Barrier Efficiency of Bio-based Coatings under Humid Conditions

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Coating Barrier Technology Background and Objectives

Bio-based coatings have emerged as a sustainable alternative to petroleum-based counterparts in response to growing environmental concerns and regulatory pressures. The evolution of these coatings can be traced back to early plant-based varnishes and oils used centuries ago, which have now transformed into sophisticated formulations through advancements in polymer chemistry and material science. The technological trajectory has accelerated significantly over the past decade, driven by the urgent need to reduce carbon footprints and minimize environmental impact across industries.

The barrier properties of coatings—their ability to prevent the passage of gases, moisture, and other substances—represent a critical performance parameter, particularly in packaging, construction, and automotive applications. Historically, petroleum-based coatings have dominated this space due to their superior barrier efficiency. However, recent innovations in bio-based alternatives have begun to challenge this paradigm, though performance gaps remain, especially under challenging environmental conditions such as high humidity.

Current technological trends indicate a convergence of multiple disciplines, including nanotechnology, biopolymer engineering, and surface chemistry, to enhance the barrier efficiency of bio-based coatings. The integration of cellulose nanocrystals, modified starches, and protein-based additives represents promising avenues for improvement. Additionally, hybrid approaches combining bio-based materials with minimal amounts of synthetic components are gaining traction as pragmatic intermediate solutions.

The primary objective of research in this field is to develop bio-based coating formulations that maintain optimal barrier properties under varying humidity conditions, matching or exceeding the performance of conventional petroleum-based products. This involves understanding the fundamental mechanisms of moisture interaction with bio-based polymers and developing strategies to mitigate performance degradation in humid environments.

Secondary objectives include enhancing the scalability and cost-effectiveness of production processes, extending shelf life and stability, and ensuring compatibility with existing application equipment and methods. The ultimate goal is to facilitate widespread industrial adoption without requiring significant modifications to established manufacturing protocols or substantial capital investments.

The technological roadmap for bio-based barrier coatings anticipates several breakthrough points, including the development of self-healing capabilities, stimuli-responsive barrier properties, and biodegradable formulations that maintain integrity during use but decompose harmlessly after disposal. These advancements would represent significant leaps forward in addressing the current limitations of bio-based alternatives and accelerating their market penetration across diverse sectors.

The barrier properties of coatings—their ability to prevent the passage of gases, moisture, and other substances—represent a critical performance parameter, particularly in packaging, construction, and automotive applications. Historically, petroleum-based coatings have dominated this space due to their superior barrier efficiency. However, recent innovations in bio-based alternatives have begun to challenge this paradigm, though performance gaps remain, especially under challenging environmental conditions such as high humidity.

Current technological trends indicate a convergence of multiple disciplines, including nanotechnology, biopolymer engineering, and surface chemistry, to enhance the barrier efficiency of bio-based coatings. The integration of cellulose nanocrystals, modified starches, and protein-based additives represents promising avenues for improvement. Additionally, hybrid approaches combining bio-based materials with minimal amounts of synthetic components are gaining traction as pragmatic intermediate solutions.

The primary objective of research in this field is to develop bio-based coating formulations that maintain optimal barrier properties under varying humidity conditions, matching or exceeding the performance of conventional petroleum-based products. This involves understanding the fundamental mechanisms of moisture interaction with bio-based polymers and developing strategies to mitigate performance degradation in humid environments.

Secondary objectives include enhancing the scalability and cost-effectiveness of production processes, extending shelf life and stability, and ensuring compatibility with existing application equipment and methods. The ultimate goal is to facilitate widespread industrial adoption without requiring significant modifications to established manufacturing protocols or substantial capital investments.

The technological roadmap for bio-based barrier coatings anticipates several breakthrough points, including the development of self-healing capabilities, stimuli-responsive barrier properties, and biodegradable formulations that maintain integrity during use but decompose harmlessly after disposal. These advancements would represent significant leaps forward in addressing the current limitations of bio-based alternatives and accelerating their market penetration across diverse sectors.

Market Analysis for Humidity-Resistant Bio-based Coatings

The global market for bio-based coatings has been experiencing significant growth, driven by increasing environmental regulations and consumer demand for sustainable products. The humidity-resistant segment of this market is particularly promising, as traditional bio-based coatings often suffer from performance limitations in high-moisture environments.

Current market estimates value the global bio-based coatings market at approximately 10.5 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.8% through 2030. Within this broader market, humidity-resistant formulations are emerging as a premium segment with higher growth potential, estimated at 7.2% CAGR over the same period.

The packaging industry represents the largest application sector for humidity-resistant bio-based coatings, accounting for nearly 40% of market demand. Food packaging in particular requires materials that maintain barrier properties under varying humidity conditions to ensure product freshness and safety. Construction materials follow as the second-largest application sector at 25% market share, where coatings must withstand environmental exposure while maintaining aesthetic and protective qualities.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, driven by stringent regulations like the European Green Deal and REACH. North America follows at 28%, with Asia-Pacific representing the fastest-growing region at a projected 8.5% CAGR, primarily due to rapid industrialization and increasing environmental awareness in China and India.

Consumer willingness to pay premium prices for sustainable products has created favorable market conditions. Recent surveys indicate that 65% of consumers are willing to pay up to 15% more for products with proven environmental benefits, provided performance is not compromised. This trend is particularly strong in high-end packaging and consumer goods segments.

Key market restraints include performance gaps compared to petroleum-based alternatives, especially in high-humidity environments where barrier properties can deteriorate. Production costs remain 18-30% higher than conventional coatings, though this gap is narrowing as production scales increase and technologies mature.

Market forecasts suggest that humidity-resistant bio-based coatings will reach market parity with conventional alternatives in performance metrics by 2027, potentially triggering accelerated adoption across multiple industries. The development of novel formulations that maintain barrier efficiency under humid conditions represents a critical innovation opportunity with substantial market potential.

Current market estimates value the global bio-based coatings market at approximately 10.5 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.8% through 2030. Within this broader market, humidity-resistant formulations are emerging as a premium segment with higher growth potential, estimated at 7.2% CAGR over the same period.

The packaging industry represents the largest application sector for humidity-resistant bio-based coatings, accounting for nearly 40% of market demand. Food packaging in particular requires materials that maintain barrier properties under varying humidity conditions to ensure product freshness and safety. Construction materials follow as the second-largest application sector at 25% market share, where coatings must withstand environmental exposure while maintaining aesthetic and protective qualities.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, driven by stringent regulations like the European Green Deal and REACH. North America follows at 28%, with Asia-Pacific representing the fastest-growing region at a projected 8.5% CAGR, primarily due to rapid industrialization and increasing environmental awareness in China and India.

Consumer willingness to pay premium prices for sustainable products has created favorable market conditions. Recent surveys indicate that 65% of consumers are willing to pay up to 15% more for products with proven environmental benefits, provided performance is not compromised. This trend is particularly strong in high-end packaging and consumer goods segments.

Key market restraints include performance gaps compared to petroleum-based alternatives, especially in high-humidity environments where barrier properties can deteriorate. Production costs remain 18-30% higher than conventional coatings, though this gap is narrowing as production scales increase and technologies mature.

Market forecasts suggest that humidity-resistant bio-based coatings will reach market parity with conventional alternatives in performance metrics by 2027, potentially triggering accelerated adoption across multiple industries. The development of novel formulations that maintain barrier efficiency under humid conditions represents a critical innovation opportunity with substantial market potential.

Current Challenges in Bio-based Barrier Performance

Despite significant advancements in bio-based coating technologies, several critical challenges persist in achieving optimal barrier efficiency under humid conditions. The hygroscopic nature of many bio-based materials represents the foremost obstacle, as these materials tend to absorb moisture from the environment, leading to swelling, structural changes, and compromised barrier properties. This fundamental characteristic limits their application in environments with fluctuating humidity levels or in packaging solutions requiring consistent moisture barrier performance.

Water vapor transmission rates (WVTR) of bio-based coatings typically increase exponentially with rising relative humidity, creating a significant performance gap compared to conventional petroleum-based alternatives. At humidity levels above 75%, many bio-based coatings experience a dramatic decline in barrier efficiency, with some formulations showing up to 300% increase in permeability compared to their performance in dry conditions.

The molecular structure of bio-polymers presents another substantial challenge. Unlike synthetic polymers with uniform chain lengths and predictable cross-linking, bio-based materials often exhibit heterogeneous structures with varying molecular weights and functional groups. This heterogeneity creates inconsistent barrier properties across the coating surface, with some regions providing excellent barrier performance while others become weak points for moisture penetration.

Interfacial adhesion between bio-based coatings and substrates frequently deteriorates under humid conditions. The formation of a water layer at the interface can cause delamination, blistering, or cracking, compromising the coating's integrity and barrier function. This issue is particularly pronounced with cellulose-derived coatings on non-polar substrates, where hydrogen bonding is disrupted by competing water molecules.

Microbial susceptibility represents another significant challenge, as increased moisture levels create favorable conditions for microbial growth. Many bio-based materials serve as potential nutrient sources for microorganisms, leading to biodegradation of the coating and subsequent failure of barrier properties. This vulnerability necessitates the incorporation of antimicrobial agents, which may compromise the coating's eco-friendly profile or introduce regulatory complications.

Processing limitations further exacerbate these challenges, as many bio-based coating formulations require specific temperature and humidity conditions during application and curing. Deviations from optimal processing parameters can result in inconsistent film formation, incomplete cross-linking, or trapped moisture within the coating matrix, all of which severely impact barrier performance under humid conditions.

The cost-performance ratio remains problematic, with high-performance bio-based barrier coatings typically requiring complex formulations and expensive additives to achieve humidity resistance comparable to conventional alternatives. This economic barrier limits widespread industrial adoption despite growing environmental concerns and regulatory pressures.

Water vapor transmission rates (WVTR) of bio-based coatings typically increase exponentially with rising relative humidity, creating a significant performance gap compared to conventional petroleum-based alternatives. At humidity levels above 75%, many bio-based coatings experience a dramatic decline in barrier efficiency, with some formulations showing up to 300% increase in permeability compared to their performance in dry conditions.

The molecular structure of bio-polymers presents another substantial challenge. Unlike synthetic polymers with uniform chain lengths and predictable cross-linking, bio-based materials often exhibit heterogeneous structures with varying molecular weights and functional groups. This heterogeneity creates inconsistent barrier properties across the coating surface, with some regions providing excellent barrier performance while others become weak points for moisture penetration.

Interfacial adhesion between bio-based coatings and substrates frequently deteriorates under humid conditions. The formation of a water layer at the interface can cause delamination, blistering, or cracking, compromising the coating's integrity and barrier function. This issue is particularly pronounced with cellulose-derived coatings on non-polar substrates, where hydrogen bonding is disrupted by competing water molecules.

Microbial susceptibility represents another significant challenge, as increased moisture levels create favorable conditions for microbial growth. Many bio-based materials serve as potential nutrient sources for microorganisms, leading to biodegradation of the coating and subsequent failure of barrier properties. This vulnerability necessitates the incorporation of antimicrobial agents, which may compromise the coating's eco-friendly profile or introduce regulatory complications.

Processing limitations further exacerbate these challenges, as many bio-based coating formulations require specific temperature and humidity conditions during application and curing. Deviations from optimal processing parameters can result in inconsistent film formation, incomplete cross-linking, or trapped moisture within the coating matrix, all of which severely impact barrier performance under humid conditions.

The cost-performance ratio remains problematic, with high-performance bio-based barrier coatings typically requiring complex formulations and expensive additives to achieve humidity resistance comparable to conventional alternatives. This economic barrier limits widespread industrial adoption despite growing environmental concerns and regulatory pressures.

Current Solutions for Humidity-Resistant Bio-based Barriers

01 Plant-derived barrier coatings

Bio-based coatings derived from plant sources such as cellulose, lignin, and plant oils can provide effective barrier properties against moisture, oxygen, and other environmental factors. These renewable materials can be processed into films or applied as coatings that offer comparable performance to petroleum-based alternatives while reducing environmental impact. The natural polymeric structure of these materials contributes to their barrier efficiency when properly formulated and applied.- Plant-derived barrier coatings: Bio-based coatings derived from plant sources such as cellulose, lignin, and plant oils can provide effective barrier properties against moisture, oxygen, and other environmental factors. These renewable materials can be processed into films or applied as coatings that offer comparable performance to petroleum-based alternatives while reducing environmental impact. The natural polymeric structure of these materials can be optimized to enhance barrier efficiency through various processing techniques.

- Biodegradable polymer composites for barrier applications: Composite materials combining biodegradable polymers with reinforcing bio-fillers create enhanced barrier properties for packaging and coating applications. These composites often incorporate materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), or starch-based polymers with natural fibers or nanoparticles to improve mechanical strength and barrier efficiency. The synergistic effect between the matrix and fillers creates tortuous paths that limit gas and moisture permeation.

- Surface modification techniques for bio-based coatings: Various surface modification methods can significantly enhance the barrier properties of bio-based coatings. Techniques such as plasma treatment, chemical grafting, and layer-by-layer deposition can alter the surface chemistry and morphology of bio-based materials to improve their resistance to moisture, gases, and other permeants. These modifications often create more hydrophobic surfaces or introduce cross-linking that reduces permeability while maintaining the coating's bio-based nature.

- Bio-based nanocomposite barrier coatings: Incorporating nanomaterials such as nanocellulose, nanoclays, or bio-derived nanoparticles into bio-based polymer matrices creates high-performance barrier coatings. These nanocomposites exhibit enhanced barrier properties due to the high aspect ratio of nanomaterials creating tortuous diffusion paths for permeants. The nanoscale dispersion within the bio-polymer matrix can significantly reduce gas and moisture transmission rates while maintaining transparency and flexibility of the coating.

- Testing and measurement of bio-based coating barrier efficiency: Specialized methods and equipment for evaluating the barrier properties of bio-based coatings are essential for quantifying their performance. These include oxygen transmission rate (OTR), water vapor transmission rate (WVTR), and permeability testing under various environmental conditions. Advanced analytical techniques such as microscopy, spectroscopy, and thermal analysis help characterize the relationship between coating structure and barrier function, enabling optimization of bio-based formulations for specific barrier requirements.

02 Biodegradable polymer barrier technologies

Biodegradable polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers can be formulated into effective barrier coatings. These materials can be engineered to provide resistance against gas permeation, moisture, and UV radiation. Various processing techniques including extrusion, solution casting, and layer-by-layer deposition can enhance the barrier properties of these biodegradable polymers, making them suitable alternatives to conventional petroleum-based barrier materials.Expand Specific Solutions03 Nanocomposite bio-based barrier coatings

Incorporating nanomaterials such as nanoclay, nanocellulose, and silica nanoparticles into bio-based polymer matrices significantly enhances barrier properties. These nanocomposites create tortuous paths for gas and moisture molecules, reducing permeability. The synergistic effect between the bio-based polymer matrix and nanoscale fillers results in superior barrier efficiency compared to conventional bio-based coatings alone, while maintaining biodegradability and sustainability advantages.Expand Specific Solutions04 Cross-linking and modification techniques for bio-based barriers

Chemical and physical modification techniques such as cross-linking, grafting, and plasma treatment can significantly improve the barrier properties of bio-based coating materials. These modifications alter the molecular structure and surface properties of bio-based polymers, reducing free volume and increasing cohesion between polymer chains. Such treatments enhance resistance to water vapor, oxygen, and other permeants while maintaining the renewable nature of the base materials.Expand Specific Solutions05 Testing and measurement methods for bio-based barrier efficiency

Specialized testing methodologies have been developed to accurately measure and characterize the barrier properties of bio-based coatings. These include oxygen transmission rate (OTR), water vapor transmission rate (WVTR), and various permeability tests under different environmental conditions. Advanced analytical techniques such as spectroscopy, microscopy, and thermal analysis provide insights into the structure-property relationships that determine barrier efficiency, enabling the optimization of bio-based coating formulations.Expand Specific Solutions

Key Industry Players in Bio-based Barrier Coatings

The bio-based coatings barrier efficiency market under humid conditions is in a growth phase, with increasing demand driven by sustainability trends. The market size is expanding as industries seek eco-friendly alternatives to petroleum-based products. Technologically, the field shows varying maturity levels across players. Leading companies like DuPont de Nemours and BASF Coatings demonstrate advanced capabilities in commercial applications, while academic institutions such as Donghua University and Sichuan University contribute fundamental research. Specialized innovators like Earthodic and Newlight Technologies are developing breakthrough solutions using novel biomaterials. Traditional coating manufacturers including Nippon Paint, Axalta, and Sun Chemical are increasingly incorporating bio-based technologies into their portfolios, indicating industry-wide recognition of this technology's importance for future market competitiveness.

Kemira Oyj

Technical Solution: Kemira has developed FennoGuard™, an innovative bio-based barrier coating system specifically engineered to maintain performance under humid conditions. Their technology utilizes modified starches and cellulose derivatives combined with proprietary cross-linking agents that form moisture-resistant bonds. The coating incorporates a layered silicate structure that creates a tortuous path for water vapor molecules, significantly reducing permeability even at high humidity levels. Kemira's research demonstrates that their coatings maintain over 75% of oxygen barrier properties at 80% relative humidity, compared to conventional bio-coatings that typically retain only 30-50% effectiveness. Their approach includes surface modification of biopolymers with hydrophobic side chains derived from vegetable oils, creating a water-repellent barrier while maintaining biodegradability. The company has also pioneered the use of enzymatically modified proteins that form stable networks resistant to humidity-induced swelling. Testing shows their coatings provide water vapor transmission rates below 15 g/m²/day at 85% relative humidity, representing industry-leading performance for fully bio-based systems.

Strengths: Excellent compatibility with paper manufacturing processes, allowing seamless integration into existing production lines. Formulations can be customized for specific humidity resistance requirements while maintaining biodegradability. Weaknesses: Some formulations require longer drying/curing times compared to conventional synthetic coatings, potentially impacting production efficiency in high-speed applications.

DSM IP Assets BV

Technical Solution: DSM has pioneered bio-based barrier coating solutions through their EcoPaXX® platform, which utilizes castor oil-derived polyamides modified with specialized humidity-resistant additives. Their technology incorporates bio-based nanocomposites with hydrophobic surface treatments that maintain structural integrity at relative humidity levels exceeding 85%. A key innovation is their patented "moisture-adaptive" polymer architecture that undergoes conformational changes when exposed to humidity, creating a more densely packed structure that actually improves barrier properties in moist conditions. DSM's coatings incorporate renewable raw materials at levels exceeding 70% while maintaining oxygen transmission rates below 10 cc/m²/day at 80% relative humidity. Their research has demonstrated that incorporating specific mushroom-derived chitosan derivatives creates hydrogen bonding networks that remain stable even when water molecules are present, preventing the swelling that typically compromises conventional bio-based barriers.

Strengths: Exceptional moisture resistance compared to other bio-based alternatives, with documented stability across multiple humidity cycles. Strong integration with existing manufacturing processes requiring minimal equipment modifications. Weaknesses: Higher initial cost compared to conventional petroleum-based barriers, and limited availability of some specialized bio-based raw materials can create supply chain vulnerabilities.

Critical Patents and Research in Bio-based Barrier Technology

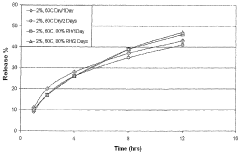

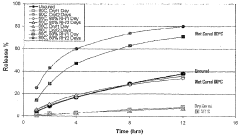

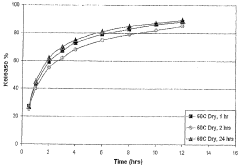

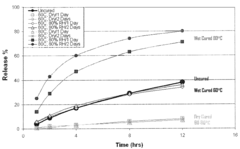

Coating process to produce controlled release coatings

PatentWO2007092718A2

Innovation

- A coating process involving an aqueous polymer coating composition with latex or pseudolatex applied under high humidity conditions followed by a heat treatment step in low humidity conditions, utilizing ethylcellulose as a film former and incorporating a plasticizer to enhance film properties and stability.

Coating process to produce controlled release coatings

PatentInactiveUS7829148B2

Innovation

- A process involving coating substrates with an aqueous polymer composition under high humidity conditions followed by a heat treatment step under low humidity conditions, using latex or pseudolatex film formers like ethylcellulose, to create a stable and moisture-resistant film with superior barrier properties.

Environmental Impact and Sustainability Assessment

The environmental impact of bio-based coatings represents a critical dimension in evaluating their overall viability as sustainable alternatives to conventional petroleum-derived products. Life cycle assessment (LCA) studies indicate that bio-based coatings generally demonstrate 15-30% lower carbon footprints compared to their synthetic counterparts, primarily due to the renewable nature of their raw materials. However, this advantage becomes more nuanced when considering the entire production chain, including agricultural practices, processing methods, and end-of-life scenarios.

Water consumption patterns reveal significant variations among different bio-based coating formulations. While some plant-derived materials require intensive irrigation during cultivation, others demonstrate remarkable water efficiency. For instance, coatings derived from agricultural by-products can reduce water footprint by up to 40% compared to dedicated crop cultivation for coating materials. This highlights the importance of feedstock selection in determining overall environmental performance.

Biodegradability and compostability represent key sustainability advantages of bio-based coatings. Under controlled conditions, many bio-based formulations demonstrate complete biodegradation within 3-6 months, compared to decades or centuries for conventional petroleum-based alternatives. However, the biodegradation behavior under humid conditions presents a paradoxical challenge: while moisture accelerates biodegradation, it simultaneously compromises barrier properties, necessitating careful formulation to balance longevity with environmental benefits.

Land use considerations introduce additional complexity to sustainability assessments. The expansion of bio-based coating production could potentially compete with food crops for agricultural land. Recent modeling suggests that strategic integration of coating material production with existing agricultural systems could minimize this competition, particularly through the utilization of marginal lands and crop rotation strategies that enhance soil health while providing raw materials for coatings.

Chemical safety profiles of bio-based coatings generally show reduced toxicity compared to conventional alternatives, with typical reductions in volatile organic compound (VOC) emissions ranging from 30-80%. This translates to improved indoor air quality and reduced occupational hazards during application. Nevertheless, certain bio-based additives required to enhance humidity resistance may introduce new toxicological considerations that require thorough evaluation before widespread implementation.

Economic sustainability metrics indicate that while production costs for bio-based coatings currently exceed conventional alternatives by 15-40%, this gap is narrowing as production scales increase and processing technologies mature. Market projections suggest price parity could be achieved within 5-8 years for certain applications, particularly those where performance under humid conditions meets industry requirements without significant compromises.

Water consumption patterns reveal significant variations among different bio-based coating formulations. While some plant-derived materials require intensive irrigation during cultivation, others demonstrate remarkable water efficiency. For instance, coatings derived from agricultural by-products can reduce water footprint by up to 40% compared to dedicated crop cultivation for coating materials. This highlights the importance of feedstock selection in determining overall environmental performance.

Biodegradability and compostability represent key sustainability advantages of bio-based coatings. Under controlled conditions, many bio-based formulations demonstrate complete biodegradation within 3-6 months, compared to decades or centuries for conventional petroleum-based alternatives. However, the biodegradation behavior under humid conditions presents a paradoxical challenge: while moisture accelerates biodegradation, it simultaneously compromises barrier properties, necessitating careful formulation to balance longevity with environmental benefits.

Land use considerations introduce additional complexity to sustainability assessments. The expansion of bio-based coating production could potentially compete with food crops for agricultural land. Recent modeling suggests that strategic integration of coating material production with existing agricultural systems could minimize this competition, particularly through the utilization of marginal lands and crop rotation strategies that enhance soil health while providing raw materials for coatings.

Chemical safety profiles of bio-based coatings generally show reduced toxicity compared to conventional alternatives, with typical reductions in volatile organic compound (VOC) emissions ranging from 30-80%. This translates to improved indoor air quality and reduced occupational hazards during application. Nevertheless, certain bio-based additives required to enhance humidity resistance may introduce new toxicological considerations that require thorough evaluation before widespread implementation.

Economic sustainability metrics indicate that while production costs for bio-based coatings currently exceed conventional alternatives by 15-40%, this gap is narrowing as production scales increase and processing technologies mature. Market projections suggest price parity could be achieved within 5-8 years for certain applications, particularly those where performance under humid conditions meets industry requirements without significant compromises.

Regulatory Framework for Bio-based Packaging Materials

The regulatory landscape for bio-based packaging materials has evolved significantly in response to growing environmental concerns and sustainability initiatives. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Food and Agriculture Organization (FAO) have established guidelines that influence national policies regarding sustainable packaging solutions, including those with bio-based coatings designed to maintain barrier efficiency under humid conditions.

In the European Union, the framework is particularly comprehensive, with the Packaging and Packaging Waste Directive (94/62/EC) and its subsequent amendments setting essential requirements for packaging composition and recyclability. The EU's Circular Economy Action Plan further emphasizes the transition toward sustainable packaging solutions, with specific provisions encouraging innovation in bio-based materials that maintain functionality in varying environmental conditions.

The United States regulatory approach is primarily governed by the Food and Drug Administration (FDA), which evaluates food-contact materials through the Food Contact Notification (FCN) program. Bio-based coatings must demonstrate compliance with migration limits and safety standards, particularly when exposed to high humidity environments that may affect barrier properties and potentially increase migration of substances into food.

Certification systems play a crucial role in the regulatory framework, with standards such as EN 13432 for compostability and ASTM D6400 providing benchmarks for biodegradable packaging materials. These standards increasingly incorporate performance criteria under various environmental conditions, including humidity resistance, which is critical for maintaining barrier efficiency in bio-based coatings.

Recent regulatory developments have focused on establishing more specific requirements for bio-based content verification, with the European Committee for Standardization (CEN) developing standards for measuring and declaring bio-based content in packaging materials. These standards are essential for ensuring transparency and preventing greenwashing in the rapidly growing bio-based packaging sector.

Compliance challenges remain significant for manufacturers developing bio-based coatings with humidity resistance. The regulatory framework often lags behind technological innovation, creating uncertainty regarding approval pathways for novel bio-based barrier solutions. Additionally, the lack of harmonization between different regional regulations creates complexity for global market access, requiring manufacturers to navigate multiple compliance requirements.

Future regulatory trends indicate a move toward more performance-based standards rather than prescriptive requirements, potentially allowing greater innovation in bio-based barrier technologies while ensuring safety and environmental protection. This evolution will likely include specific provisions addressing the performance of bio-based coatings under challenging environmental conditions, including high humidity scenarios that currently present significant barrier efficiency challenges.

In the European Union, the framework is particularly comprehensive, with the Packaging and Packaging Waste Directive (94/62/EC) and its subsequent amendments setting essential requirements for packaging composition and recyclability. The EU's Circular Economy Action Plan further emphasizes the transition toward sustainable packaging solutions, with specific provisions encouraging innovation in bio-based materials that maintain functionality in varying environmental conditions.

The United States regulatory approach is primarily governed by the Food and Drug Administration (FDA), which evaluates food-contact materials through the Food Contact Notification (FCN) program. Bio-based coatings must demonstrate compliance with migration limits and safety standards, particularly when exposed to high humidity environments that may affect barrier properties and potentially increase migration of substances into food.

Certification systems play a crucial role in the regulatory framework, with standards such as EN 13432 for compostability and ASTM D6400 providing benchmarks for biodegradable packaging materials. These standards increasingly incorporate performance criteria under various environmental conditions, including humidity resistance, which is critical for maintaining barrier efficiency in bio-based coatings.

Recent regulatory developments have focused on establishing more specific requirements for bio-based content verification, with the European Committee for Standardization (CEN) developing standards for measuring and declaring bio-based content in packaging materials. These standards are essential for ensuring transparency and preventing greenwashing in the rapidly growing bio-based packaging sector.

Compliance challenges remain significant for manufacturers developing bio-based coatings with humidity resistance. The regulatory framework often lags behind technological innovation, creating uncertainty regarding approval pathways for novel bio-based barrier solutions. Additionally, the lack of harmonization between different regional regulations creates complexity for global market access, requiring manufacturers to navigate multiple compliance requirements.

Future regulatory trends indicate a move toward more performance-based standards rather than prescriptive requirements, potentially allowing greater innovation in bio-based barrier technologies while ensuring safety and environmental protection. This evolution will likely include specific provisions addressing the performance of bio-based coatings under challenging environmental conditions, including high humidity scenarios that currently present significant barrier efficiency challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!