Comparative Analysis of Soft Pneumatic Actuator Materials

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Background and Objectives

Soft pneumatic actuators (SPAs) have emerged as a transformative technology in the field of robotics and automation over the past three decades. These flexible, compliant mechanisms utilize pneumatic pressure to generate motion and force, offering advantages in safety, adaptability, and biomimetic capabilities compared to traditional rigid actuators. The evolution of SPAs can be traced back to the early 1990s with pioneering work in pneumatic artificial muscles, but significant advancements have accelerated since the 2010s with the rise of soft robotics as a distinct discipline.

The technological trajectory of SPAs has been characterized by progressive improvements in material science, manufacturing techniques, and control methodologies. Early iterations primarily utilized silicone elastomers, while contemporary research has expanded to explore a diverse range of materials including thermoplastic polyurethanes (TPUs), natural rubbers, fabric-reinforced composites, and biodegradable polymers. This material diversification represents a critical trend in addressing application-specific requirements and performance optimization.

The primary objective of comparative material analysis for SPAs is to establish comprehensive performance metrics that enable informed material selection based on specific application requirements. These metrics encompass mechanical properties (elasticity, durability, hysteresis), operational characteristics (response time, force output, pressure tolerance), manufacturing considerations (processability, scalability, cost), and environmental factors (chemical resistance, temperature range, biodegradability).

Current research aims to develop standardized testing protocols for SPA materials to facilitate direct comparisons across different material classes. This standardization is essential for advancing the field beyond empirical material selection toward a more systematic engineering approach. Additionally, there is growing interest in multi-material and composite approaches that combine complementary material properties to achieve enhanced performance characteristics.

The technological goals for SPA material development include achieving greater actuation strains (>100%), improved energy efficiency, enhanced durability (>1 million cycles), reduced hysteresis, and expanded operational temperature ranges. There is also significant focus on developing materials with embedded sensing capabilities to enable closed-loop control and adaptive behaviors without compromising the inherent compliance of soft actuators.

Looking forward, the field is trending toward biomimetic materials that more closely replicate the hierarchical structures found in natural muscle tissues, as well as stimuli-responsive materials that can change properties in response to external triggers beyond pneumatic pressure. These advancements aim to bridge the performance gap between artificial actuators and biological systems while maintaining the inherent safety and adaptability that make SPAs particularly valuable for human-robot interaction applications.

The technological trajectory of SPAs has been characterized by progressive improvements in material science, manufacturing techniques, and control methodologies. Early iterations primarily utilized silicone elastomers, while contemporary research has expanded to explore a diverse range of materials including thermoplastic polyurethanes (TPUs), natural rubbers, fabric-reinforced composites, and biodegradable polymers. This material diversification represents a critical trend in addressing application-specific requirements and performance optimization.

The primary objective of comparative material analysis for SPAs is to establish comprehensive performance metrics that enable informed material selection based on specific application requirements. These metrics encompass mechanical properties (elasticity, durability, hysteresis), operational characteristics (response time, force output, pressure tolerance), manufacturing considerations (processability, scalability, cost), and environmental factors (chemical resistance, temperature range, biodegradability).

Current research aims to develop standardized testing protocols for SPA materials to facilitate direct comparisons across different material classes. This standardization is essential for advancing the field beyond empirical material selection toward a more systematic engineering approach. Additionally, there is growing interest in multi-material and composite approaches that combine complementary material properties to achieve enhanced performance characteristics.

The technological goals for SPA material development include achieving greater actuation strains (>100%), improved energy efficiency, enhanced durability (>1 million cycles), reduced hysteresis, and expanded operational temperature ranges. There is also significant focus on developing materials with embedded sensing capabilities to enable closed-loop control and adaptive behaviors without compromising the inherent compliance of soft actuators.

Looking forward, the field is trending toward biomimetic materials that more closely replicate the hierarchical structures found in natural muscle tissues, as well as stimuli-responsive materials that can change properties in response to external triggers beyond pneumatic pressure. These advancements aim to bridge the performance gap between artificial actuators and biological systems while maintaining the inherent safety and adaptability that make SPAs particularly valuable for human-robot interaction applications.

Market Applications and Demand Analysis

The soft pneumatic actuator (SPA) market is experiencing significant growth driven by increasing demand across multiple industries seeking flexible, lightweight, and safe automation solutions. The global market for soft robotics, which includes SPAs, was valued at approximately 645 million USD in 2020 and is projected to reach 2.1 billion USD by 2026, representing a compound annual growth rate of 22.5%. This remarkable growth trajectory is fueled by the unique capabilities of soft actuators to interact safely with humans and delicate objects.

Healthcare and medical applications represent the largest market segment for soft pneumatic actuators, accounting for nearly 35% of the total market share. The demand is particularly strong for rehabilitation devices, surgical assistants, and prosthetics where the compliant nature of SPAs provides safer patient interaction compared to rigid alternatives. The aging population in developed countries further amplifies this demand, with over 700 million people expected to be over 65 by 2030 globally.

Manufacturing and industrial automation constitute another rapidly expanding market segment. As collaborative robotics gains traction, the need for actuators that can work alongside humans without safety cages has increased substantially. This sector values SPAs for their inherent safety, adaptability to irregular objects, and ability to operate in variable environments. The industrial soft robotics market segment is growing at approximately 25% annually, outpacing the overall robotics market.

Consumer electronics and wearable technology represent emerging application areas with substantial growth potential. The demand for haptic feedback devices, adaptive grippers for consumer robots, and assistive wearables is creating new opportunities for SPA materials. This segment is expected to grow at 30% annually over the next five years as miniaturization and energy efficiency of SPAs improve.

The aerospace and automotive industries are increasingly adopting SPAs for specialized applications including adaptive structures, morphing components, and human-machine interfaces. These high-value sectors demand materials with exceptional durability, temperature resistance, and reliability, driving innovation in advanced SPA materials.

Geographically, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 27% annually, driven by rapid industrialization and significant investments in healthcare and manufacturing automation in countries like China, Japan, and South Korea.

The market analysis reveals a clear correlation between material performance characteristics and application-specific requirements, highlighting the need for continued material innovation to address unmet market needs in terms of durability, response time, and energy efficiency.

Healthcare and medical applications represent the largest market segment for soft pneumatic actuators, accounting for nearly 35% of the total market share. The demand is particularly strong for rehabilitation devices, surgical assistants, and prosthetics where the compliant nature of SPAs provides safer patient interaction compared to rigid alternatives. The aging population in developed countries further amplifies this demand, with over 700 million people expected to be over 65 by 2030 globally.

Manufacturing and industrial automation constitute another rapidly expanding market segment. As collaborative robotics gains traction, the need for actuators that can work alongside humans without safety cages has increased substantially. This sector values SPAs for their inherent safety, adaptability to irregular objects, and ability to operate in variable environments. The industrial soft robotics market segment is growing at approximately 25% annually, outpacing the overall robotics market.

Consumer electronics and wearable technology represent emerging application areas with substantial growth potential. The demand for haptic feedback devices, adaptive grippers for consumer robots, and assistive wearables is creating new opportunities for SPA materials. This segment is expected to grow at 30% annually over the next five years as miniaturization and energy efficiency of SPAs improve.

The aerospace and automotive industries are increasingly adopting SPAs for specialized applications including adaptive structures, morphing components, and human-machine interfaces. These high-value sectors demand materials with exceptional durability, temperature resistance, and reliability, driving innovation in advanced SPA materials.

Geographically, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 27% annually, driven by rapid industrialization and significant investments in healthcare and manufacturing automation in countries like China, Japan, and South Korea.

The market analysis reveals a clear correlation between material performance characteristics and application-specific requirements, highlighting the need for continued material innovation to address unmet market needs in terms of durability, response time, and energy efficiency.

Current Material Technologies and Limitations

Soft pneumatic actuators (SPAs) currently employ a variety of materials, each with distinct properties and limitations. Silicone elastomers, particularly polydimethylsiloxane (PDMS) and room temperature vulcanizing (RTV) silicones, dominate the field due to their excellent elasticity, thermal stability, and chemical resistance. These materials offer Shore A hardness values ranging from 10 to 80, allowing customization for specific applications. However, silicones exhibit relatively low tensile strength (typically 2-10 MPa) and are prone to tearing, limiting their durability in high-stress environments.

Thermoplastic elastomers (TPEs) represent another significant material category, with thermoplastic polyurethanes (TPUs) being particularly prevalent. TPUs offer superior tear resistance compared to silicones, with tensile strengths reaching 20-60 MPa, and can be processed using conventional thermoplastic techniques including injection molding and 3D printing. Nevertheless, TPUs generally exhibit higher hysteresis and stress relaxation than silicones, resulting in performance degradation during cyclic operation.

Natural rubber and its derivatives provide exceptional elasticity with elongation at break values exceeding 700%, but suffer from poor environmental resistance, particularly to UV radiation and ozone. Additionally, processing natural rubber requires specialized equipment and expertise, limiting its accessibility for research applications.

Recent developments have introduced hydrogels as potential SPA materials, offering water content above 90% and biocompatibility advantages. However, hydrogels face significant challenges including low mechanical strength, dehydration concerns, and limited longevity, restricting their practical applications despite theoretical promise.

Fiber-reinforced composites attempt to address the limitations of single materials by combining elastomeric matrices with high-strength fibers. While these composites demonstrate improved mechanical properties, they introduce manufacturing complexities and anisotropic behavior that complicates design and modeling efforts.

A critical limitation across all current materials is the inherent trade-off between elasticity and strength. Materials with sufficient elasticity for large deformations typically lack the strength to withstand high pressures, while stronger materials restrict the actuator's range of motion. This fundamental challenge has prompted ongoing research into novel material formulations and composite structures.

Manufacturing constraints further limit material selection, as many potential materials require complex processing techniques incompatible with the intricate geometries of pneumatic actuators. Additionally, most current materials exhibit poor self-healing capabilities and limited resistance to environmental factors, reducing their long-term reliability in real-world applications.

Thermoplastic elastomers (TPEs) represent another significant material category, with thermoplastic polyurethanes (TPUs) being particularly prevalent. TPUs offer superior tear resistance compared to silicones, with tensile strengths reaching 20-60 MPa, and can be processed using conventional thermoplastic techniques including injection molding and 3D printing. Nevertheless, TPUs generally exhibit higher hysteresis and stress relaxation than silicones, resulting in performance degradation during cyclic operation.

Natural rubber and its derivatives provide exceptional elasticity with elongation at break values exceeding 700%, but suffer from poor environmental resistance, particularly to UV radiation and ozone. Additionally, processing natural rubber requires specialized equipment and expertise, limiting its accessibility for research applications.

Recent developments have introduced hydrogels as potential SPA materials, offering water content above 90% and biocompatibility advantages. However, hydrogels face significant challenges including low mechanical strength, dehydration concerns, and limited longevity, restricting their practical applications despite theoretical promise.

Fiber-reinforced composites attempt to address the limitations of single materials by combining elastomeric matrices with high-strength fibers. While these composites demonstrate improved mechanical properties, they introduce manufacturing complexities and anisotropic behavior that complicates design and modeling efforts.

A critical limitation across all current materials is the inherent trade-off between elasticity and strength. Materials with sufficient elasticity for large deformations typically lack the strength to withstand high pressures, while stronger materials restrict the actuator's range of motion. This fundamental challenge has prompted ongoing research into novel material formulations and composite structures.

Manufacturing constraints further limit material selection, as many potential materials require complex processing techniques incompatible with the intricate geometries of pneumatic actuators. Additionally, most current materials exhibit poor self-healing capabilities and limited resistance to environmental factors, reducing their long-term reliability in real-world applications.

Existing Material Solutions Comparison

01 Elastomeric materials for soft pneumatic actuators

Elastomeric materials such as silicone rubber and polyurethane are commonly used in soft pneumatic actuators due to their flexibility, elasticity, and durability. These materials can undergo large deformations while maintaining their structural integrity, making them ideal for applications requiring repeated inflation and deflation cycles. The elastomeric nature allows for complex movements and adaptable configurations in soft robotics applications.- Elastomeric materials for soft pneumatic actuators: Elastomeric materials such as silicone rubber, polyurethane, and natural rubber are commonly used in soft pneumatic actuators due to their high elasticity, flexibility, and durability. These materials can undergo large deformations under pneumatic pressure and return to their original shape when the pressure is released. The elastomeric materials can be engineered with specific properties to achieve desired actuation behaviors, including different stiffness levels and response characteristics.

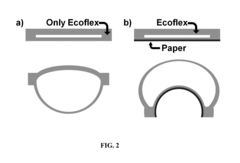

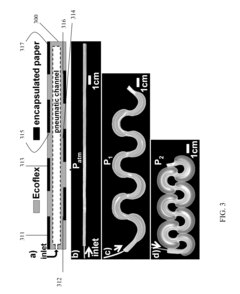

- Composite and reinforced materials for enhanced performance: Composite materials combining elastomers with reinforcing elements such as fibers, fabrics, or particles are used to enhance the performance of soft pneumatic actuators. These reinforcements can control the deformation direction, increase the actuator's strength, and improve durability while maintaining flexibility. Fiber-reinforced elastomers, in particular, allow for programmable motion patterns by strategically placing reinforcement in specific orientations to direct expansion and contraction.

- Smart and responsive materials for advanced actuation: Smart materials that respond to external stimuli are being incorporated into soft pneumatic actuators to create multi-responsive systems. These include shape memory polymers, temperature-responsive materials, and electrically conductive elastomers. By combining pneumatic actuation with these responsive materials, actuators can achieve complex movements and functionalities, such as self-sensing capabilities, variable stiffness, and adaptive behavior based on environmental conditions.

- Biodegradable and sustainable materials for eco-friendly applications: Biodegradable and sustainable materials are emerging as alternatives for soft pneumatic actuators in environmentally sensitive applications. These include natural polymers, biodegradable elastomers, and bio-based composites that can provide the necessary mechanical properties while reducing environmental impact. These materials are particularly valuable for soft robots designed for agricultural, medical, or marine environments where conventional elastomers might pose contamination risks.

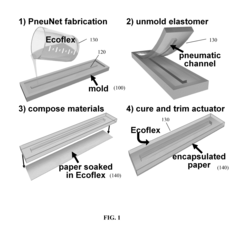

- Manufacturing techniques for soft pneumatic actuator materials: Advanced manufacturing techniques are crucial for processing soft pneumatic actuator materials into functional devices. These include 3D printing of elastomers, multi-material printing, molding processes, and lamination techniques. These manufacturing methods enable the creation of complex internal channels, variable wall thicknesses, and integrated sensing elements within the actuator structure. The choice of manufacturing technique significantly impacts the material properties and performance of the resulting soft pneumatic actuators.

02 Composite and reinforced materials for enhanced performance

Composite materials combining elastomers with reinforcing elements such as fibers, fabrics, or particles can enhance the performance of soft pneumatic actuators. These reinforcements control deformation patterns, increase strength, and improve pressure resistance while maintaining flexibility. Strategic placement of reinforcing materials enables directional actuation and complex motion patterns that would be impossible with homogeneous materials alone.Expand Specific Solutions03 Smart and responsive materials for advanced actuation

Smart materials that respond to external stimuli beyond just pneumatic pressure are being incorporated into soft actuators. These include shape memory polymers, electroactive polymers, and materials with temperature or light-responsive properties. Such materials enable multi-modal actuation, self-sensing capabilities, and adaptive responses to environmental conditions, expanding the functionality of soft pneumatic systems.Expand Specific Solutions04 Biodegradable and sustainable materials for soft actuators

Research is advancing in developing biodegradable and environmentally friendly materials for soft pneumatic actuators. These include natural polymers, bioplastics, and other sustainable alternatives to traditional elastomers. Such materials address environmental concerns while maintaining the necessary mechanical properties for effective actuation, making them suitable for applications in environmental monitoring, agriculture, and biomedical fields.Expand Specific Solutions05 Manufacturing techniques for soft pneumatic actuator materials

Advanced manufacturing techniques are crucial for processing soft pneumatic actuator materials into functional devices. These include 3D printing, molding, casting, and hybrid fabrication approaches that enable complex geometries and multi-material integration. Novel processing methods allow for the creation of actuators with variable stiffness, embedded channels, and integrated sensing capabilities, expanding the design possibilities for soft robotic systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The soft pneumatic actuator materials market is in a growth phase, characterized by increasing research and development activities across academic institutions and commercial entities. The market is expanding due to rising applications in robotics, healthcare, and industrial automation, with an estimated global market size of several hundred million dollars. From a technological maturity perspective, leading academic institutions like Harvard College, MIT, Cornell University, and Zhejiang University are pioneering fundamental research, while companies such as Beijing Soft Robot Technology, Parker-Hannifin, and BASF are commercializing applications. The competitive landscape shows a balanced distribution between academic innovation and industrial implementation, with materials development being led by chemical companies like Shin-Etsu Chemical and W.L. Gore & Associates, who are advancing specialized elastomers and polymers for enhanced actuator performance.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuator materials through their groundbreaking research on fiber-reinforced elastomeric enclosures (FREEs). Their technology utilizes silicone elastomers (primarily Ecoflex and Dragon Skin) with embedded fiber reinforcements in specific patterns to control deformation modes. Harvard researchers have developed a comprehensive material selection framework that considers hyperelastic properties, durability, and manufacturing compatibility. Their recent innovations include multi-material 3D printing techniques for creating actuators with programmable stiffness gradients and embedded sensing capabilities. Harvard has also developed hybrid actuator systems combining traditional elastomers with liquid crystal elastomers to achieve enhanced force output and controlled directional movement. Their material characterization protocols have become industry standards, particularly their cyclic loading tests that predict material fatigue in pneumatic applications.

Strengths: Exceptional material characterization capabilities, pioneering multi-material fabrication techniques, and strong integration with sensing technologies. Their research provides comprehensive performance metrics across diverse operating conditions. Weaknesses: Their advanced materials often require specialized manufacturing equipment and expertise, limiting widespread adoption. Some of their high-performance elastomer formulations face challenges in scaling to industrial production volumes.

Cornell University

Technical Solution: Cornell University has pioneered fiber-reinforced composite materials for soft pneumatic actuators, focusing on biomimetic designs. Their research centers on elastomeric matrices (primarily silicone-based) with strategically embedded fiber reinforcements that control deformation patterns. Cornell's innovation includes developing anisotropic fiber arrangements that enable complex, multi-directional movements from simple pressure inputs. Their material system incorporates variable stiffness regions achieved through localized variations in fiber density and orientation. Cornell researchers have developed specialized manufacturing techniques including automated fiber winding and embedding processes that ensure precise fiber placement within the elastomeric matrix. Their recent work includes developing responsive materials that change properties based on environmental stimuli, such as temperature-responsive elastomers that stiffen at specific temperature thresholds to provide adaptive control capabilities. Cornell has also created specialized testing protocols for characterizing the unique mechanical properties of these composite materials under pneumatic loading conditions.

Strengths: Superior directional control of actuation through anisotropic material properties, excellent force-to-weight ratios compared to homogeneous elastomers, and highly customizable deformation patterns. Weaknesses: Manufacturing complexity requiring specialized equipment for fiber placement, challenges in scaling production to industrial volumes, and higher material costs compared to standard elastomers.

Key Material Properties and Performance Metrics

Apparatus, system, and method for providing fabric-elastomer composites as pneumatic actuators

PatentActiveUS20150070904A1

Innovation

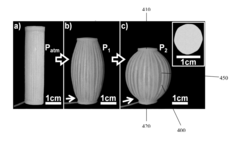

- The development of soft robotics using composite actuators made from elastomers and embedded flexible sheets, such as paper, which introduce controlled anisotropy to enable a range of motions including extension, contraction, twisting, and bending through pneumatic actuation, allowing for flexible control and practical design.

Manufacturing Processes and Scalability

The manufacturing processes for soft pneumatic actuators (SPAs) represent a critical factor in determining their commercial viability and widespread adoption. Traditional manufacturing approaches for SPAs have primarily relied on labor-intensive molding techniques, which present significant challenges for mass production and cost efficiency. The silicone-based actuators typically require multi-step casting processes involving master molds, which demand precision and time, limiting production throughput.

Recent advancements have introduced more scalable manufacturing methodologies, including 3D printing and automated molding systems. Fused deposition modeling (FDM) enables rapid prototyping of complex actuator geometries but faces limitations in material selection and resolution. More promising is the emergence of specialized 3D printing techniques for soft materials, such as direct ink writing and digital light processing (DLP), which allow for greater design freedom and reduced manual intervention.

Injection molding represents another scalable approach for thermoplastic elastomers (TPEs), offering high-volume production capabilities with consistent quality. However, this process requires significant initial investment in tooling and equipment, making it economically viable only at larger production scales. For silicone-based actuators, automated dispensing systems have been developed to improve consistency and reduce labor costs in the casting process.

Material selection significantly impacts manufacturing scalability. Silicones, while offering excellent performance characteristics, present challenges in automated processing due to their curing requirements and handling properties. TPEs provide advantages in manufacturing speed through thermal processing but may compromise on certain performance metrics. Fabric-reinforced composites introduce additional complexity in manufacturing but deliver enhanced durability and force output.

The integration of embedded sensors and electronic components presents another manufacturing challenge, requiring precise alignment and secure bonding between dissimilar materials. Current research focuses on developing in-line manufacturing processes that can incorporate sensing elements during the primary fabrication stage rather than as secondary operations.

Cost considerations vary significantly across manufacturing methods. While 3D printing offers low setup costs for small production runs, the material costs and slower production speeds become prohibitive at scale. Conversely, injection molding and automated casting systems provide economies of scale but require substantial initial investment. The optimal manufacturing approach ultimately depends on production volume, design complexity, and performance requirements of the specific SPA application.

Recent advancements have introduced more scalable manufacturing methodologies, including 3D printing and automated molding systems. Fused deposition modeling (FDM) enables rapid prototyping of complex actuator geometries but faces limitations in material selection and resolution. More promising is the emergence of specialized 3D printing techniques for soft materials, such as direct ink writing and digital light processing (DLP), which allow for greater design freedom and reduced manual intervention.

Injection molding represents another scalable approach for thermoplastic elastomers (TPEs), offering high-volume production capabilities with consistent quality. However, this process requires significant initial investment in tooling and equipment, making it economically viable only at larger production scales. For silicone-based actuators, automated dispensing systems have been developed to improve consistency and reduce labor costs in the casting process.

Material selection significantly impacts manufacturing scalability. Silicones, while offering excellent performance characteristics, present challenges in automated processing due to their curing requirements and handling properties. TPEs provide advantages in manufacturing speed through thermal processing but may compromise on certain performance metrics. Fabric-reinforced composites introduce additional complexity in manufacturing but deliver enhanced durability and force output.

The integration of embedded sensors and electronic components presents another manufacturing challenge, requiring precise alignment and secure bonding between dissimilar materials. Current research focuses on developing in-line manufacturing processes that can incorporate sensing elements during the primary fabrication stage rather than as secondary operations.

Cost considerations vary significantly across manufacturing methods. While 3D printing offers low setup costs for small production runs, the material costs and slower production speeds become prohibitive at scale. Conversely, injection molding and automated casting systems provide economies of scale but require substantial initial investment. The optimal manufacturing approach ultimately depends on production volume, design complexity, and performance requirements of the specific SPA application.

Environmental Impact and Sustainability Considerations

The environmental impact of soft pneumatic actuator (SPA) materials represents a critical consideration in their development and application. Traditional actuator systems often rely on materials with significant ecological footprints, including metals and petroleum-based polymers that present end-of-life disposal challenges. In contrast, many SPA materials offer potential sustainability advantages that warrant systematic evaluation.

Silicone elastomers, commonly used in SPAs, present a mixed environmental profile. While their production requires energy-intensive processes and petroleum-derived raw materials, their exceptional durability extends product lifecycles, potentially offsetting initial environmental costs. Recent advancements in bio-based silicones derived from agricultural waste streams show promise for reducing the carbon footprint of these essential SPA components.

Thermoplastic polyurethanes (TPUs) offer recyclability advantages over thermoset alternatives, enabling material recovery and reprocessing at end-of-life. This circular economy potential significantly reduces waste compared to single-use materials. However, the environmental benefits must be weighed against the energy requirements for recycling processes and potential material property degradation through multiple recycling cycles.

Emerging biodegradable elastomers represent perhaps the most promising direction for environmentally conscious SPA development. Materials such as polylactic acid (PLA) blends and natural rubber composites can provide suitable mechanical properties while offering controlled degradation under specific environmental conditions. These materials minimize persistent waste but may currently deliver lower performance or durability than conventional alternatives.

Manufacturing processes for SPAs also carry significant environmental implications. Additive manufacturing approaches can reduce material waste compared to traditional subtractive methods, but may consume more energy per unit produced. Water-based manufacturing processes for hydrogel actuators typically generate fewer toxic byproducts than solvent-based alternatives used for some elastomers.

Life cycle assessment (LCA) studies reveal that the operational phase often dominates the environmental impact of pneumatic systems through compressed air generation. Energy-efficient actuator designs that operate at lower pressures can therefore deliver substantial sustainability benefits regardless of material selection. This highlights the importance of system-level environmental analysis rather than focusing exclusively on material properties.

Regulatory frameworks increasingly influence material selection for SPAs, with restrictions on certain plasticizers, flame retardants, and other additives driving reformulation efforts. Forward-looking manufacturers are proactively adopting green chemistry principles in material development to anticipate future regulatory requirements and consumer preferences for environmentally responsible products.

Silicone elastomers, commonly used in SPAs, present a mixed environmental profile. While their production requires energy-intensive processes and petroleum-derived raw materials, their exceptional durability extends product lifecycles, potentially offsetting initial environmental costs. Recent advancements in bio-based silicones derived from agricultural waste streams show promise for reducing the carbon footprint of these essential SPA components.

Thermoplastic polyurethanes (TPUs) offer recyclability advantages over thermoset alternatives, enabling material recovery and reprocessing at end-of-life. This circular economy potential significantly reduces waste compared to single-use materials. However, the environmental benefits must be weighed against the energy requirements for recycling processes and potential material property degradation through multiple recycling cycles.

Emerging biodegradable elastomers represent perhaps the most promising direction for environmentally conscious SPA development. Materials such as polylactic acid (PLA) blends and natural rubber composites can provide suitable mechanical properties while offering controlled degradation under specific environmental conditions. These materials minimize persistent waste but may currently deliver lower performance or durability than conventional alternatives.

Manufacturing processes for SPAs also carry significant environmental implications. Additive manufacturing approaches can reduce material waste compared to traditional subtractive methods, but may consume more energy per unit produced. Water-based manufacturing processes for hydrogel actuators typically generate fewer toxic byproducts than solvent-based alternatives used for some elastomers.

Life cycle assessment (LCA) studies reveal that the operational phase often dominates the environmental impact of pneumatic systems through compressed air generation. Energy-efficient actuator designs that operate at lower pressures can therefore deliver substantial sustainability benefits regardless of material selection. This highlights the importance of system-level environmental analysis rather than focusing exclusively on material properties.

Regulatory frameworks increasingly influence material selection for SPAs, with restrictions on certain plasticizers, flame retardants, and other additives driving reformulation efforts. Forward-looking manufacturers are proactively adopting green chemistry principles in material development to anticipate future regulatory requirements and consumer preferences for environmentally responsible products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!