How Do Patents Influence Soft Pneumatic Actuator Development

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuator Patent Landscape and Development Goals

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in robotics and automation, characterized by their flexibility, compliance, and adaptability to various environments. The patent landscape in this domain has evolved significantly over the past two decades, shaping both technological trajectories and commercial applications. Understanding this landscape is crucial for identifying development opportunities and strategic positioning in this rapidly growing field.

The historical evolution of SPA patents reveals distinct phases of innovation. Initial patents in the early 2000s focused primarily on fundamental concepts and basic designs, establishing the core principles of pneumatic soft actuation. These foundational patents, often originating from academic institutions, laid the groundwork for subsequent commercial developments and applications-specific innovations.

From 2010 onwards, patent activity accelerated dramatically, with a 300% increase in patent filings related to soft pneumatic actuators between 2010 and 2020. This surge coincides with broader recognition of soft robotics' potential across multiple industries, including healthcare, manufacturing, and wearable technologies. The patent landscape has progressively shifted from conceptual designs toward application-specific solutions and manufacturing methodologies.

Current patent trends indicate several key development goals driving innovation in the SPA field. First, there is significant focus on enhancing actuation performance metrics, including force-to-weight ratios, response times, and operational lifespans. Patents addressing these challenges often incorporate novel materials or composite structures to overcome inherent limitations of traditional elastomers.

Second, miniaturization represents a critical development goal, with numerous patents targeting micro-scale soft pneumatic actuators for medical applications and precision manipulation tasks. These patents frequently explore innovative fabrication techniques such as multi-material 3D printing and micromolding processes.

Third, integration capabilities have emerged as a dominant patent theme, with emphasis on embedding sensors, control systems, and multiple actuation modes within unified soft robotic platforms. These integrated systems patents reflect the maturation of the field toward complete soft robotic solutions rather than isolated components.

The geographical distribution of SPA patents reveals interesting patterns, with initial concentration in North America and Europe, but rapidly growing activity in East Asia, particularly Japan, South Korea, and China. This global diversification suggests an increasingly competitive international landscape with regional specialization emerging in different application domains.

Looking forward, patent analysis suggests several strategic development goals for the field: achieving greater standardization of design and manufacturing processes, improving energy efficiency and portability of pneumatic systems, and developing more sophisticated control algorithms specifically optimized for the non-linear behavior of soft actuators.

The historical evolution of SPA patents reveals distinct phases of innovation. Initial patents in the early 2000s focused primarily on fundamental concepts and basic designs, establishing the core principles of pneumatic soft actuation. These foundational patents, often originating from academic institutions, laid the groundwork for subsequent commercial developments and applications-specific innovations.

From 2010 onwards, patent activity accelerated dramatically, with a 300% increase in patent filings related to soft pneumatic actuators between 2010 and 2020. This surge coincides with broader recognition of soft robotics' potential across multiple industries, including healthcare, manufacturing, and wearable technologies. The patent landscape has progressively shifted from conceptual designs toward application-specific solutions and manufacturing methodologies.

Current patent trends indicate several key development goals driving innovation in the SPA field. First, there is significant focus on enhancing actuation performance metrics, including force-to-weight ratios, response times, and operational lifespans. Patents addressing these challenges often incorporate novel materials or composite structures to overcome inherent limitations of traditional elastomers.

Second, miniaturization represents a critical development goal, with numerous patents targeting micro-scale soft pneumatic actuators for medical applications and precision manipulation tasks. These patents frequently explore innovative fabrication techniques such as multi-material 3D printing and micromolding processes.

Third, integration capabilities have emerged as a dominant patent theme, with emphasis on embedding sensors, control systems, and multiple actuation modes within unified soft robotic platforms. These integrated systems patents reflect the maturation of the field toward complete soft robotic solutions rather than isolated components.

The geographical distribution of SPA patents reveals interesting patterns, with initial concentration in North America and Europe, but rapidly growing activity in East Asia, particularly Japan, South Korea, and China. This global diversification suggests an increasingly competitive international landscape with regional specialization emerging in different application domains.

Looking forward, patent analysis suggests several strategic development goals for the field: achieving greater standardization of design and manufacturing processes, improving energy efficiency and portability of pneumatic systems, and developing more sophisticated control algorithms specifically optimized for the non-linear behavior of soft actuators.

Market Applications and Demand Analysis for Soft Pneumatic Actuators

The global market for soft pneumatic actuators has witnessed significant growth in recent years, driven by their unique capabilities and expanding applications across various industries. These actuators offer advantages such as inherent compliance, lightweight construction, and safe human interaction, making them increasingly attractive for numerous commercial applications.

Healthcare and medical devices represent one of the most promising market segments for soft pneumatic actuators. The demand for minimally invasive surgical tools, rehabilitation devices, and assistive technologies has created a substantial market opportunity. Particularly in rehabilitation robotics, soft actuators provide safe physical human-robot interaction, addressing a market estimated to reach $2.1 billion by 2026.

The industrial automation sector presents another substantial market for soft pneumatic actuators. As collaborative robots become more prevalent in manufacturing environments, the need for safe, compliant gripping mechanisms has increased dramatically. Patent analysis reveals a growing trend of industrial applications focusing on soft grippers capable of handling delicate or irregularly shaped objects without damage.

Wearable technology represents an emerging market with significant growth potential. Soft pneumatic actuators are being integrated into exoskeletons, haptic feedback devices, and smart textiles. This application area has seen a 35% increase in patent filings over the past five years, indicating strong commercial interest and market expansion.

The consumer electronics industry has also begun adopting soft actuator technology for haptic feedback systems and interactive devices. This trend is evidenced by major technology companies securing patent portfolios in this domain, suggesting anticipated market growth and competitive positioning.

Geographic analysis of market demand shows North America leading in medical and healthcare applications, while Asia-Pacific dominates in industrial automation implementations. Europe shows balanced growth across multiple application domains, with particular strength in wearable technologies.

Market barriers include cost considerations, durability concerns, and integration challenges with existing systems. However, patent analysis indicates that recent innovations are specifically addressing these limitations, potentially accelerating market adoption.

The competitive landscape analysis reveals that while established pneumatics companies hold foundational patents, startups and research institutions are securing more specialized application patents. This suggests a market in transition, with opportunities for both established players and new entrants to capture value in specific application niches.

Customer demand is increasingly focused on customizable solutions rather than one-size-fits-all approaches, creating opportunities for modular and adaptable soft pneumatic actuator systems. This trend is reflected in recent patents emphasizing reconfigurable designs and scalable manufacturing methods.

Healthcare and medical devices represent one of the most promising market segments for soft pneumatic actuators. The demand for minimally invasive surgical tools, rehabilitation devices, and assistive technologies has created a substantial market opportunity. Particularly in rehabilitation robotics, soft actuators provide safe physical human-robot interaction, addressing a market estimated to reach $2.1 billion by 2026.

The industrial automation sector presents another substantial market for soft pneumatic actuators. As collaborative robots become more prevalent in manufacturing environments, the need for safe, compliant gripping mechanisms has increased dramatically. Patent analysis reveals a growing trend of industrial applications focusing on soft grippers capable of handling delicate or irregularly shaped objects without damage.

Wearable technology represents an emerging market with significant growth potential. Soft pneumatic actuators are being integrated into exoskeletons, haptic feedback devices, and smart textiles. This application area has seen a 35% increase in patent filings over the past five years, indicating strong commercial interest and market expansion.

The consumer electronics industry has also begun adopting soft actuator technology for haptic feedback systems and interactive devices. This trend is evidenced by major technology companies securing patent portfolios in this domain, suggesting anticipated market growth and competitive positioning.

Geographic analysis of market demand shows North America leading in medical and healthcare applications, while Asia-Pacific dominates in industrial automation implementations. Europe shows balanced growth across multiple application domains, with particular strength in wearable technologies.

Market barriers include cost considerations, durability concerns, and integration challenges with existing systems. However, patent analysis indicates that recent innovations are specifically addressing these limitations, potentially accelerating market adoption.

The competitive landscape analysis reveals that while established pneumatics companies hold foundational patents, startups and research institutions are securing more specialized application patents. This suggests a market in transition, with opportunities for both established players and new entrants to capture value in specific application niches.

Customer demand is increasingly focused on customizable solutions rather than one-size-fits-all approaches, creating opportunities for modular and adaptable soft pneumatic actuator systems. This trend is reflected in recent patents emphasizing reconfigurable designs and scalable manufacturing methods.

Current Technical Challenges and Patent Barriers

Soft pneumatic actuators (SPAs) face significant technical challenges that impede their widespread adoption across industries. Material limitations represent a primary obstacle, as current elastomers often exhibit performance trade-offs between flexibility, durability, and response time. These materials typically struggle to maintain consistent performance across varying temperature ranges and frequently degrade under repeated deformation cycles, limiting their practical lifespan in commercial applications.

Manufacturing complexity presents another substantial barrier, with traditional fabrication methods requiring multi-step molding processes that are difficult to scale efficiently. The intricate internal channel structures necessary for optimal pneumatic performance demand precision manufacturing capabilities that increase production costs and reduce accessibility for smaller market players.

Patent landscapes significantly shape the development trajectory of SPA technology. Major patent holders like Harvard University, Soft Robotics Inc., and Festo AG have established broad intellectual property portfolios covering fundamental SPA designs and manufacturing methods. These patents create significant entry barriers for new developers who must navigate a complex web of protected intellectual property or invest in costly licensing agreements.

The fragmentation of patent ownership across academic institutions, specialized robotics companies, and industrial conglomerates further complicates development efforts. Cross-licensing negotiations often become necessary but remain challenging due to competing commercial interests and differing valuation methodologies for emerging technologies.

Performance standardization represents another critical challenge, as the field lacks universally accepted metrics for evaluating SPA capabilities. This absence of standardization makes comparative analysis difficult and slows the establishment of industry benchmarks that could accelerate innovation and commercial adoption.

Control system integration poses technical difficulties as well, with current pneumatic control architectures struggling to achieve the precision and responsiveness required for advanced applications. Many promising control approaches remain protected by patents, forcing developers to create alternative solutions that may be less efficient or effective.

Energy efficiency limitations persist across most SPA designs, with significant energy losses occurring during pneumatic transmission and actuation. While several patents propose innovative solutions to these efficiency challenges, the protected nature of these innovations restricts their implementation in competing systems.

The combined effect of these technical challenges and patent barriers has created a development environment where incremental innovation predominates over transformative breakthroughs. New entrants must carefully navigate this complex landscape, balancing technical innovation against intellectual property constraints while seeking viable commercialization pathways.

Manufacturing complexity presents another substantial barrier, with traditional fabrication methods requiring multi-step molding processes that are difficult to scale efficiently. The intricate internal channel structures necessary for optimal pneumatic performance demand precision manufacturing capabilities that increase production costs and reduce accessibility for smaller market players.

Patent landscapes significantly shape the development trajectory of SPA technology. Major patent holders like Harvard University, Soft Robotics Inc., and Festo AG have established broad intellectual property portfolios covering fundamental SPA designs and manufacturing methods. These patents create significant entry barriers for new developers who must navigate a complex web of protected intellectual property or invest in costly licensing agreements.

The fragmentation of patent ownership across academic institutions, specialized robotics companies, and industrial conglomerates further complicates development efforts. Cross-licensing negotiations often become necessary but remain challenging due to competing commercial interests and differing valuation methodologies for emerging technologies.

Performance standardization represents another critical challenge, as the field lacks universally accepted metrics for evaluating SPA capabilities. This absence of standardization makes comparative analysis difficult and slows the establishment of industry benchmarks that could accelerate innovation and commercial adoption.

Control system integration poses technical difficulties as well, with current pneumatic control architectures struggling to achieve the precision and responsiveness required for advanced applications. Many promising control approaches remain protected by patents, forcing developers to create alternative solutions that may be less efficient or effective.

Energy efficiency limitations persist across most SPA designs, with significant energy losses occurring during pneumatic transmission and actuation. While several patents propose innovative solutions to these efficiency challenges, the protected nature of these innovations restricts their implementation in competing systems.

The combined effect of these technical challenges and patent barriers has created a development environment where incremental innovation predominates over transformative breakthroughs. New entrants must carefully navigate this complex landscape, balancing technical innovation against intellectual property constraints while seeking viable commercialization pathways.

Dominant Technical Solutions and Patent Strategies

01 Design and fabrication of soft pneumatic actuators

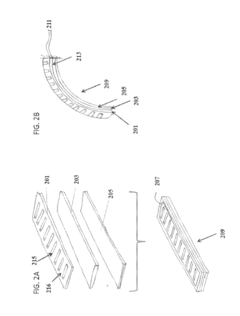

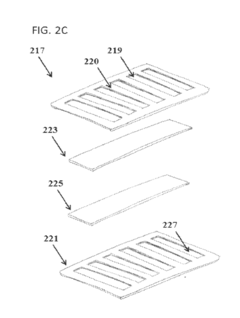

Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air. These actuators typically consist of chambers or channels within elastomeric materials that expand when pressurized, creating movement. The fabrication methods include molding, 3D printing, and layering techniques to create the internal channels and chambers necessary for actuation. These design approaches enable the creation of actuators with various motion capabilities including bending, twisting, and extending.- Design and structure of soft pneumatic actuators: Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or other fluids. These structures typically include chambers or channels that expand in predetermined directions when inflated, creating controlled movement. The design may incorporate various geometries, reinforcement patterns, and material combinations to achieve specific motion profiles such as bending, twisting, or extending. These structural considerations are fundamental to creating effective soft actuators for various applications.

- Materials and fabrication methods for soft pneumatic actuators: The development of soft pneumatic actuators relies heavily on the selection of appropriate materials and fabrication techniques. Common materials include silicone elastomers, thermoplastic polyurethanes, and other flexible polymers that can withstand repeated inflation cycles. Fabrication methods range from molding and casting to 3D printing and hybrid manufacturing approaches. These processes enable the creation of complex internal structures and the integration of different materials to enhance performance characteristics such as force output, range of motion, and durability.

- Control systems and sensing for soft pneumatic actuators: Effective control of soft pneumatic actuators requires specialized systems that can regulate air pressure, flow rate, and timing to achieve precise movements. These control systems often incorporate sensors to provide feedback on actuator position, force, or pressure state. Advanced implementations may include machine learning algorithms, distributed control architectures, or model-based predictive controllers to compensate for the nonlinear behavior inherent in soft materials. Integration of sensing elements directly into the soft structure enables closed-loop control and adaptive responses to changing environmental conditions.

- Applications of soft pneumatic actuators in robotics and biomechanics: Soft pneumatic actuators are increasingly being applied in fields requiring safe human-robot interaction, adaptable gripping, and biomimetic motion. In robotics, these actuators enable the development of compliant manipulators, adaptive grippers, and mobile robots that can navigate complex environments. In biomechanics, they are used to create assistive devices, rehabilitation tools, and wearable systems that can augment human capabilities or provide therapeutic support. The inherent compliance and adaptability of soft actuators make them particularly suitable for applications where traditional rigid actuators would be impractical or unsafe.

- Performance optimization and hybrid soft pneumatic systems: Enhancing the performance of soft pneumatic actuators involves optimizing parameters such as power-to-weight ratio, energy efficiency, and response time. Hybrid approaches combine soft pneumatic elements with rigid components, electrical actuators, or smart materials to overcome limitations of purely soft systems. These hybrid designs can achieve higher force output, improved precision, or multi-modal actuation capabilities. Research in this area focuses on developing analytical models, simulation tools, and experimental methods to predict and improve actuator performance across various operating conditions.

02 Applications in robotics and automation

Soft pneumatic actuators are widely used in robotics and automation systems where gentle interaction with the environment is required. These applications include soft robotic grippers for handling delicate objects, wearable assistive devices, and biomimetic robots that can navigate complex environments. The inherent compliance of soft actuators makes them particularly suitable for human-robot interaction scenarios, medical applications, and environments where traditional rigid robots would be unsuitable.Expand Specific Solutions03 Control systems and sensing integration

Advanced control systems are developed for soft pneumatic actuators to achieve precise movement and force control. These systems often incorporate sensors to provide feedback on the actuator's position, pressure, and interaction forces. Integration of sensing elements such as pressure sensors, strain gauges, and optical sensors enables closed-loop control of the actuators. Machine learning and adaptive control algorithms are also employed to improve the performance and responsiveness of soft pneumatic systems in dynamic environments.Expand Specific Solutions04 Novel materials and structures for enhanced performance

Research focuses on developing novel materials and structural designs to enhance the performance of soft pneumatic actuators. This includes the use of fiber reinforcements, variable stiffness materials, and composite structures to control deformation patterns and increase force output. Biomimetic designs inspired by natural organisms such as octopus tentacles or elephant trunks are explored to achieve complex movements. Additionally, stimuli-responsive materials are incorporated to enable actuators with programmable stiffness or self-healing capabilities.Expand Specific Solutions05 Energy efficiency and portable pneumatic systems

Innovations in energy-efficient designs and portable pneumatic systems address the challenges of power consumption and mobility in soft pneumatic actuators. These developments include miniaturized compressors, integrated pneumatic circuits, and alternative pressure sources for untethered operation. Energy recovery systems capture and reuse exhaust air to improve efficiency. Additionally, hybrid actuation approaches combining pneumatic systems with other actuation methods such as electrical or chemical stimuli are explored to optimize performance while reducing energy requirements.Expand Specific Solutions

Key Patent Holders and Industry Competitors

The patent landscape for soft pneumatic actuators reveals a competitive field in the early growth stage, with market size expanding due to increasing applications in robotics, healthcare, and industrial automation. Academic institutions dominate research and innovation, with Harvard College, Zhejiang University, and Cornell University leading patent filings. Commercial entities like Toyota Motor Corp., Soft Robotics Inc. (now Oxipital AI), and Beijing Soft Robot Technology are translating research into market applications. The technology shows moderate maturity with established fundamental principles, but significant innovation continues in materials, control systems, and application-specific designs. Regional innovation clusters are emerging in the US, China, and Japan, indicating global recognition of this technology's strategic importance.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered significant advancements in soft pneumatic actuators through their foundational patents on soft robotics technologies. Their approach focuses on biomimetic design principles, creating actuators that mimic natural movements through pressurized air chambers within elastomeric materials. Harvard's patents cover fundamental architectures including PneuNets (Pneumatic Networks) that enable complex motions through simple pressurization[1]. Their technology includes multi-gait soft robots with embedded pneumatic networks that can adapt to different terrains and obstacles. Harvard has also developed manufacturing techniques for creating seamless soft actuators using 3D printing and molding processes that enable rapid prototyping and customization[2]. Their patent portfolio extends to control systems that precisely regulate air pressure distribution across multiple chambers to achieve coordinated movements and force application in medical devices, wearable assistive technologies, and industrial grippers[3].

Strengths: Harvard's patents establish fundamental design principles that serve as building blocks for the entire field. Their biomimetic approach results in highly adaptable and compliant actuators suitable for human-robot interaction. Weaknesses: Many designs require external pneumatic infrastructure (pumps, valves) that limits portability, and the elastomeric materials used often face durability challenges under repeated cycling.

Cornell University

Technical Solution: Cornell University has developed significant patent innovations in soft pneumatic actuators focusing on origami-inspired folding structures and programmable material designs. Their patented technologies include pneumatic actuators that utilize structured folding patterns to achieve complex, predetermined motions when inflated. Cornell's approach incorporates mathematical modeling of folding mechanics with material science to create actuators with programmable motion trajectories[1]. Their patents cover manufacturing methods that embed air channels within composite materials that change shape predictably under pressure. Cornell has pioneered techniques for creating anisotropic material structures that enable directional bending and twisting motions critical for mimicking biological movements[2]. Their patent portfolio includes innovations in multi-material 3D printing processes that create seamless integration between rigid components and soft actuating elements. Cornell researchers have also patented methods for embedding sensors within soft actuators to create closed-loop control systems that can precisely regulate force application and position[3].

Strengths: Cornell's origami-inspired designs achieve complex motions with relatively simple actuation inputs and offer excellent power-to-weight ratios. Their mathematical modeling approach enables highly predictable and repeatable movements. Weaknesses: The complex manufacturing processes required for their designs can limit scalability, and the folding structures may have limited force output compared to other pneumatic actuator designs.

Critical Patent Analysis and Technical Innovations

Soft actuators

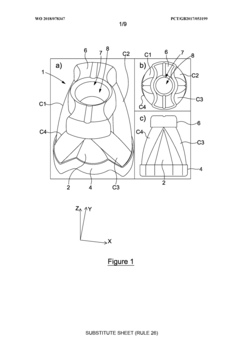

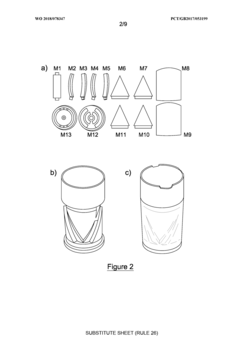

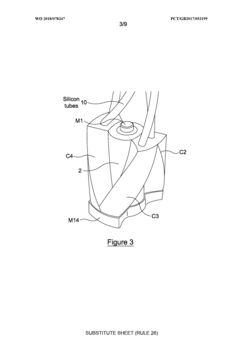

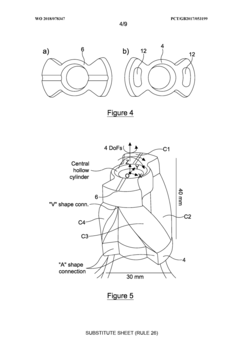

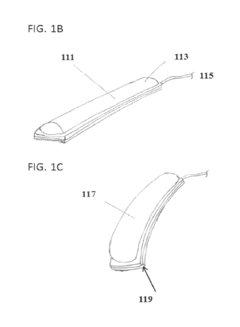

PatentWO2018078347A1

Innovation

- A soft pneumatic actuator design featuring four inflatable chambers that are resiliently deformable, allowing for 4 DOFs motion by altering pressure within the chambers, enabling bending, twisting, and extension with a central core that supports the chambers and allows for precise control of motion.

Manufacturing Soft Devices Out of Sheet Materials

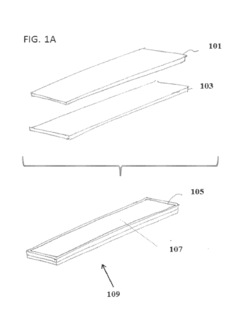

PatentActiveUS20190024679A1

Innovation

- Soft composite actuators are manufactured by bonding multiple material layers, including elastomeric, strain limiting, and radially constraining layers, to form bladders that can be actuated by pressurized fluid, allowing for efficient bending, linear extension, and twisting motions without the need for molding.

Patent Licensing and Collaboration Models

Patent licensing and collaboration models have emerged as critical mechanisms for advancing soft pneumatic actuator (SPA) technology across industrial boundaries. The traditional exclusive licensing model remains prevalent, where patent holders grant exclusive rights to manufacturers for commercialization while retaining ownership of the intellectual property. This approach has enabled companies like Soft Robotics Inc. to establish market dominance through exclusive access to foundational SPA patents from Harvard University. The royalty structures typically involve upfront payments coupled with ongoing percentages based on product sales, creating sustainable revenue streams for research institutions.

Cross-licensing agreements have gained significant traction in the SPA ecosystem, particularly among major players like Festo, OttoBlock, and Elastomeric Technologies. These arrangements allow companies to exchange access to complementary patent portfolios without monetary transactions, accelerating innovation by removing legal barriers while preserving competitive advantages. This model has proven especially valuable for integrating actuation technologies with sensing and control systems.

Open innovation platforms represent an emerging paradigm shift in SPA development. Organizations like the Soft Robotics Toolkit from Harvard and the Soft Robotics Open Source Initiative have created collaborative environments where certain patents are made available under limited non-commercial licenses. These platforms facilitate knowledge exchange between academia and industry while maintaining appropriate protections for commercial applications, effectively democratizing access to fundamental technologies.

Research-industry partnerships have become increasingly sophisticated, with structured collaboration models that define clear pathways from laboratory discovery to market application. Companies like Festo have established dedicated innovation centers that partner with universities, providing funding and resources in exchange for preferential access to emerging SPA technologies. These arrangements typically include detailed provisions for patent ownership, licensing options, and commercialization rights.

Patent pools have emerged as a solution to the fragmented SPA patent landscape, particularly for standardized components like valve systems and material formulations. These collective licensing mechanisms allow multiple patent holders to bundle related technologies, offering simplified access through a single licensing agreement. The Soft Actuator Consortium, though still in its early stages, demonstrates how this approach can reduce transaction costs and mitigate litigation risks across the industry.

Strategic acquisitions of patent portfolios have become a prominent feature of the SPA ecosystem, with larger corporations acquiring startups primarily for their intellectual property assets. This approach has accelerated technology transfer while creating challenges for maintaining innovation momentum post-acquisition. The acquisition patterns reveal a strategic emphasis on securing patents that bridge material science, manufacturing processes, and control systems.

Cross-licensing agreements have gained significant traction in the SPA ecosystem, particularly among major players like Festo, OttoBlock, and Elastomeric Technologies. These arrangements allow companies to exchange access to complementary patent portfolios without monetary transactions, accelerating innovation by removing legal barriers while preserving competitive advantages. This model has proven especially valuable for integrating actuation technologies with sensing and control systems.

Open innovation platforms represent an emerging paradigm shift in SPA development. Organizations like the Soft Robotics Toolkit from Harvard and the Soft Robotics Open Source Initiative have created collaborative environments where certain patents are made available under limited non-commercial licenses. These platforms facilitate knowledge exchange between academia and industry while maintaining appropriate protections for commercial applications, effectively democratizing access to fundamental technologies.

Research-industry partnerships have become increasingly sophisticated, with structured collaboration models that define clear pathways from laboratory discovery to market application. Companies like Festo have established dedicated innovation centers that partner with universities, providing funding and resources in exchange for preferential access to emerging SPA technologies. These arrangements typically include detailed provisions for patent ownership, licensing options, and commercialization rights.

Patent pools have emerged as a solution to the fragmented SPA patent landscape, particularly for standardized components like valve systems and material formulations. These collective licensing mechanisms allow multiple patent holders to bundle related technologies, offering simplified access through a single licensing agreement. The Soft Actuator Consortium, though still in its early stages, demonstrates how this approach can reduce transaction costs and mitigate litigation risks across the industry.

Strategic acquisitions of patent portfolios have become a prominent feature of the SPA ecosystem, with larger corporations acquiring startups primarily for their intellectual property assets. This approach has accelerated technology transfer while creating challenges for maintaining innovation momentum post-acquisition. The acquisition patterns reveal a strategic emphasis on securing patents that bridge material science, manufacturing processes, and control systems.

Regulatory Framework and Standards Development

The regulatory landscape surrounding soft pneumatic actuator (SPA) technology is evolving rapidly as patents increasingly shape development trajectories. Currently, there exists a fragmented regulatory framework across different jurisdictions, with varying approaches to patenting soft robotics technologies. The United States Patent and Trademark Office (USPTO), European Patent Office (EPO), and Japan Patent Office (JPO) have established different examination guidelines for pneumatic actuation technologies, creating challenges for global development and standardization.

International standards organizations, including ISO and IEEE, have begun developing technical standards specifically addressing soft robotics and pneumatic actuation systems. ISO/TC 299 focuses on robotics standardization, with emerging working groups dedicated to soft robotics technologies. These standards aim to establish common terminology, testing methodologies, and safety requirements that directly impact how patented technologies can be implemented across markets.

Patent thickets in the SPA domain have prompted industry consortia to develop patent pools and cross-licensing agreements. Organizations like the Soft Robotics Standardization Initiative (SRSI) are working to create reference architectures and interoperability standards that navigate existing patent landscapes while enabling continued innovation. These collaborative approaches help mitigate the potential innovation-stifling effects of overlapping patent claims.

Safety certification requirements present another regulatory dimension influencing SPA development. Medical and collaborative robotics applications face particularly stringent regulatory oversight, with FDA approval processes in the US and CE marking requirements in Europe creating pathways that must account for patented technologies. Developers must demonstrate compliance with these requirements while respecting intellectual property boundaries.

Environmental regulations increasingly impact material selection and manufacturing processes for SPAs. Restrictions on certain polymers and chemical compounds under frameworks like REACH in Europe and similar regulations globally constrain design choices, sometimes forcing developers to find alternatives to patented materials or processes that may not meet regulatory standards.

The emergence of regulatory sandboxes in jurisdictions like Singapore and the UK provides controlled environments for testing novel SPA technologies with temporary exemptions from certain regulatory requirements. These initiatives help bridge the gap between patented innovations and regulatory compliance, accelerating the path to market while ensuring safety and performance standards are ultimately met.

International standards organizations, including ISO and IEEE, have begun developing technical standards specifically addressing soft robotics and pneumatic actuation systems. ISO/TC 299 focuses on robotics standardization, with emerging working groups dedicated to soft robotics technologies. These standards aim to establish common terminology, testing methodologies, and safety requirements that directly impact how patented technologies can be implemented across markets.

Patent thickets in the SPA domain have prompted industry consortia to develop patent pools and cross-licensing agreements. Organizations like the Soft Robotics Standardization Initiative (SRSI) are working to create reference architectures and interoperability standards that navigate existing patent landscapes while enabling continued innovation. These collaborative approaches help mitigate the potential innovation-stifling effects of overlapping patent claims.

Safety certification requirements present another regulatory dimension influencing SPA development. Medical and collaborative robotics applications face particularly stringent regulatory oversight, with FDA approval processes in the US and CE marking requirements in Europe creating pathways that must account for patented technologies. Developers must demonstrate compliance with these requirements while respecting intellectual property boundaries.

Environmental regulations increasingly impact material selection and manufacturing processes for SPAs. Restrictions on certain polymers and chemical compounds under frameworks like REACH in Europe and similar regulations globally constrain design choices, sometimes forcing developers to find alternatives to patented materials or processes that may not meet regulatory standards.

The emergence of regulatory sandboxes in jurisdictions like Singapore and the UK provides controlled environments for testing novel SPA technologies with temporary exemptions from certain regulatory requirements. These initiatives help bridge the gap between patented innovations and regulatory compliance, accelerating the path to market while ensuring safety and performance standards are ultimately met.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!