has created demand for thermally stable micro-actuators that can function reliably despite heat generated by densely packed components.

Market analysis reveals several key customer requirements driving product development: temperature resistance range (typically 80-150°C for standard applications, 150-300°C for specialized uses), cycle durability under thermal stress, response time maintenance at elevated temperatures, and cost-effectiveness compared to traditional solutions. Customers increasingly demand materials that maintain elasticity and pneumatic responsiveness across wider temperature ranges.

Regional market distribution shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). However, the Asia-Pacific region demonstrates the highest growth potential due to rapid industrialization and increasing adoption of automation technologies in manufacturing hubs like China, South Korea, and Singapore.

Price sensitivity varies significantly by application, with healthcare applications commanding premium pricing due to regulatory requirements and performance demands, while industrial applications remain more cost-conscious despite requiring similar thermal performance specifications.

Current Challenges in High-Temperature Pneumatic Applications

High-temperature environments present significant challenges for pneumatic systems, particularly for soft pneumatic actuators (SPAs) designed with elastomeric materials. The primary limitation stems from the inherent thermal properties of elastomers commonly used in SPAs, such as silicone rubber, polyurethane, and thermoplastic elastomers, which typically begin to degrade at temperatures above 100-150°C. This thermal degradation manifests as material stiffening, reduced elasticity, and eventual structural failure.

In industrial settings where temperatures can exceed 200°C, conventional SPAs experience rapid performance deterioration. The elastomer matrix undergoes chemical changes including cross-linking alterations and oxidation processes, leading to permanent deformation and loss of actuation capabilities. Additionally, thermal expansion creates dimensional instability, affecting precision in applications requiring accurate positioning.

Sealing integrity represents another critical challenge. At elevated temperatures, the interface between different materials in pneumatic systems—particularly between rigid components and flexible elements—becomes vulnerable to leakage. Thermal expansion differentials create micro-gaps that compromise pressure containment, resulting in reduced force output and control precision. Current sealing technologies struggle to maintain effectiveness across wide temperature ranges while remaining compatible with the flexible nature of soft actuators.

The pneumatic fluid itself introduces complications at high temperatures. Air viscosity increases, altering flow dynamics through valves and channels. This affects response time and control precision, particularly in applications requiring rapid actuation cycles. Furthermore, moisture content in compressed air can vaporize at high temperatures, creating unpredictable pressure fluctuations and potential system damage.

Electronic components integrated into advanced pneumatic systems for sensing and control face reliability issues in high-temperature environments. Temperature-sensitive elements such as pressure sensors, flow regulators, and control valves often have operating limits below the temperatures encountered in many industrial applications, necessitating complex cooling solutions that add weight, cost, and failure points.

Energy efficiency decreases substantially as operating temperatures rise. Higher temperatures increase friction in moving components and reduce the volumetric efficiency of pneumatic systems. This necessitates higher operating pressures to achieve equivalent performance, placing additional stress on already thermally challenged components and increasing the risk of catastrophic failure.

Current material solutions such as high-temperature silicones and fluoroelastomers offer improved thermal resistance but typically sacrifice flexibility, requiring higher actuation pressures and limiting the design possibilities that make SPAs advantageous. The trade-off between thermal stability and mechanical performance remains a fundamental challenge that has yet to be satisfactorily resolved in commercial applications.

In industrial settings where temperatures can exceed 200°C, conventional SPAs experience rapid performance deterioration. The elastomer matrix undergoes chemical changes including cross-linking alterations and oxidation processes, leading to permanent deformation and loss of actuation capabilities. Additionally, thermal expansion creates dimensional instability, affecting precision in applications requiring accurate positioning.

Sealing integrity represents another critical challenge. At elevated temperatures, the interface between different materials in pneumatic systems—particularly between rigid components and flexible elements—becomes vulnerable to leakage. Thermal expansion differentials create micro-gaps that compromise pressure containment, resulting in reduced force output and control precision. Current sealing technologies struggle to maintain effectiveness across wide temperature ranges while remaining compatible with the flexible nature of soft actuators.

The pneumatic fluid itself introduces complications at high temperatures. Air viscosity increases, altering flow dynamics through valves and channels. This affects response time and control precision, particularly in applications requiring rapid actuation cycles. Furthermore, moisture content in compressed air can vaporize at high temperatures, creating unpredictable pressure fluctuations and potential system damage.

Electronic components integrated into advanced pneumatic systems for sensing and control face reliability issues in high-temperature environments. Temperature-sensitive elements such as pressure sensors, flow regulators, and control valves often have operating limits below the temperatures encountered in many industrial applications, necessitating complex cooling solutions that add weight, cost, and failure points.

Energy efficiency decreases substantially as operating temperatures rise. Higher temperatures increase friction in moving components and reduce the volumetric efficiency of pneumatic systems. This necessitates higher operating pressures to achieve equivalent performance, placing additional stress on already thermally challenged components and increasing the risk of catastrophic failure.

Current material solutions such as high-temperature silicones and fluoroelastomers offer improved thermal resistance but typically sacrifice flexibility, requiring higher actuation pressures and limiting the design possibilities that make SPAs advantageous. The trade-off between thermal stability and mechanical performance remains a fundamental challenge that has yet to be satisfactorily resolved in commercial applications.

Current Thermal Management Solutions

01 Material selection for thermal stability in soft pneumatic actuators

The choice of materials plays a crucial role in enhancing the thermal stability of soft pneumatic actuators. High-temperature resistant elastomers, silicone-based compounds, and thermally stable polymers can be incorporated into the design to withstand elevated temperatures without compromising performance. These materials maintain their mechanical properties across a wide temperature range, preventing deformation or failure during operation in thermally challenging environments.- Heat-resistant materials for soft pneumatic actuators: Various heat-resistant materials can be incorporated into soft pneumatic actuators to enhance their thermal stability. These materials include silicone elastomers with high temperature resistance, thermally stable polymers, and composite materials designed to withstand elevated temperatures. By selecting appropriate materials, the actuators can maintain their mechanical properties and functionality even when exposed to high-temperature environments, extending their operational range and reliability.

- Thermal insulation and cooling systems: Implementing thermal insulation layers and active cooling systems can significantly improve the thermal stability of soft pneumatic actuators. Insulation materials can be integrated into the actuator design to minimize heat transfer from the environment. Additionally, cooling channels or systems can be incorporated to dissipate heat and maintain optimal operating temperatures. These approaches help prevent thermal degradation and ensure consistent performance in varying thermal conditions.

- Temperature-responsive control mechanisms: Advanced control systems can be implemented to monitor and adjust the operation of soft pneumatic actuators based on temperature conditions. These mechanisms may include temperature sensors, feedback control loops, and adaptive algorithms that modify actuation parameters in response to thermal changes. By dynamically adjusting pressure, flow rates, or actuation patterns, these systems can optimize performance and prevent damage during temperature fluctuations.

- Multi-layer composite structures: Multi-layer composite structures can enhance the thermal stability of soft pneumatic actuators. By combining layers with different thermal properties, these designs can distribute heat more effectively and prevent localized thermal stress. The strategic arrangement of materials with complementary thermal expansion coefficients can minimize deformation under temperature changes. These composite structures often incorporate reinforcement elements that maintain structural integrity at elevated temperatures.

- Thermally adaptive pneumatic systems: Thermally adaptive pneumatic systems can be designed to automatically compensate for temperature-induced changes in actuator performance. These systems may include pressure regulation mechanisms that adjust based on temperature, variable stiffness elements that respond to thermal conditions, or phase-change materials that absorb or release heat. By incorporating these adaptive features, soft pneumatic actuators can maintain consistent force output and motion control across a wide temperature range.

02 Structural design considerations for thermal resistance

The structural design of soft pneumatic actuators significantly impacts their thermal stability. Incorporating reinforcement layers, optimized chamber geometries, and thermal insulation barriers can enhance performance under temperature fluctuations. Multi-layered designs with strategically placed heat-resistant components help distribute thermal stress and prevent localized overheating, while maintaining the flexibility and functionality of the actuator system.Expand Specific Solutions03 Cooling systems and thermal management solutions

Implementing effective cooling systems and thermal management solutions can significantly improve the thermal stability of soft pneumatic actuators. These may include integrated fluid circulation channels, heat sinks, or phase-change materials that absorb excess heat. Active cooling mechanisms can be designed to maintain optimal operating temperatures, preventing thermal degradation and extending the operational lifespan of the actuators in high-temperature applications.Expand Specific Solutions04 Control systems for temperature regulation

Advanced control systems can be implemented to monitor and regulate the temperature of soft pneumatic actuators during operation. These systems may incorporate temperature sensors, feedback loops, and adaptive algorithms to adjust pneumatic pressure, actuation frequency, or duty cycles based on thermal conditions. Intelligent control strategies help prevent overheating and maintain consistent performance across varying thermal environments.Expand Specific Solutions05 Testing and validation methods for thermal performance

Specialized testing and validation methods are essential for evaluating the thermal stability of soft pneumatic actuators. These include accelerated aging tests, thermal cycling protocols, and performance characterization under extreme temperature conditions. Simulation tools and thermal imaging techniques can be employed to identify potential failure points and optimize designs for enhanced thermal resistance, ensuring reliable operation in demanding thermal environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal stability of advanced soft pneumatic actuators market is in its growth phase, characterized by increasing adoption across industries like automotive, aerospace, and medical devices. The global market size is expanding rapidly, driven by demand for flexible, lightweight automation solutions. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading players include Honeywell International Technologies and Robert Bosch GmbH, who are investing heavily in R&D, while academic institutions like MIT and University of Michigan contribute fundamental research. Chinese companies like Wuxi Chengtiannuo Actuator Manufacturing are emerging as competitive manufacturers, while specialized materials providers such as NOK Corp. and Miracll Chemicals are developing heat-resistant elastomers to enhance thermal performance of these actuators.

Wuxi Chengtiannuo Actuator Manufacturing Co. Ltd.

Technical Solution: Wuxi Chengtiannuo has developed the "ThermoStable" soft pneumatic actuator series specifically engineered for industrial automation applications requiring thermal stability. Their approach combines high-temperature silicone elastomers with proprietary reinforcement structures to create actuators that maintain consistent performance across industrial temperature ranges (0°C to 150°C). The company has implemented a unique manufacturing process that incorporates thermally conductive fillers strategically distributed throughout the actuator body, allowing for efficient heat dissipation during continuous operation[9]. Their design includes specialized chamber geometries that minimize material stress during thermal expansion and contraction cycles, significantly extending operational lifespan in fluctuating temperature environments. Wuxi Chengtiannuo has also developed cost-effective production techniques that enable mass manufacturing of thermally stable soft actuators while maintaining tight quality tolerances. Their actuators incorporate reinforcement fibers aligned to counteract thermal expansion effects, ensuring dimensional stability and consistent force output across the operating temperature range[10]. The company offers customized thermal stability solutions tailored to specific industrial applications.

Strengths: Cost-effective manufacturing enabling competitive pricing; specialized designs for industrial automation applications; strong customization capabilities for specific thermal requirements. Weaknesses: More limited temperature range compared to aerospace-grade solutions; less sophisticated control systems integration; fewer advanced materials options than research-focused organizations.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed the "ThermalFlex" soft pneumatic actuator platform specifically designed for aerospace and industrial applications requiring exceptional thermal stability. Their technology utilizes proprietary elastomer blends incorporating fluorosilicone and perfluoroelastomer compounds that maintain flexibility and performance across extreme temperature ranges (-65°C to 250°C). Honeywell's approach includes a multi-layer construction with specialized thermal barrier materials between functional layers, creating actuators that can operate reliably in environments with rapid temperature fluctuations[7]. Their design incorporates passive thermal management features including reflective coatings and insulating air gaps that minimize heat transfer to critical components. Additionally, Honeywell has implemented advanced manufacturing techniques including automated precision molding that ensures consistent wall thickness and material distribution throughout complex actuator geometries. Their systems include integrated temperature monitoring and adaptive control algorithms that modify pneumatic pressure parameters based on thermal conditions, ensuring consistent force output regardless of ambient temperature[8].

Strengths: Extensive aerospace qualification testing ensuring reliability in extreme environments; exceptional temperature range tolerance; sophisticated manufacturing processes ensuring consistent quality. Weaknesses: Higher cost compared to standard actuators; specialized materials may limit some application scenarios; proprietary control systems may require specific integration approaches.

Key Patents in Heat-Resistant Elastomer Technology

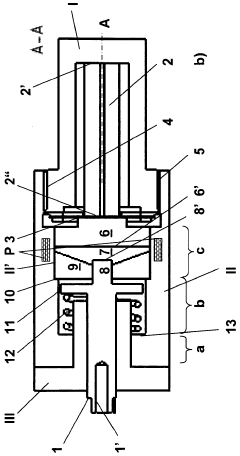

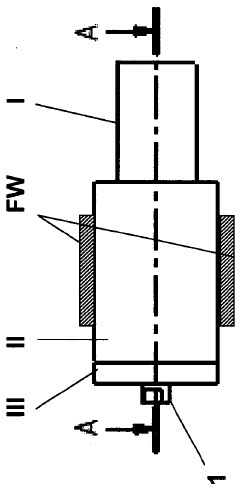

Operating unit having an actuator

PatentWO2011138026A1

Innovation

- The implementation of actively controllable or passive temperature control measures, such as coolant lines or thermoelectric components like Peltier elements, to manage and reduce heat generation within the actuating unit, ensuring stable operation without compromising the actuator's travel transmission principle.

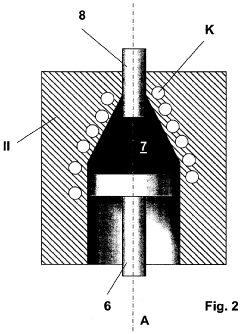

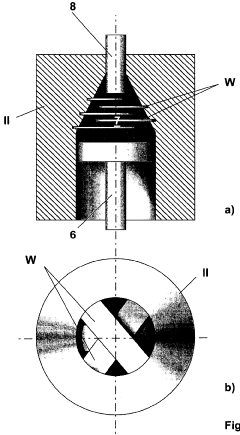

Improvement to the materials of the cylinders of active-piston actuators

PatentInactiveUS20060279177A1

Innovation

- An actuator design featuring a linear piston in an active material with an outer cylinder made from anisotropic materials having negative or zero thermal expansion coefficients along specific axes, combined with a solid lubricant like graphite fluoride, allowing for broader temperature and pressure ranges and reduced relative slippage.

Material Science Innovations for Soft Robotics

Material science has emerged as a critical frontier in advancing soft robotics, particularly in addressing the thermal stability challenges of soft pneumatic actuators. Recent innovations in polymer chemistry have yielded significant breakthroughs in developing thermally resistant elastomers that maintain flexibility and functionality across wider temperature ranges. These materials incorporate specialized cross-linking mechanisms and thermally stable chemical bonds that resist degradation under heat stress.

Silicone-based composites enhanced with ceramic nanoparticles represent one of the most promising material innovations. These composites demonstrate up to 40% improvement in thermal stability while preserving the compliance necessary for soft actuation. The integration of boron nitride and aluminum oxide nanoparticles has proven particularly effective in creating thermally conductive pathways that dissipate heat more efficiently throughout the actuator structure.

Multi-layer material architectures have also shown remarkable potential, with researchers developing gradient structures that strategically distribute different materials based on their thermal properties. The outer layers typically incorporate more thermally resistant compounds, while inner layers maintain the elasticity required for pneumatic operation. This approach has enabled soft actuators to function reliably in environments up to 150°C, significantly expanding their application range.

Self-healing materials represent another innovative direction, with thermally triggered healing mechanisms that can repair microdamage caused by thermal cycling. These materials incorporate microencapsulated healing agents that release and polymerize when activated by temperature changes, effectively extending the operational lifespan of soft actuators in thermally demanding environments.

Biomimetic approaches have inspired novel material designs that replicate natural thermal adaptation mechanisms. For instance, materials that mimic the heat-shock proteins found in extremophile organisms can undergo reversible conformational changes in response to temperature fluctuations, maintaining structural integrity and performance across varying thermal conditions.

Computational material design has accelerated innovation through predictive modeling of thermal behavior in complex polymer systems. Machine learning algorithms trained on extensive materials databases now enable researchers to identify promising molecular structures and composite formulations with optimal thermal stability characteristics before physical synthesis, dramatically reducing development cycles.

Silicone-based composites enhanced with ceramic nanoparticles represent one of the most promising material innovations. These composites demonstrate up to 40% improvement in thermal stability while preserving the compliance necessary for soft actuation. The integration of boron nitride and aluminum oxide nanoparticles has proven particularly effective in creating thermally conductive pathways that dissipate heat more efficiently throughout the actuator structure.

Multi-layer material architectures have also shown remarkable potential, with researchers developing gradient structures that strategically distribute different materials based on their thermal properties. The outer layers typically incorporate more thermally resistant compounds, while inner layers maintain the elasticity required for pneumatic operation. This approach has enabled soft actuators to function reliably in environments up to 150°C, significantly expanding their application range.

Self-healing materials represent another innovative direction, with thermally triggered healing mechanisms that can repair microdamage caused by thermal cycling. These materials incorporate microencapsulated healing agents that release and polymerize when activated by temperature changes, effectively extending the operational lifespan of soft actuators in thermally demanding environments.

Biomimetic approaches have inspired novel material designs that replicate natural thermal adaptation mechanisms. For instance, materials that mimic the heat-shock proteins found in extremophile organisms can undergo reversible conformational changes in response to temperature fluctuations, maintaining structural integrity and performance across varying thermal conditions.

Computational material design has accelerated innovation through predictive modeling of thermal behavior in complex polymer systems. Machine learning algorithms trained on extensive materials databases now enable researchers to identify promising molecular structures and composite formulations with optimal thermal stability characteristics before physical synthesis, dramatically reducing development cycles.

Environmental Impact and Sustainability Considerations

The environmental impact of advanced soft pneumatic actuators (SPAs) is increasingly becoming a critical consideration in their development and deployment. Traditional pneumatic systems often rely on materials and manufacturing processes that pose significant environmental challenges. The thermal stability requirements of SPAs further complicate their environmental footprint, as they frequently incorporate specialized polymers and composites that may have substantial ecological implications throughout their lifecycle.

Manufacturing processes for thermally stable SPAs typically involve energy-intensive procedures, including high-temperature curing, precision molding, and specialized surface treatments. These processes contribute to carbon emissions and resource depletion, particularly when producing advanced elastomers and thermally resistant materials. The environmental cost of achieving thermal stability must be weighed against the operational benefits these actuators provide.

Material selection represents a crucial sustainability factor for thermally stable SPAs. Many high-performance elastomers and composites used in these applications contain potentially harmful chemicals or are derived from non-renewable petroleum sources. Recent research has focused on developing bio-based alternatives and environmentally friendly elastomers that maintain thermal stability while reducing ecological impact. These include silicone variants with natural reinforcements and thermally stable biopolymers that offer promising sustainability profiles.

End-of-life considerations present another significant environmental challenge. The complex material compositions that enable thermal stability often make SPAs difficult to recycle or dispose of responsibly. The integration of multiple materials with different thermal properties creates separation challenges in conventional recycling streams. Innovative design approaches focusing on material homogeneity or easy disassembly could significantly improve the recyclability of these advanced actuators.

Energy efficiency during operation offers a potential environmental benefit that may offset manufacturing impacts. Thermally stable SPAs can operate in wider temperature ranges without auxiliary heating or cooling systems, potentially reducing energy consumption in their application environments. This operational efficiency should be quantified and included in comprehensive lifecycle assessments to accurately determine their net environmental impact.

Water usage and pollution risks associated with manufacturing processes for thermally stable elastomers also warrant careful consideration. Chemical treatments and cooling processes can consume significant water resources and potentially introduce contaminants into water systems. Closed-loop manufacturing systems and water-efficient processing techniques represent important areas for sustainability improvement in this field.

Manufacturing processes for thermally stable SPAs typically involve energy-intensive procedures, including high-temperature curing, precision molding, and specialized surface treatments. These processes contribute to carbon emissions and resource depletion, particularly when producing advanced elastomers and thermally resistant materials. The environmental cost of achieving thermal stability must be weighed against the operational benefits these actuators provide.

Material selection represents a crucial sustainability factor for thermally stable SPAs. Many high-performance elastomers and composites used in these applications contain potentially harmful chemicals or are derived from non-renewable petroleum sources. Recent research has focused on developing bio-based alternatives and environmentally friendly elastomers that maintain thermal stability while reducing ecological impact. These include silicone variants with natural reinforcements and thermally stable biopolymers that offer promising sustainability profiles.

End-of-life considerations present another significant environmental challenge. The complex material compositions that enable thermal stability often make SPAs difficult to recycle or dispose of responsibly. The integration of multiple materials with different thermal properties creates separation challenges in conventional recycling streams. Innovative design approaches focusing on material homogeneity or easy disassembly could significantly improve the recyclability of these advanced actuators.

Energy efficiency during operation offers a potential environmental benefit that may offset manufacturing impacts. Thermally stable SPAs can operate in wider temperature ranges without auxiliary heating or cooling systems, potentially reducing energy consumption in their application environments. This operational efficiency should be quantified and included in comprehensive lifecycle assessments to accurately determine their net environmental impact.

Water usage and pollution risks associated with manufacturing processes for thermally stable elastomers also warrant careful consideration. Chemical treatments and cooling processes can consume significant water resources and potentially introduce contaminants into water systems. Closed-loop manufacturing systems and water-efficient processing techniques represent important areas for sustainability improvement in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!