Bio-based Barrier Coatings Reinforced with Nanocellulose Additives

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Barrier Coatings Background and Objectives

Nanocellulose-based barrier coatings represent a significant advancement in sustainable packaging solutions, emerging from decades of research into renewable materials. The evolution of these technologies can be traced back to the early 2000s when concerns about petroleum-based packaging materials began driving research into bio-alternatives. Nanocellulose, derived from plant cellulose fibers through mechanical or chemical processes, has emerged as a particularly promising material due to its exceptional mechanical properties, biodegradability, and renewable nature.

The development trajectory of nanocellulose barrier coatings has accelerated significantly in the past decade, with breakthroughs in extraction methods, surface modification techniques, and composite formulations. Initially, research focused primarily on basic characterization of nanocellulose properties, but has since expanded to include sophisticated applications in food packaging, pharmaceutical packaging, and other high-performance barrier applications.

Current technological trends indicate a shift toward hybrid systems that combine nanocellulose with other bio-based polymers to enhance barrier properties against oxygen, water vapor, and grease. The integration of nanocellulose as an additive rather than a standalone material represents a pragmatic approach to overcoming some of the material's inherent limitations while maximizing its benefits.

The primary objective of research in this field is to develop commercially viable bio-based barrier coatings that can match or exceed the performance of conventional petroleum-based alternatives. Specific technical goals include achieving oxygen transmission rates below 1 cc/m²/day and water vapor transmission rates under 10 g/m²/day under standard conditions, while maintaining mechanical integrity and processability compatible with existing manufacturing infrastructure.

Additional objectives include addressing scalability challenges, reducing production costs, and ensuring consistent quality across large-scale manufacturing processes. Research aims to optimize nanocellulose extraction and modification techniques to enhance compatibility with various coating formulations and substrates.

Long-term goals extend to developing multifunctional barrier coatings that not only provide protection against environmental factors but also incorporate active properties such as antimicrobial activity, controlled release of preservatives, or intelligent response to environmental changes. These advanced functionalities represent the next frontier in sustainable packaging solutions.

The ultimate technological objective is to establish nanocellulose-reinforced barrier coatings as a mainstream alternative to conventional packaging materials, contributing significantly to global sustainability goals by reducing plastic waste and petroleum dependence while maintaining or improving product protection and shelf life.

The development trajectory of nanocellulose barrier coatings has accelerated significantly in the past decade, with breakthroughs in extraction methods, surface modification techniques, and composite formulations. Initially, research focused primarily on basic characterization of nanocellulose properties, but has since expanded to include sophisticated applications in food packaging, pharmaceutical packaging, and other high-performance barrier applications.

Current technological trends indicate a shift toward hybrid systems that combine nanocellulose with other bio-based polymers to enhance barrier properties against oxygen, water vapor, and grease. The integration of nanocellulose as an additive rather than a standalone material represents a pragmatic approach to overcoming some of the material's inherent limitations while maximizing its benefits.

The primary objective of research in this field is to develop commercially viable bio-based barrier coatings that can match or exceed the performance of conventional petroleum-based alternatives. Specific technical goals include achieving oxygen transmission rates below 1 cc/m²/day and water vapor transmission rates under 10 g/m²/day under standard conditions, while maintaining mechanical integrity and processability compatible with existing manufacturing infrastructure.

Additional objectives include addressing scalability challenges, reducing production costs, and ensuring consistent quality across large-scale manufacturing processes. Research aims to optimize nanocellulose extraction and modification techniques to enhance compatibility with various coating formulations and substrates.

Long-term goals extend to developing multifunctional barrier coatings that not only provide protection against environmental factors but also incorporate active properties such as antimicrobial activity, controlled release of preservatives, or intelligent response to environmental changes. These advanced functionalities represent the next frontier in sustainable packaging solutions.

The ultimate technological objective is to establish nanocellulose-reinforced barrier coatings as a mainstream alternative to conventional packaging materials, contributing significantly to global sustainability goals by reducing plastic waste and petroleum dependence while maintaining or improving product protection and shelf life.

Market Demand Analysis for Sustainable Packaging Solutions

The global packaging industry is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and regulatory pressures. The market for eco-friendly packaging materials is projected to reach $413.8 billion by 2027, growing at a CAGR of 6.1% from 2020. This growth is particularly evident in the food and beverage sector, which accounts for approximately 70% of the packaging market and faces stringent requirements for both sustainability and barrier properties.

Consumer demand for sustainable packaging has reached unprecedented levels, with recent surveys indicating that 74% of consumers are willing to pay more for environmentally friendly packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, with many pledging to use 100% recyclable, reusable, or compostable packaging by 2025-2030.

The regulatory landscape is also evolving rapidly, with the European Union's Single-Use Plastics Directive and similar legislation worldwide creating urgent market demand for alternatives to conventional plastic packaging. These regulations have accelerated research and development in bio-based barrier materials, including those reinforced with nanocellulose additives.

Bio-based barrier coatings represent a particularly promising segment within sustainable packaging solutions. The market for these materials is expected to grow at 8.3% annually through 2028, outpacing the broader packaging industry. This growth is driven by their ability to address the critical "barrier gap" - providing the moisture, oxygen, and grease resistance properties of conventional plastics while maintaining biodegradability and recyclability.

Nanocellulose-reinforced coatings are emerging as a key innovation within this space, offering superior barrier properties compared to conventional bio-based alternatives. Early commercial applications have demonstrated oxygen transmission rates comparable to metallized films and water vapor barrier properties approaching those of polyethylene, while maintaining biodegradability.

Food packaging applications represent the largest market opportunity, particularly for perishable goods requiring moderate to high barrier protection. The dairy, bakery, and prepared foods segments have shown particular interest in these solutions, with several major brands conducting pilot programs using nanocellulose-enhanced packaging.

The pharmaceutical and personal care sectors are also exploring these materials, driven by both sustainability goals and the potential for enhanced product protection. The premium positioning of many products in these categories makes them well-suited to absorb the currently higher costs of bio-based barrier solutions.

Consumer demand for sustainable packaging has reached unprecedented levels, with recent surveys indicating that 74% of consumers are willing to pay more for environmentally friendly packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, with many pledging to use 100% recyclable, reusable, or compostable packaging by 2025-2030.

The regulatory landscape is also evolving rapidly, with the European Union's Single-Use Plastics Directive and similar legislation worldwide creating urgent market demand for alternatives to conventional plastic packaging. These regulations have accelerated research and development in bio-based barrier materials, including those reinforced with nanocellulose additives.

Bio-based barrier coatings represent a particularly promising segment within sustainable packaging solutions. The market for these materials is expected to grow at 8.3% annually through 2028, outpacing the broader packaging industry. This growth is driven by their ability to address the critical "barrier gap" - providing the moisture, oxygen, and grease resistance properties of conventional plastics while maintaining biodegradability and recyclability.

Nanocellulose-reinforced coatings are emerging as a key innovation within this space, offering superior barrier properties compared to conventional bio-based alternatives. Early commercial applications have demonstrated oxygen transmission rates comparable to metallized films and water vapor barrier properties approaching those of polyethylene, while maintaining biodegradability.

Food packaging applications represent the largest market opportunity, particularly for perishable goods requiring moderate to high barrier protection. The dairy, bakery, and prepared foods segments have shown particular interest in these solutions, with several major brands conducting pilot programs using nanocellulose-enhanced packaging.

The pharmaceutical and personal care sectors are also exploring these materials, driven by both sustainability goals and the potential for enhanced product protection. The premium positioning of many products in these categories makes them well-suited to absorb the currently higher costs of bio-based barrier solutions.

Current Status and Challenges in Bio-based Barrier Technologies

The global landscape of bio-based barrier technologies has witnessed significant advancement in recent years, driven by increasing environmental concerns and regulatory pressures against petroleum-based packaging materials. Currently, several bio-based polymers including polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives are being commercially utilized as barrier materials in packaging applications. These materials offer biodegradability and renewability advantages over conventional petroleum-based polymers.

Nanocellulose-reinforced bio-based barrier coatings represent a particularly promising segment within this field. Research indicates that crystalline nanocellulose (CNC) and cellulose nanofibrils (CNF) can enhance oxygen, water vapor, and grease barrier properties when incorporated into biopolymer matrices. Leading research institutions in Scandinavia, North America, and Japan have demonstrated oxygen permeability reductions of up to 90% in certain biopolymer films with optimal nanocellulose loading.

Despite these advancements, significant technical challenges persist. The hydrophilic nature of most bio-based polymers and nanocellulose results in moisture sensitivity, causing barrier performance deterioration in humid conditions. This remains one of the most critical limitations for widespread commercial adoption. Additionally, achieving uniform dispersion of nanocellulose within hydrophobic polymer matrices presents considerable processing difficulties, often requiring chemical modification or compatibilization strategies.

Scalability represents another major hurdle. While laboratory-scale production of nanocellulose-reinforced barriers shows promising results, transitioning to industrial-scale manufacturing faces challenges in maintaining consistent quality, controlling processing parameters, and managing increased production costs. Current industrial production methods struggle to achieve the same level of nanocellulose dispersion and orientation observed in laboratory settings.

Market penetration is further constrained by cost factors. Bio-based barrier materials typically command a 20-40% price premium over conventional alternatives, limiting their adoption to premium or specialty applications. The production of nanocellulose itself remains relatively expensive, with costs ranging from $10-100/kg depending on production method and quality specifications.

Regulatory frameworks also present challenges, with inconsistent global standards for biodegradability claims and food contact approvals. While Europe has established clearer pathways for bio-based packaging approval, many regions lack specific regulations, creating market uncertainty and hindering investment in new technologies.

Recent technological developments show promise in addressing these challenges, including surface modification techniques for nanocellulose to enhance hydrophobicity, multilayer coating approaches to combine complementary barrier properties, and emerging processing technologies like high-pressure homogenization and supercritical CO2 processing to improve nanocellulose dispersion.

Nanocellulose-reinforced bio-based barrier coatings represent a particularly promising segment within this field. Research indicates that crystalline nanocellulose (CNC) and cellulose nanofibrils (CNF) can enhance oxygen, water vapor, and grease barrier properties when incorporated into biopolymer matrices. Leading research institutions in Scandinavia, North America, and Japan have demonstrated oxygen permeability reductions of up to 90% in certain biopolymer films with optimal nanocellulose loading.

Despite these advancements, significant technical challenges persist. The hydrophilic nature of most bio-based polymers and nanocellulose results in moisture sensitivity, causing barrier performance deterioration in humid conditions. This remains one of the most critical limitations for widespread commercial adoption. Additionally, achieving uniform dispersion of nanocellulose within hydrophobic polymer matrices presents considerable processing difficulties, often requiring chemical modification or compatibilization strategies.

Scalability represents another major hurdle. While laboratory-scale production of nanocellulose-reinforced barriers shows promising results, transitioning to industrial-scale manufacturing faces challenges in maintaining consistent quality, controlling processing parameters, and managing increased production costs. Current industrial production methods struggle to achieve the same level of nanocellulose dispersion and orientation observed in laboratory settings.

Market penetration is further constrained by cost factors. Bio-based barrier materials typically command a 20-40% price premium over conventional alternatives, limiting their adoption to premium or specialty applications. The production of nanocellulose itself remains relatively expensive, with costs ranging from $10-100/kg depending on production method and quality specifications.

Regulatory frameworks also present challenges, with inconsistent global standards for biodegradability claims and food contact approvals. While Europe has established clearer pathways for bio-based packaging approval, many regions lack specific regulations, creating market uncertainty and hindering investment in new technologies.

Recent technological developments show promise in addressing these challenges, including surface modification techniques for nanocellulose to enhance hydrophobicity, multilayer coating approaches to combine complementary barrier properties, and emerging processing technologies like high-pressure homogenization and supercritical CO2 processing to improve nanocellulose dispersion.

Current Technical Solutions for Nanocellulose Barrier Enhancement

01 Nanocellulose as barrier enhancement in bio-based coatings

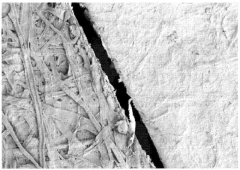

Nanocellulose materials, including cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC), can significantly enhance the barrier properties of bio-based coatings. When incorporated into coating formulations, these nanomaterials create a tortuous path that restricts the passage of gases, moisture, and other substances. The high aspect ratio and crystallinity of nanocellulose contribute to improved oxygen, water vapor, and grease barrier properties, making these coatings suitable for packaging applications requiring extended shelf life.- Nanocellulose as barrier enhancement in bio-based coatings: Nanocellulose materials, including cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC), can significantly enhance the barrier properties of bio-based coatings. When incorporated into coating formulations, these nanomaterials create a dense network structure that restricts the passage of gases, moisture, and other substances. The high aspect ratio and crystallinity of nanocellulose particles contribute to the formation of tortuous pathways, making it difficult for molecules to penetrate through the coating. This results in improved oxygen, water vapor, and grease barrier properties compared to conventional bio-based coatings.

- Surface modification of nanocellulose for compatibility in coatings: Surface modification techniques can be applied to nanocellulose to improve its compatibility with various polymer matrices used in bio-based barrier coatings. Methods such as silylation, acetylation, and grafting of hydrophobic groups onto the nanocellulose surface reduce its hydrophilicity and improve dispersion in non-polar matrices. Modified nanocellulose demonstrates better interfacial adhesion with the coating matrix, resulting in more homogeneous films with fewer defects. These modifications also help maintain barrier performance under varying humidity conditions and extend the shelf life of coated products.

- Multilayer coating systems with nanocellulose: Multilayer coating systems incorporating nanocellulose in specific layers can provide enhanced barrier properties while maintaining other functional requirements. These systems typically consist of a base layer for adhesion, a middle layer containing nanocellulose for barrier properties, and a top layer for surface protection or additional functionality. The strategic placement of nanocellulose in the coating architecture allows for optimization of barrier performance while addressing limitations such as moisture sensitivity. This approach enables the development of tailored barrier solutions for various applications including food packaging, electronics protection, and pharmaceutical packaging.

- Processing techniques for nanocellulose-reinforced barrier coatings: Various processing techniques can be employed to optimize the performance of nanocellulose-reinforced barrier coatings. Methods such as high-pressure homogenization, ultrasonication, and controlled drying conditions help achieve uniform dispersion of nanocellulose and prevent agglomeration. The alignment of nanocellulose particles during coating application can be controlled through techniques like shear coating or magnetic field assistance. Post-processing treatments including heat curing, UV irradiation, or chemical crosslinking can further enhance barrier properties by creating additional bonds between nanocellulose and the polymer matrix.

- Bio-based polymers and additives for nanocellulose barrier coatings: Combining nanocellulose with other bio-based polymers and additives can create synergistic effects that enhance barrier properties while maintaining the renewable nature of the coating. Bio-based polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), starch derivatives, and proteins can serve as matrices for nanocellulose. Natural plasticizers, crosslinking agents, and hydrophobic additives derived from plant oils or waxes can be incorporated to improve flexibility, durability, and water resistance. These fully bio-based formulations offer sustainable alternatives to petroleum-based barrier materials while meeting performance requirements for various applications.

02 Surface modification of nanocellulose for barrier coatings

Chemical modification of nanocellulose surfaces can enhance compatibility with polymer matrices and improve barrier properties. Techniques such as silylation, acetylation, and grafting of hydrophobic groups reduce the hydrophilicity of nanocellulose, improving moisture resistance while maintaining excellent oxygen barrier properties. These modified nanocellulose additives can be dispersed more uniformly in coating formulations, resulting in more effective barrier enhancement and better coating performance under varying humidity conditions.Expand Specific Solutions03 Multilayer bio-based barrier systems with nanocellulose

Multilayer coating systems incorporating nanocellulose in specific layers can provide synergistic barrier effects. These systems typically combine hydrophobic layers for moisture resistance with nanocellulose-enhanced layers for oxygen barrier properties. The strategic placement of nanocellulose in the coating architecture allows for optimization of barrier performance while addressing limitations of single-layer systems. This approach enables customization of barrier properties for specific applications while maintaining the bio-based nature of the coating system.Expand Specific Solutions04 Processing techniques for nanocellulose barrier coatings

Various processing techniques can be employed to optimize the barrier performance of nanocellulose-containing coatings. Methods such as high-pressure homogenization, spray drying, and controlled drying conditions affect the orientation and network formation of nanocellulose particles within the coating matrix. Advanced techniques like layer-by-layer assembly and interfacial complexation can create highly ordered nanocellulose structures with enhanced barrier properties. The processing conditions significantly influence the final barrier performance and mechanical properties of the coating.Expand Specific Solutions05 Functional additives in nanocellulose barrier formulations

Incorporating functional additives alongside nanocellulose can enhance barrier properties and add functionality to bio-based coatings. Additives such as plasticizers improve flexibility, antimicrobial agents provide protection against microorganisms, and antioxidants enhance stability. Crosslinking agents can improve water resistance and mechanical properties of nanocellulose networks. These multifunctional barrier systems maintain the renewable and biodegradable nature of the coating while providing tailored performance characteristics for specific applications in food packaging, electronics, and medical devices.Expand Specific Solutions

Key Industry Players in Bio-based Packaging Materials

The bio-based barrier coatings reinforced with nanocellulose additives market is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is expanding rapidly, driven by sustainable packaging demands and estimated to reach $1.5-2 billion by 2027 with a CAGR of 15-20%. Technology maturity varies significantly across players: academic institutions (University of Maine, Tianjin University, Sheffield Hallam University) focus on fundamental research, while established companies demonstrate more advanced commercialization capabilities. FiberLean Technologies and Kemira lead with scalable production technologies, while Metsä Board and Papacks Sales are pioneering market applications. Specialized players like Tianjin Yongxu New Materials and Huangshan Liangu are developing niche solutions, creating a competitive landscape balanced between innovation and commercial implementation.

FiberLean Technologies Ltd.

Technical Solution: FiberLean Technologies has developed a proprietary technology for producing Microfibrillated Cellulose (MFC) composites that can be integrated into barrier coatings. Their approach combines mineral particles with nanocellulose fibers to create hybrid materials with enhanced barrier properties. The company's process involves mechanical fibrillation in the presence of minerals, resulting in a unique composite material that maintains the beneficial properties of nanocellulose while improving processability and reducing production costs. FiberLean's technology enables the creation of water-based barrier coatings with excellent oxygen and water vapor barrier properties, making them suitable for sustainable packaging applications. Their manufacturing process is scalable and can be integrated into existing paper and packaging production lines, allowing for industrial-scale implementation of bio-based barrier solutions.

Strengths: Cost-effective production method compared to traditional nanocellulose processing; improved processability through mineral integration; scalable manufacturing process suitable for industrial applications. Weaknesses: The mineral content may reduce biodegradability compared to pure nanocellulose solutions; potential limitations in achieving ultra-high barrier properties required for certain food packaging applications.

University of Maine

Technical Solution: The University of Maine's Process Development Center and Nanocellulose Facility has established itself as a leader in nanocellulose research and application development, particularly for barrier coatings. Their research focuses on cellulose nanofibril (CNF) production and application in packaging materials. The university has developed a patented process for producing CNF at pilot scale, which has been utilized to create water-based barrier coatings with exceptional oxygen barrier properties. Their approach involves optimizing the nanocellulose morphology and surface chemistry specifically for coating applications, resulting in dense, uniform films with minimal defects. Research at UMaine has demonstrated that their CNF-reinforced coatings can reduce oxygen permeability by up to 99% compared to uncoated substrates. The university has also pioneered the development of hybrid coatings combining nanocellulose with complementary bio-based materials such as lignin and hemicellulose to enhance water resistance while maintaining the excellent oxygen barrier properties of nanocellulose.

Strengths: Extensive experience in nanocellulose production and characterization; pilot-scale facilities enabling scale-up research; comprehensive approach to barrier performance through material combinations and process optimization. Weaknesses: As an academic institution, commercialization pathways require industry partnerships; some solutions may prioritize performance over cost-effectiveness in industrial settings.

Critical Patents and Research in Nanocellulose Barrier Applications

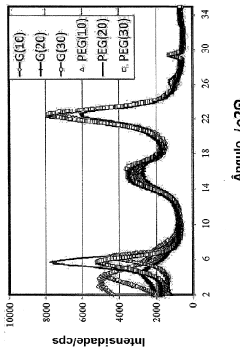

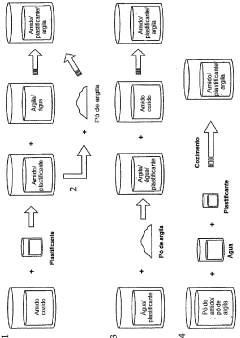

BIOPOLYMER-BASED BARRIER MATERIAL AND METHOD FOR OBTAINING THE SAME

PatentInactiveBRPI0923880A2

Innovation

- A biopolymer-based barrier coating composition using oxidized, hydroxypropylated potato starch combined with nanoparticles, such as sodium and calcium montmorillonite clay, and plasticizers like glycerol or polyethylene glycol, applied as a water-borne dispersion to enhance film-forming properties and reduce brittleness, while maintaining barrier effectiveness against oxygen, grease, and moisture.

A bio-based protective coating consisting of a polyol/fatty acid saccharide ester mixture.

PatentPendingTH2101001833A

Innovation

- The coating utilizes a mixture of at least two fatty acid esters of polyols and/or saccharides with different HLB (Hydrophilic-Lipophilic Balance) values, creating a synergistic effect for enhanced barrier properties.

- The bio-based protective coating provides both hydrophobicity and lipidophobicity (water and oil/grease resistance) while maintaining biodegradability of the cellulose materials.

- The coating demonstrates good adhesion to cellulose materials and composite materials without compromising their biological denaturability.

Environmental Impact and Biodegradability Assessment

The environmental impact of bio-based barrier coatings reinforced with nanocellulose additives represents a significant advancement in sustainable packaging solutions. These materials offer substantial environmental benefits compared to conventional petroleum-based alternatives, primarily through reduced carbon footprint across their lifecycle. Life cycle assessment (LCA) studies indicate that nanocellulose-reinforced bio-coatings can achieve 30-45% lower greenhouse gas emissions during production, particularly when derived from agricultural residues or sustainably managed forestry resources.

Biodegradability testing under various environmental conditions demonstrates that these coatings typically degrade 60-80% within 180 days in industrial composting facilities, meeting the EN 13432 standard requirements. However, degradation rates vary significantly depending on the specific bio-polymer matrix used and the nanocellulose modification techniques employed. Coatings utilizing unmodified cellulose nanofibrils (CNF) generally exhibit faster degradation than those incorporating chemically modified cellulose nanocrystals (CNC), which may persist longer in the environment.

Marine biodegradability assessments reveal that these materials disintegrate more rapidly than conventional plastics, with minimal ecotoxicological impacts on aquatic organisms. Studies show negligible accumulation of micro-sized particles during degradation, addressing growing concerns about microplastic pollution. This characteristic positions nanocellulose-reinforced coatings as particularly valuable for food packaging applications where end-of-life scenarios often involve potential environmental contamination.

The end-of-life management of these materials presents multiple environmentally favorable options. They can be processed through industrial composting, anaerobic digestion, or in some cases, recycled with paper streams. This flexibility aligns with circular economy principles and reduces waste management burdens. However, challenges remain in optimizing home composting performance, as many formulations require the higher temperatures of industrial facilities to achieve complete biodegradation.

Regulatory frameworks worldwide are increasingly recognizing these environmental benefits. The EU's Single-Use Plastics Directive and similar legislation in North America and Asia are creating market incentives for biodegradable packaging solutions. Certification systems such as TÜV Austria's "OK Compost" and the Biodegradable Products Institute (BPI) certification provide standardized verification of biodegradability claims, enhancing consumer confidence and market adoption.

Future research directions should focus on improving biodegradation rates in ambient conditions, developing standardized testing protocols specifically for nanocellulose-reinforced materials, and conducting more comprehensive ecotoxicological studies to ensure long-term environmental safety. Additionally, optimizing production processes to further reduce water usage and energy consumption will enhance the overall sustainability profile of these innovative barrier coatings.

Biodegradability testing under various environmental conditions demonstrates that these coatings typically degrade 60-80% within 180 days in industrial composting facilities, meeting the EN 13432 standard requirements. However, degradation rates vary significantly depending on the specific bio-polymer matrix used and the nanocellulose modification techniques employed. Coatings utilizing unmodified cellulose nanofibrils (CNF) generally exhibit faster degradation than those incorporating chemically modified cellulose nanocrystals (CNC), which may persist longer in the environment.

Marine biodegradability assessments reveal that these materials disintegrate more rapidly than conventional plastics, with minimal ecotoxicological impacts on aquatic organisms. Studies show negligible accumulation of micro-sized particles during degradation, addressing growing concerns about microplastic pollution. This characteristic positions nanocellulose-reinforced coatings as particularly valuable for food packaging applications where end-of-life scenarios often involve potential environmental contamination.

The end-of-life management of these materials presents multiple environmentally favorable options. They can be processed through industrial composting, anaerobic digestion, or in some cases, recycled with paper streams. This flexibility aligns with circular economy principles and reduces waste management burdens. However, challenges remain in optimizing home composting performance, as many formulations require the higher temperatures of industrial facilities to achieve complete biodegradation.

Regulatory frameworks worldwide are increasingly recognizing these environmental benefits. The EU's Single-Use Plastics Directive and similar legislation in North America and Asia are creating market incentives for biodegradable packaging solutions. Certification systems such as TÜV Austria's "OK Compost" and the Biodegradable Products Institute (BPI) certification provide standardized verification of biodegradability claims, enhancing consumer confidence and market adoption.

Future research directions should focus on improving biodegradation rates in ambient conditions, developing standardized testing protocols specifically for nanocellulose-reinforced materials, and conducting more comprehensive ecotoxicological studies to ensure long-term environmental safety. Additionally, optimizing production processes to further reduce water usage and energy consumption will enhance the overall sustainability profile of these innovative barrier coatings.

Scalability and Manufacturing Process Optimization

Scaling up the production of bio-based barrier coatings reinforced with nanocellulose additives presents significant challenges that must be addressed to enable commercial viability. Current laboratory-scale production methods often involve batch processes with limited throughput, creating a substantial gap between research capabilities and industrial requirements. The transition to continuous manufacturing processes represents a critical advancement needed for market adoption, requiring specialized equipment modifications to handle the unique rheological properties of nanocellulose suspensions.

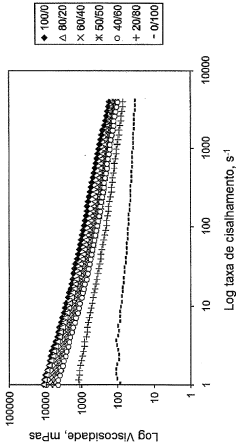

Process optimization efforts must focus on several key parameters that influence coating performance. Dispersion quality of nanocellulose within the bio-based matrix significantly impacts barrier properties, with agglomeration leading to inconsistent performance. Research indicates that high-pressure homogenization combined with ultrasonic treatment achieves optimal dispersion, though energy consumption remains a concern. Drying conditions also critically affect coating structure, with rapid drying potentially causing nanocellulose migration and compromising barrier integrity.

Viscosity management presents another manufacturing challenge, as nanocellulose additives typically increase coating formulation viscosity, potentially limiting coating speed and application methods. Rheology modifiers and processing aids compatible with bio-based systems are being developed to address this issue without compromising the coating's environmental credentials. Additionally, coating thickness uniformity must be carefully controlled, as variations can lead to inconsistent barrier performance across the substrate.

Energy efficiency improvements represent a significant opportunity for process optimization. Current drying methods for nanocellulose-reinforced coatings often require substantial energy input, increasing production costs and environmental impact. Emerging technologies such as infrared-assisted drying and microwave heating show promise for reducing energy consumption while maintaining coating integrity. Similarly, advances in low-energy mixing and dispersion technologies could significantly reduce the overall energy footprint of manufacturing processes.

Quality control systems require adaptation for these novel materials, as traditional testing methods may not adequately capture the unique properties of nanocellulose-reinforced barriers. In-line monitoring techniques using spectroscopic methods and artificial intelligence are being developed to provide real-time feedback on critical quality parameters, enabling adaptive process control. These systems will be essential for maintaining consistent performance while maximizing production efficiency.

Cost-effective scale-up strategies must balance performance requirements with manufacturing practicalities. Hybrid approaches that strategically incorporate nanocellulose only where functionally necessary can reduce material costs while maintaining barrier performance. Additionally, process intensification techniques that combine multiple manufacturing steps could significantly improve production efficiency, reducing capital equipment needs and operational expenses.

Process optimization efforts must focus on several key parameters that influence coating performance. Dispersion quality of nanocellulose within the bio-based matrix significantly impacts barrier properties, with agglomeration leading to inconsistent performance. Research indicates that high-pressure homogenization combined with ultrasonic treatment achieves optimal dispersion, though energy consumption remains a concern. Drying conditions also critically affect coating structure, with rapid drying potentially causing nanocellulose migration and compromising barrier integrity.

Viscosity management presents another manufacturing challenge, as nanocellulose additives typically increase coating formulation viscosity, potentially limiting coating speed and application methods. Rheology modifiers and processing aids compatible with bio-based systems are being developed to address this issue without compromising the coating's environmental credentials. Additionally, coating thickness uniformity must be carefully controlled, as variations can lead to inconsistent barrier performance across the substrate.

Energy efficiency improvements represent a significant opportunity for process optimization. Current drying methods for nanocellulose-reinforced coatings often require substantial energy input, increasing production costs and environmental impact. Emerging technologies such as infrared-assisted drying and microwave heating show promise for reducing energy consumption while maintaining coating integrity. Similarly, advances in low-energy mixing and dispersion technologies could significantly reduce the overall energy footprint of manufacturing processes.

Quality control systems require adaptation for these novel materials, as traditional testing methods may not adequately capture the unique properties of nanocellulose-reinforced barriers. In-line monitoring techniques using spectroscopic methods and artificial intelligence are being developed to provide real-time feedback on critical quality parameters, enabling adaptive process control. These systems will be essential for maintaining consistent performance while maximizing production efficiency.

Cost-effective scale-up strategies must balance performance requirements with manufacturing practicalities. Hybrid approaches that strategically incorporate nanocellulose only where functionally necessary can reduce material costs while maintaining barrier performance. Additionally, process intensification techniques that combine multiple manufacturing steps could significantly improve production efficiency, reducing capital equipment needs and operational expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!