Bio-based Barrier Coatings for Flexible Packaging Sustainability

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

Flexible packaging has undergone significant evolution since its inception in the early 20th century, transitioning from simple paper wrappings to sophisticated multi-layer structures incorporating various polymers and barrier materials. The development trajectory has been primarily driven by the need for extended shelf life, product protection, and convenience. However, the last decade has witnessed a paradigm shift in packaging priorities, with sustainability emerging as a critical consideration alongside traditional performance metrics.

Bio-based barrier coatings represent a promising frontier in sustainable packaging solutions, offering potential alternatives to conventional petroleum-derived materials that dominate the current market. These coatings, derived from renewable biological resources such as cellulose, chitosan, proteins, and plant-based oils, aim to provide comparable barrier properties against oxygen, moisture, and other permeants while reducing environmental footprint.

The historical development of bio-based barrier coatings can be traced back to early experiments with natural waxes and resins in the mid-20th century. However, significant technological advancements have only materialized in the past 15-20 years, catalyzed by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable packaging options. The field has experienced accelerated growth since 2010, with research publications in this domain increasing by approximately 300% between 2010 and 2020.

The primary technical objective of this research is to develop bio-based barrier coatings that can match or exceed the performance characteristics of conventional synthetic barriers while offering enhanced environmental benefits. Specifically, the research aims to achieve oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates under 10 g/m²/day—performance levels necessary for many food packaging applications.

Additional objectives include ensuring compatibility with existing converting equipment to facilitate industrial adoption, maintaining cost competitiveness with conventional solutions, and developing formulations that comply with food safety regulations across major markets. The research also seeks to quantify the environmental benefits through comprehensive life cycle assessments, focusing on carbon footprint reduction, biodegradability, and compostability.

The technology evolution trend indicates a movement toward hybrid systems that combine multiple bio-based components to achieve synergistic effects, as well as the integration of nanotechnology to enhance barrier properties at reduced coating thicknesses. Recent developments in bio-based plasticizers and cross-linking agents have also opened new possibilities for improving flexibility and durability without compromising the renewable nature of these coatings.

Bio-based barrier coatings represent a promising frontier in sustainable packaging solutions, offering potential alternatives to conventional petroleum-derived materials that dominate the current market. These coatings, derived from renewable biological resources such as cellulose, chitosan, proteins, and plant-based oils, aim to provide comparable barrier properties against oxygen, moisture, and other permeants while reducing environmental footprint.

The historical development of bio-based barrier coatings can be traced back to early experiments with natural waxes and resins in the mid-20th century. However, significant technological advancements have only materialized in the past 15-20 years, catalyzed by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable packaging options. The field has experienced accelerated growth since 2010, with research publications in this domain increasing by approximately 300% between 2010 and 2020.

The primary technical objective of this research is to develop bio-based barrier coatings that can match or exceed the performance characteristics of conventional synthetic barriers while offering enhanced environmental benefits. Specifically, the research aims to achieve oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates under 10 g/m²/day—performance levels necessary for many food packaging applications.

Additional objectives include ensuring compatibility with existing converting equipment to facilitate industrial adoption, maintaining cost competitiveness with conventional solutions, and developing formulations that comply with food safety regulations across major markets. The research also seeks to quantify the environmental benefits through comprehensive life cycle assessments, focusing on carbon footprint reduction, biodegradability, and compostability.

The technology evolution trend indicates a movement toward hybrid systems that combine multiple bio-based components to achieve synergistic effects, as well as the integration of nanotechnology to enhance barrier properties at reduced coating thicknesses. Recent developments in bio-based plasticizers and cross-linking agents have also opened new possibilities for improving flexibility and durability without compromising the renewable nature of these coatings.

Sustainable Packaging Market Analysis

The sustainable packaging market has witnessed remarkable growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global sustainable packaging market was valued at approximately $247 billion in 2020 and is projected to reach $348 billion by 2026, growing at a CAGR of 5.9% during the forecast period. This growth trajectory reflects the shifting consumer preferences and corporate sustainability commitments across industries.

Flexible packaging represents a significant segment within the sustainable packaging market, accounting for nearly 40% of the total market share. This dominance can be attributed to its versatility, cost-effectiveness, and reduced material usage compared to rigid packaging alternatives. The bio-based barrier coatings segment specifically is experiencing accelerated growth, with market analysts predicting a compound annual growth rate of 7.2% through 2028.

Consumer demand has emerged as a primary driver for sustainable packaging solutions. Recent market surveys indicate that 73% of consumers are willing to pay a premium for products with sustainable packaging, while 68% consider environmental impact when making purchasing decisions. This consumer sentiment has compelled major brands to reconsider their packaging strategies, with many pledging to transition to fully recyclable, compostable, or biodegradable packaging within the next decade.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and packaging waste. The European Union's Circular Economy Action Plan, China's ban on non-biodegradable single-use plastics, and similar initiatives in North America have created a regulatory landscape that favors sustainable packaging innovations. These regulations have accelerated research and development in bio-based barrier coatings as alternatives to conventional petroleum-based materials.

The food and beverage industry represents the largest end-user segment for sustainable flexible packaging, accounting for approximately 65% of market applications. This is followed by personal care products (15%), pharmaceuticals (10%), and other consumer goods (10%). The demand for extended shelf life without compromising sustainability has positioned bio-based barrier coatings as a critical technology for these industries.

Regional analysis reveals that Europe leads the sustainable packaging market with a 35% share, followed by North America (28%), Asia-Pacific (25%), and rest of the world (12%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Market challenges include the price premium associated with bio-based materials, which typically cost 20-30% more than conventional alternatives, and technical limitations regarding barrier properties and processing compatibility. Despite these challenges, the market outlook remains positive as technological advancements continue to address performance gaps while reducing production costs.

Flexible packaging represents a significant segment within the sustainable packaging market, accounting for nearly 40% of the total market share. This dominance can be attributed to its versatility, cost-effectiveness, and reduced material usage compared to rigid packaging alternatives. The bio-based barrier coatings segment specifically is experiencing accelerated growth, with market analysts predicting a compound annual growth rate of 7.2% through 2028.

Consumer demand has emerged as a primary driver for sustainable packaging solutions. Recent market surveys indicate that 73% of consumers are willing to pay a premium for products with sustainable packaging, while 68% consider environmental impact when making purchasing decisions. This consumer sentiment has compelled major brands to reconsider their packaging strategies, with many pledging to transition to fully recyclable, compostable, or biodegradable packaging within the next decade.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and packaging waste. The European Union's Circular Economy Action Plan, China's ban on non-biodegradable single-use plastics, and similar initiatives in North America have created a regulatory landscape that favors sustainable packaging innovations. These regulations have accelerated research and development in bio-based barrier coatings as alternatives to conventional petroleum-based materials.

The food and beverage industry represents the largest end-user segment for sustainable flexible packaging, accounting for approximately 65% of market applications. This is followed by personal care products (15%), pharmaceuticals (10%), and other consumer goods (10%). The demand for extended shelf life without compromising sustainability has positioned bio-based barrier coatings as a critical technology for these industries.

Regional analysis reveals that Europe leads the sustainable packaging market with a 35% share, followed by North America (28%), Asia-Pacific (25%), and rest of the world (12%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Market challenges include the price premium associated with bio-based materials, which typically cost 20-30% more than conventional alternatives, and technical limitations regarding barrier properties and processing compatibility. Despite these challenges, the market outlook remains positive as technological advancements continue to address performance gaps while reducing production costs.

Current Status and Challenges in Bio-based Barrier Technology

Bio-based barrier coatings for flexible packaging have gained significant attention globally, with research efforts intensifying over the past decade. Currently, the technology has reached a stage where several bio-based materials demonstrate promising barrier properties against oxygen, water vapor, and grease. Polysaccharides such as cellulose, chitosan, and starch derivatives have emerged as leading candidates, with commercial applications beginning to appear in food packaging sectors.

Despite these advancements, bio-based barrier coatings face substantial technical challenges. The inherent hydrophilicity of most bio-based materials results in moisture sensitivity that compromises barrier performance in humid environments. This represents a critical limitation for food packaging applications where consistent barrier properties are essential throughout the product lifecycle.

Scalability remains another significant hurdle. Laboratory-scale successes often encounter difficulties when transitioning to industrial production. Current coating technologies require adaptation to accommodate the rheological properties of bio-based formulations, which differ substantially from conventional petroleum-based alternatives. Production speeds for bio-based coatings typically remain 30-40% slower than conventional systems.

The geographical distribution of bio-based barrier technology development shows concentration in Europe, North America, and increasingly in Asia. European countries, particularly Finland, Sweden, and Germany, lead in cellulose-based technologies, while North American research focuses more on protein-based and hybrid systems. Asian development, especially in Japan and China, emphasizes starch derivatives and chitosan applications.

Cost competitiveness presents an ongoing challenge, with bio-based barrier coatings typically commanding a 25-45% premium over conventional alternatives. This price differential has limited widespread adoption, particularly in price-sensitive market segments. The economic viability threshold appears to be approximately 15-20% above conventional solutions, suggesting further cost optimization is necessary.

Regulatory frameworks worldwide are still evolving regarding bio-based packaging materials. While the European Union has established clear guidelines through its Bioplastics Framework, regulations in other regions remain fragmented, creating market uncertainty and impeding standardization efforts. This regulatory inconsistency complicates global commercialization strategies.

Technical performance gaps persist in areas of oxygen transmission rates (OTR) and water vapor transmission rates (WVTR). Current bio-based solutions achieve approximately 70-85% of the barrier performance of conventional metallized films or EVOH coatings. Bridging this performance gap while maintaining biodegradability and compostability represents a central technical challenge for researchers and developers.

Despite these advancements, bio-based barrier coatings face substantial technical challenges. The inherent hydrophilicity of most bio-based materials results in moisture sensitivity that compromises barrier performance in humid environments. This represents a critical limitation for food packaging applications where consistent barrier properties are essential throughout the product lifecycle.

Scalability remains another significant hurdle. Laboratory-scale successes often encounter difficulties when transitioning to industrial production. Current coating technologies require adaptation to accommodate the rheological properties of bio-based formulations, which differ substantially from conventional petroleum-based alternatives. Production speeds for bio-based coatings typically remain 30-40% slower than conventional systems.

The geographical distribution of bio-based barrier technology development shows concentration in Europe, North America, and increasingly in Asia. European countries, particularly Finland, Sweden, and Germany, lead in cellulose-based technologies, while North American research focuses more on protein-based and hybrid systems. Asian development, especially in Japan and China, emphasizes starch derivatives and chitosan applications.

Cost competitiveness presents an ongoing challenge, with bio-based barrier coatings typically commanding a 25-45% premium over conventional alternatives. This price differential has limited widespread adoption, particularly in price-sensitive market segments. The economic viability threshold appears to be approximately 15-20% above conventional solutions, suggesting further cost optimization is necessary.

Regulatory frameworks worldwide are still evolving regarding bio-based packaging materials. While the European Union has established clear guidelines through its Bioplastics Framework, regulations in other regions remain fragmented, creating market uncertainty and impeding standardization efforts. This regulatory inconsistency complicates global commercialization strategies.

Technical performance gaps persist in areas of oxygen transmission rates (OTR) and water vapor transmission rates (WVTR). Current bio-based solutions achieve approximately 70-85% of the barrier performance of conventional metallized films or EVOH coatings. Bridging this performance gap while maintaining biodegradability and compostability represents a central technical challenge for researchers and developers.

Current Bio-based Barrier Solutions for Flexible Packaging

01 Cellulose-based barrier coatings

Cellulose-derived materials are used to create bio-based barrier coatings with excellent oxygen and moisture barrier properties. These coatings utilize nanocellulose, cellulose nanofibrils, or modified cellulose derivatives to form dense, crystalline networks that restrict the passage of gases and moisture. The renewable nature of cellulose makes these coatings environmentally friendly while providing comparable performance to synthetic alternatives. These coatings can be applied to various substrates including paper, paperboard, and flexible packaging materials.- Cellulose-based barrier coatings: Cellulose-derived materials, such as nanocellulose, microfibrillated cellulose, and cellulose nanocrystals, can be used to create effective bio-based barrier coatings. These materials provide excellent oxygen and water vapor barrier properties due to their high crystallinity and dense packing. The cellulose fibers create a tortuous path that inhibits gas and moisture penetration, making them suitable for food packaging and other applications requiring high barrier performance.

- Protein and polysaccharide composite barriers: Composite barrier coatings combining proteins (such as whey, soy, or zein) with polysaccharides (like chitosan, pectin, or alginate) demonstrate enhanced barrier properties compared to single-component systems. These bio-based composites create synergistic effects where the protein provides good oxygen barrier properties while the polysaccharide component improves moisture resistance. Cross-linking between these components can further enhance barrier performance and mechanical strength for sustainable packaging applications.

- Bio-based waxes and lipids for moisture barriers: Natural waxes, oils, and lipids derived from plant sources can be incorporated into bio-based barrier coatings to significantly improve water vapor barrier properties. Materials such as carnauba wax, beeswax, and plant-derived fatty acids create hydrophobic layers that effectively repel moisture. These bio-based lipid components can be emulsified or dispersed within other biopolymer matrices to create coatings with balanced barrier properties against both oxygen and water vapor transmission.

- Biopolymer-clay nanocomposite barriers: Incorporating nanoclays into biopolymer matrices creates high-performance barrier coatings with significantly improved gas and moisture barrier properties. The layered silicate structure of clays creates a tortuous path for permeating molecules, while the biopolymer matrix provides flexibility and adhesion. These bio-based nanocomposite coatings can achieve barrier properties comparable to synthetic polymers while maintaining biodegradability and sustainability advantages.

- Cross-linked biopolymer barrier systems: Chemical or enzymatic cross-linking of biopolymers can significantly enhance barrier properties by creating more dense and cohesive coating structures. Cross-linking agents like citric acid, tannic acid, or enzymes like transglutaminase can form covalent bonds between biopolymer chains, reducing free volume and limiting molecular mobility. This approach improves both oxygen and water vapor barrier properties while also enhancing the mechanical strength and chemical resistance of bio-based barrier coatings.

02 Protein and starch-based barrier materials

Proteins and starches derived from agricultural sources can be formulated into effective barrier coatings. These biomaterials can be modified through various processes including crosslinking, blending with other biopolymers, or chemical modification to enhance their barrier properties against oxygen, moisture, and oils. The coatings are typically biodegradable and compostable, making them suitable for sustainable packaging applications. Their barrier performance can be tailored by adjusting processing conditions and incorporating complementary bio-based additives.Expand Specific Solutions03 Bio-based composite barrier systems

Composite systems combining multiple bio-based materials create synergistic barrier properties superior to single-component systems. These composites often utilize layered structures of different biopolymers, each contributing specific barrier functions. For example, combining hydrophobic plant waxes with hydrophilic polysaccharides creates comprehensive barriers against both moisture and oxygen. Nanomaterials such as clay, silica, or cellulose nanocrystals can be incorporated to create tortuous paths for gas molecules, significantly improving barrier performance while maintaining the renewable nature of the coating.Expand Specific Solutions04 Biodegradable barrier coatings for food packaging

Specialized bio-based barrier coatings for food packaging applications focus on food safety while providing protection against moisture, oxygen, and microbial contamination. These coatings often incorporate natural antimicrobial compounds such as essential oils or chitosan to extend shelf life. The formulations are designed to maintain food quality without migration of coating components into the food. These systems can replace conventional plastic-based food packaging while offering comparable barrier properties and the additional benefit of biodegradability at end-of-life.Expand Specific Solutions05 Processing techniques for bio-based barrier coatings

Advanced processing techniques are crucial for optimizing the barrier properties of bio-based coatings. Methods include specialized drying processes to prevent crack formation, surface treatments to enhance adhesion to substrates, and controlled crosslinking to improve water resistance. Novel application techniques such as layer-by-layer deposition allow for precise control of coating thickness and composition. Post-processing treatments including heat, UV, or plasma treatments can further enhance barrier performance by increasing density and reducing permeability of the bio-based coating layers.Expand Specific Solutions

Key Industry Players in Sustainable Packaging

The bio-based barrier coatings market for flexible packaging is in a growth phase, driven by increasing sustainability demands. The market is expanding rapidly as companies seek alternatives to traditional petroleum-based coatings. Leading players like Stora Enso, UPM-Kymmene, and Metsä Board are leveraging their forestry expertise to develop innovative cellulose-based solutions, while chemical specialists such as Kemira and Solenis are focusing on water-resistant bio-polymers. Consumer goods giants including Procter & Gamble and Nestlé are investing in sustainable packaging technologies to meet environmental commitments. Academic institutions like Delft University of Technology and Anna University are advancing fundamental research, while specialized innovators such as Earthodic are commercializing novel bio-coating technologies, indicating a maturing but still evolving technical landscape.

Stora Enso Oyj

Technical Solution: Stora Enso has developed advanced bio-based barrier coatings through their Biobarrier technology platform, which utilizes lignin, hemicellulose, and microfibrillated cellulose (MFC) derived from sustainable wood sources. Their proprietary dispersion coating technology applies these bio-polymers to create oxygen, water vapor, and oil-resistant barriers for flexible packaging applications. The company has successfully commercialized Natura™ barrier coatings that replace fossil-based PE coatings with bio-based alternatives while maintaining equivalent barrier properties. Their recent innovation includes water-based dispersions containing up to 95% bio-based content that can be applied using conventional coating equipment, making adoption easier for packaging converters. Stora Enso has also developed bio-based heat-sealable coatings that eliminate the need for additional fossil-based sealing layers.

Strengths: Vertical integration with access to sustainable forest resources provides reliable raw material supply; extensive R&D capabilities with dedicated bioeconomy research centers; commercial-scale production capacity. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives; some bio-based formulations may have more limited shelf-life than synthetic counterparts.

UPM-Kymmene Oyj

Technical Solution: UPM has pioneered the development of bio-based barrier coatings through their UPM Solide Bio technology platform. This innovative approach utilizes side streams from their pulp production process to create cellulose-based barrier materials that provide excellent oxygen, water vapor, and grease resistance properties. Their technology incorporates modified cellulose nanofibrils (CNF) and hemicellulose derivatives to create multi-functional barrier layers that can be applied through conventional coating processes. UPM's barrier solutions are designed for direct food contact and have been proven to maintain product freshness while being fully recyclable and biodegradable. The company has also developed bio-based adhesives that complement their barrier coatings, creating fully bio-based packaging solutions. Their recent innovations include transparent barrier coatings with enhanced printability and heat-sealing capabilities.

Strengths: Strong integration of forestry resources with biorefinery operations enables consistent raw material quality; extensive coating expertise and equipment for industrial-scale production; comprehensive sustainability approach covering the entire value chain. Weaknesses: Performance in high-humidity environments may be less consistent than synthetic alternatives; requires specific processing conditions that may limit compatibility with some existing manufacturing lines.

Critical Patents and Innovations in Bio-based Barrier Materials

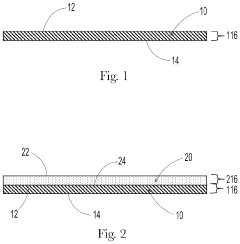

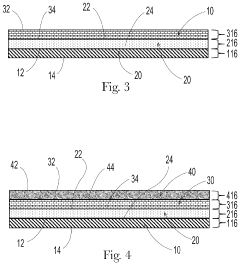

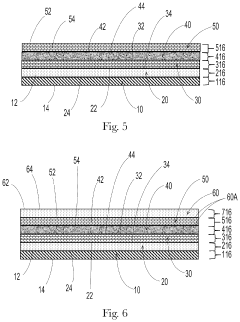

Biodegradable and recyclable barrier paper laminate

PatentPendingUS20240158990A1

Innovation

- A biodegradable and recyclable barrier paper laminate comprising a biodegradable paper layer, polymeric layers, primer layers, and an inorganic barrier layer, designed to provide moisture and sealant properties while ensuring compatibility with composting and recycling processes.

Paper, coated paper, use thereof, paper packaging and methods

PatentWO2024239082A1

Innovation

- Development of a paper comprising 60-95% short fibers and 2-15% mineral filler, with a coated version incorporating a barrier composition including a sealing agent, biobinding agent, and anti-blocking agent, providing improved mechanical properties, printability, and biodegradability, suitable for flexible packaging that mimics the performance of plastic films.

Environmental Impact Assessment and Life Cycle Analysis

Environmental impact assessment and life cycle analysis of bio-based barrier coatings reveal significant sustainability advantages compared to conventional petroleum-based alternatives. Studies indicate that bio-based coatings can reduce carbon footprint by 30-60% depending on feedstock source and processing methods. The cradle-to-grave analysis demonstrates lower environmental impacts across multiple categories including greenhouse gas emissions, fossil resource depletion, and aquatic ecotoxicity.

The production phase of bio-based barrier coatings shows particular environmental benefits, with reduced energy consumption averaging 25-40% less than traditional coating systems. Agricultural feedstocks like cellulose, starch, and protein derivatives utilize renewable carbon sources, creating a more circular material flow compared to the linear extraction model of petroleum-based alternatives. However, land use impacts remain a critical consideration, especially when first-generation biomass competes with food production.

Water usage presents a complex trade-off in the environmental profile of bio-based coatings. While processing may require significant water inputs, particularly for purification of biopolymers, the end-of-life scenario typically demonstrates improved biodegradability and reduced microplastic formation. Comprehensive life cycle assessments indicate that water-based bio-coatings generally outperform solvent-based systems across most environmental impact categories.

End-of-life scenarios demonstrate perhaps the most significant environmental advantage of bio-based barrier coatings. Biodegradability testing shows that many formulations can decompose in industrial composting conditions within 3-6 months, compared to centuries for conventional plastics. This characteristic substantially reduces waste accumulation and marine pollution potential. However, the actual environmental benefit depends heavily on regional waste management infrastructure and consumer disposal behavior.

Regional variations in environmental impact are substantial, with the greatest benefits observed when bio-based coatings utilize locally-sourced feedstocks and renewable energy for processing. Transportation emissions can significantly offset sustainability gains when global supply chains are involved. Additionally, the environmental performance varies considerably based on the specific bio-based material selected, with second-generation feedstocks (non-food agricultural residues) generally showing superior environmental profiles compared to first-generation alternatives.

Sensitivity analysis reveals that technological maturity and scale remain limiting factors in realizing the full environmental potential of bio-based barrier coatings. As production volumes increase and processing technologies advance, life cycle impacts are expected to decrease further, enhancing the sustainability proposition of these materials for flexible packaging applications.

The production phase of bio-based barrier coatings shows particular environmental benefits, with reduced energy consumption averaging 25-40% less than traditional coating systems. Agricultural feedstocks like cellulose, starch, and protein derivatives utilize renewable carbon sources, creating a more circular material flow compared to the linear extraction model of petroleum-based alternatives. However, land use impacts remain a critical consideration, especially when first-generation biomass competes with food production.

Water usage presents a complex trade-off in the environmental profile of bio-based coatings. While processing may require significant water inputs, particularly for purification of biopolymers, the end-of-life scenario typically demonstrates improved biodegradability and reduced microplastic formation. Comprehensive life cycle assessments indicate that water-based bio-coatings generally outperform solvent-based systems across most environmental impact categories.

End-of-life scenarios demonstrate perhaps the most significant environmental advantage of bio-based barrier coatings. Biodegradability testing shows that many formulations can decompose in industrial composting conditions within 3-6 months, compared to centuries for conventional plastics. This characteristic substantially reduces waste accumulation and marine pollution potential. However, the actual environmental benefit depends heavily on regional waste management infrastructure and consumer disposal behavior.

Regional variations in environmental impact are substantial, with the greatest benefits observed when bio-based coatings utilize locally-sourced feedstocks and renewable energy for processing. Transportation emissions can significantly offset sustainability gains when global supply chains are involved. Additionally, the environmental performance varies considerably based on the specific bio-based material selected, with second-generation feedstocks (non-food agricultural residues) generally showing superior environmental profiles compared to first-generation alternatives.

Sensitivity analysis reveals that technological maturity and scale remain limiting factors in realizing the full environmental potential of bio-based barrier coatings. As production volumes increase and processing technologies advance, life cycle impacts are expected to decrease further, enhancing the sustainability proposition of these materials for flexible packaging applications.

Regulatory Framework for Food-Contact Sustainable Packaging

The regulatory landscape for food-contact sustainable packaging has evolved significantly in response to growing environmental concerns and consumer demand for eco-friendly solutions. At the global level, the Food and Agriculture Organization (FAO) and World Health Organization (WHO) have established the Codex Alimentarius Commission, which provides international standards for food safety including guidelines for packaging materials that come into contact with food products.

In the European Union, Regulation (EC) No 1935/2004 serves as the cornerstone legislation for all food contact materials, requiring that they do not transfer constituents to food in quantities that could endanger human health. The EU has further strengthened its regulatory framework with Regulation (EU) No 10/2011 specifically addressing plastic materials and articles intended to come into contact with food. For bio-based barrier coatings, these regulations mandate rigorous migration testing and safety assessments.

The United States Food and Drug Administration (FDA) regulates food packaging materials under the Federal Food, Drug, and Cosmetic Act. Bio-based barrier coatings must comply with FDA's requirements for food contact substances, which include demonstrating safety through scientific data and obtaining FDA clearance before market introduction. The FDA's Food Contact Notification (FCN) program provides a streamlined process for manufacturers to establish the safety of new food contact substances.

Recent regulatory developments have increasingly focused on sustainability aspects. The EU's Circular Economy Action Plan and Single-Use Plastics Directive have created additional requirements for packaging sustainability, including recyclability and biodegradability standards. These regulations are driving innovation in bio-based barrier coatings as alternatives to conventional plastic barriers.

Japan's Food Sanitation Law and China's GB standards also impose strict requirements on food contact materials, with specific provisions for novel materials like bio-based coatings. These regulatory frameworks emphasize the importance of safety assessments and migration testing to ensure consumer protection.

Certification schemes such as EN 13432 for compostability and ASTM D6400 for biodegradability provide standardized methods to verify environmental claims for bio-based packaging materials. These standards are increasingly referenced in regulatory frameworks and market requirements, creating additional compliance considerations for developers of bio-based barrier coatings.

The regulatory landscape continues to evolve, with increasing emphasis on harmonization of standards across jurisdictions to facilitate international trade while maintaining high levels of consumer protection. For manufacturers developing bio-based barrier coatings, navigating this complex regulatory environment requires comprehensive understanding of both safety requirements and sustainability criteria across target markets.

In the European Union, Regulation (EC) No 1935/2004 serves as the cornerstone legislation for all food contact materials, requiring that they do not transfer constituents to food in quantities that could endanger human health. The EU has further strengthened its regulatory framework with Regulation (EU) No 10/2011 specifically addressing plastic materials and articles intended to come into contact with food. For bio-based barrier coatings, these regulations mandate rigorous migration testing and safety assessments.

The United States Food and Drug Administration (FDA) regulates food packaging materials under the Federal Food, Drug, and Cosmetic Act. Bio-based barrier coatings must comply with FDA's requirements for food contact substances, which include demonstrating safety through scientific data and obtaining FDA clearance before market introduction. The FDA's Food Contact Notification (FCN) program provides a streamlined process for manufacturers to establish the safety of new food contact substances.

Recent regulatory developments have increasingly focused on sustainability aspects. The EU's Circular Economy Action Plan and Single-Use Plastics Directive have created additional requirements for packaging sustainability, including recyclability and biodegradability standards. These regulations are driving innovation in bio-based barrier coatings as alternatives to conventional plastic barriers.

Japan's Food Sanitation Law and China's GB standards also impose strict requirements on food contact materials, with specific provisions for novel materials like bio-based coatings. These regulatory frameworks emphasize the importance of safety assessments and migration testing to ensure consumer protection.

Certification schemes such as EN 13432 for compostability and ASTM D6400 for biodegradability provide standardized methods to verify environmental claims for bio-based packaging materials. These standards are increasingly referenced in regulatory frameworks and market requirements, creating additional compliance considerations for developers of bio-based barrier coatings.

The regulatory landscape continues to evolve, with increasing emphasis on harmonization of standards across jurisdictions to facilitate international trade while maintaining high levels of consumer protection. For manufacturers developing bio-based barrier coatings, navigating this complex regulatory environment requires comprehensive understanding of both safety requirements and sustainability criteria across target markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!