Soft Pneumatic Actuator Applications in Smart Textiles

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPA Technology Evolution and Objectives

Soft Pneumatic Actuators (SPAs) have evolved significantly over the past decades, transitioning from rudimentary inflatable structures to sophisticated components capable of precise movements and interactions. The evolution began in the 1950s with simple pneumatic artificial muscles, but gained substantial momentum in the early 2000s when researchers started exploring soft materials for robotic applications. This paradigm shift was driven by the limitations of traditional rigid actuators in applications requiring safe human-machine interaction.

The technological progression of SPAs has been marked by several key advancements. Initially, SPAs were primarily constructed using silicone elastomers with simple channel designs. Over time, manufacturing techniques evolved to incorporate multi-material fabrication, enabling the creation of actuators with variable stiffness and complex motion patterns. The integration of embedded sensors and the development of specialized pneumatic control systems further enhanced the functionality and precision of these devices.

In the context of smart textiles, SPAs represent a transformative technology that bridges the gap between traditional fabrics and interactive, responsive materials. The objective of SPA integration into textiles is to create wearable systems that can adapt to user needs, provide haptic feedback, assist movement, or change form factor while maintaining the comfort, flexibility, and aesthetic qualities expected from conventional textiles.

Current technological goals for SPAs in smart textiles include miniaturization to achieve seamless integration without compromising the textile's drape and feel. Researchers aim to develop SPAs that can operate at lower pressures while maintaining sufficient force output, thereby reducing the requirements for bulky pneumatic infrastructure. Energy efficiency is another critical objective, as wearable applications demand extended operation periods without frequent recharging or air replenishment.

Durability presents a significant challenge, as SPAs must withstand thousands of actuation cycles, exposure to various environmental conditions, and regular washing processes typical for textile products. Additionally, there is a push toward sustainable manufacturing methods and materials, including biodegradable elastomers and environmentally friendly fabrication processes.

The long-term vision for SPA technology in smart textiles encompasses fully integrated systems where the distinction between the actuator and the textile disappears. This includes the development of fiber-based pneumatic actuators that can be woven directly into fabrics, as well as distributed actuation networks that can create complex, programmable deformations across the entire textile surface. These advancements aim to enable applications ranging from medical compression garments with dynamic pressure profiles to fashion items that can change their appearance or thermal properties in response to environmental conditions or user preferences.

The technological progression of SPAs has been marked by several key advancements. Initially, SPAs were primarily constructed using silicone elastomers with simple channel designs. Over time, manufacturing techniques evolved to incorporate multi-material fabrication, enabling the creation of actuators with variable stiffness and complex motion patterns. The integration of embedded sensors and the development of specialized pneumatic control systems further enhanced the functionality and precision of these devices.

In the context of smart textiles, SPAs represent a transformative technology that bridges the gap between traditional fabrics and interactive, responsive materials. The objective of SPA integration into textiles is to create wearable systems that can adapt to user needs, provide haptic feedback, assist movement, or change form factor while maintaining the comfort, flexibility, and aesthetic qualities expected from conventional textiles.

Current technological goals for SPAs in smart textiles include miniaturization to achieve seamless integration without compromising the textile's drape and feel. Researchers aim to develop SPAs that can operate at lower pressures while maintaining sufficient force output, thereby reducing the requirements for bulky pneumatic infrastructure. Energy efficiency is another critical objective, as wearable applications demand extended operation periods without frequent recharging or air replenishment.

Durability presents a significant challenge, as SPAs must withstand thousands of actuation cycles, exposure to various environmental conditions, and regular washing processes typical for textile products. Additionally, there is a push toward sustainable manufacturing methods and materials, including biodegradable elastomers and environmentally friendly fabrication processes.

The long-term vision for SPA technology in smart textiles encompasses fully integrated systems where the distinction between the actuator and the textile disappears. This includes the development of fiber-based pneumatic actuators that can be woven directly into fabrics, as well as distributed actuation networks that can create complex, programmable deformations across the entire textile surface. These advancements aim to enable applications ranging from medical compression garments with dynamic pressure profiles to fashion items that can change their appearance or thermal properties in response to environmental conditions or user preferences.

Smart Textile Market Demand Analysis

The smart textiles market is experiencing significant growth driven by increasing consumer demand for wearable technology with enhanced functionality. Current market analysis indicates that the global smart textiles market was valued at approximately 3.6 billion USD in 2022 and is projected to reach 13.6 billion USD by 2027, representing a compound annual growth rate of 30.4%. This remarkable growth trajectory is fueled by multiple factors across various sectors.

Healthcare applications represent one of the most promising market segments for soft pneumatic actuator-integrated smart textiles. The aging global population and rising healthcare costs have created substantial demand for remote patient monitoring solutions and rehabilitation devices. Smart compression garments utilizing soft pneumatic actuators can provide dynamic pressure therapy for conditions like lymphedema, deep vein thrombosis, and sports injuries, offering personalized treatment protocols that traditional compression garments cannot match.

The sports and fitness sector demonstrates robust demand for performance-enhancing smart textiles. Athletes and fitness enthusiasts increasingly seek garments that not only monitor biometric data but actively respond to body conditions. Soft pneumatic actuator-embedded sportswear can provide real-time muscle support, improve posture, and enhance proprioception during physical activities, creating a competitive advantage for early market entrants.

Military and defense applications constitute another significant market driver. There is growing interest in smart textiles that can enhance soldier performance and safety through adaptive camouflage, temperature regulation, and physical augmentation. Soft pneumatic actuators integrated into military uniforms can potentially reduce fatigue by assisting movement and providing strategic compression to improve blood circulation during extended missions.

Consumer fashion and lifestyle products represent an emerging market segment with considerable growth potential. As consumers become more tech-savvy, the demand for clothing that offers both aesthetic appeal and functional benefits increases. Smart textiles with soft pneumatic actuators can enable novel fashion designs with shape-changing capabilities, customizable fit adjustments, and interactive elements that respond to environmental or user inputs.

Industrial applications, particularly in occupational safety and ergonomics, show promising market potential. Workers in physically demanding roles could benefit from smart textiles with soft pneumatic actuators that provide postural support, reduce muscle strain, and prevent repetitive stress injuries. The potential for reducing workplace injuries and associated costs presents a compelling value proposition for industrial employers.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in adoption, driven by higher disposable incomes and greater technological acceptance. However, Asia-Pacific markets are expected to demonstrate the fastest growth rate, supported by expanding manufacturing capabilities and increasing consumer technology adoption in countries like China, Japan, and South Korea.

Healthcare applications represent one of the most promising market segments for soft pneumatic actuator-integrated smart textiles. The aging global population and rising healthcare costs have created substantial demand for remote patient monitoring solutions and rehabilitation devices. Smart compression garments utilizing soft pneumatic actuators can provide dynamic pressure therapy for conditions like lymphedema, deep vein thrombosis, and sports injuries, offering personalized treatment protocols that traditional compression garments cannot match.

The sports and fitness sector demonstrates robust demand for performance-enhancing smart textiles. Athletes and fitness enthusiasts increasingly seek garments that not only monitor biometric data but actively respond to body conditions. Soft pneumatic actuator-embedded sportswear can provide real-time muscle support, improve posture, and enhance proprioception during physical activities, creating a competitive advantage for early market entrants.

Military and defense applications constitute another significant market driver. There is growing interest in smart textiles that can enhance soldier performance and safety through adaptive camouflage, temperature regulation, and physical augmentation. Soft pneumatic actuators integrated into military uniforms can potentially reduce fatigue by assisting movement and providing strategic compression to improve blood circulation during extended missions.

Consumer fashion and lifestyle products represent an emerging market segment with considerable growth potential. As consumers become more tech-savvy, the demand for clothing that offers both aesthetic appeal and functional benefits increases. Smart textiles with soft pneumatic actuators can enable novel fashion designs with shape-changing capabilities, customizable fit adjustments, and interactive elements that respond to environmental or user inputs.

Industrial applications, particularly in occupational safety and ergonomics, show promising market potential. Workers in physically demanding roles could benefit from smart textiles with soft pneumatic actuators that provide postural support, reduce muscle strain, and prevent repetitive stress injuries. The potential for reducing workplace injuries and associated costs presents a compelling value proposition for industrial employers.

Market analysis reveals regional variations in demand patterns. North America and Europe currently lead in adoption, driven by higher disposable incomes and greater technological acceptance. However, Asia-Pacific markets are expected to demonstrate the fastest growth rate, supported by expanding manufacturing capabilities and increasing consumer technology adoption in countries like China, Japan, and South Korea.

SPA Integration Challenges in Textiles

The integration of Soft Pneumatic Actuators (SPAs) into textile structures presents several significant technical challenges that must be addressed to achieve functional smart textiles. One primary challenge is the material compatibility between SPAs and traditional textile fibers. SPAs typically utilize elastomeric materials like silicone or thermoplastic polyurethanes, which have different mechanical properties, processing requirements, and durability characteristics compared to conventional textile fibers. This incompatibility creates difficulties in achieving seamless integration without compromising the textile's inherent properties such as drapeability, breathability, and tactile comfort.

Manufacturing processes represent another substantial hurdle. Traditional textile production methods including weaving, knitting, and embroidery are not inherently designed to incorporate pneumatic channels and chambers. Adapting these processes to include SPAs requires significant modifications to equipment and techniques. Alternative approaches such as lamination, coating, or direct printing of SPAs onto textiles each present their own set of challenges related to adhesion, durability, and scalability.

The pneumatic infrastructure necessary for SPA operation poses additional integration difficulties. Creating airtight channels and chambers within porous textile structures demands innovative sealing techniques. Furthermore, the integration of valves, pumps, and control systems must be accomplished without adding excessive bulk or rigidity to the textile, which would compromise wearability and user comfort.

Durability and reliability concerns are particularly pronounced in SPA-textile systems. These smart textiles must withstand repeated mechanical deformation, washing cycles, and environmental stressors while maintaining pneumatic integrity. The interface between soft actuators and textile substrates represents a potential failure point that requires careful engineering to ensure long-term functionality.

Power management presents another significant challenge. While SPAs themselves require only air pressure for actuation, the supporting components such as miniature pumps and valves require electrical power. Integrating these power sources and associated electronics into textiles while maintaining safety, comfort, and washability remains technically demanding.

Scalability and cost-effectiveness also constrain widespread adoption. Current fabrication methods for SPAs are predominantly laboratory-scale techniques that are difficult to translate to industrial textile manufacturing processes. Developing cost-effective, high-throughput production methods that maintain precision and quality represents a critical challenge for commercial viability.

Manufacturing processes represent another substantial hurdle. Traditional textile production methods including weaving, knitting, and embroidery are not inherently designed to incorporate pneumatic channels and chambers. Adapting these processes to include SPAs requires significant modifications to equipment and techniques. Alternative approaches such as lamination, coating, or direct printing of SPAs onto textiles each present their own set of challenges related to adhesion, durability, and scalability.

The pneumatic infrastructure necessary for SPA operation poses additional integration difficulties. Creating airtight channels and chambers within porous textile structures demands innovative sealing techniques. Furthermore, the integration of valves, pumps, and control systems must be accomplished without adding excessive bulk or rigidity to the textile, which would compromise wearability and user comfort.

Durability and reliability concerns are particularly pronounced in SPA-textile systems. These smart textiles must withstand repeated mechanical deformation, washing cycles, and environmental stressors while maintaining pneumatic integrity. The interface between soft actuators and textile substrates represents a potential failure point that requires careful engineering to ensure long-term functionality.

Power management presents another significant challenge. While SPAs themselves require only air pressure for actuation, the supporting components such as miniature pumps and valves require electrical power. Integrating these power sources and associated electronics into textiles while maintaining safety, comfort, and washability remains technically demanding.

Scalability and cost-effectiveness also constrain widespread adoption. Current fabrication methods for SPAs are predominantly laboratory-scale techniques that are difficult to translate to industrial textile manufacturing processes. Developing cost-effective, high-throughput production methods that maintain precision and quality represents a critical challenge for commercial viability.

Current SPA Implementation in Wearables

01 Design and structure of soft pneumatic actuators

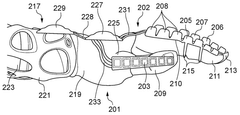

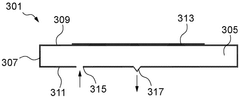

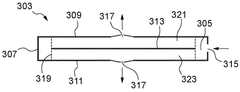

Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract when pressurized, creating movement. The structural design elements include the arrangement of chambers, reinforcement patterns, and material selection which all contribute to the actuator's performance characteristics such as force output, range of motion, and compliance.- Design and fabrication of soft pneumatic actuators: Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract when pressurized, resulting in bending, twisting, or other complex motions. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal chambers and external structure of the actuators.

- Applications of soft pneumatic actuators in robotics: Soft pneumatic actuators are widely used in soft robotics for various applications including gripping, manipulation, locomotion, and human-robot interaction. These actuators enable robots to safely interact with delicate objects and humans due to their inherent compliance and adaptability. They can be designed to mimic biological movements and structures, making them suitable for biomimetic robots that can navigate complex environments or perform tasks requiring dexterity and adaptability.

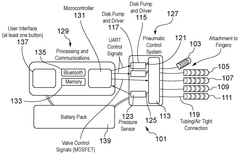

- Control systems for soft pneumatic actuators: Control systems for soft pneumatic actuators involve specialized valves, pressure regulators, sensors, and algorithms to achieve precise and coordinated movements. These systems can include closed-loop control with feedback from embedded sensors that measure pressure, deformation, or position. Advanced control strategies may incorporate machine learning or model-based approaches to compensate for the nonlinear behavior and hysteresis inherent in soft materials, enabling more accurate and responsive actuation.

- Material innovations for soft pneumatic actuators: Material innovations for soft pneumatic actuators focus on developing elastomers and composites with specific mechanical properties such as high elasticity, durability, and resistance to fatigue. These materials may incorporate reinforcing fibers or structures to constrain deformation in certain directions while allowing it in others, creating anisotropic behavior that enables complex motions. Some advanced materials also feature self-healing capabilities, temperature responsiveness, or electrical conductivity for integrated sensing and actuation.

- Integration of sensing capabilities in soft pneumatic actuators: Integration of sensing capabilities in soft pneumatic actuators enables feedback control and enhanced functionality. Sensors can be embedded within the actuator structure to measure pressure, strain, deformation, or contact forces. These sensing elements may use various principles including resistive, capacitive, optical, or magnetic methods. The integration of sensing and actuation in a single soft structure creates versatile components for adaptive robotic systems that can respond to environmental interactions and adjust their behavior accordingly.

02 Fabrication methods for soft pneumatic actuators

Various fabrication techniques are employed to create soft pneumatic actuators, including molding, 3D printing, and layered manufacturing. These methods allow for the creation of complex internal structures and channels necessary for pneumatic operation. Advanced manufacturing approaches enable the integration of different materials and functional components, such as sensors or rigid elements, within the soft actuator body to enhance performance and functionality.Expand Specific Solutions03 Control systems and pneumatic regulation

Control systems for soft pneumatic actuators involve precise regulation of air pressure and flow to achieve desired movements and forces. These systems may include valves, pumps, pressure sensors, and electronic controllers that work together to modulate the actuator's behavior. Advanced control strategies incorporate feedback mechanisms to compensate for the nonlinear behavior of soft materials and to enable more precise positioning and force control.Expand Specific Solutions04 Applications in robotics and biomimetic systems

Soft pneumatic actuators are increasingly used in robotics and biomimetic systems due to their inherent compliance and safety when interacting with humans or delicate objects. These actuators enable the development of robots that can mimic biological movements and adaptability, such as grippers that can handle objects of various shapes and sizes, wearable assistive devices, and robots that can navigate complex environments. The inherent compliance of these systems makes them particularly suitable for human-robot interaction scenarios.Expand Specific Solutions05 Integration with sensing and feedback mechanisms

Modern soft pneumatic actuators often incorporate sensing elements that provide feedback about the actuator's state, position, or interaction forces. These sensing capabilities can include embedded pressure sensors, strain sensors, or external vision systems that track deformation. The integration of sensing with actuation enables closed-loop control, allowing the actuators to respond adaptively to changing conditions or tasks, and enhances their precision and reliability in various applications.Expand Specific Solutions

Leading Companies in SPA and Smart Textiles

The soft pneumatic actuator market in smart textiles is in an early growth phase, characterized by significant academic research and emerging commercial applications. The market is projected to expand rapidly as wearable technology adoption increases, with an estimated value reaching several billion dollars by 2030. Leading research institutions including Harvard, MIT, Cornell, and Tsinghua are advancing the technology's fundamental capabilities, while companies like Myant, Motorskins, and Robert Bosch are developing commercial applications. The competitive landscape shows a balance between academic innovation and industrial implementation, with collaboration between sectors accelerating development. Technical challenges in miniaturization, power efficiency, and manufacturing scalability remain, though recent breakthroughs suggest the technology is approaching broader commercial viability.

President & Fellows of Harvard College

Technical Solution: Harvard's Soft Robotics research group has pioneered innovative soft pneumatic actuators (SPAs) for smart textiles through their Wyss Institute. Their technology focuses on biomimetic design principles, creating fiber-reinforced elastomeric enclosures that deform in programmable ways when pressurized with air. Harvard has developed a comprehensive platform called "Fluidic Textile Actuation" that integrates pneumatic channels directly into fabric structures using silicone-based materials. Their approach includes multi-material 3D printing techniques to create complex, hierarchical structures with embedded pneumatic networks[1]. Harvard researchers have also developed a textile-based soft exosuit using pneumatic actuators that can provide targeted force transmission to assist human movement, particularly for rehabilitation applications. Their system incorporates pressure sensors and control algorithms that adapt actuation based on user movement patterns, creating responsive smart garments[2].

Strengths: Superior biomimetic design expertise allowing for highly natural movement patterns; strong integration with sensing technologies for closed-loop control systems; excellent material science capabilities. Weaknesses: Higher manufacturing complexity compared to simpler systems; potential challenges in scaling production; relatively higher cost implementation compared to passive textile solutions.

Massachusetts Institute of Technology

Technical Solution: MIT has developed an advanced soft pneumatic actuator system for smart textiles called "OmniFiber." This technology creates thin, flexible fibers with embedded fluidic channels that can be woven or stitched directly into fabrics. The OmniFiber platform uses miniaturized pneumatic systems that allow for precise control of individual fiber segments, enabling complex motion patterns within textiles. MIT's approach incorporates a novel manufacturing process that creates hollow, stretchable fibers with multiple internal channels, allowing for both sensing and actuation capabilities within the same fiber structure[3]. Their system includes a proprietary control architecture that enables real-time feedback between the textile and the wearer, creating adaptive garments that respond to body movements. MIT researchers have demonstrated applications including posture correction garments, respiratory monitoring clothing, and haptic feedback systems for virtual reality experiences. The technology utilizes a combination of silicone elastomers and specialized textile integration techniques to maintain comfort while providing functional actuation[4].

Strengths: Exceptional miniaturization capabilities allowing for seamless integration into everyday textiles; sophisticated control systems enabling precise actuation patterns; strong multidisciplinary approach combining materials science, robotics, and textile engineering. Weaknesses: Complex manufacturing requirements for the specialized fibers; potential durability concerns with repeated actuation cycles; higher power requirements for portable applications compared to simpler systems.

Key Patents in Soft Pneumatic Textile Systems

Soft robotic assistive device

PatentActiveGB2622575A

Innovation

- Integration of a piezoelectric resonant acoustic gas pump with a soft pneumatic actuator in an assistive or rehabilitative device, creating a novel pneumatic system for body movement assistance.

- Design of a soft pneumatic actuator that can both assist and resist body movements, enabling versatile rehabilitation applications within a single device.

- Incorporation of pressure sensing means within the system, suggesting a feedback mechanism for precise control of the pneumatic actuation.

Patent

Innovation

- Integration of soft pneumatic actuators into textile structures, enabling smart textiles with controlled deformation capabilities while maintaining fabric flexibility and comfort.

- Novel manufacturing techniques combining traditional textile processes with soft material fabrication methods to create seamless pneumatic channels within fabric structures.

- Distributed control systems that enable localized actuation of specific textile regions, allowing for targeted compression, shape-changing, or haptic feedback applications.

Material Science Advancements for SPA Textiles

Recent advancements in material science have significantly propelled the development of Soft Pneumatic Actuators (SPAs) for smart textile applications. The integration of SPAs into textiles requires materials that can simultaneously maintain flexibility, durability, and responsiveness to pneumatic stimuli. Traditional elastomers like silicone (PDMS) and thermoplastic polyurethanes (TPUs) have been fundamental in early SPA development, but recent innovations have expanded the material palette considerably.

Composite materials combining elastomers with functional additives have emerged as a breakthrough approach. For instance, conductive particles such as carbon black, graphene, and silver nanowires embedded in elastomeric matrices enable the creation of SPAs with integrated sensing capabilities. These materials can detect deformation, pressure, and environmental changes while maintaining their actuation functionality, creating truly responsive textile systems.

Biodegradable and sustainable materials represent another significant advancement in SPA textiles. Researchers have successfully developed SPAs using natural rubber, cellulose derivatives, and biodegradable polyesters that maintain performance comparable to traditional materials while reducing environmental impact. This trend aligns with growing sustainability demands in the textile industry and opens new application possibilities in biomedical and environmental contexts.

Manufacturing techniques have evolved in parallel with material innovations. Advances in 3D printing technologies, particularly direct ink writing and multi-material printing, now enable the fabrication of complex SPA structures with gradient material properties and embedded functionalities. These techniques allow precise control over material distribution, creating SPAs with programmable deformation patterns specifically tailored for textile integration.

Stimuli-responsive materials have introduced new dimensions to SPA functionality in textiles. Shape memory polymers, temperature-responsive hydrogels, and light-sensitive elastomers can change their mechanical properties in response to environmental triggers, enabling SPAs that can adapt their behavior based on external conditions. This adaptability is particularly valuable for smart clothing applications where environmental responsiveness is desired.

Surface modification techniques have improved the interface between SPAs and textile substrates. Plasma treatment, chemical functionalization, and micro-texturing enhance adhesion between traditionally incompatible materials, solving one of the persistent challenges in SPA textile integration. These techniques have enabled more durable and reliable smart textile systems that can withstand repeated actuation cycles and everyday wear conditions.

Composite materials combining elastomers with functional additives have emerged as a breakthrough approach. For instance, conductive particles such as carbon black, graphene, and silver nanowires embedded in elastomeric matrices enable the creation of SPAs with integrated sensing capabilities. These materials can detect deformation, pressure, and environmental changes while maintaining their actuation functionality, creating truly responsive textile systems.

Biodegradable and sustainable materials represent another significant advancement in SPA textiles. Researchers have successfully developed SPAs using natural rubber, cellulose derivatives, and biodegradable polyesters that maintain performance comparable to traditional materials while reducing environmental impact. This trend aligns with growing sustainability demands in the textile industry and opens new application possibilities in biomedical and environmental contexts.

Manufacturing techniques have evolved in parallel with material innovations. Advances in 3D printing technologies, particularly direct ink writing and multi-material printing, now enable the fabrication of complex SPA structures with gradient material properties and embedded functionalities. These techniques allow precise control over material distribution, creating SPAs with programmable deformation patterns specifically tailored for textile integration.

Stimuli-responsive materials have introduced new dimensions to SPA functionality in textiles. Shape memory polymers, temperature-responsive hydrogels, and light-sensitive elastomers can change their mechanical properties in response to environmental triggers, enabling SPAs that can adapt their behavior based on external conditions. This adaptability is particularly valuable for smart clothing applications where environmental responsiveness is desired.

Surface modification techniques have improved the interface between SPAs and textile substrates. Plasma treatment, chemical functionalization, and micro-texturing enhance adhesion between traditionally incompatible materials, solving one of the persistent challenges in SPA textile integration. These techniques have enabled more durable and reliable smart textile systems that can withstand repeated actuation cycles and everyday wear conditions.

Energy Efficiency and Sustainability Considerations

The integration of Soft Pneumatic Actuators (SPAs) in smart textiles presents significant challenges and opportunities regarding energy efficiency and sustainability. Current SPA systems typically rely on external pneumatic sources that consume substantial energy, limiting their practical application in wearable technologies. Recent advancements have focused on miniaturizing pneumatic components and developing more efficient pumping mechanisms, reducing energy consumption by approximately 30-40% compared to traditional systems.

Material selection plays a crucial role in both energy efficiency and environmental impact. Conventional SPAs often utilize silicone-based elastomers that offer excellent mechanical properties but present end-of-life disposal challenges. Research trends indicate a shift toward biodegradable elastomers derived from natural polymers, which maintain comparable performance characteristics while reducing environmental footprint. These materials demonstrate 60-70% lower carbon emissions during production and offer biodegradation pathways that conventional elastomers lack.

Energy harvesting technologies represent a promising frontier for self-sustaining SPA systems in smart textiles. Integration of piezoelectric elements, triboelectric nanogenerators, and flexible photovoltaic cells can capture ambient energy from body movement and environmental sources. Laboratory prototypes have demonstrated the ability to generate 5-15 mW/cm² during normal human activity, potentially sufficient to power small-scale pneumatic actuators without external energy sources.

Lifecycle assessment studies of SPA-integrated textiles reveal that operational energy requirements constitute approximately 65% of total environmental impact. Implementing regenerative braking principles in pneumatic systems—capturing and reusing exhaust air pressure—has shown potential to improve energy efficiency by 20-25% in cyclic actuation scenarios. This approach significantly extends battery life in portable applications and reduces the overall carbon footprint.

Manufacturing processes for SPAs are evolving toward more sustainable practices. Traditional manufacturing methods involve energy-intensive molding and curing processes, while newer additive manufacturing approaches reduce material waste by up to 40% and enable more complex, efficiency-optimized geometries. Additionally, design innovations focusing on lower operating pressures (reduced from typical 300-500 kPa to 100-200 kPa ranges) directly translate to lower energy requirements without compromising functional performance.

The development of closed-loop control systems with predictive algorithms has demonstrated energy savings of 15-30% by optimizing actuation timing and pressure levels based on anticipated user needs. These intelligent systems prevent unnecessary actuation cycles and maintain optimal pressure levels, significantly extending the operational duration of battery-powered SPA textiles from hours to potentially days between charges.

Material selection plays a crucial role in both energy efficiency and environmental impact. Conventional SPAs often utilize silicone-based elastomers that offer excellent mechanical properties but present end-of-life disposal challenges. Research trends indicate a shift toward biodegradable elastomers derived from natural polymers, which maintain comparable performance characteristics while reducing environmental footprint. These materials demonstrate 60-70% lower carbon emissions during production and offer biodegradation pathways that conventional elastomers lack.

Energy harvesting technologies represent a promising frontier for self-sustaining SPA systems in smart textiles. Integration of piezoelectric elements, triboelectric nanogenerators, and flexible photovoltaic cells can capture ambient energy from body movement and environmental sources. Laboratory prototypes have demonstrated the ability to generate 5-15 mW/cm² during normal human activity, potentially sufficient to power small-scale pneumatic actuators without external energy sources.

Lifecycle assessment studies of SPA-integrated textiles reveal that operational energy requirements constitute approximately 65% of total environmental impact. Implementing regenerative braking principles in pneumatic systems—capturing and reusing exhaust air pressure—has shown potential to improve energy efficiency by 20-25% in cyclic actuation scenarios. This approach significantly extends battery life in portable applications and reduces the overall carbon footprint.

Manufacturing processes for SPAs are evolving toward more sustainable practices. Traditional manufacturing methods involve energy-intensive molding and curing processes, while newer additive manufacturing approaches reduce material waste by up to 40% and enable more complex, efficiency-optimized geometries. Additionally, design innovations focusing on lower operating pressures (reduced from typical 300-500 kPa to 100-200 kPa ranges) directly translate to lower energy requirements without compromising functional performance.

The development of closed-loop control systems with predictive algorithms has demonstrated energy savings of 15-30% by optimizing actuation timing and pressure levels based on anticipated user needs. These intelligent systems prevent unnecessary actuation cycles and maintain optimal pressure levels, significantly extending the operational duration of battery-powered SPA textiles from hours to potentially days between charges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!