Soft Pneumatic Actuators in Advanced Manufacturing Systems

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pneumatic Actuation Technology Evolution and Objectives

Pneumatic actuation technology has evolved significantly over the past century, transitioning from simple mechanical systems to sophisticated, computer-controlled solutions. The earliest pneumatic systems emerged in the early 20th century, primarily used for basic industrial automation tasks. These systems relied on compressed air to generate mechanical force, offering a safe alternative to hydraulic systems in environments where fluid leakage posed risks.

The 1950s and 1960s marked a pivotal era with the introduction of standardized pneumatic components and control systems, enabling more complex automation sequences. By the 1980s, the integration of electronic controls with pneumatic systems created the foundation for modern pneumatic automation, allowing for precise control and monitoring of pneumatic actuators.

The most recent evolutionary phase began in the early 2000s with the emergence of soft pneumatic actuators (SPAs), representing a paradigm shift from rigid to compliant systems. Unlike traditional hard actuators, SPAs are fabricated from elastomeric materials that deform when pressurized, enabling complex movements and adaptable interactions with the environment. This development has been particularly transformative for applications requiring safe human-machine interaction.

Current technological trends in pneumatic actuation focus on miniaturization, energy efficiency, and integration with digital systems. The development of micro-pneumatic components has enabled the creation of compact, lightweight actuators suitable for portable and wearable applications. Simultaneously, advances in materials science have produced elastomers with enhanced durability and responsiveness, expanding the operational capabilities of soft pneumatic systems.

The primary objective of modern pneumatic actuation research is to develop systems that combine the compliance and adaptability of biological structures with the precision and reliability of engineered systems. This bio-inspired approach aims to create actuators capable of complex, coordinated movements while maintaining inherent safety characteristics. Additional goals include reducing energy consumption through improved valve designs and developing self-sensing capabilities that eliminate the need for external sensors.

In the context of advanced manufacturing, pneumatic actuation technology aims to enable flexible automation systems that can adapt to varying production requirements. The development of collaborative robots powered by soft pneumatic actuators represents a key objective, potentially revolutionizing human-machine interaction in factory settings. Furthermore, researchers are working toward pneumatic systems with enhanced durability and reduced maintenance requirements, addressing traditional limitations of pneumatic technology in industrial environments.

The 1950s and 1960s marked a pivotal era with the introduction of standardized pneumatic components and control systems, enabling more complex automation sequences. By the 1980s, the integration of electronic controls with pneumatic systems created the foundation for modern pneumatic automation, allowing for precise control and monitoring of pneumatic actuators.

The most recent evolutionary phase began in the early 2000s with the emergence of soft pneumatic actuators (SPAs), representing a paradigm shift from rigid to compliant systems. Unlike traditional hard actuators, SPAs are fabricated from elastomeric materials that deform when pressurized, enabling complex movements and adaptable interactions with the environment. This development has been particularly transformative for applications requiring safe human-machine interaction.

Current technological trends in pneumatic actuation focus on miniaturization, energy efficiency, and integration with digital systems. The development of micro-pneumatic components has enabled the creation of compact, lightweight actuators suitable for portable and wearable applications. Simultaneously, advances in materials science have produced elastomers with enhanced durability and responsiveness, expanding the operational capabilities of soft pneumatic systems.

The primary objective of modern pneumatic actuation research is to develop systems that combine the compliance and adaptability of biological structures with the precision and reliability of engineered systems. This bio-inspired approach aims to create actuators capable of complex, coordinated movements while maintaining inherent safety characteristics. Additional goals include reducing energy consumption through improved valve designs and developing self-sensing capabilities that eliminate the need for external sensors.

In the context of advanced manufacturing, pneumatic actuation technology aims to enable flexible automation systems that can adapt to varying production requirements. The development of collaborative robots powered by soft pneumatic actuators represents a key objective, potentially revolutionizing human-machine interaction in factory settings. Furthermore, researchers are working toward pneumatic systems with enhanced durability and reduced maintenance requirements, addressing traditional limitations of pneumatic technology in industrial environments.

Market Demand Analysis for Soft Robotics in Manufacturing

The global market for soft robotics in manufacturing is experiencing significant growth, driven by the increasing demand for flexible automation solutions that can safely interact with humans and handle delicate objects. According to recent market research, the soft robotics market is projected to reach $3.27 billion by 2026, with a compound annual growth rate of 40.5% from 2021 to 2026. This remarkable growth trajectory underscores the expanding adoption of soft pneumatic actuators across various manufacturing sectors.

Manufacturing industries, particularly electronics, food processing, pharmaceuticals, and automotive, are increasingly seeking alternatives to traditional rigid robots. These industries require handling solutions for fragile components, irregular shapes, and variable products that conventional robotics cannot efficiently address. Soft pneumatic actuators offer compelling advantages in these scenarios, including inherent compliance, adaptability to object geometry, and safer human-robot collaboration capabilities.

The food processing industry represents one of the fastest-growing application areas, with a market share of approximately 28% in the soft robotics manufacturing segment. The ability of soft pneumatic actuators to handle delicate produce, meat products, and baked goods without damage has created substantial demand in this sector. Similarly, the electronics industry is adopting these technologies for handling sensitive components during assembly processes.

Consumer preferences are also driving market demand, as there is increasing pressure for customized products requiring flexible manufacturing systems. This trend toward mass customization necessitates adaptable automation solutions that can quickly reconfigure for different product variants without extensive retooling—a capability well-suited to soft pneumatic actuator systems.

Regional analysis indicates that North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, particularly in China, Japan, and South Korea, where manufacturing automation is being aggressively pursued.

Labor shortages and rising labor costs in developed economies are further accelerating the adoption of soft robotics in manufacturing. Companies are increasingly looking to automate tasks that require dexterity and adaptability but have traditionally been difficult to automate with conventional rigid robots. This demographic shift is expected to contribute an additional 15% to market growth over the next five years.

Despite the promising outlook, price sensitivity remains a significant factor influencing market penetration. Currently, the implementation cost for soft pneumatic actuator systems is approximately 30% higher than traditional automation solutions, creating adoption barriers particularly for small and medium-sized enterprises. However, as technology matures and economies of scale are realized, this price differential is expected to narrow substantially by 2025.

Manufacturing industries, particularly electronics, food processing, pharmaceuticals, and automotive, are increasingly seeking alternatives to traditional rigid robots. These industries require handling solutions for fragile components, irregular shapes, and variable products that conventional robotics cannot efficiently address. Soft pneumatic actuators offer compelling advantages in these scenarios, including inherent compliance, adaptability to object geometry, and safer human-robot collaboration capabilities.

The food processing industry represents one of the fastest-growing application areas, with a market share of approximately 28% in the soft robotics manufacturing segment. The ability of soft pneumatic actuators to handle delicate produce, meat products, and baked goods without damage has created substantial demand in this sector. Similarly, the electronics industry is adopting these technologies for handling sensitive components during assembly processes.

Consumer preferences are also driving market demand, as there is increasing pressure for customized products requiring flexible manufacturing systems. This trend toward mass customization necessitates adaptable automation solutions that can quickly reconfigure for different product variants without extensive retooling—a capability well-suited to soft pneumatic actuator systems.

Regional analysis indicates that North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, particularly in China, Japan, and South Korea, where manufacturing automation is being aggressively pursued.

Labor shortages and rising labor costs in developed economies are further accelerating the adoption of soft robotics in manufacturing. Companies are increasingly looking to automate tasks that require dexterity and adaptability but have traditionally been difficult to automate with conventional rigid robots. This demographic shift is expected to contribute an additional 15% to market growth over the next five years.

Despite the promising outlook, price sensitivity remains a significant factor influencing market penetration. Currently, the implementation cost for soft pneumatic actuator systems is approximately 30% higher than traditional automation solutions, creating adoption barriers particularly for small and medium-sized enterprises. However, as technology matures and economies of scale are realized, this price differential is expected to narrow substantially by 2025.

Current State and Challenges in Soft Pneumatic Actuator Development

Soft pneumatic actuators (SPAs) have emerged as a promising technology in advanced manufacturing systems, offering unique advantages in flexibility, adaptability, and safety. Currently, the global research landscape shows significant advancements in SPA development across North America, Europe, and Asia, with each region contributing distinct technological approaches and applications.

In North America, research institutions like Harvard University and MIT have pioneered fundamental SPA designs utilizing silicone elastomers and innovative fabrication techniques. European contributions, particularly from ETH Zurich and the Italian Institute of Technology, have focused on biomimetic approaches and integration with traditional manufacturing systems. Asian research, led by institutions in Japan, South Korea, and China, has emphasized miniaturization and mass production methodologies.

Despite these advancements, several critical technical challenges persist in SPA development. Material limitations represent a primary constraint, as current elastomers exhibit suboptimal combinations of elasticity, durability, and response time. Most commercially available materials either lack sufficient elasticity for complex movements or deteriorate rapidly under repeated actuation cycles, limiting long-term deployment in manufacturing environments.

Control precision presents another significant challenge. Unlike rigid actuators with predictable motion paths, SPAs exhibit non-linear deformation behaviors that complicate precise positioning and force application. Current control algorithms struggle to account for material hysteresis, environmental variations, and wear-induced performance changes, resulting in inconsistent operation over time.

Manufacturing scalability remains problematic, with most SPAs still produced through labor-intensive molding processes. The transition from laboratory prototypes to mass-produced components faces barriers in standardization, quality control, and cost-effectiveness. The intricate internal channel structures essential for pneumatic operation are particularly difficult to reproduce consistently at scale.

Energy efficiency constitutes a persistent limitation, as pneumatic systems inherently suffer from energy losses during compression and transmission. SPAs typically require continuous pressure maintenance even in static positions, resulting in higher energy consumption compared to electromagnetic alternatives.

Integration challenges with existing manufacturing infrastructure further impede widespread adoption. Current industrial systems are predominantly designed for rigid actuators with standardized interfaces, creating compatibility issues for soft pneumatic solutions. The lack of standardized connectors, control protocols, and performance metrics complicates the incorporation of SPAs into established manufacturing lines.

Regulatory and safety considerations also present obstacles, particularly in collaborative manufacturing environments where SPAs interact directly with human operators. The absence of comprehensive safety standards specifically addressing soft robotics creates uncertainty regarding certification and compliance requirements.

In North America, research institutions like Harvard University and MIT have pioneered fundamental SPA designs utilizing silicone elastomers and innovative fabrication techniques. European contributions, particularly from ETH Zurich and the Italian Institute of Technology, have focused on biomimetic approaches and integration with traditional manufacturing systems. Asian research, led by institutions in Japan, South Korea, and China, has emphasized miniaturization and mass production methodologies.

Despite these advancements, several critical technical challenges persist in SPA development. Material limitations represent a primary constraint, as current elastomers exhibit suboptimal combinations of elasticity, durability, and response time. Most commercially available materials either lack sufficient elasticity for complex movements or deteriorate rapidly under repeated actuation cycles, limiting long-term deployment in manufacturing environments.

Control precision presents another significant challenge. Unlike rigid actuators with predictable motion paths, SPAs exhibit non-linear deformation behaviors that complicate precise positioning and force application. Current control algorithms struggle to account for material hysteresis, environmental variations, and wear-induced performance changes, resulting in inconsistent operation over time.

Manufacturing scalability remains problematic, with most SPAs still produced through labor-intensive molding processes. The transition from laboratory prototypes to mass-produced components faces barriers in standardization, quality control, and cost-effectiveness. The intricate internal channel structures essential for pneumatic operation are particularly difficult to reproduce consistently at scale.

Energy efficiency constitutes a persistent limitation, as pneumatic systems inherently suffer from energy losses during compression and transmission. SPAs typically require continuous pressure maintenance even in static positions, resulting in higher energy consumption compared to electromagnetic alternatives.

Integration challenges with existing manufacturing infrastructure further impede widespread adoption. Current industrial systems are predominantly designed for rigid actuators with standardized interfaces, creating compatibility issues for soft pneumatic solutions. The lack of standardized connectors, control protocols, and performance metrics complicates the incorporation of SPAs into established manufacturing lines.

Regulatory and safety considerations also present obstacles, particularly in collaborative manufacturing environments where SPAs interact directly with human operators. The absence of comprehensive safety standards specifically addressing soft robotics creates uncertainty regarding certification and compliance requirements.

Current Implementation Solutions for Manufacturing Applications

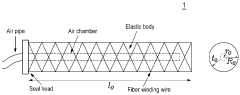

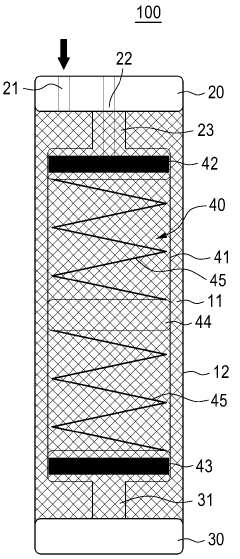

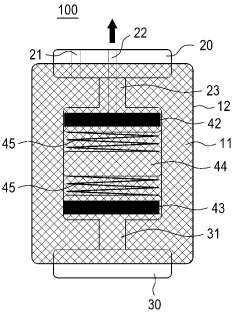

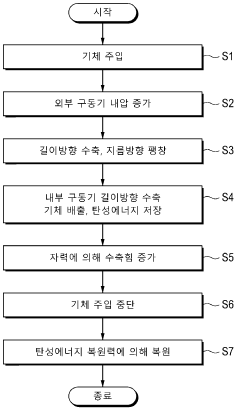

01 Design and structure of soft pneumatic actuators

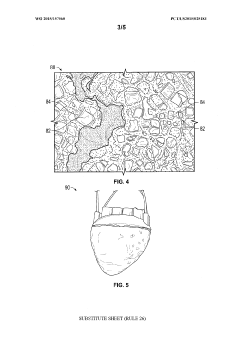

Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or fluid. These structures typically include chambers or channels that expand in predetermined directions when inflated, creating controlled movement. The design may incorporate various geometries, reinforcement patterns, or multi-layer constructions to achieve specific motion profiles such as bending, twisting, or extending. These design principles enable the creation of lightweight, compliant mechanisms suitable for safe human interaction.- Design and fabrication of soft pneumatic actuators: Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract when pressurized, resulting in bending, twisting, or other complex motions. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal channels and chambers necessary for actuation.

- Applications of soft pneumatic actuators in robotics: Soft pneumatic actuators are widely used in soft robotics applications where safe human-robot interaction is required. These actuators enable the development of robots that can perform delicate tasks, navigate complex environments, and interact safely with humans and fragile objects. Applications include robotic grippers, manipulators, wearable assistive devices, and biomimetic robots that mimic natural movements of organisms. The inherent compliance of these actuators makes them ideal for environments where traditional rigid robots would be unsuitable.

- Control systems for soft pneumatic actuators: Control systems for soft pneumatic actuators involve specialized algorithms and hardware to manage the pressure distribution within the actuator chambers. These systems often incorporate sensors for feedback control, allowing precise manipulation of the actuator's position, force, and stiffness. Advanced control strategies may include machine learning approaches, model-based control, or hybrid control systems that combine multiple techniques to achieve desired performance characteristics while accounting for the nonlinear behavior inherent to soft materials.

- Material innovations for improved actuator performance: Material innovations play a crucial role in enhancing the performance of soft pneumatic actuators. Researchers are developing new elastomeric materials with improved durability, elasticity, and response characteristics. These materials may incorporate reinforcing structures, variable stiffness elements, or smart materials that respond to external stimuli. Some advanced materials enable actuators to withstand higher pressures, achieve greater force output, or operate in extreme environments while maintaining their soft and compliant nature.

- Integration of sensing capabilities in soft actuators: Integration of sensing capabilities within soft pneumatic actuators enables closed-loop control and enhanced functionality. Various sensing modalities, including pressure sensors, strain sensors, and tactile sensors, can be embedded directly into the actuator structure. These integrated sensing systems allow the actuator to detect contact forces, measure its own deformation state, and interact intelligently with its environment. The combination of actuation and sensing in a single soft structure creates multifunctional devices that can adapt to changing conditions and perform complex tasks autonomously.

02 Materials for soft pneumatic actuators

The selection of materials is crucial for soft pneumatic actuator performance. Elastomers such as silicone rubber, thermoplastic polyurethanes, and other flexible polymers are commonly used due to their elastic properties and durability. Some designs incorporate fiber reinforcements, fabric layers, or composite structures to control deformation patterns and enhance mechanical properties. Advanced materials may include stimuli-responsive polymers or biomimetic composites that provide additional functionality such as self-healing or variable stiffness capabilities.Expand Specific Solutions03 Control systems and sensing for soft actuators

Control systems for soft pneumatic actuators often involve pressure regulation, valve control, and feedback mechanisms to achieve precise movements. These systems may incorporate sensors to monitor pressure, deformation, position, or force, enabling closed-loop control. Advanced control strategies might include machine learning algorithms, model-based controllers, or distributed control systems for complex multi-actuator setups. Integration of embedded sensing elements within the soft structure itself allows for more responsive and adaptive behavior in various applications.Expand Specific Solutions04 Fabrication methods for soft pneumatic actuators

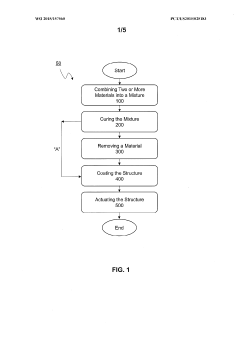

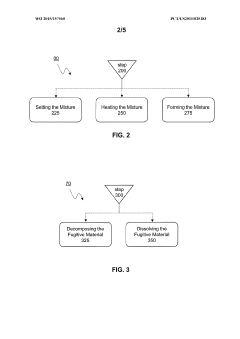

Various fabrication techniques are employed to create soft pneumatic actuators, including molding, 3D printing, and layered manufacturing. Molding processes often involve creating negative molds into which elastomeric materials are cast and cured. Advanced manufacturing methods may include multi-material 3D printing, embedded components during fabrication, or automated assembly techniques. These fabrication approaches enable complex internal channel geometries, integrated sensing elements, or variable material properties throughout the structure to achieve desired performance characteristics.Expand Specific Solutions05 Applications of soft pneumatic actuators

Soft pneumatic actuators find applications across numerous fields including robotics, medical devices, assistive technologies, and industrial automation. In robotics, they enable safe human-robot interaction and adaptable gripping of delicate objects. Medical applications include surgical tools, rehabilitation devices, and wearable assistive technologies. Industrial uses range from handling fragile items to conformable fixtures. The inherent compliance, lightweight nature, and customizable motion profiles of these actuators make them particularly valuable in scenarios requiring safe interaction with humans or delicate environments.Expand Specific Solutions

Leading Companies and Research Institutions in Soft Robotics

Soft Pneumatic Actuators in Advanced Manufacturing Systems are currently in a growth phase, with the market expanding rapidly due to increasing automation demands. The global market size is projected to reach significant value as industries adopt these flexible solutions for complex manipulation tasks. Technology maturity varies across players, with academic institutions like Harvard College, MIT, and Cornell University leading fundamental research, while companies such as Artimus Robotics, Oxipital AI, and Toyota Motor Corp. focus on commercial applications. Established manufacturers like Airbus Operations and Porsche AG are integrating these technologies into high-value manufacturing processes. Chinese companies including Beijing Soft Robot Technology and Zhejiang Shenyi are rapidly advancing in this space, particularly in industrial valve applications and flexible gripping systems.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators through their groundbreaking work on soft robotics. Their technology focuses on biomimetic design principles, creating actuators that mimic natural movements found in organisms. They've developed a comprehensive platform called PneuNets (Pneumatic Networks), which consists of a series of small air channels and chambers embedded in elastomeric materials. When pressurized, these networks create complex motions without rigid components. Harvard researchers have also innovated in manufacturing methods, utilizing multi-material 3D printing and soft lithography techniques to create intricate pneumatic structures with embedded sensing capabilities. Their recent advancements include self-healing soft actuators and hybrid systems that combine pneumatic actuation with other modalities such as electrical or chemical stimuli for enhanced functionality and control precision in manufacturing environments.

Strengths: Superior biomimetic capabilities allowing for natural, compliant motion; extensive intellectual property portfolio; advanced fabrication techniques enabling complex geometries. Weaknesses: Higher production costs compared to traditional actuators; challenges in scaling production for industrial applications; potential durability concerns in harsh manufacturing environments.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a comprehensive soft pneumatic actuator technology platform centered around their proprietary "Fluid-driven Origami-inspired Artificial Muscles" (FOAM). These actuators utilize principles of origami folding patterns to create programmable motion when inflated, achieving force amplification of over 1000 times their weight. MIT's approach integrates advanced materials science with computational design, allowing for precise control of actuator behavior through geometric programming rather than material properties alone. Their manufacturing process employs a combination of laser cutting, soft lithography, and automated assembly techniques to create scalable production of complex actuator geometries. MIT researchers have also pioneered embedded sensing systems within their actuators, using conductive elastomers and microfluidic channels to provide real-time feedback on actuator state, position, and applied forces - critical for advanced manufacturing applications requiring precision and repeatability.

Strengths: Exceptional force-to-weight ratio; highly programmable motion through geometric design; integrated sensing capabilities for closed-loop control. Weaknesses: Complex manufacturing process requiring specialized equipment; potential air leakage issues in high-cycle industrial applications; thermal sensitivity affecting performance consistency in variable temperature environments.

Key Patents and Technical Innovations in Soft Pneumatic Systems

A Power-efficient Soft Pneumatic Actuator Using Magnet Chamber Structure

PatentActiveKR1020220156694A

Innovation

- A soft pneumatic actuator with a magnet chamber structure that includes an internal actuator surrounded by elastic vinyl and a braided tube, utilizing a magnet-spring mechanism to generate force through pressure differences, allowing for faster operation with reduced air consumption and increased contraction force.

Soft actuator and methods of fabrication

PatentWO2015157560A1

Innovation

- Soft actuators are fabricated using a combination of elastomer materials and fugitive or foaming agent materials, which are cured to form an open-celled architecture that can be manipulated by inflation/deflation, allowing for controlled movement and actuation through the use of pressure from a power source, such as pneumatic pressure.

Material Science Advancements for Soft Actuator Performance

Recent advancements in material science have significantly propelled the development of soft pneumatic actuators, enabling unprecedented capabilities in advanced manufacturing systems. Traditional rigid actuators are increasingly being complemented or replaced by soft alternatives that offer superior adaptability and safety in human-machine interactions. The evolution of elastomeric materials has been particularly transformative, with silicone-based compounds such as polydimethylsiloxane (PDMS) and Ecoflex emerging as industry standards due to their exceptional elasticity and durability.

Research breakthroughs in composite materials have yielded soft actuators with enhanced mechanical properties. Fiber-reinforced elastomers, for instance, demonstrate improved tensile strength while maintaining flexibility, addressing previous limitations in load-bearing capacity. These composites strategically combine soft matrices with reinforcing elements to achieve directional stiffness, enabling more precise control over deformation patterns during actuation.

Smart materials represent another frontier in soft actuator development. Shape memory polymers (SMPs) and electroactive polymers (EAPs) respond to external stimuli such as temperature or electric fields, offering programmable behavior that conventional materials cannot match. These materials facilitate multi-modal actuation mechanisms that can be tailored to specific manufacturing requirements, expanding the functional versatility of soft pneumatic systems.

Manufacturing techniques have evolved in parallel with material innovations. Advanced 3D printing methodologies now enable the fabrication of complex, multi-material soft actuators with embedded channels and varying material properties throughout their structure. This manufacturing precision allows for optimized pneumatic pathways that enhance response time and force output while reducing air consumption.

Surface modification technologies have also contributed significantly to actuator performance. Treatments such as plasma oxidation and chemical functionalization alter material surface properties, improving air retention and reducing internal friction. These modifications extend operational lifespans and maintain consistent performance characteristics over prolonged use cycles.

Biomimetic approaches are increasingly informing material selection and design. Materials that emulate biological tissues—such as artificial muscles with anisotropic properties—demonstrate superior performance in applications requiring complex motion patterns. These bio-inspired materials often exhibit non-linear stress-strain relationships that more closely approximate natural movement, enhancing their effectiveness in delicate manufacturing tasks.

The integration of self-healing capabilities represents perhaps the most promising development for industrial applications. Materials incorporating microcapsules of healing agents or dynamic chemical bonds can autonomously repair minor damage, dramatically extending service life and reducing maintenance requirements in manufacturing environments where continuous operation is critical.

Research breakthroughs in composite materials have yielded soft actuators with enhanced mechanical properties. Fiber-reinforced elastomers, for instance, demonstrate improved tensile strength while maintaining flexibility, addressing previous limitations in load-bearing capacity. These composites strategically combine soft matrices with reinforcing elements to achieve directional stiffness, enabling more precise control over deformation patterns during actuation.

Smart materials represent another frontier in soft actuator development. Shape memory polymers (SMPs) and electroactive polymers (EAPs) respond to external stimuli such as temperature or electric fields, offering programmable behavior that conventional materials cannot match. These materials facilitate multi-modal actuation mechanisms that can be tailored to specific manufacturing requirements, expanding the functional versatility of soft pneumatic systems.

Manufacturing techniques have evolved in parallel with material innovations. Advanced 3D printing methodologies now enable the fabrication of complex, multi-material soft actuators with embedded channels and varying material properties throughout their structure. This manufacturing precision allows for optimized pneumatic pathways that enhance response time and force output while reducing air consumption.

Surface modification technologies have also contributed significantly to actuator performance. Treatments such as plasma oxidation and chemical functionalization alter material surface properties, improving air retention and reducing internal friction. These modifications extend operational lifespans and maintain consistent performance characteristics over prolonged use cycles.

Biomimetic approaches are increasingly informing material selection and design. Materials that emulate biological tissues—such as artificial muscles with anisotropic properties—demonstrate superior performance in applications requiring complex motion patterns. These bio-inspired materials often exhibit non-linear stress-strain relationships that more closely approximate natural movement, enhancing their effectiveness in delicate manufacturing tasks.

The integration of self-healing capabilities represents perhaps the most promising development for industrial applications. Materials incorporating microcapsules of healing agents or dynamic chemical bonds can autonomously repair minor damage, dramatically extending service life and reducing maintenance requirements in manufacturing environments where continuous operation is critical.

Safety Standards and Compliance for Human-Robot Collaboration

The integration of Soft Pneumatic Actuators (SPAs) in collaborative manufacturing environments necessitates adherence to comprehensive safety standards to ensure human-robot collaboration remains safe and effective. Current regulatory frameworks such as ISO/TS 15066:2016 specifically address collaborative robot operations, establishing force and pressure thresholds for different body regions during human-robot contact scenarios. These standards are particularly relevant for SPAs, which offer inherent compliance and reduced impact forces compared to traditional rigid actuators.

Risk assessment methodologies for SPA-equipped systems must follow ISO 12100 principles, with particular attention to the unique characteristics of soft actuators including their variable stiffness properties and non-linear behavior under different pneumatic pressures. Manufacturers must document these assessments thoroughly to demonstrate compliance with regional safety directives such as the EU Machinery Directive 2006/42/EC or OSHA regulations in the United States.

Performance Level (PL) requirements as defined in ISO 13849-1 apply to the safety-related control systems of SPA implementations. The inherent compliance of soft actuators may allow for lower PL classifications in certain applications, potentially reducing implementation costs while maintaining safety integrity. However, the pneumatic control systems that regulate pressure within these actuators require careful consideration regarding failure modes and fault detection capabilities.

Technical protective measures for SPA-based collaborative systems typically include pressure-limiting devices, speed monitoring systems, and emergency stop functions. The pneumatic infrastructure supporting these actuators requires specific safety considerations including overpressure protection, leak detection, and redundant pressure regulation to prevent unexpected actuator behavior that could endanger operators.

Validation and verification protocols for SPA safety systems must include testing under various operational conditions and failure modes. This includes pressure loss scenarios, response to external forces, and behavior during emergency situations. Certification bodies increasingly recognize the need for specialized testing methodologies for soft robotic systems that differ from traditional rigid robot safety assessments.

Emerging standards are beginning to address the unique characteristics of soft robotics in industrial settings. Organizations such as the IEEE RAS Soft Robotics Technical Committee are developing guidelines specifically for compliant actuator technologies. These efforts aim to establish performance metrics and safety parameters tailored to the non-linear behavior and variable compliance of pneumatic soft actuators, ensuring they can be safely integrated into human-collaborative manufacturing environments while maximizing their inherent safety advantages.

Risk assessment methodologies for SPA-equipped systems must follow ISO 12100 principles, with particular attention to the unique characteristics of soft actuators including their variable stiffness properties and non-linear behavior under different pneumatic pressures. Manufacturers must document these assessments thoroughly to demonstrate compliance with regional safety directives such as the EU Machinery Directive 2006/42/EC or OSHA regulations in the United States.

Performance Level (PL) requirements as defined in ISO 13849-1 apply to the safety-related control systems of SPA implementations. The inherent compliance of soft actuators may allow for lower PL classifications in certain applications, potentially reducing implementation costs while maintaining safety integrity. However, the pneumatic control systems that regulate pressure within these actuators require careful consideration regarding failure modes and fault detection capabilities.

Technical protective measures for SPA-based collaborative systems typically include pressure-limiting devices, speed monitoring systems, and emergency stop functions. The pneumatic infrastructure supporting these actuators requires specific safety considerations including overpressure protection, leak detection, and redundant pressure regulation to prevent unexpected actuator behavior that could endanger operators.

Validation and verification protocols for SPA safety systems must include testing under various operational conditions and failure modes. This includes pressure loss scenarios, response to external forces, and behavior during emergency situations. Certification bodies increasingly recognize the need for specialized testing methodologies for soft robotic systems that differ from traditional rigid robot safety assessments.

Emerging standards are beginning to address the unique characteristics of soft robotics in industrial settings. Organizations such as the IEEE RAS Soft Robotics Technical Committee are developing guidelines specifically for compliant actuator technologies. These efforts aim to establish performance metrics and safety parameters tailored to the non-linear behavior and variable compliance of pneumatic soft actuators, ensuring they can be safely integrated into human-collaborative manufacturing environments while maximizing their inherent safety advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!