Analysis of Gas Permeability in Bio-based Coating Layers

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Coating Gas Barrier Technology Evolution

Bio-based coating technologies have undergone significant evolution over the past decades, transitioning from simple plant-derived waxes and resins to sophisticated multi-functional barrier systems. The earliest documented use of bio-based coatings dates back to ancient civilizations that utilized beeswax and plant oils to preserve foods and protect surfaces. However, modern scientific development began in the 1940s with the exploration of cellulose derivatives as packaging materials.

The 1970s marked a pivotal shift with the oil crisis driving interest in renewable resources, leading to increased research in starch-based and protein-based coatings. These early bio-coatings exhibited limited gas barrier properties compared to their petroleum-based counterparts, primarily due to their hydrophilic nature and inconsistent molecular organization.

A significant breakthrough occurred in the 1990s with the development of nanoclay-reinforced biopolymer composites, which demonstrated substantially improved oxygen barrier properties. This period also saw the emergence of chitosan-based coatings, derived from crustacean shells, offering both antimicrobial and gas barrier functionalities.

The early 2000s witnessed the rise of multilayer bio-coating systems, strategically combining hydrophobic and hydrophilic layers to enhance gas barrier performance. Researchers began incorporating crystalline nanocellulose and other nano-scale bio-derived materials to create tortuous paths for gas molecules, effectively reducing permeability rates by 40-60% compared to conventional bio-coatings.

Between 2010 and 2015, significant advancements in protein-based coatings emerged, particularly those utilizing whey protein isolate and zein (corn protein), which demonstrated oxygen permeability rates approaching those of synthetic polymers when properly processed and formulated. These developments coincided with new processing techniques such as high-pressure homogenization and electrospinning that enabled better control over coating microstructure.

The most recent evolution (2015-present) has focused on "smart" bio-based barrier coatings with stimuli-responsive properties. These advanced systems can adapt their barrier properties in response to environmental conditions such as humidity, temperature, or microbial presence. Additionally, hybrid systems combining bio-based materials with minimal amounts of synthetic components have achieved gas permeability values competitive with fully synthetic coatings while maintaining over 85% bio-based content.

Current research frontiers include the development of crystallinity-controlled bio-coatings, where the degree and orientation of crystalline regions are precisely engineered to create highly tortuous pathways for gas molecules, potentially reducing oxygen transmission rates below 1 cc/m²·day under standard conditions.

The 1970s marked a pivotal shift with the oil crisis driving interest in renewable resources, leading to increased research in starch-based and protein-based coatings. These early bio-coatings exhibited limited gas barrier properties compared to their petroleum-based counterparts, primarily due to their hydrophilic nature and inconsistent molecular organization.

A significant breakthrough occurred in the 1990s with the development of nanoclay-reinforced biopolymer composites, which demonstrated substantially improved oxygen barrier properties. This period also saw the emergence of chitosan-based coatings, derived from crustacean shells, offering both antimicrobial and gas barrier functionalities.

The early 2000s witnessed the rise of multilayer bio-coating systems, strategically combining hydrophobic and hydrophilic layers to enhance gas barrier performance. Researchers began incorporating crystalline nanocellulose and other nano-scale bio-derived materials to create tortuous paths for gas molecules, effectively reducing permeability rates by 40-60% compared to conventional bio-coatings.

Between 2010 and 2015, significant advancements in protein-based coatings emerged, particularly those utilizing whey protein isolate and zein (corn protein), which demonstrated oxygen permeability rates approaching those of synthetic polymers when properly processed and formulated. These developments coincided with new processing techniques such as high-pressure homogenization and electrospinning that enabled better control over coating microstructure.

The most recent evolution (2015-present) has focused on "smart" bio-based barrier coatings with stimuli-responsive properties. These advanced systems can adapt their barrier properties in response to environmental conditions such as humidity, temperature, or microbial presence. Additionally, hybrid systems combining bio-based materials with minimal amounts of synthetic components have achieved gas permeability values competitive with fully synthetic coatings while maintaining over 85% bio-based content.

Current research frontiers include the development of crystallinity-controlled bio-coatings, where the degree and orientation of crystalline regions are precisely engineered to create highly tortuous pathways for gas molecules, potentially reducing oxygen transmission rates below 1 cc/m²·day under standard conditions.

Market Demand for Sustainable Packaging Solutions

The global packaging industry is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and regulatory pressures. The market for sustainable packaging is projected to reach $440 billion by 2025, growing at a CAGR of 7.7% from 2020. This growth is particularly evident in the food and beverage sector, where bio-based coating layers are gaining prominence as alternatives to conventional petroleum-based materials.

Consumer awareness regarding environmental issues has reached unprecedented levels, with recent surveys indicating that 73% of consumers are willing to pay a premium for sustainable packaging options. Major retail chains and food service companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in gas-permeable bio-based coatings.

The regulatory landscape is increasingly favorable for sustainable packaging solutions. The European Union's Single-Use Plastics Directive, China's National Sword policy, and similar regulations in North America have created urgent market demand for compliant alternatives. These regulatory frameworks are expected to become more stringent, further accelerating the transition toward bio-based materials with appropriate gas permeability properties.

Food waste reduction represents another significant market driver. Approximately one-third of all food produced globally is wasted, with inadequate packaging being a contributing factor. Bio-based coating layers with optimized gas permeability can extend shelf life by controlling moisture and gas exchange, potentially reducing food waste by 15-20% according to industry estimates.

The fresh produce segment demonstrates particularly strong demand for advanced gas-permeable bio-based coatings. These products require packaging that maintains optimal internal atmosphere conditions to preserve freshness. The market for such specialized packaging solutions is growing at 9.2% annually, outpacing the broader packaging industry.

E-commerce expansion has created additional market opportunities for sustainable packaging with controlled permeability. Online grocery shopping has grown by 54% since 2020, necessitating packaging solutions that can maintain product integrity throughout extended supply chains while meeting sustainability requirements.

Corporate sustainability commitments from major consumer packaged goods companies represent another significant market force. Companies including Nestlé, Unilever, and PepsiCo have pledged to make 100% of their packaging recyclable, reusable, or compostable by 2025, creating immediate demand for bio-based coating technologies that maintain necessary barrier properties while improving environmental performance.

The premium and organic food sectors show particularly strong willingness to adopt advanced sustainable packaging solutions, with consumers in these segments demonstrating 40% higher purchase intent for products with environmentally responsible packaging that maintains product quality through appropriate gas exchange properties.

Consumer awareness regarding environmental issues has reached unprecedented levels, with recent surveys indicating that 73% of consumers are willing to pay a premium for sustainable packaging options. Major retail chains and food service companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in gas-permeable bio-based coatings.

The regulatory landscape is increasingly favorable for sustainable packaging solutions. The European Union's Single-Use Plastics Directive, China's National Sword policy, and similar regulations in North America have created urgent market demand for compliant alternatives. These regulatory frameworks are expected to become more stringent, further accelerating the transition toward bio-based materials with appropriate gas permeability properties.

Food waste reduction represents another significant market driver. Approximately one-third of all food produced globally is wasted, with inadequate packaging being a contributing factor. Bio-based coating layers with optimized gas permeability can extend shelf life by controlling moisture and gas exchange, potentially reducing food waste by 15-20% according to industry estimates.

The fresh produce segment demonstrates particularly strong demand for advanced gas-permeable bio-based coatings. These products require packaging that maintains optimal internal atmosphere conditions to preserve freshness. The market for such specialized packaging solutions is growing at 9.2% annually, outpacing the broader packaging industry.

E-commerce expansion has created additional market opportunities for sustainable packaging with controlled permeability. Online grocery shopping has grown by 54% since 2020, necessitating packaging solutions that can maintain product integrity throughout extended supply chains while meeting sustainability requirements.

Corporate sustainability commitments from major consumer packaged goods companies represent another significant market force. Companies including Nestlé, Unilever, and PepsiCo have pledged to make 100% of their packaging recyclable, reusable, or compostable by 2025, creating immediate demand for bio-based coating technologies that maintain necessary barrier properties while improving environmental performance.

The premium and organic food sectors show particularly strong willingness to adopt advanced sustainable packaging solutions, with consumers in these segments demonstrating 40% higher purchase intent for products with environmentally responsible packaging that maintains product quality through appropriate gas exchange properties.

Current Challenges in Bio-coating Gas Permeability

Despite significant advancements in bio-based coating technologies, gas permeability remains one of the most critical challenges facing the industry today. Bio-based coatings, derived from renewable resources such as polysaccharides, proteins, and lipids, often struggle to achieve the same barrier properties as their petroleum-based counterparts. This performance gap represents a significant hurdle for wider commercial adoption across packaging, construction, and medical applications.

The fundamental challenge lies in the inherent hydrophilic nature of many bio-based polymers, which creates a trade-off between moisture sensitivity and oxygen barrier properties. When exposed to varying humidity conditions, these materials undergo structural changes that significantly alter their gas permeability characteristics. For instance, polysaccharide-based coatings like starch and cellulose derivatives exhibit excellent oxygen barrier properties in dry conditions but lose this functionality dramatically as relative humidity increases.

Inconsistent film formation presents another major obstacle. Bio-polymers often demonstrate poor film-forming capabilities compared to synthetic alternatives, resulting in micro-defects and non-uniform coating layers. These structural imperfections create pathways for gas molecules to penetrate through the coating, compromising the overall barrier performance. The challenge is particularly pronounced when scaling up from laboratory to industrial production.

The compatibility between different bio-based components in composite coatings remains problematic. While blending various bio-polymers can theoretically combine their beneficial properties, phase separation and poor interfacial adhesion frequently occur, creating weak points in the coating structure that facilitate gas transmission. This incompatibility limits the effectiveness of multi-component systems designed to address permeability issues.

Processing limitations further exacerbate these challenges. Many bio-based materials are sensitive to thermal degradation, limiting the processing window during coating application. This sensitivity restricts the use of conventional high-temperature processing techniques that might otherwise improve film density and reduce permeability. Additionally, the viscosity behavior of bio-polymer solutions often proves difficult to control during industrial coating operations.

Long-term stability represents perhaps the most significant barrier to widespread adoption. Bio-based coatings typically demonstrate accelerated aging compared to conventional alternatives, with barrier properties deteriorating over time due to ongoing biochemical processes within the material. This degradation is particularly problematic in applications requiring extended shelf life or long-term protection.

Regulatory hurdles and standardization issues compound these technical challenges. The lack of universally accepted testing protocols specifically designed for bio-based coatings makes it difficult to reliably compare performance across different formulations and applications, slowing innovation and market acceptance.

The fundamental challenge lies in the inherent hydrophilic nature of many bio-based polymers, which creates a trade-off between moisture sensitivity and oxygen barrier properties. When exposed to varying humidity conditions, these materials undergo structural changes that significantly alter their gas permeability characteristics. For instance, polysaccharide-based coatings like starch and cellulose derivatives exhibit excellent oxygen barrier properties in dry conditions but lose this functionality dramatically as relative humidity increases.

Inconsistent film formation presents another major obstacle. Bio-polymers often demonstrate poor film-forming capabilities compared to synthetic alternatives, resulting in micro-defects and non-uniform coating layers. These structural imperfections create pathways for gas molecules to penetrate through the coating, compromising the overall barrier performance. The challenge is particularly pronounced when scaling up from laboratory to industrial production.

The compatibility between different bio-based components in composite coatings remains problematic. While blending various bio-polymers can theoretically combine their beneficial properties, phase separation and poor interfacial adhesion frequently occur, creating weak points in the coating structure that facilitate gas transmission. This incompatibility limits the effectiveness of multi-component systems designed to address permeability issues.

Processing limitations further exacerbate these challenges. Many bio-based materials are sensitive to thermal degradation, limiting the processing window during coating application. This sensitivity restricts the use of conventional high-temperature processing techniques that might otherwise improve film density and reduce permeability. Additionally, the viscosity behavior of bio-polymer solutions often proves difficult to control during industrial coating operations.

Long-term stability represents perhaps the most significant barrier to widespread adoption. Bio-based coatings typically demonstrate accelerated aging compared to conventional alternatives, with barrier properties deteriorating over time due to ongoing biochemical processes within the material. This degradation is particularly problematic in applications requiring extended shelf life or long-term protection.

Regulatory hurdles and standardization issues compound these technical challenges. The lack of universally accepted testing protocols specifically designed for bio-based coatings makes it difficult to reliably compare performance across different formulations and applications, slowing innovation and market acceptance.

Existing Gas Permeability Measurement Methods

01 Bio-based barrier coatings for improved gas permeability

Bio-based materials can be formulated into coating layers that provide effective barriers against gas permeation. These environmentally friendly alternatives to synthetic polymers can be derived from renewable resources such as plant cellulose, proteins, and polysaccharides. When properly formulated, these bio-based coatings create a tortuous path for gas molecules, significantly reducing oxygen, carbon dioxide, and water vapor transmission rates through packaging materials and other substrates.- Bio-based polymers for gas barrier coatings: Bio-based polymers derived from renewable resources can be formulated into coating layers with excellent gas barrier properties. These polymers, such as polylactic acid (PLA), cellulose derivatives, and starch-based materials, can be processed into films or coatings that effectively reduce oxygen, carbon dioxide, and water vapor permeability. The natural structure of these biopolymers often provides inherent barrier properties that can be further enhanced through various processing techniques.

- Nanocomposite coatings for enhanced barrier performance: Incorporating nanomaterials such as nanoclay, nanocellulose, or silica nanoparticles into bio-based coating formulations significantly enhances gas barrier properties. These nanoparticles create tortuous paths for gas molecules, effectively increasing the diffusion path length and reducing permeability. The nanocomposite approach allows for thinner coatings while maintaining or improving barrier performance, which is particularly valuable for food packaging and other applications requiring controlled atmosphere conditions.

- Multilayer coating systems with complementary barrier properties: Multilayer coating systems that combine different bio-based materials can achieve superior gas barrier properties compared to single-layer coatings. Each layer in the system can be designed to address specific permeability concerns, with some layers providing oxygen barriers while others focus on moisture resistance. This approach allows for customization of the overall barrier performance while maintaining the renewable and sustainable nature of the coating system.

- Surface modification techniques for improved adhesion and barrier properties: Various surface modification techniques can be applied to bio-based coating layers to improve both adhesion to substrates and gas barrier properties. These techniques include plasma treatment, corona discharge, chemical grafting, and crosslinking reactions. Modified surfaces often show reduced permeability to gases and improved mechanical properties, extending the shelf life of packaged products and enhancing the overall performance of the coating system.

- Environmentally responsive bio-based barrier coatings: Smart bio-based coating systems can be designed to respond to environmental conditions, adjusting their barrier properties based on temperature, humidity, or other external factors. These responsive coatings may incorporate phase-change materials, humidity-sensitive polymers, or temperature-responsive components that optimize gas permeability under varying conditions. This adaptive behavior is particularly valuable for applications where controlled gas exchange is required, such as in fresh produce packaging or medical device coatings.

02 Cellulose-based coating formulations for gas barrier properties

Cellulose derivatives and nanocellulose materials can be incorporated into coating formulations to enhance gas barrier properties. These renewable materials form dense, crystalline structures that effectively block gas molecules. Modifications such as acetylation or addition of plasticizers can further improve the barrier performance while maintaining biodegradability. These coatings are particularly effective when applied to paper, cardboard, or flexible packaging materials to reduce oxygen and moisture transmission.Expand Specific Solutions03 Protein and polysaccharide composite coatings for gas impermeability

Composite coatings combining proteins (such as soy, whey, or zein) with polysaccharides (like chitosan, alginate, or pectin) create synergistic barrier effects against gas permeation. The protein components provide structural integrity while polysaccharides fill interstitial spaces, creating a dense network that restricts gas molecule movement. These natural polymer combinations can be cross-linked to enhance durability and water resistance while maintaining their excellent oxygen barrier properties under varying humidity conditions.Expand Specific Solutions04 Bio-based waxes and lipids for moisture vapor barrier applications

Natural waxes, oils, and lipids derived from plant and animal sources can be formulated into hydrophobic coating layers that effectively control water vapor transmission. These bio-based materials create a water-repellent surface that prevents moisture migration through packaging materials. Carnauba wax, beeswax, and plant-derived fatty acids can be emulsified or combined with other bio-polymers to create coatings that maintain product freshness by controlling humidity levels while being fully biodegradable.Expand Specific Solutions05 Nanocomposite bio-based coatings with enhanced barrier performance

Incorporating nanomaterials such as clay, silica, or cellulose nanocrystals into bio-based polymer matrices creates high-performance barrier coatings with significantly reduced gas permeability. These nanoparticles increase the tortuosity of the diffusion path for gas molecules and fill free volume within the polymer matrix. The resulting nanocomposite coatings maintain the renewable and biodegradable nature of the base materials while achieving barrier properties comparable to conventional petroleum-based polymers, making them suitable for food packaging and other applications requiring controlled atmosphere.Expand Specific Solutions

Key Industry Players in Bio-based Coating Market

The gas permeability market in bio-based coating layers is currently in a growth phase, with increasing demand driven by sustainable packaging solutions. The market is expanding at a significant rate as industries shift toward eco-friendly alternatives, estimated to reach several billion dollars by 2025. Technologically, the field shows varying maturity levels, with companies at different development stages. Industry leaders like PPG Industries and FUJIFILM have established advanced proprietary technologies, while Toyobo, Toray Plastics, and Air Liquide are making significant R&D investments. Academic-industrial collaborations with institutions like Texas A&M and California Institute of Technology are accelerating innovation. The competitive landscape is diversifying with specialized players like Molecular Plasma Group developing novel functionalization approaches for enhanced barrier properties.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed advanced bio-based coating technologies that incorporate natural polymers like cellulose derivatives, chitosan, and plant-based oils to create sustainable barrier films with controlled gas permeability. Their proprietary multi-layer coating system utilizes cross-linking agents to form dense molecular networks that effectively regulate oxygen and carbon dioxide transmission rates. The company employs nano-structured clay particles as fillers to create tortuous paths for gas molecules, significantly reducing permeation rates while maintaining coating flexibility. PPG's water-based formulations eliminate the need for harmful solvents while achieving comparable barrier properties to conventional petroleum-based coatings. Their technology includes specialized surface treatments that enhance adhesion to various substrates while maintaining barrier integrity during mechanical stress and environmental exposure.

Strengths: Superior barrier performance with environmentally friendly materials; scalable manufacturing processes suitable for industrial applications; customizable permeability rates for different applications. Weaknesses: Higher production costs compared to conventional coatings; potential limitations in extreme temperature conditions; may require specialized application equipment.

FUJIFILM Corp.

Technical Solution: FUJIFILM has pioneered bio-based gas barrier coatings utilizing their expertise in thin-film technology. Their approach combines modified cellulose nanofibers (CNF) with proprietary bio-polyesters to create ultra-thin barrier layers with exceptional oxygen and moisture resistance. The company's Bio-Barrier™ technology employs a unique layer-by-layer deposition process that creates highly ordered molecular structures, effectively blocking gas molecules while maintaining coating transparency. FUJIFILM has developed specialized bio-based cross-linking agents that create covalent bonds between polymer chains, significantly reducing free volume and gas diffusion pathways. Their coatings incorporate naturally derived antioxidants that prevent oxidative degradation, extending the functional lifetime of the barrier properties. The company has successfully commercialized these coatings for food packaging applications, demonstrating oxygen transmission rates below 1 cc/m²/day and water vapor transmission rates under 1 g/m²/day at standard conditions.

Strengths: Exceptional barrier properties with minimal thickness; high optical clarity suitable for transparent packaging; proven commercial viability with established manufacturing infrastructure. Weaknesses: Higher cost compared to conventional petroleum-based alternatives; performance may degrade under high humidity conditions; limited heat resistance compared to some synthetic barriers.

Critical Patents in Bio-coating Barrier Properties

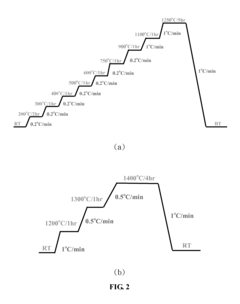

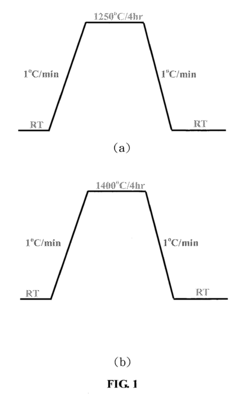

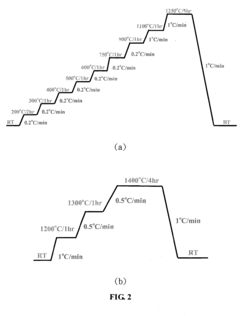

Innovation control process for specific porosity/gas permeability of electrode layers of SOFC-MEA through combination of sintering and pore former scheme and technology

PatentInactiveUS20090166908A1

Innovation

- A novel manufacturing process combining pore former and sintering technology is used to produce the electrode layer for solid oxide fuel cell-membrane electrode assembly, specifically adjusting the composition and sintering conditions to achieve desired porosity and gas permeability, including the use of graphite as a pore former and controlled sintering temperatures and atmospheres.

Control process for specific porosity/gas permeability of electrode layers of SOFC-MEA through combination of sintering and pore former technology

PatentInactiveEP2117067B1

Innovation

- A novel process combining pore former and sintering technology is used, where graphite is added to an anode slurry, uniformly mixed, and then tape casted into green substrates, followed by high-temperature sintering with controlled temperature profiles and gas flow rates to produce anode supported cells with optimal porosity and gas permeability.

Biodegradability vs Performance Trade-offs

The fundamental challenge in bio-based coating development lies in the inherent trade-off between biodegradability and barrier performance. As materials become more biodegradable, they typically exhibit increased susceptibility to moisture and gas permeation, compromising their effectiveness as protective barriers. This inverse relationship creates significant engineering challenges for manufacturers seeking to develop sustainable packaging solutions.

Bio-based polymers with excellent biodegradability, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), generally demonstrate higher oxygen transmission rates (OTR) and water vapor transmission rates (WVTR) compared to conventional petroleum-based polymers like polyethylene terephthalate (PET) or polyethylene (PE). For instance, unmodified PLA typically exhibits an OTR of 200-250 cc/m²/day compared to PET's 10-20 cc/m²/day under standard testing conditions.

The molecular structure of biodegradable polymers contributes significantly to this performance gap. The presence of hydrophilic functional groups that facilitate biodegradation also increases water sensitivity and creates more permeable pathways for gas molecules. Additionally, the lower crystallinity often found in bio-based materials results in less tortuous diffusion paths for permeating molecules.

Various strategies have emerged to address this trade-off. Multilayer systems combining biodegradable substrates with thin high-barrier layers represent one approach, though these can complicate end-of-life recycling or composting. Another promising direction involves nanocomposite technology, where nanomaterials like clay, cellulose nanocrystals, or graphene oxide create tortuous paths for diffusing molecules while maintaining biodegradability.

Surface modification techniques, including plasma treatment and chemical grafting, have demonstrated potential for enhancing barrier properties without significantly impacting biodegradability. These approaches alter the surface chemistry while preserving the bulk material properties necessary for biodegradation.

Recent advances in bio-based coating formulations have narrowed the performance gap. For example, certain modified cellulose-based coatings have achieved OTR values below 50 cc/m²/day while maintaining industrial compostability standards. However, these improvements often come with increased production costs or more complex processing requirements.

The economic implications of this trade-off remain significant. Bio-based coatings with comparable barrier performance to conventional materials typically command a 20-40% price premium, limiting widespread adoption despite growing consumer demand for sustainable packaging solutions. This economic barrier underscores the need for continued innovation in material science and processing technologies to optimize the biodegradability-performance balance.

Bio-based polymers with excellent biodegradability, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), generally demonstrate higher oxygen transmission rates (OTR) and water vapor transmission rates (WVTR) compared to conventional petroleum-based polymers like polyethylene terephthalate (PET) or polyethylene (PE). For instance, unmodified PLA typically exhibits an OTR of 200-250 cc/m²/day compared to PET's 10-20 cc/m²/day under standard testing conditions.

The molecular structure of biodegradable polymers contributes significantly to this performance gap. The presence of hydrophilic functional groups that facilitate biodegradation also increases water sensitivity and creates more permeable pathways for gas molecules. Additionally, the lower crystallinity often found in bio-based materials results in less tortuous diffusion paths for permeating molecules.

Various strategies have emerged to address this trade-off. Multilayer systems combining biodegradable substrates with thin high-barrier layers represent one approach, though these can complicate end-of-life recycling or composting. Another promising direction involves nanocomposite technology, where nanomaterials like clay, cellulose nanocrystals, or graphene oxide create tortuous paths for diffusing molecules while maintaining biodegradability.

Surface modification techniques, including plasma treatment and chemical grafting, have demonstrated potential for enhancing barrier properties without significantly impacting biodegradability. These approaches alter the surface chemistry while preserving the bulk material properties necessary for biodegradation.

Recent advances in bio-based coating formulations have narrowed the performance gap. For example, certain modified cellulose-based coatings have achieved OTR values below 50 cc/m²/day while maintaining industrial compostability standards. However, these improvements often come with increased production costs or more complex processing requirements.

The economic implications of this trade-off remain significant. Bio-based coatings with comparable barrier performance to conventional materials typically command a 20-40% price premium, limiting widespread adoption despite growing consumer demand for sustainable packaging solutions. This economic barrier underscores the need for continued innovation in material science and processing technologies to optimize the biodegradability-performance balance.

Regulatory Framework for Food-Contact Materials

The regulatory landscape governing food-contact materials (FCMs) plays a crucial role in the development and commercialization of bio-based coating layers with specific gas permeability properties. These regulations ensure that materials used in food packaging meet stringent safety standards while maintaining appropriate barrier properties against gases like oxygen, carbon dioxide, and water vapor.

In the United States, the Food and Drug Administration (FDA) regulates food-contact materials through the Food, Drug, and Cosmetic Act, specifically under the Food Contact Notification (FCN) program. Bio-based coatings must demonstrate compliance with migration limits and undergo thorough safety assessments before market approval. The FDA's Threshold of Regulation (TOR) exemptions may apply to certain bio-based components if migration levels remain below 0.5 ppb.

The European Union implements a more comprehensive approach through Regulation (EC) No. 1935/2004, which establishes the general framework for all food-contact materials. For bio-based coatings specifically, Commission Regulation (EU) No. 10/2011 on plastic materials is often applicable, requiring extensive migration testing and compliance with specific migration limits (SMLs). The EU also maintains a positive list of authorized substances that can be used in food-contact applications.

Japan employs a hybrid regulatory system through its Food Sanitation Law, which includes both positive lists and compliance standards. The Japanese regulatory framework places particular emphasis on biodegradable materials, potentially offering a more streamlined pathway for certain bio-based coating technologies with controlled gas permeability properties.

Emerging economies like China and India are rapidly developing their regulatory frameworks for food-contact materials. China's GB standards (particularly GB 9685) govern food-contact additives, while India follows the Food Safety and Standards Authority of India (FSSAI) guidelines. These frameworks are increasingly harmonizing with international standards but may present unique compliance challenges for novel bio-based coating technologies.

International standards organizations like ISO and ASTM provide standardized testing methodologies for gas permeability measurements in food packaging materials. These standards (such as ASTM D3985 for oxygen transmission rate) are essential for demonstrating regulatory compliance and ensuring consistent performance evaluation across different jurisdictions.

The regulatory landscape continues to evolve with increasing focus on sustainable materials. Several jurisdictions are developing specific frameworks for bio-based and biodegradable materials, potentially creating new pathways for innovative gas-permeable coatings derived from renewable resources. These emerging regulations aim to balance safety requirements with sustainability objectives, potentially accelerating market adoption of advanced bio-based coating technologies.

In the United States, the Food and Drug Administration (FDA) regulates food-contact materials through the Food, Drug, and Cosmetic Act, specifically under the Food Contact Notification (FCN) program. Bio-based coatings must demonstrate compliance with migration limits and undergo thorough safety assessments before market approval. The FDA's Threshold of Regulation (TOR) exemptions may apply to certain bio-based components if migration levels remain below 0.5 ppb.

The European Union implements a more comprehensive approach through Regulation (EC) No. 1935/2004, which establishes the general framework for all food-contact materials. For bio-based coatings specifically, Commission Regulation (EU) No. 10/2011 on plastic materials is often applicable, requiring extensive migration testing and compliance with specific migration limits (SMLs). The EU also maintains a positive list of authorized substances that can be used in food-contact applications.

Japan employs a hybrid regulatory system through its Food Sanitation Law, which includes both positive lists and compliance standards. The Japanese regulatory framework places particular emphasis on biodegradable materials, potentially offering a more streamlined pathway for certain bio-based coating technologies with controlled gas permeability properties.

Emerging economies like China and India are rapidly developing their regulatory frameworks for food-contact materials. China's GB standards (particularly GB 9685) govern food-contact additives, while India follows the Food Safety and Standards Authority of India (FSSAI) guidelines. These frameworks are increasingly harmonizing with international standards but may present unique compliance challenges for novel bio-based coating technologies.

International standards organizations like ISO and ASTM provide standardized testing methodologies for gas permeability measurements in food packaging materials. These standards (such as ASTM D3985 for oxygen transmission rate) are essential for demonstrating regulatory compliance and ensuring consistent performance evaluation across different jurisdictions.

The regulatory landscape continues to evolve with increasing focus on sustainable materials. Several jurisdictions are developing specific frameworks for bio-based and biodegradable materials, potentially creating new pathways for innovative gas-permeable coatings derived from renewable resources. These emerging regulations aim to balance safety requirements with sustainability objectives, potentially accelerating market adoption of advanced bio-based coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!