Comparative Analysis of PLA and PHA-Based Barrier Coatings

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA and PHA Barrier Coating Background and Objectives

Biodegradable polymers have emerged as promising alternatives to conventional petroleum-based plastics in packaging applications, with polylactic acid (PLA) and polyhydroxyalkanoates (PHA) gaining significant attention. The evolution of these materials spans several decades, with PLA first synthesized in the 1920s by Wallace Carothers at DuPont, while PHA was discovered in 1926 by Maurice Lemoigne at the Pasteur Institute. However, commercial development of both polymers only gained momentum in the late 20th century as environmental concerns intensified.

The technical trajectory of these biopolymers has been characterized by continuous improvements in production efficiency, material properties, and cost-effectiveness. PLA, derived from renewable resources such as corn starch or sugarcane, has seen significant advancements in polymerization techniques and molecular weight control. Similarly, PHA production has evolved from expensive laboratory-scale fermentation to more economical industrial processes utilizing various bacterial strains and carbon feedstocks.

In packaging applications, barrier properties against oxygen, water vapor, and other permeants represent critical performance parameters. Traditional petroleum-based polymers like polyethylene terephthalate (PET) and polyethylene (PE) have set high standards for barrier performance that bio-based alternatives must meet to achieve market acceptance. The technical goal of this research is to comprehensively compare and evaluate the barrier properties of PLA and PHA-based coatings, identifying their respective strengths, limitations, and potential synergistic effects when combined.

Current technical objectives include enhancing the inherent barrier properties of these biopolymers through various approaches such as blending with other polymers, incorporating nanofillers, applying surface treatments, or developing multilayer structures. The ultimate aim is to develop cost-effective, environmentally friendly barrier coatings that can match or exceed the performance of conventional materials while maintaining biodegradability.

The technological evolution trend points toward hybrid solutions that leverage the complementary properties of PLA and PHA. PLA offers good transparency and processability but moderate barrier properties, while certain PHA variants demonstrate superior oxygen barrier capabilities but may present processing challenges. Research is increasingly focused on optimizing these combinations to create tailored barrier solutions for specific packaging requirements.

As regulatory pressures against single-use plastics intensify globally and consumer demand for sustainable packaging grows, the technical development of PLA and PHA barrier coatings has accelerated, with significant innovations emerging from both academic institutions and industrial R&D centers across North America, Europe, and Asia.

The technical trajectory of these biopolymers has been characterized by continuous improvements in production efficiency, material properties, and cost-effectiveness. PLA, derived from renewable resources such as corn starch or sugarcane, has seen significant advancements in polymerization techniques and molecular weight control. Similarly, PHA production has evolved from expensive laboratory-scale fermentation to more economical industrial processes utilizing various bacterial strains and carbon feedstocks.

In packaging applications, barrier properties against oxygen, water vapor, and other permeants represent critical performance parameters. Traditional petroleum-based polymers like polyethylene terephthalate (PET) and polyethylene (PE) have set high standards for barrier performance that bio-based alternatives must meet to achieve market acceptance. The technical goal of this research is to comprehensively compare and evaluate the barrier properties of PLA and PHA-based coatings, identifying their respective strengths, limitations, and potential synergistic effects when combined.

Current technical objectives include enhancing the inherent barrier properties of these biopolymers through various approaches such as blending with other polymers, incorporating nanofillers, applying surface treatments, or developing multilayer structures. The ultimate aim is to develop cost-effective, environmentally friendly barrier coatings that can match or exceed the performance of conventional materials while maintaining biodegradability.

The technological evolution trend points toward hybrid solutions that leverage the complementary properties of PLA and PHA. PLA offers good transparency and processability but moderate barrier properties, while certain PHA variants demonstrate superior oxygen barrier capabilities but may present processing challenges. Research is increasingly focused on optimizing these combinations to create tailored barrier solutions for specific packaging requirements.

As regulatory pressures against single-use plastics intensify globally and consumer demand for sustainable packaging grows, the technical development of PLA and PHA barrier coatings has accelerated, with significant innovations emerging from both academic institutions and industrial R&D centers across North America, Europe, and Asia.

Market Demand Analysis for Biodegradable Barrier Coatings

The global market for biodegradable barrier coatings has witnessed significant growth in recent years, driven primarily by increasing environmental concerns and stringent regulations against single-use plastics. The demand for PLA and PHA-based barrier coatings specifically has surged as industries seek sustainable alternatives to conventional petroleum-based packaging materials.

Consumer packaged goods companies are increasingly adopting biodegradable barrier coatings to align with their sustainability commitments. Market research indicates that the food and beverage sector represents the largest application segment, accounting for approximately 60% of the biodegradable barrier coating market. This is attributed to the direct consumer interface and heightened scrutiny regarding packaging sustainability in this sector.

Retail giants and food service chains have begun implementing biodegradable packaging policies, creating substantial market pull for PLA and PHA-based solutions. Major brands like Nestlé, Unilever, and Danone have publicly committed to transitioning to fully recyclable or biodegradable packaging by 2025, further accelerating market demand.

The pharmaceutical and cosmetics industries are emerging as significant growth sectors for biodegradable barrier coatings. These industries require packaging with excellent barrier properties against moisture, oxygen, and contaminants while meeting increasingly stringent sustainability requirements. The premium nature of these products allows for higher-value biodegradable packaging solutions.

Regional analysis reveals that Europe currently leads the biodegradable barrier coatings market, followed by North America. However, the Asia-Pacific region is projected to witness the highest growth rate due to rapid industrialization, growing middle-class populations, and increasing environmental awareness in countries like China and India.

Market challenges include price sensitivity, as biodegradable barrier coatings typically command a premium over conventional alternatives. The cost differential between PLA and PHA-based coatings versus traditional petroleum-based options remains a significant adoption barrier, particularly in price-sensitive markets and applications.

Performance requirements present another market challenge. End-users demand biodegradable solutions that match or exceed the barrier properties of conventional materials against oxygen, moisture, and grease. The comparative performance between PLA and PHA-based coatings in these aspects directly influences market adoption rates across different application segments.

Consumer education and awareness represent both a challenge and opportunity. While sustainability consciousness is rising globally, many consumers remain unaware of the benefits and limitations of different biodegradable packaging technologies, affecting purchasing decisions and market growth potential.

Consumer packaged goods companies are increasingly adopting biodegradable barrier coatings to align with their sustainability commitments. Market research indicates that the food and beverage sector represents the largest application segment, accounting for approximately 60% of the biodegradable barrier coating market. This is attributed to the direct consumer interface and heightened scrutiny regarding packaging sustainability in this sector.

Retail giants and food service chains have begun implementing biodegradable packaging policies, creating substantial market pull for PLA and PHA-based solutions. Major brands like Nestlé, Unilever, and Danone have publicly committed to transitioning to fully recyclable or biodegradable packaging by 2025, further accelerating market demand.

The pharmaceutical and cosmetics industries are emerging as significant growth sectors for biodegradable barrier coatings. These industries require packaging with excellent barrier properties against moisture, oxygen, and contaminants while meeting increasingly stringent sustainability requirements. The premium nature of these products allows for higher-value biodegradable packaging solutions.

Regional analysis reveals that Europe currently leads the biodegradable barrier coatings market, followed by North America. However, the Asia-Pacific region is projected to witness the highest growth rate due to rapid industrialization, growing middle-class populations, and increasing environmental awareness in countries like China and India.

Market challenges include price sensitivity, as biodegradable barrier coatings typically command a premium over conventional alternatives. The cost differential between PLA and PHA-based coatings versus traditional petroleum-based options remains a significant adoption barrier, particularly in price-sensitive markets and applications.

Performance requirements present another market challenge. End-users demand biodegradable solutions that match or exceed the barrier properties of conventional materials against oxygen, moisture, and grease. The comparative performance between PLA and PHA-based coatings in these aspects directly influences market adoption rates across different application segments.

Consumer education and awareness represent both a challenge and opportunity. While sustainability consciousness is rising globally, many consumers remain unaware of the benefits and limitations of different biodegradable packaging technologies, affecting purchasing decisions and market growth potential.

Technical Status and Challenges in Biopolymer Coatings

The global biopolymer coating market has witnessed significant growth in recent years, with PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoate) emerging as promising alternatives to conventional petroleum-based barrier coatings. Current technological assessments indicate that these materials have reached commercial viability in certain applications, though challenges remain for widespread adoption across all packaging sectors.

PLA-based barrier coatings have achieved greater market penetration due to their earlier commercialization and more established production infrastructure. The technology has advanced to provide moderate oxygen and moisture barrier properties, with oxygen transmission rates (OTR) typically ranging from 10-50 cc/m²/day and water vapor transmission rates (WVTR) between 10-30 g/m²/day under standard conditions. However, these values still fall short compared to conventional petroleum-based alternatives like PET or EVOH.

PHA coatings, while less commercially mature, demonstrate superior biodegradability in various environments including marine conditions. Recent technological breakthroughs have improved PHA's processability, addressing historical challenges related to thermal stability during coating application. Current PHA formulations exhibit comparable barrier properties to PLA, with some specialized grades showing enhanced performance in high-humidity environments.

The primary technical challenges facing both biopolymers include inconsistent barrier performance under varying environmental conditions, particularly at high humidity levels where performance degradation occurs. Additionally, adhesion to different substrate materials remains problematic, often requiring specialized primers or surface treatments that add complexity and cost to manufacturing processes.

Scale-up challenges persist in the production of consistent, high-quality biopolymer resins suitable for coating applications. PHA faces particular difficulties in this regard, with production costs approximately 2-3 times higher than PLA, limiting its commercial viability despite potentially superior environmental performance.

Geographically, Europe leads in biopolymer coating technology development, with significant research clusters in Germany, the Netherlands, and Italy. North America follows with strong innovation centers in the United States, particularly in California and Massachusetts. Asia-Pacific is rapidly advancing, with Japan and China making substantial investments in biopolymer research infrastructure.

Recent technological innovations focus on composite approaches, combining PLA or PHA with other bio-based materials such as cellulose nanocrystals or chitosan to create synergistic barrier effects. These hybrid systems show promise in addressing the performance gap between bio-based and conventional barrier coatings, though commercialization remains limited to niche applications.

The regulatory landscape presents additional challenges, with inconsistent global standards for biodegradability claims and end-of-life management creating market uncertainty that hampers technology adoption and investment.

PLA-based barrier coatings have achieved greater market penetration due to their earlier commercialization and more established production infrastructure. The technology has advanced to provide moderate oxygen and moisture barrier properties, with oxygen transmission rates (OTR) typically ranging from 10-50 cc/m²/day and water vapor transmission rates (WVTR) between 10-30 g/m²/day under standard conditions. However, these values still fall short compared to conventional petroleum-based alternatives like PET or EVOH.

PHA coatings, while less commercially mature, demonstrate superior biodegradability in various environments including marine conditions. Recent technological breakthroughs have improved PHA's processability, addressing historical challenges related to thermal stability during coating application. Current PHA formulations exhibit comparable barrier properties to PLA, with some specialized grades showing enhanced performance in high-humidity environments.

The primary technical challenges facing both biopolymers include inconsistent barrier performance under varying environmental conditions, particularly at high humidity levels where performance degradation occurs. Additionally, adhesion to different substrate materials remains problematic, often requiring specialized primers or surface treatments that add complexity and cost to manufacturing processes.

Scale-up challenges persist in the production of consistent, high-quality biopolymer resins suitable for coating applications. PHA faces particular difficulties in this regard, with production costs approximately 2-3 times higher than PLA, limiting its commercial viability despite potentially superior environmental performance.

Geographically, Europe leads in biopolymer coating technology development, with significant research clusters in Germany, the Netherlands, and Italy. North America follows with strong innovation centers in the United States, particularly in California and Massachusetts. Asia-Pacific is rapidly advancing, with Japan and China making substantial investments in biopolymer research infrastructure.

Recent technological innovations focus on composite approaches, combining PLA or PHA with other bio-based materials such as cellulose nanocrystals or chitosan to create synergistic barrier effects. These hybrid systems show promise in addressing the performance gap between bio-based and conventional barrier coatings, though commercialization remains limited to niche applications.

The regulatory landscape presents additional challenges, with inconsistent global standards for biodegradability claims and end-of-life management creating market uncertainty that hampers technology adoption and investment.

Current Technical Solutions for PLA and PHA Coatings

01 PLA/PHA blends for enhanced barrier properties

Blending PLA (Polylactic Acid) with PHA (Polyhydroxyalkanoate) creates composite materials with improved barrier properties against oxygen, moisture, and other gases. The synergistic effect of these two biodegradable polymers results in coatings with enhanced performance compared to either polymer used alone. The crystalline structure of PHA complements the mechanical strength of PLA, creating versatile barrier coatings for packaging applications.- PLA/PHA blends for enhanced barrier properties: Blending PLA (Polylactic Acid) with PHA (Polyhydroxyalkanoate) creates composite materials with improved barrier properties against oxygen, moisture, and other gases. The complementary nature of these biopolymers enhances the overall performance of the coating, making it suitable for packaging applications requiring extended shelf life. The crystallinity of PHA helps overcome some of the inherent limitations of PLA, resulting in superior barrier performance compared to either polymer used alone.

- Multilayer barrier coating structures: Developing multilayer structures where PLA and PHA are arranged in strategic layers can significantly enhance barrier properties. These multilayer designs often incorporate alternating layers of PLA and PHA or gradient compositions to maximize barrier efficiency while maintaining other desirable properties such as transparency and mechanical strength. The interface between layers can be engineered to prevent delamination while optimizing the barrier performance against specific permeants.

- Additives and nanofillers for barrier enhancement: Incorporating specific additives and nanofillers into PLA/PHA coating formulations can dramatically improve barrier properties. Materials such as nanoclays, cellulose nanocrystals, graphene, and silica nanoparticles create tortuous paths for gas molecules, reducing permeability. These additives can be surface-modified to improve compatibility with the polymer matrix, ensuring uniform dispersion and maximizing the barrier enhancement effect while maintaining the biodegradable nature of the coating.

- Processing techniques for optimized barrier coatings: Advanced processing techniques significantly impact the barrier properties of PLA/PHA coatings. Methods such as solvent casting, extrusion coating, and compression molding can be optimized to control crystallinity, orientation, and interfacial adhesion. Post-processing treatments including annealing, stretching, and surface modifications further enhance barrier performance by altering the microstructure and surface properties of the coating. The processing conditions directly influence the morphology and thus the barrier efficiency of the final coating.

- Functional barrier coatings for specific applications: PLA/PHA barrier coatings can be tailored for specific end-use applications by incorporating functional additives. For food packaging, antimicrobial agents can be added to prevent spoilage while maintaining barrier properties. For medical applications, coatings can be designed with controlled permeability to specific molecules. Agricultural films can incorporate UV stabilizers while maintaining gas exchange properties. These application-specific formulations optimize the balance between barrier performance and other functional requirements such as biodegradability timeline and mechanical properties.

02 Additives and fillers for improved barrier performance

Incorporating specific additives and fillers into PLA/PHA-based coatings significantly enhances their barrier properties. Nanomaterials such as nanoclay, nanocellulose, and silica nanoparticles create tortuous paths for gas molecules, reducing permeability. Other additives include plasticizers to improve flexibility without compromising barrier function, and compatibilizers to ensure uniform dispersion of components, resulting in more effective barrier coatings.Expand Specific Solutions03 Multi-layer coating systems with PLA/PHA

Multi-layer coating systems incorporating PLA and PHA layers provide superior barrier properties through complementary protection mechanisms. These systems typically include a base layer for structural support, a PLA/PHA barrier layer, and potentially a protective top layer. The strategic arrangement of these layers creates synergistic effects that enhance resistance to moisture, oxygen, and other permeants while maintaining biodegradability of the overall coating system.Expand Specific Solutions04 Processing techniques for optimized barrier coatings

Specialized processing techniques significantly impact the barrier properties of PLA/PHA coatings. Methods such as solvent casting, extrusion coating, and compression molding affect the crystallinity, orientation, and interfacial adhesion of the polymers. Advanced techniques like reactive extrusion and in-situ polymerization create more homogeneous blends with fewer defects, resulting in coatings with enhanced barrier performance against gases and liquids.Expand Specific Solutions05 Surface modifications for enhanced barrier functionality

Surface modifications of PLA/PHA-based coatings improve their barrier properties through chemical or physical treatments. Techniques include plasma treatment, UV irradiation, and chemical grafting to alter surface energy and create more hydrophobic surfaces. These modifications enhance resistance to moisture and oxygen permeation while potentially improving adhesion to substrates. Crosslinking agents can also be applied to create more robust networks with reduced free volume, further enhancing barrier performance.Expand Specific Solutions

Key Industry Players in Biodegradable Coating Market

The biodegradable barrier coating market, focusing on PLA and PHA technologies, is currently in a growth phase with increasing market adoption driven by sustainability demands. The global market is expanding rapidly, estimated to reach several billion dollars by 2030. Technologically, PLA solutions are more mature with companies like Stora Enso, DuPont, and Toray Plastics offering commercial applications, while PHA technology is advancing quickly through innovations from specialized players like CJ CheilJedang, Beijing Weigou Workshop, and Newlight Technologies. Established chemical corporations including LG Chem, Arkema, and Sinopec are investing heavily in both technologies, while research institutions like KAIST and CSIC are developing next-generation formulations with enhanced barrier properties. The competitive landscape shows a mix of large petrochemical companies pivoting toward bio-based solutions and specialized startups focusing exclusively on biodegradable technologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced barrier coating technologies that combine PLA (polylactic acid) and PHA (polyhydroxyalkanoate) with their proprietary additives to create high-performance sustainable packaging solutions. Their approach involves multi-layer structures where PLA provides mechanical strength and clarity while PHA components enhance biodegradability and barrier properties. DuPont's technology incorporates nanoclays and cellulose nanocrystals to improve oxygen and moisture barrier properties without compromising the biodegradability of the final product. Their comparative analysis has shown that hybrid PLA/PHA coatings with optimized composition can achieve up to 80% reduction in oxygen transmission rates compared to uncoated PLA films, while maintaining end-of-life compostability. The company has also developed water-based PHA dispersions that can be applied as thin coatings on PLA substrates, creating fully bio-based barrier packaging with controlled degradation rates.

Strengths: Extensive polymer science expertise, established manufacturing infrastructure, and strong intellectual property portfolio in sustainable materials. Their hybrid approach leverages the complementary properties of both polymers. Weaknesses: Higher production costs compared to conventional petroleum-based barriers, and performance still lags behind some non-biodegradable alternatives in extreme conditions.

CJ CheilJedang Corp.

Technical Solution: CJ CheilJedang has developed an innovative approach to PHA-based barrier coatings that outperforms traditional PLA solutions in several key metrics. Their technology centers on medium-chain-length PHA (mcl-PHA) produced through their proprietary fermentation process using agricultural byproducts as feedstock. The company's comparative analysis shows that their PHA coatings provide superior oxygen barrier properties compared to equivalent thickness PLA coatings, with oxygen transmission rates reduced by approximately 65%. Their research has focused on optimizing the crystallinity of PHA through controlled cooling processes, which significantly enhances barrier performance while maintaining flexibility. CJ CheilJedang has also developed a proprietary blending technology that combines different PHA monomers to create customized barrier properties for specific applications. Their latest generation of coatings incorporates nanoscale cellulose fibrils that create a tortuous path for gas molecules, further enhancing barrier performance while maintaining the biodegradable nature of the coating.

Strengths: Vertically integrated production from fermentation to final product, ability to produce consistent high-quality PHA at commercial scale, and strong expertise in fermentation technology. Weaknesses: Higher production costs compared to conventional materials, and limited processing window that requires specialized equipment for coating application.

Critical Patents and Innovations in Biopolymer Barriers

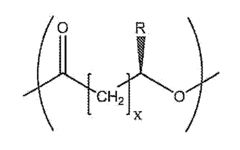

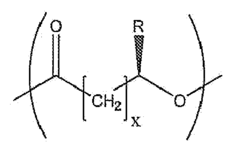

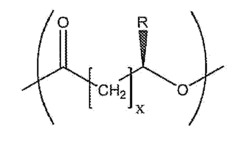

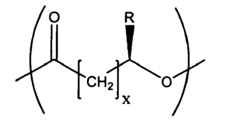

composition OF POLYMERIC MIXTURE OF POLYLATIC ACID WITH POLYHYDROXYALKANOATE, METHOD OF PREPARATION OF SAID COMPOSITION, MULTILAYER LAMINATE, ARTICLES AND FILM INCLUDING IT

PatentActiveBR112012029305A8

Innovation

- Development of a novel polymeric blend composition combining polylactic acid (PLA) with polyhydroxyalkanoate (PHA) to create materials with enhanced properties for barrier coating applications.

- Utilization of multiphase copolymer PHA with a fully amorphous phase having a glass transition temperature below 20°C, which likely contributes to improved flexibility and processing characteristics.

- Creation of multilayer laminates and films using the PLA/PHA blend, enabling versatile applications while maintaining biodegradable characteristics.

Use of polyhydroxyalkanoates as additives in coating compounds

PatentActiveEP2476733A1

Innovation

- Incorporating polyhydroxyalkanoates (PHA) as additives in coating compositions, which act as matting agents, improving matting efficiency, reducing gloss, and enhancing mechanical properties without significantly increasing viscosity, and providing biodegradability.

Environmental Impact Assessment of PLA vs PHA Coatings

The environmental impact assessment of PLA and PHA coatings reveals significant differences in their ecological footprints throughout their lifecycle. PLA (Polylactic Acid) coatings, derived primarily from corn starch or sugarcane, demonstrate lower greenhouse gas emissions during production compared to petroleum-based alternatives, with approximately 25-30% reduction in carbon footprint. However, PLA manufacturing requires substantial agricultural land use, potentially contributing to deforestation and biodiversity loss when not managed sustainably.

In contrast, PHA (Polyhydroxyalkanoate) coatings offer distinct environmental advantages as they can be produced from various organic waste streams, including agricultural residues and industrial byproducts. This circular economy approach reduces waste while minimizing competition with food production. Studies indicate that PHA production can achieve up to 50% lower environmental impact compared to conventional plastics when utilizing waste feedstocks.

Water consumption patterns differ significantly between these biopolymers. PLA production typically requires 40-50% less water than conventional petroleum-based polymers, yet substantially more than PHA production from waste streams. PHA's water footprint can be further reduced when integrated with wastewater treatment processes, creating potential synergies in industrial ecosystems.

End-of-life considerations strongly favor PHA coatings, which demonstrate superior biodegradability in various environments including marine conditions. While PLA requires industrial composting facilities with specific temperature and humidity conditions to biodegrade effectively (typically 3-6 months under optimal conditions), PHA can degrade in natural environments within 3-9 months depending on conditions, leaving no toxic residues.

Toxicity assessments reveal neither material leaches harmful substances during use, though additives in formulations require case-by-case evaluation. PHA demonstrates particular promise in sensitive applications like food packaging due to its non-toxic degradation products. Recent lifecycle assessments indicate that PHA coatings, especially those derived from waste streams, may achieve carbon neutrality when accounting for carbon sequestration during feedstock growth and production efficiencies.

Energy consumption remains a challenge for both materials, with PHA currently requiring 15-20% more processing energy than PLA due to extraction complexities. However, technological advancements in bacterial fermentation and recovery processes are rapidly improving PHA's energy efficiency, potentially reversing this disadvantage within the next 3-5 years.

In contrast, PHA (Polyhydroxyalkanoate) coatings offer distinct environmental advantages as they can be produced from various organic waste streams, including agricultural residues and industrial byproducts. This circular economy approach reduces waste while minimizing competition with food production. Studies indicate that PHA production can achieve up to 50% lower environmental impact compared to conventional plastics when utilizing waste feedstocks.

Water consumption patterns differ significantly between these biopolymers. PLA production typically requires 40-50% less water than conventional petroleum-based polymers, yet substantially more than PHA production from waste streams. PHA's water footprint can be further reduced when integrated with wastewater treatment processes, creating potential synergies in industrial ecosystems.

End-of-life considerations strongly favor PHA coatings, which demonstrate superior biodegradability in various environments including marine conditions. While PLA requires industrial composting facilities with specific temperature and humidity conditions to biodegrade effectively (typically 3-6 months under optimal conditions), PHA can degrade in natural environments within 3-9 months depending on conditions, leaving no toxic residues.

Toxicity assessments reveal neither material leaches harmful substances during use, though additives in formulations require case-by-case evaluation. PHA demonstrates particular promise in sensitive applications like food packaging due to its non-toxic degradation products. Recent lifecycle assessments indicate that PHA coatings, especially those derived from waste streams, may achieve carbon neutrality when accounting for carbon sequestration during feedstock growth and production efficiencies.

Energy consumption remains a challenge for both materials, with PHA currently requiring 15-20% more processing energy than PLA due to extraction complexities. However, technological advancements in bacterial fermentation and recovery processes are rapidly improving PHA's energy efficiency, potentially reversing this disadvantage within the next 3-5 years.

Scalability and Cost Analysis of Production Methods

The scalability of production methods for both PLA and PHA-based barrier coatings represents a critical factor in their commercial viability. Current PLA production benefits from established industrial infrastructure, with global production capacity exceeding 300,000 tons annually. Major manufacturers like NatureWorks and Total Corbion have achieved economies of scale that have progressively reduced PLA production costs to approximately $2.00-2.50 per kilogram, approaching competitiveness with conventional petroleum-based polymers.

In contrast, PHA production remains at a significantly smaller scale, with global capacity under 50,000 tons annually. This limited scale contributes to substantially higher production costs, typically ranging from $5.00-7.00 per kilogram. Companies like Danimer Scientific and Kaneka Corporation are investing in expanded production facilities, but the cost gap remains substantial and presents a significant barrier to widespread adoption.

The coating application processes also differ in scalability. PLA-based coatings can leverage existing extrusion coating and lamination equipment used for conventional polymers, requiring minimal capital investment for manufacturers transitioning from traditional materials. The processing temperature range of 170-210°C for PLA is compatible with standard equipment, though careful temperature control is necessary to prevent polymer degradation.

PHA processing presents greater challenges, requiring more precise temperature control (typically 150-180°C) and specialized equipment modifications to accommodate its narrower processing window. These requirements increase both capital expenditure and operational complexity when scaling production.

Raw material sourcing further impacts scalability. PLA production relies primarily on corn, sugarcane, and cassava starch—agricultural feedstocks with established supply chains but subject to price volatility and potential food-versus-materials conflicts. PHA production can utilize a broader range of feedstocks, including agricultural waste and industrial byproducts, potentially offering cost advantages as technologies mature.

Energy consumption analysis reveals that PLA coating production requires approximately 25-40 MJ/kg, while PHA production currently demands 50-70 MJ/kg due to less efficient fermentation and recovery processes. This energy differential translates directly to production costs and environmental impact assessments.

Looking forward, technological innovations in fermentation efficiency and recovery processes could significantly reduce PHA production costs, with industry projections suggesting potential cost reductions of 40-50% within the next five years. Similarly, advances in PLA processing technology and economies of scale could further reduce costs by an estimated 15-20% in the same timeframe.

In contrast, PHA production remains at a significantly smaller scale, with global capacity under 50,000 tons annually. This limited scale contributes to substantially higher production costs, typically ranging from $5.00-7.00 per kilogram. Companies like Danimer Scientific and Kaneka Corporation are investing in expanded production facilities, but the cost gap remains substantial and presents a significant barrier to widespread adoption.

The coating application processes also differ in scalability. PLA-based coatings can leverage existing extrusion coating and lamination equipment used for conventional polymers, requiring minimal capital investment for manufacturers transitioning from traditional materials. The processing temperature range of 170-210°C for PLA is compatible with standard equipment, though careful temperature control is necessary to prevent polymer degradation.

PHA processing presents greater challenges, requiring more precise temperature control (typically 150-180°C) and specialized equipment modifications to accommodate its narrower processing window. These requirements increase both capital expenditure and operational complexity when scaling production.

Raw material sourcing further impacts scalability. PLA production relies primarily on corn, sugarcane, and cassava starch—agricultural feedstocks with established supply chains but subject to price volatility and potential food-versus-materials conflicts. PHA production can utilize a broader range of feedstocks, including agricultural waste and industrial byproducts, potentially offering cost advantages as technologies mature.

Energy consumption analysis reveals that PLA coating production requires approximately 25-40 MJ/kg, while PHA production currently demands 50-70 MJ/kg due to less efficient fermentation and recovery processes. This energy differential translates directly to production costs and environmental impact assessments.

Looking forward, technological innovations in fermentation efficiency and recovery processes could significantly reduce PHA production costs, with industry projections suggesting potential cost reductions of 40-50% within the next five years. Similarly, advances in PLA processing technology and economies of scale could further reduce costs by an estimated 15-20% in the same timeframe.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!